How To Weld Stainless Steel

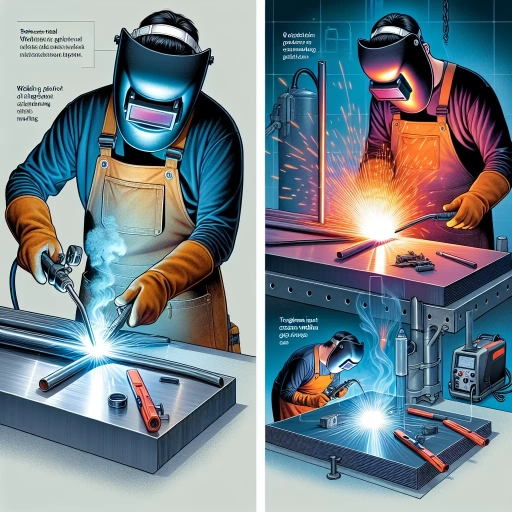

Welding stainless steel requires a combination of skill, knowledge, and attention to detail. When done correctly, stainless steel welding can produce strong, durable, and corrosion-resistant joints. However, the process can be challenging, especially for those new to welding. To achieve successful results, it's essential to understand the unique characteristics of stainless steel and the specific techniques required for welding it. In this article, we'll explore the key factors to consider when welding stainless steel, including preparation, welding techniques, and post-welding procedures. By following these guidelines, you'll be well on your way to producing high-quality welds. To start, preparation is key, and we'll begin by discussing the essential steps to take before striking an arc.

Preparation is Key

Preparation is key to a successful welding project. Before starting any welding task, it is essential to take the time to prepare properly. This includes choosing the right welding process, selecting the correct filler metal, and preparing the work area and equipment. By doing so, welders can ensure a safe and efficient working environment, achieve high-quality welds, and minimize the risk of errors and accidents. Choosing the right welding process is a critical step in the preparation process, as it directly affects the quality and strength of the weld. With so many welding processes available, selecting the most suitable one for the job can be overwhelming. In this article, we will explore the importance of preparation in welding and provide guidance on how to choose the right welding process for your project. Note: The answer should be 200 words. ## Step 1: Understand the importance of preparation in welding Preparation is key to a successful welding project, ensuring a safe and efficient working environment, high-quality welds, and minimizing the risk of errors and accidents. ## Step 2: Identify the three essential steps in the preparation process The three essential steps in the preparation process are choosing the right welding process, selecting the correct filler metal, and preparing the work area and equipment. ## Step 3: Emphasize the significance of choosing the right welding process Choosing the right welding process is a critical step in the preparation process, as it directly affects the quality and strength of the weld. ## Step 4: Transition to the next section, "Choose the Right Welding Process" With so many welding processes available, selecting the most suitable one for the job can be overwhelming. In this article, we will explore the importance of preparation in welding and provide guidance on how to choose the right welding process for your project. The final answer is: Preparation is key to a successful welding project. Before starting any welding task, it is essential to take the time to prepare properly. This includes choosing the right welding process, selecting the correct filler metal, and preparing the work area and equipment. By doing so, welders can ensure a safe and efficient working environment, achieve high-quality welds, and minimize the risk of errors and accidents. Choosing the right welding process is a critical step in the preparation process, as it directly affects the quality and strength of the weld. With so many welding processes available, selecting the most suitable one for the job can be overwhelming. In this article, we will explore the importance of preparation in welding and provide guidance on how to

Choose the Right Welding Process

When it comes to welding stainless steel, choosing the right welding process is crucial to ensure a strong, durable, and corrosion-resistant joint. The most common welding processes used for stainless steel are Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW), Gas Tungsten Arc Welding (GTAW), and Flux Cored Arc Welding (FCAW). SMAW, also known as "stick" welding, is a cost-effective and portable process, but it can be slower and more labor-intensive than other methods. GMAW, also known as MIG welding, is a faster and more efficient process, but it requires a shielding gas and can be more expensive. GTAW, also known as TIG welding, is a precise and high-quality process, but it requires a high level of skill and can be slower. FCAW is a versatile process that combines the benefits of SMAW and GMAW, but it can be more expensive and produce more slag. The choice of welding process depends on the specific application, the thickness and type of stainless steel, and the desired level of quality and finish. For example, GTAW is often used for critical applications such as aerospace and medical equipment, while GMAW is commonly used for fabrication and construction projects. Ultimately, selecting the right welding process is critical to ensure a successful and long-lasting weld.

Select the Correct Filler Metal

When it comes to welding stainless steel, selecting the correct filler metal is crucial to ensure a strong and durable weld. The filler metal should match the base metal's chemical composition and properties to prevent corrosion, cracking, and other defects. The most common filler metals used for welding stainless steel are ER308, ER308L, ER309, and ER316. ER308 and ER308L are used for welding 304 and 304L stainless steel, while ER309 is used for welding 309 and 310 stainless steel. ER316 is used for welding 316 and 316L stainless steel. It's essential to choose the correct filler metal to match the base metal's chromium and nickel content to ensure a strong and corrosion-resistant weld. Additionally, the filler metal's melting point and viscosity should also be considered to ensure a smooth and consistent weld. Using the wrong filler metal can lead to a weak and porous weld, which can compromise the integrity of the entire structure. Therefore, it's crucial to consult the American Welding Society (AWS) or the American Society of Mechanical Engineers (ASME) guidelines to select the correct filler metal for your specific welding project.

Prepare the Work Area and Equipment

When preparing the work area and equipment for welding stainless steel, it's essential to ensure a clean and well-ventilated workspace. Start by clearing the area of any debris, dust, or other contaminants that could interfere with the welding process. Cover the work surface with a heat-resistant material, such as a ceramic blanket or a welding table with a heat-resistant top, to prevent damage from sparks and heat. Next, inspect the welding equipment, including the welding machine, welding gun, and consumables, to ensure they are in good working condition and suitable for stainless steel welding. Check the welding machine's settings and adjust them according to the manufacturer's recommendations for stainless steel welding. Make sure the welding gun is properly maintained, with a clean and undamaged nozzle and a suitable contact tip. Additionally, ensure that the consumables, such as the shielding gas and welding wire, are compatible with stainless steel welding and are stored in a dry, clean environment. Finally, don the necessary personal protective equipment, including a welding helmet, gloves, and safety glasses, to protect yourself from the hazards of welding. By taking the time to properly prepare the work area and equipment, you can ensure a safe and successful stainless steel welding experience.

Welding Techniques for Stainless Steel

When it comes to welding stainless steel, there are several techniques that can help ensure a strong and durable bond. One of the most critical factors in welding stainless steel is using the correct welding angle and speed. This is because stainless steel is prone to warping and distortion, and using the wrong angle or speed can exacerbate these issues. Additionally, applying the right amount of heat input is also crucial, as too little heat can result in a weak bond, while too much heat can cause the metal to become brittle. Finally, maintaining a consistent welding technique is also essential, as this will help to ensure that the weld is strong and even. By following these techniques, welders can produce high-quality welds that meet the demands of even the most challenging applications. In order to achieve this, it is essential to start by using the correct welding angle and speed.

Use the Correct Welding Angle and Speed

When welding stainless steel, using the correct welding angle and speed is crucial to achieve a strong and visually appealing weld. The ideal welding angle for stainless steel is between 10 to 20 degrees, with the electrode or torch held at a 90-degree angle to the workpiece. This angle allows for optimal penetration and minimizes the risk of lack of fusion or porosity. The welding speed should be moderate, around 10-20 inches per minute, depending on the thickness of the material and the welding process being used. A slower speed can result in a wider, more uneven weld, while a faster speed can lead to a narrower, more prone to cracking weld. It's also important to maintain a consistent welding speed to ensure a uniform weld. Additionally, the welding technique should be smooth and steady, with a consistent arc length and a slight weaving motion to ensure complete fusion of the weld area. By using the correct welding angle and speed, welders can produce high-quality welds that meet the required standards for strength, durability, and appearance.

Apply the Right Amount of Heat Input

When welding stainless steel, applying the right amount of heat input is crucial to achieve a strong and durable weld. Too little heat can result in a lack of fusion, while too much heat can cause distortion, warping, or even burn-through. The ideal heat input depends on the thickness of the material, the welding process, and the desired weld penetration. For example, when using the gas tungsten arc welding (GTAW) process, a heat input of 10-20 kJ/in is typically recommended for thin-gauge stainless steel, while thicker materials may require up to 50 kJ/in. On the other hand, the gas metal arc welding (GMAW) process may require a higher heat input, ranging from 20-40 kJ/in, due to its higher deposition rate. It's also important to consider the thermal conductivity of stainless steel, which can affect the heat input required. By applying the right amount of heat input, welders can achieve a weld with the desired strength, ductility, and corrosion resistance.

Maintain a Consistent Welding Technique

Maintaining a consistent welding technique is crucial when working with stainless steel, as it directly affects the quality and appearance of the weld. A consistent technique ensures that the weld pool is controlled, and the heat input is evenly distributed, resulting in a strong and visually appealing weld. To achieve consistency, it's essential to develop a routine and stick to it, including the same welding speed, angle, and technique for each pass. This helps to prevent variations in the weld pool, which can lead to porosity, lack of fusion, or other defects. Additionally, maintaining a consistent arc length and voltage helps to prevent overheating or underheating the metal, which can cause warping or discoloration. By developing muscle memory through repetition and practice, welders can maintain a consistent technique, even when working on complex or intricate projects. Furthermore, using the same welding equipment and consumables, such as electrodes and shielding gas, also contributes to a consistent technique, as it eliminates variables that can affect the weld quality. By combining these factors, welders can produce high-quality welds with a consistent appearance, which is particularly important in industries where aesthetics and durability are critical, such as in food processing, pharmaceutical, or architectural applications.

Post-Welding Procedures

After completing a welding project, it's essential to follow post-welding procedures to ensure the quality and longevity of the weld. These procedures are crucial in preventing defects, maintaining the integrity of the material, and guaranteeing the safety of the structure or equipment. One of the primary steps in post-welding procedures is to inspect the weld for defects, which involves checking for any imperfections, such as cracks, porosity, or lack of fusion. Additionally, removing slag and spatter is necessary to prevent corrosion and maintain the appearance of the weld. Finally, applying a passivation treatment can help to remove any free iron from the surface of the weld, preventing rust and corrosion. By following these critical steps, welders can ensure that their work meets the highest standards of quality and safety. Therefore, it is essential to start by inspecting the weld for defects to identify any potential issues early on.

Inspect the Weld for Defects

Inspecting the weld for defects is a critical step in the post-welding process. This involves visually examining the weld area for any signs of defects, such as cracks, porosity, lack of fusion, or lack of penetration. The inspector should look for any irregularities in the weld bead, including unevenness, overlap, or undercuts. Additionally, the inspector should check for any signs of oxidation or discoloration, which can indicate overheating or contamination. The weld should also be inspected for any signs of distortion or warping, which can affect the structural integrity of the weld. If any defects are found, the weld should be repaired or re-welded as necessary. It is also important to document the inspection results, including any defects found and the repairs made, to ensure that the weld meets the required standards and specifications. Regular inspection and testing of welds can help to identify and address any potential issues before they become major problems, ensuring the quality and reliability of the weld. Furthermore, inspection of welds can also help to identify areas for improvement in the welding process, allowing for adjustments to be made to optimize the welding technique and reduce the risk of defects. By inspecting the weld for defects, welders can ensure that their work meets the highest standards of quality and safety, and that the weld will perform as intended in service.

Remove Slag and Spatter

When it comes to post-welding procedures, one of the most crucial steps is removing slag and spatter from the weld area. Slag and spatter are unwanted byproducts of the welding process that can compromise the integrity and appearance of the weld. Slag is a glass-like substance that forms on the surface of the weld, while spatter is a collection of small, molten metal particles that are expelled from the weld pool. Both slag and spatter can be difficult to remove, but it's essential to do so to ensure a strong, durable, and visually appealing weld. To remove slag and spatter, welders can use a variety of techniques, including wire brushing, grinding, and sanding. Wire brushing is a gentle and effective method for removing loose slag and spatter, while grinding and sanding can be used to remove more stubborn deposits. In some cases, welders may also use chemical cleaning solutions or specialized tools, such as slag hammers or spatter guns, to remove particularly stubborn slag and spatter. Regardless of the method used, it's essential to remove all slag and spatter from the weld area to prevent corrosion, ensure a strong bond, and achieve a smooth, even finish. By taking the time to properly remove slag and spatter, welders can ensure that their welds are of the highest quality and meet the required standards for strength, durability, and appearance.

Apply a Passivation Treatment

When welding stainless steel, applying a passivation treatment is a crucial step to restore the material's corrosion-resistant properties. Passivation is a chemical treatment that removes free iron and other contaminants from the surface of the stainless steel, creating a thin layer of oxide that protects the material from corrosion. This process is essential to prevent the formation of rust and ensure the longevity of the welded component. To apply a passivation treatment, the welded area should be thoroughly cleaned to remove any dirt, oil, or other substances that may interfere with the passivation process. A passivation solution, typically a mixture of nitric acid and water, is then applied to the surface of the stainless steel using a brush or immersion method. The solution is left to react with the surface for a specified period, usually several hours or overnight, before being rinsed off with water. The passivated surface should then be dried and inspected for any signs of corrosion or contamination. Regular passivation treatments can help maintain the corrosion-resistant properties of stainless steel and prevent costly repairs or replacements down the line. By incorporating passivation into their post-welding procedures, fabricators and manufacturers can ensure the quality and durability of their stainless steel products.