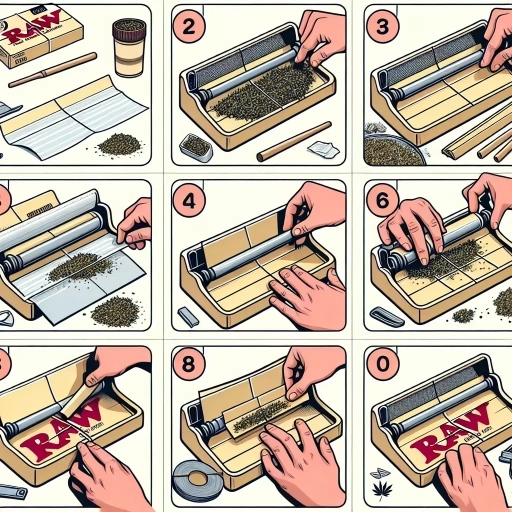

How To Use Raw Rolling Machine

Here is the introduction paragraph: Using a raw rolling machine can be a game-changer for those who enjoy rolling their own cigarettes or cannabis products. Not only does it save time and effort, but it also allows for a more precise and consistent roll. However, to get the most out of this device, it's essential to understand how to use it properly. In this article, we'll take you through the process of using a raw rolling machine, from understanding its components and features to preparing it for use and operating it effectively. First, we'll start by breaking down the raw rolling machine itself, exploring its various parts and how they work together to produce a perfectly rolled product. By understanding the raw rolling machine, you'll be able to unlock its full potential and start rolling like a pro.

Understanding the Raw Rolling Machine

The raw rolling machine is a crucial piece of equipment in various industries, including manufacturing, construction, and agriculture. It plays a vital role in shaping and processing raw materials into desired forms. To understand the raw rolling machine, it is essential to delve into its components, types, and functions. This article will explore the raw rolling machine in-depth, starting with its definition and purpose. We will examine the components that make up a raw rolling machine, including the rollers, bearings, and drive system. Additionally, we will discuss the different types of raw rolling machines, such as the two-high, four-high, and cluster rolling machines. By understanding these aspects, we can appreciate the importance of the raw rolling machine in various industries. So, let's begin by exploring what a raw rolling machine is and its significance in modern manufacturing.

What is a Raw Rolling Machine?

A raw rolling machine is a device designed to roll and shape raw materials, such as tobacco, herbs, or other plant-based substances, into a cylindrical form. The machine is typically used to create uniform and consistent rolls, which can be used for various purposes, including smoking, vaping, or as a base for other products. Raw rolling machines come in different sizes and types, ranging from small, handheld devices to large, industrial-scale machines. They usually consist of a rolling chamber, a handle or lever, and a mechanism for adjusting the pressure and density of the roll. Some machines may also feature additional features, such as a built-in grinder or a system for applying a filter tip. The primary function of a raw rolling machine is to simplify the process of rolling and shaping raw materials, making it easier and more efficient for users to create their desired products.

Components of a Raw Rolling Machine

A raw rolling machine is a complex piece of equipment that consists of several key components working together to produce high-quality rolled products. The main components of a raw rolling machine include the rolling mill, which is the heart of the machine, responsible for shaping and forming the raw material into the desired shape. The rolling mill is typically composed of a series of rollers, each with a specific function, such as breaking down the raw material, shaping, and smoothing. The rollers are usually made of high-strength materials, such as steel or tungsten carbide, to withstand the high pressures and temperatures involved in the rolling process. Another crucial component is the drive system, which powers the rolling mill and controls the speed and torque of the rollers. The drive system typically consists of an electric motor, gearbox, and transmission system, which work together to provide the necessary power and control to the rolling mill. Additionally, the raw rolling machine also includes a control system, which monitors and regulates the rolling process, ensuring that the final product meets the desired specifications. The control system typically includes sensors, actuators, and a computerized control panel, which work together to monitor and adjust the rolling process in real-time. Other important components of a raw rolling machine include the feeding system, which supplies the raw material to the rolling mill, and the cooling system, which helps to regulate the temperature of the rollers and prevent overheating. Overall, the components of a raw rolling machine work together to produce high-quality rolled products, and understanding how each component functions is essential for optimal machine performance and product quality.

Types of Raw Rolling Machines

Raw rolling machines come in various types, each designed to cater to specific needs and preferences. The most common types include the classic raw rolling machine, which is a simple and compact device that allows for easy rolling of cones. The electric raw rolling machine is another popular option, offering a more efficient and faster way to roll cones with minimal effort. The automatic raw rolling machine is a high-end option that can produce multiple cones at once, making it ideal for heavy users or those who want to roll cones in bulk. The manual raw rolling machine is a more affordable and portable option that requires manual effort to roll cones. The cone rolling machine is a specialized device designed specifically for rolling cones, offering a more precise and consistent result. The king size raw rolling machine is designed for rolling larger cones, making it a great option for those who prefer bigger cones. The mini raw rolling machine is a compact and portable option that is perfect for rolling smaller cones on-the-go. The raw rolling machine with a built-in grinder is a convenient option that allows users to grind their herbs and roll cones in one device. The raw rolling machine with a built-in filter is another option that allows users to filter out impurities and contaminants from their herbs before rolling cones. Each type of raw rolling machine has its unique features and benefits, and choosing the right one depends on individual preferences and needs.

Preparing to Use the Raw Rolling Machine

Preparing to use a raw rolling machine requires attention to detail and a few simple steps to ensure a smooth and efficient rolling experience. To start, it's essential to choose the right rolling paper, as this will directly impact the quality of your final product. This involves considering factors such as paper thickness, size, and material. Once you have selected the perfect paper, you'll need to measure and cut it to the correct size, taking into account the specific requirements of your raw rolling machine. Finally, you'll need to load the machine with the prepared rolling paper, making sure it's properly aligned and seated. By following these steps, you'll be well on your way to creating perfectly rolled products every time. In this article, we'll dive deeper into each of these steps, starting with the crucial process of choosing the right rolling paper.

Choosing the Right Rolling Paper

When it comes to choosing the right rolling paper for your Raw Rolling Machine, there are several factors to consider. First and foremost, you'll want to think about the size of the paper. Raw Rolling Machines come in a variety of sizes, so make sure to choose a paper that matches your machine's specifications. You can choose from a range of sizes, including 1 1/4", 1 1/2", and king-size. Next, consider the material of the paper. Raw Rolling Papers are made from a variety of materials, including hemp, bamboo, and flax. Hemp papers are a popular choice because they are durable and have a natural, earthy flavor. Bamboo papers, on the other hand, are known for their sustainability and smooth burn. Flax papers are a good option for those looking for a paper that is both durable and environmentally friendly. You'll also want to think about the thickness of the paper. Thicker papers are more durable and less prone to tearing, but they can be more difficult to roll. Thinner papers, on the other hand, are easier to roll but may not be as durable. Finally, consider the flavor and texture of the paper. Some papers have a natural flavor, while others may have a more pronounced taste. You may also want to consider papers with a textured finish, which can add an extra layer of enjoyment to your smoking experience. By considering these factors, you can choose the right rolling paper for your Raw Rolling Machine and enjoy a smooth, enjoyable smoking experience.

Measuring and Cutting the Rolling Paper

When it comes to measuring and cutting the rolling paper, precision is key to achieving a smooth and even roll. To start, take a sheet of rolling paper and place it on a flat surface, ensuring it is aligned with the edge of the surface. Next, use a ruler or a straightedge to measure the desired width of the roll, typically around 1-2 inches. Mark the width with a small notch or a faint line using a pencil, taking care not to crease the paper. Then, using a sharp utility knife or a pair of scissors, carefully cut along the marked line, applying gentle pressure to avoid tearing the paper. It's essential to cut in a smooth, continuous motion, following the edge of the ruler or straightedge to maintain a straight cut. If necessary, use a cutting mat or a piece of cardboard underneath the paper to prevent damage to the surface. Once the paper is cut to the desired width, set it aside and repeat the process for the remaining sheets. By taking the time to accurately measure and cut the rolling paper, you'll be able to achieve a consistent and professional-looking roll every time.

Loading the Machine with Rolling Paper

Loading the machine with rolling paper is a crucial step in preparing to use the Raw rolling machine. To do this, start by selecting the desired rolling paper size and type, taking into account the size of the machine and the desired thickness of the roll. Next, locate the paper tray or loading area on the machine, which is usually marked with a paper icon or a small opening. Gently lift the tray or open the loading area, and carefully place the rolling paper into the machine, making sure it is aligned with the guides or rollers. If the machine has a paper tension adjustment, adjust it according to the manufacturer's instructions to ensure the paper is fed smoothly and evenly. Once the paper is loaded, close the tray or loading area, and the machine is ready to use. It's essential to handle the rolling paper with care to avoid creasing or tearing, which can affect the quality of the roll. By loading the machine correctly, you'll be able to produce high-quality rolls with ease and efficiency.

Operating the Raw Rolling Machine

Operating a raw rolling machine requires attention to detail and a thorough understanding of its components and functions. To produce high-quality rolled products, it is essential to follow a step-by-step process. First, the machine must be set to the desired rolling size, ensuring that the final product meets the required specifications. Next, the rolling paper must be fed into the machine, which involves aligning the paper with the machine's rollers and adjusting the tension to prevent wrinkles or tears. Finally, the rolled product must be collected, which requires careful handling to prevent damage or deformation. By following these steps, operators can ensure that their raw rolling machine produces consistent, high-quality results. To begin, it is crucial to set the machine to the desired rolling size, which is a critical step in the rolling process.

Setting the Machine to the Desired Rolling Size

Setting the machine to the desired rolling size is a crucial step in operating a raw rolling machine. To do this, locate the adjustment dial or lever on the machine, which is usually found on the side or top of the device. This dial or lever controls the distance between the rolling surfaces, allowing you to customize the size of the roll. Next, refer to the machine's user manual or the manufacturer's guidelines to determine the recommended settings for the desired rolling size. Typically, the settings will be measured in millimeters or inches, and you may need to adjust the dial or lever in small increments to achieve the precise size you need. As you adjust the machine, pay attention to the rolling surfaces and ensure they are properly aligned to prevent any uneven rolling or damage to the machine. Once you have set the machine to the desired rolling size, double-check the settings to ensure accuracy and make any necessary adjustments before proceeding with the rolling process.

Feeding the Rolling Paper into the Machine

Feeding the rolling paper into the machine is a crucial step in operating a raw rolling machine. To do this, start by holding the rolling paper in one hand, with the adhesive strip facing upwards. Locate the paper feed slot on the machine, which is usually marked with an arrow indicating the direction of the paper feed. Gently insert the rolling paper into the slot, making sure it is aligned with the guides and the adhesive strip is facing the correct direction. As you insert the paper, the machine's sensors will detect its presence and the rollers will begin to rotate, pulling the paper into the machine. Continue to feed the paper into the machine until it is fully inserted and the rollers stop rotating. It's essential to ensure the paper is fed smoothly and evenly to prevent any wrinkles or creases that can affect the quality of the roll. If the paper becomes jammed or misaligned, stop the machine immediately and carefully remove the paper to avoid any damage. By following these steps, you can successfully feed the rolling paper into the machine and prepare it for rolling.

Collecting the Rolled Product

Collecting the rolled product is a crucial step in the raw rolling machine process. Once the rolling process is complete, the rolled product is collected and prepared for further processing or packaging. The collection process typically involves removing the rolled product from the machine and placing it onto a conveyor belt or a collection tray. The product is then inspected for quality and consistency, and any defects or irregularities are removed. The collected product is then packaged or further processed according to the desired specifications. It is essential to handle the rolled product with care to prevent damage or contamination, which can affect the final product's quality. Proper collection and handling of the rolled product ensure that the final product meets the required standards and is ready for distribution or use.