How To Open Shipping Container

Typically seen crisscrossing the oceans or piled high in ports, shipping containers have become a popular choice for a variety of applications far beyond their basic purpose of transporting goods. Whether you're breathing new life into them as an ultra-modern home, using them for storage, or modifying them for commercial purposes, understanding the intricacies of how to open a shipping container is paramount. In this high-quality, enlightening, and engaging article, we will venture into the intriguing world of shipping containers. We will start by understanding the mechanics of a shipping container, exploring the pivotal hardware and components that set the stage for successful operation. Then, we take a step-by-step journey on how to open the formidable steel giant, demystifying the process while empowering you with actionable knowledge. Finally, we'll delve into maintaining ease of use and ensuring effortless future access to your shipping container, ensuring a smooth sail in your container usage voyage. Let's embark on this journey by first delving into understanding the mechanics of a shipping container.

Typically seen crisscrossing the oceans or piled high in ports, shipping containers have become a popular choice for a variety of applications far beyond their basic purpose of transporting goods. Whether you're breathing new life into them as an ultra-modern home, using them for storage, or modifying them for commercial purposes, understanding the intricacies of how to open a shipping container is paramount. In this high-quality, enlightening, and engaging article, we will venture into the intriguing world of shipping containers. We will start by understanding the mechanics of a shipping container, exploring the pivotal hardware and components that set the stage for successful operation. Then, we take a step-by-step journey on how to open the formidable steel giant, demystifying the process while empowering you with actionable knowledge. Finally, we'll delve into maintaining ease of use and ensuring effortless future access to your shipping container, ensuring a smooth sail in your container usage voyage. Let's embark on this journey by first delving into understanding the mechanics of a shipping container.Understanding the Mechanics of a Shipping Container

In the dynamic world of logistics, shipping containers play an indispensable role. Garnering a thorough understanding of the mechanics of a shipping container can be instrumental in managing shipping projects effectively. Three crucial components define these robust transportation units. The structural integrity, established by well-built materials and design, sets the foundation for a shipping container's functionality. The locking mechanism, a corner-stone of security, ensures the safe delivery of consignments. Moreover, understanding the essence of proper handling can greatly influence the lifespan of these containers and preserve their maximum utility. These vital facets underline the multifaceted complexity beyond the mere steel exterior of a shipping container. As we embark on an in-depth exploration, let's begin with an examination of the structure of a shipping container, where every dimension adds to its formidable strength and versatility.

The Structure of a Shipping Container

Understanding the mechanics of a shipping container begins with deciphering its structure. A shipping container, often interchangeably referred to as an intermodal container, exhibits sheer resilience and a precisely engineered structure that underlines the backbone of modern maritime cargo transport. Delving into this modular matter, the structure of a shipping container majors in steel, lending its rigidity and durability to the high seas' relentless impact. A typical shipping container is made from high strength weathering steel, a corrosion-resistant material that logically fits into the maritime environment's harsh nature. The anatomy of a shipping container features four primary parts: the roof, the floor, the walls, and the doors. Each plays a critical role in maintaining the integrity and functionality of the container. For instance, the top and sides, composed of corrugated sheets of steel, serve to enhance the structural rigidity and prevent dents from heavy loads, while the wooden floor provides a non-slip surface for cargo while also serving as a cushion against vibrations and shocks. The doors, however, are where the intrigue lies. They are the point of access into the container's world of cargo transport operations and come equipped with a unique locking mechanism. The double doors open inwards, covering a full 270 degrees. Their strong steel construction with four vertically hinged locking rods protects goods from theft, damage, and the elements, all crucial aspects for any shipping company. Understanding the structure of a shipping container is a testament to the ingenuity of its design. Despite its apparent simplicity, their construction caters to various factors such as durability, security, and cargo protection, painting a vivid picture of the intricate engineering behind this pivotal instrument in global trade. Examining its structural pillars bridges the understanding gap of how to navigate through the task of opening a shipping container, shedding light on the subtle complexities that lie hidden behind its steel facade.

Details About the Locking Mechanism

The locking mechanism of a shipping container is an integral part of its structural design, ensuring the safety of the contents during transit. To comprehend how this functions, familiarize yourself with the key components: the handle, cam, cam keeper, and container door rod. When the door is ready to close, the handle is rotated, activating the cam and pushing it beneath the cam keeper. This creates a secure, fixed connection between the top and bottom container door rods, effectively locking the container. Rotating the handle to the upright position disengages the cam from the keeper, disconnecting the rods and unlocking the door. It's a simple yet efficient mechanism. However, over time, environmental elements like rust, dirt, and freezing conditions may affect its smooth operation. Occasional maintenance, particularly lubrication, can ensure its optimal functionality. Also, it's essential to unlock both door handles for complete access. Attempting to force open or shut a partially locked door can lead to unnecessary damage. Moreover, shipping containers are often equipped with a "lock box", a large, steel box welded on the door to protect the padlock from being tampered by thieves and extreme weather conditions. This level of protection enhances security by providing an additional safeguard against forced entry. In summary, the locking mechanism of a shipping container is a sturdy, practical design strengthened by few simple yet significant parts. By understanding how it works not only aides in smooth operation but also prolongs its lifetime through proper care and maintenance. This knowledge is crucial whether you’re using the container for storage, conversion projects, or international shipping. It's a grand testament to the robust and intricate engineering that goes into every aspect of these versatile structures.

The Importance of Proper Handling

The Importance of Proper Handling Understanding the functionality and mechanics of a shipping container is crucial in ensuring efficient shipping processes. However, the significance of proper handling should never be understated. Proper handling of shipping containers goes far beyond merely moving the cargo from one point to another. It is an intricate process whose execution and management directly impact the safety, integrity, and timely delivery of the goods in transit. Primarily, the correct maneuvering of shipping containers reduces potential risks and associated costs. Accidents during handling can damage the container's structure and, worse still, the cargo inside. Any compromise on the goods' quality or quantity could lead to heavy losses in terms of cost, time, and reputation. Hence, careful handling not only preserves the integrity of the items but also safeguards businesses from unnecessary expenditure and legal implications. Furthermore, proper handling practices facilitate the smooth transition of goods, bolstering shipping efficiencies. Optimizing the way containers are loaded, moved, stacked, and locked can expedicably strengthen the throughput rate, minimizing delays and boosting economic efficiency. This optimized productivity is vital in rapidly growing sectors that hinge on fast, reliable, and cost-effective logistics. Moreover, appropriate handling procedures have a direct influence on employees' health and safety. Some containers can weigh up to 30 tons when fully loaded. Handling such heavyweights can be hazardous, resulting in serious injuries or even fatalities. Instituting best practices in handling these blocks of steel is therefore essential for workers' safety, morale, and retention rate. It fulfills the moral and legal obligation that every company has to ensure a healthy and risk-free working environment. Lastly, sound handling protocols contribute to the durability of the shipping containers themselves. When these steel giants are adequately managed and maintained, their lifespan significantly increases. This effective preservation of resources can become an active driver in the fight against increasing global material wastage and environmental sustainability. In essence, proper handling of shipping containers is a multifaceted and critical component of any shipping operation. It safeguards business interests, enhances logistic efficiencies, upholds workers' safety, and promotes sustainability. Therefore, reinforcing its importance and implementation should be at the forefront of every logistics and freight forwarding strategy, shaping a more efficient and responsible shipping industry.

Steps in Opening a Shipping Container

Opening a shipping container may appear like a simple task, but it in fact necessitates a deep understanding of safety precautions, the correct use of specific tools, and familiarity with pertinent procedural guidelines. This holistic operation is not only essential but also crucial when ensuring the smooth unloading of whatever goods lays within these metal giants. We aim to delve into the intricate steps involved in this process through our comprehensive analysis in this article. This exclusive guide will first launch with a thorough exploration of the indispensable safety measures. Exercising safety is paramount in mitigating risks involved in dealing with large scale objects such as shipping containers. Proper supervision, correct positioning, and use of protective gear will be some of the highlights in this segment. Subsequently we will unravel the mastery behind employing the right tools designed for this very purpose. Possessing the correct tools is just the tip of the iceberg; optimally utilizing these tools is the true secret behind a successful operation. We will explore this in detail to ensure safe and efficient container opening. Finally, this enlightening journey will navigate towards a step-by-step guide, unraveling the mystery behind the procedural aspects of opening a shipping container. Every step is a significant cog in the grand wheel of this operation, making it crucial to be performed with precision. So, prepare yourself as we embark on this remarkable voyage, beginning with identifying the paramount safety precautions.

Identifying the Safety Precautions

Safety precautions are an integral part of opening a shipping container and cannot be overlooked. This is the point where we shed light on the necessary measures one ought to take to avoid any potential hazards. Firstly, it is quintessential to ensure that the shipping container is stable before the opening process begins. This is vital because an unstable container could lead to unwanted accidents, with the chances of the container tipping over. Securing the container with blocks or wedges serves as an effective preventive measure. Secondly, anyone engaged in the opening process must wear appropriate safety equipment like gloves, sturdy footwear, safety glasses, and hard hats depending on the nature of goods contained. This is a measure that protects individuals from any form of harm during unloading. It's also important to understand that containers can house a variety of items, including hazardous substances, therefore providing a high-quality respirator mask can help to tackle issues associated with dangerous fumes or particles. Another key precaution involves checking the interior conditions before making an entry. As it is possible for the container to be a host to pests or to contain substances that may have leaked during transport, a preliminary check becomes mandatory. Don't hesitate to use flashlights for a comprehensive inspection. In addition, containers, especially coming from long-distance trips, may have a buildup of pressure due to temperature changes. Thus, opening the door cautiously and slowly regulates the depressurization process, hence preventing sudden door movements that might cause accidents. Lastly, ensure that you have adequate manpower during the unloading phase to prevent strains associated with heavy lifting. Where necessary, use mechanical devices such as forklifts to make the process seamless. It's also wise to have people trained in First Aid and CPR during the opening process in case of any emergency. In conclusion, adhering strictly to these safety precautions is not just beneficial in securing health; it's also instrumental in ensuring the seamless opening of shipping containers. Ignoring these measures could lead to delayed work, possible legal implications, and, worse, jeopardize human life. Safety is indeed paramount, and as such, these precautions must be taken seriously. When the right safety measures are adhered to, you set a precedent for a safe, orderly, and efficient shipping container opening process.

Procedures in Using the Right Tools

Procedures in Using the Right Tools for Opening a Shipping Container It is imperative to comprehend the significance of having the right tools when opening a shipping container, especially considering the shipping industry's monumental role in global commerce. Shipping containers are highly robust and fortified structures, designed intentionally to be weatherproof and impenetrable to withstand the long and often challenging voyages they endure. As a result, opening them requires an astute understanding of the proper tools and processes. Primarily, think safety first. Shipping containers can be hazardous, and if proper precautions aren't taken, injuries may occur. The container's metal doors are heavy and can cause injuries if not handled properly. Because of this, gloves and steel-toed boots are essential safety gear for anyone working with shipping containers. The most common tools used in opening a shipping container include a high-tension adjustable wrench, a lock-picking kit (in case of a malfunctioning lockbox), bolt cutters, and lubricating spray. Each of these tools has its unique purpose and intended usage process, all tailored towards ensuring the container's integrity remains uncompromised, while simplifying accessibility. A high-tension adjustable wrench's purpose is to loosen the bolt seal found on high-security containers with its long handle and adjustable jaws designed for exerting optimal rotational force. Meanwhile, bolt cutters can be utilized to cut through any additional padlocks. However, it is crucial to apply caution when cutting padlocks, as fragments can fly and cause injuries; safety glasses are recommended. In certain situations where the lockbox may be malfunctioning, a lock picking kit becomes essential. This process requires a certain finesetting and can be seen as an art form - delicate touch and an understanding of the mechanics of locks are paramount. You'll also need patience and precision, as forcing the pick can damage the lock mechanism. A lubricating spray proves useful when dealing with rusted, stuck bolts or locks. It helps reduce friction, making the bolt or lock easier to turn or open. The lubricating spray should ideally be applied and left to sink in before any attempt is made to open the lock or bolt. In conclusion, the procedure of opening a shipping container safely and efficiently is not as simple as it may seem. It requires an understanding of the necessary tools, proper application, and safety precautions. This process symbolizes an intersection between brute force and delicate finesse, personifying the balance that facilitates successful outcomes in challenges within the logistics industry and beyond.

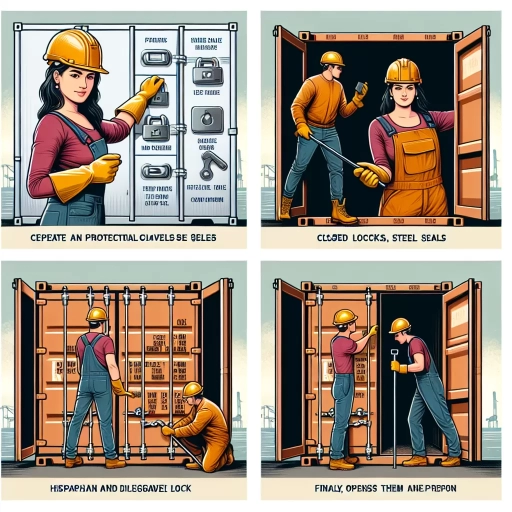

A Step-By-Step Guide to Opening a Shipping Container

As an integral step in the process of managing a shipping container, opening it requires a precise and well-considered approach. Each of these actions is crucial to the overall strategy and will ensure that the container is not only appropriately accessed but also retains its integrity and continues to offer optimal functionality. Step One begins with the important task of Equipment Assembly. This includes collecting any necessary tools such as a high-quality padlock or bolt lock cutter, a sturdy pair of safety gloves, and safety goggles to protect your eyes from potential flying fragments. As a part of this process, make sure the lock cutter is properly lubricated to ensure smooth operation and reduce the chance of equipment failure or safety risk. Follow this with Step Two, involving Safety Measures. While handling heavy machinery or tools, safety can never be emphasized enough. Make sure you are using suitable personal protective equipment (PPE) including gloves, safety goggles, and steel-toe boots. It’s also essential to clear the area around the container before commencing the unlocking process, to prevent any tripping hazards or obstructions. Step Three is Execution, or the actual process of cutting the locks or seals. The critical element here is the correct positioning of the lock cutter on the lock or bolt to ensure an effective cut. Strong, steady, and slow pressure is more beneficial than quick, hard force. It helps to prevent any unintentional damage to the container door or lock assembly. Step Four entails the Inspection phase. Once the lock or bolt is detached, carefully open the shipping container doors while inspecting for any potential hazards like falling items or destabilized contents. In the final step, Step Five, you should Strategically Unload the container if it’s filled with goods. Having a cohesive plan that prioritizes safety above all else will ensure efficient unloading. Thus, opening a shipping container involves much more than merely unlocking the doors – every decision influences the outcome, from the tools employed to the safety measures adopted. Emphasizing skillful execution, this step-by-step guide highlights the careful planning and execution needed to guarantee a seamless and safe shipping container opening process.

Maintaining Ease of Use and Future Access

In the digital landscape where user convenience is king, maintaining ease of use and future access is paramount. As consumer expectations grow and technological advancements occur at a rapid pace, it is crucial to stay ahead by consistently auditing usability and ensuring smooth operations. This narrative will delve into the importance of regular maintenance in preserving accessibility, identifying and maneuvering around common problems when opening shipping containers, and adopting key practices that promote seamless processes. By giving attention to these areas, we can drastically improve user experience and meet the future as prepared as we can be. We begin with a focus on how regular maintenance affects accessibility. As with many things in life, a proactive approach can save us a lot of trouble down the line. This holds true for the accessibility of our products and services, and with a well-planned maintenance routine, we can ensure their consistent delivery at the optimal standard.

How Regular Maintenance Affects Accessibility

Maintaining Ease of Use and Future Access is crucial when dealing with shipping containers and, as such, regular maintenance plays a key role in ensuring their accessibility. Regular maintenance isn't just about the upkeep of a physical object; it's intertwined with the function, accessibility, and overall value. Firstly, regular maintenance prevents wear and tear. Shipping containers are affected by harsh weather, extreme temperatures, and stress over time. By conducting regular maintenance, you can prevent corrosion, warping, and buckling. Thus, your container remains structurally sound and safe for usage. Rust or dents on a shipping container make it difficult to open or close, compromising accessibility. Therefore, regular oiling and surface treatment can ensure ease of use at all times. Secondly, regular maintenance ensures a smooth operating mechanism. The doors, locks, and weather sealants in a shipping container are critical components that can affect its accessibility if not properly maintained. Regular maintenance like lubricating the hinges, cleaning the lock box, keeping the weather sealant intact can ensure the container's doors can open smoothly and seal properly. Thirdly, in the context of smart shipping containers equipped with technology for tracking and remote controlling, regular software updates and maintaining the electronic components is paramount to ensure access to critical information and the container’s continued usability. Moreover, regular maintenance of shipping containers also involves trawling for potential future issues. Catching an early sign of damage saves you the headache of dealing with a massive problem down the line and reduces downtime, ensuring consistent access and usability of the container. In conclusion, regular maintenance positively affects the accessibility of shipping containers in numerous ways, such as extending the lifespan of the container, avoiding unnecessary repairs or replacement, and ensuring a smooth operational experience. Therefore, regular shipping container maintenance stands as the backbone of maintaining ease of use and future access.

Knowing the Common Problems in Opening Shipping Containers

Understanding and addressing the common problems in opening shipping containers is paramount in maintaining ease of use and future access. Shipping containers, originally designed for the tough marine environments, are built to last. This durability, while undoubtedly a benefit, can present certain challenges when first attempting to open these staunch units. A common issue faced by many individuals is the rust and corrosion that accumulates on the lock box and door handles of containers over time due to exposure to weather elements. This can lead to a significant increase in the amount of force required to open the container or, in some extreme cases, render it nearly impossible. Regular applications of anti-rust solutions and lubricants on these critical areas can help extend their longevity and ensure smoother operation. Another frequent problem lies in the handling of the door hinges. The heavy-duty design of these hinges can sometimes result in stiffness, making the door incredibly difficult to swing open or close. Regular maintenance, like the application of a lubricant, is necessary to prevent any lasting damage and ensure easy access in the future. Poorly maintained gaskets, the rubber seals around the container's doors, can also pose a challenge. If neglected, they can become brittle and lose their effectiveness, compromising the container's watertight state and affecting the condition of the goods stored within. Regular checks and timely replacements of these seals are key to preserving the contents of your container. Lastly, mismatched or misaligned door gears often lead to complications in opening and closing the container. This typically results from improper handling or misuse and necessitates a professional inspection for rectification. Understanding these common problems not only aids in mitigating any potential issues but also results in easier maintenance, promoting a hassle-free future access to your shipping containers. Ultimately, this knowledge significantly enhances the life and usability of your shipping containers, making them a reliable choice for numerous applications.