How To Build A Robot

Here is the introduction paragraph: Building a robot can be a fun and rewarding experience, especially with the advancement of technology and the availability of affordable materials. With a little creativity and some technical know-how, you can create a robot that can perform a variety of tasks, from simple automation to complex interactions. To get started, you'll need to consider three key aspects of robot building: designing the robot, building its hardware, and programming its software. In this article, we'll take a closer look at each of these steps, starting with the foundation of any successful robot: its design. By carefully planning and designing your robot, you'll be able to create a solid foundation for the rest of the build process, and set yourself up for success in the next stages of building and programming. So, let's dive in and explore the first step in building a robot: designing the robot.

Designing the Robot

Designing a robot is a complex process that requires careful consideration of several key factors. To create a high-quality robot, it is essential to define its purpose and functionality, create a detailed design plan and blueprint, and select the appropriate materials and components. By taking the time to carefully plan and design a robot, engineers and designers can ensure that it is able to perform its intended tasks efficiently and effectively. In this article, we will explore the process of designing a robot, starting with the crucial step of defining its purpose and functionality. This involves identifying the specific tasks that the robot will be required to perform, as well as the environment in which it will operate. By clearly defining the robot's purpose and functionality, designers can create a solid foundation for the rest of the design process.

Defining the Robot's Purpose and Functionality

Designing the robot's purpose and functionality is a crucial step in the robot-building process. It involves defining the robot's intended use, the tasks it will perform, and the environment in which it will operate. This step helps to determine the robot's hardware and software requirements, as well as its overall design and architecture. To define the robot's purpose and functionality, you need to consider several factors, including the robot's intended application, the tasks it will perform, and the level of autonomy it will have. For example, if you're building a robot for search and rescue operations, it will need to be designed to navigate through rubble and debris, detect and respond to different types of hazards, and communicate with its human operators. On the other hand, if you're building a robot for domestic use, such as a vacuum cleaner or a lawn mower, it will need to be designed to navigate through a home or yard, avoid obstacles, and perform its intended task efficiently. Additionally, you'll need to consider the robot's level of autonomy, including its ability to make decisions, adapt to new situations, and interact with its environment. By carefully defining the robot's purpose and functionality, you can ensure that your robot is designed to meet the needs of its intended application and perform its tasks efficiently and effectively.

Creating a Detailed Design Plan and Blueprint

Creating a detailed design plan and blueprint is a crucial step in building a robot. This involves translating the conceptual design into a precise and detailed plan, taking into account the robot's functionality, size, shape, and material requirements. The design plan should include a comprehensive list of components, including the microcontroller, sensors, actuators, and power supply, as well as the wiring and circuitry required to connect them. A detailed blueprint should also be created, showing the robot's layout, including the placement of components, wiring, and any other critical features. This blueprint will serve as a guide during the construction process, ensuring that all components are properly installed and connected. Additionally, the design plan should include a detailed bill of materials, listing all the components and materials required to build the robot, along with their specifications and quantities. This will help to ensure that all necessary components are sourced and procured, and that the construction process stays on track. By creating a detailed design plan and blueprint, robot builders can ensure that their project is well-planned, efficient, and successful.

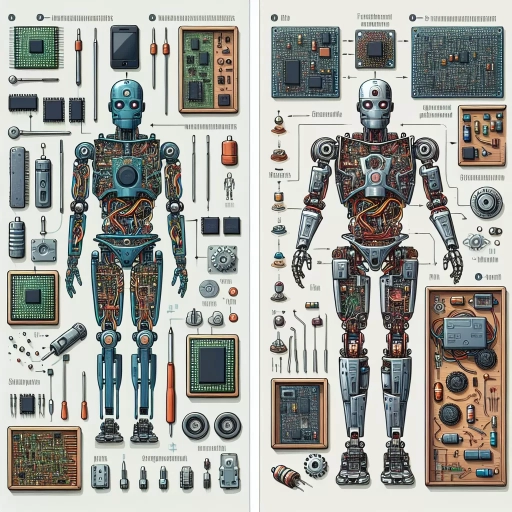

Selecting the Appropriate Materials and Components

When designing a robot, selecting the appropriate materials and components is crucial to ensure its functionality, durability, and efficiency. The choice of materials depends on the robot's intended application, environment, and required performance. For example, robots designed for outdoor use may require weather-resistant materials such as stainless steel, aluminum, or fiberglass, while those intended for indoor use may use lighter materials like plastic or carbon fiber. The selection of components, including motors, sensors, and control systems, also plays a critical role in determining the robot's capabilities and reliability. High-quality components can provide precise control, efficient energy consumption, and reliable operation, while low-quality components can lead to poor performance, frequent failures, and increased maintenance costs. Additionally, the compatibility of components with the robot's design and operating system is essential to ensure seamless integration and optimal performance. By carefully selecting materials and components, robot designers can create a robust, efficient, and reliable robot that meets its intended purpose and provides a high return on investment.

Building the Robot's Hardware

When building a robot, the hardware is the foundation upon which the entire system is constructed. A well-designed and well-built hardware platform is essential for a robot to function effectively and efficiently. In this article, we will explore the key components involved in building a robot's hardware, including assembling the robot's frame and structure, installing the robot's motors and actuators, and integrating the robot's sensors and control systems. By understanding these critical components, robot builders can create a robust and reliable hardware platform that can support a wide range of applications. From industrial automation to service robotics, a well-designed hardware platform is essential for achieving optimal performance and functionality. In the next section, we will delve into the first step of building a robot's hardware: assembling the robot's frame and structure.

Assembling the Robot's Frame and Structure

Assembling the robot's frame and structure is a crucial step in building a robot, as it provides the foundation for the entire machine. The frame serves as the skeleton of the robot, supporting the weight of the components and providing a platform for mounting the various parts. To assemble the frame, start by gathering all the necessary components, including the frame pieces, screws, and any other required hardware. Next, follow the manufacturer's instructions or a detailed blueprint to assemble the frame, ensuring that all the pieces are properly aligned and securely attached. It's essential to use the correct tools and techniques to avoid damaging the components or stripping the screws. Once the frame is assembled, attach the structural components, such as the wheels, axles, and motors, using the recommended fasteners and adhesives. Make sure to tighten all the screws and bolts securely to prevent any loose parts from causing damage or malfunction. Finally, inspect the frame and structure for any defects or weaknesses, and make any necessary adjustments or repairs before proceeding with the next step in building the robot. By carefully assembling the robot's frame and structure, you can ensure a sturdy and reliable foundation for your machine, allowing it to perform its intended functions safely and efficiently.

Installing the Robot's Motors and Actuators

Installing the robot's motors and actuators is a crucial step in building the robot's hardware. This process involves attaching the motors and actuators to the robot's frame and connecting them to the control system. The motors are responsible for providing the robot with movement and mobility, while the actuators enable the robot to perform specific tasks such as grasping and manipulation. To install the motors and actuators, start by attaching the motor mounts to the robot's frame using screws or bolts. Next, connect the motors to the motor mounts and secure them in place. Then, connect the actuators to the motors and the control system, making sure to follow the manufacturer's instructions for proper installation and wiring. It's also important to test the motors and actuators to ensure they are working properly and are calibrated correctly. This may involve running a series of tests to check the motor's speed, torque, and direction, as well as the actuator's range of motion and precision. By carefully installing and testing the motors and actuators, you can ensure that your robot is able to move and perform tasks efficiently and effectively. Additionally, it's recommended to use a motor controller to regulate the speed and direction of the motors, and to use a power supply that can handle the power requirements of the motors and actuators. By following these steps and taking the necessary precautions, you can successfully install the robot's motors and actuators and bring your robot to life.

Integrating the Robot's Sensors and Control Systems

Integrating the robot's sensors and control systems is a crucial step in building a functional robot. This involves connecting the sensors, such as cameras, lidars, and ultrasonic sensors, to the control systems, including the microcontrollers, motor drivers, and power supplies. The sensors provide the robot with the ability to perceive its environment, while the control systems enable the robot to respond to the sensor data and make decisions. To integrate the sensors and control systems, start by connecting the sensors to the microcontroller, which acts as the brain of the robot. The microcontroller processes the sensor data and sends commands to the motor drivers, which control the robot's movements. The power supplies provide the necessary power to the sensors, microcontrollers, and motor drivers. Ensure that all connections are secure and follow the manufacturer's instructions to avoid damage to the components. Additionally, consider using a sensor fusion algorithm to combine data from multiple sensors and improve the robot's perception and decision-making capabilities. By integrating the sensors and control systems, you can create a robot that can navigate its environment, avoid obstacles, and perform tasks autonomously.

Programming the Robot's Software

Programming a robot's software is a complex task that requires careful consideration of several factors. To create a high-quality, informative, and engaging article about this topic, it's essential to break down the process into manageable sections. This article will explore the key aspects of programming a robot's software, including choosing a suitable programming language and platform, writing and debugging the robot's code, and integrating the robot's software with its hardware components. By understanding these critical components, developers can create efficient, reliable, and effective robot software. In this article, we will delve into the world of robot programming, starting with the crucial step of selecting the right programming language and platform, which will lay the foundation for the entire software development process.

Choosing a Suitable Programming Language and Platform

Choosing a suitable programming language and platform is a crucial step in building a robot. The choice of language and platform depends on the robot's intended application, the type of hardware used, and the desired level of complexity. For beginners, languages like Scratch, Blockly, and Python are popular choices due to their simplicity and ease of use. Scratch and Blockly are visual programming languages that use blocks instead of text-based code, making it easy for beginners to understand and create programs. Python, on the other hand, is a text-based language that is widely used in robotics and has a vast number of libraries and resources available. For more advanced robots, languages like C++, Java, and MATLAB may be more suitable. C++ is a powerful language that provides low-level access to hardware, making it ideal for robots that require precise control. Java is a popular language for Android app development and can be used to create complex robot applications. MATLAB is a high-level language that is widely used in academia and research for its ability to quickly prototype and test algorithms. In terms of platforms, Arduino and Raspberry Pi are popular choices for robotics due to their affordability, ease of use, and large community support. Arduino is a microcontroller platform that provides a simple and intuitive way to interact with hardware, while Raspberry Pi is a single-board computer that provides a full-fledged Linux operating system. Other platforms like ROS (Robot Operating System) and Robotis OP2 provide more advanced features and are suitable for complex robots. Ultimately, the choice of programming language and platform depends on the specific needs of the project and the level of expertise of the developer.

Writing and Debugging the Robot's Code

Writing and debugging the robot's code is a crucial step in the robot-building process. This involves translating the robot's design and functionality into a programming language that the robot's microcontroller or computer can understand. The code is typically written in a high-level language such as C++, Python, or Java, and is used to control the robot's movements, interactions, and decision-making processes. Debugging is an essential part of the coding process, as it allows the programmer to identify and fix errors, or "bugs," in the code. This can be a time-consuming process, but it is necessary to ensure that the robot functions as intended. There are various tools and techniques available to help with debugging, such as print statements, debuggers, and simulation software. Additionally, many robot-building platforms, such as Arduino and Raspberry Pi, provide extensive libraries and resources to help with coding and debugging. By writing and debugging the robot's code, the programmer can bring the robot to life and enable it to perform its intended functions. This requires a combination of technical skills, problem-solving abilities, and creativity, making it a challenging but rewarding task.

Integrating the Robot's Software with its Hardware Components

Integrating the robot's software with its hardware components is a crucial step in building a robot. This process involves connecting the robot's brain, which is typically a computer or microcontroller, to its various hardware components such as sensors, actuators, and motors. The software is responsible for interpreting data from the sensors, making decisions, and sending commands to the actuators and motors to perform specific actions. To integrate the software with the hardware, the programmer must write code that communicates with the hardware components using protocols such as I2C, SPI, or UART. The code must also be able to read and write data to the hardware components, which requires a deep understanding of the hardware's specifications and functionality. Additionally, the programmer must ensure that the software is compatible with the hardware components and that the system is properly calibrated to achieve optimal performance. This integration process requires a combination of programming skills, knowledge of electronics, and problem-solving abilities, making it a challenging but rewarding task for robot builders. By successfully integrating the software with the hardware, the robot can perform complex tasks, interact with its environment, and achieve its intended purpose.