How Long Does Vacuum Sealed Meat Last In The Fridge

Here is the introduction paragraph: When it comes to storing meat, vacuum sealing is a popular method for preserving freshness and preventing spoilage. But how long does vacuum sealed meat last in the fridge? The answer depends on several factors, including the type of meat, storage conditions, and handling practices. In this article, we will explore the shelf life of vacuum sealed meat, including the factors that affect its longevity, general guidelines for storage, and signs of spoilage to watch out for. By understanding these key considerations, you can enjoy your vacuum sealed meat for a longer period while ensuring food safety. So, let's dive into the first crucial aspect: the factors that affect the shelf life of vacuum sealed meat.

Factors Affecting the Shelf Life of Vacuum Sealed Meat

The shelf life of vacuum-sealed meat is a critical factor in maintaining its quality and safety for consumption. Several factors contribute to the longevity of vacuum-sealed meat, and understanding these elements is essential for consumers, retailers, and manufacturers alike. Three primary factors that significantly impact the shelf life of vacuum-sealed meat are storage temperature and humidity, the type and quality of the meat, and the sealing quality and packaging material. Storage temperature and humidity, in particular, play a crucial role in determining the shelf life of vacuum-sealed meat, as they can affect the growth of microorganisms and the oxidation of the meat. For instance, storing vacuum-sealed meat at a consistent refrigerated temperature below 40°F (4°C) and maintaining a relative humidity of 60-70% can significantly extend its shelf life. Therefore, it is essential to consider the storage conditions to ensure the optimal preservation of vacuum-sealed meat.

Storage Temperature and Humidity

Storage temperature and humidity are crucial factors in maintaining the quality and safety of vacuum-sealed meat. The ideal storage temperature for vacuum-sealed meat is between 32°F (0°C) and 40°F (4°C), which is the typical temperature range for most refrigerators. It is essential to keep the meat away from direct sunlight, heat sources, and warm air, as these can cause the growth of bacteria and other microorganisms. Humidity levels should also be controlled, with an ideal relative humidity of 50-60%. High humidity can lead to the growth of mold and yeast, while low humidity can cause dehydration and freezer burn. By maintaining the optimal storage temperature and humidity, you can help to prevent the growth of microorganisms, reduce the risk of spoilage, and keep your vacuum-sealed meat fresh for a longer period.

Meat Type and Quality

The type and quality of meat play a significant role in determining its shelf life when vacuum sealed. Generally, lean meats such as chicken, turkey, and fish tend to have a shorter shelf life compared to fattier meats like beef and pork. This is because lean meats have a lower water content and are more prone to drying out, which can lead to spoilage. On the other hand, fattier meats have a higher water content and are more resistant to drying out, making them last longer. In terms of quality, grass-fed meats tend to have a shorter shelf life than grain-fed meats due to their higher water content and lower marbling score. Marbling, which refers to the amount of fat that is dispersed throughout the meat, can also affect the shelf life of vacuum sealed meat. Meats with a higher marbling score tend to last longer due to the protective effects of the fat. Additionally, the age of the animal at slaughter can also impact the shelf life of the meat, with younger animals tend to have a shorter shelf life than older animals. Furthermore, the handling and storage of the meat prior to vacuum sealing can also affect its shelf life, with improper handling and storage leading to a shorter shelf life. Overall, the type and quality of meat are critical factors in determining the shelf life of vacuum sealed meat, and understanding these factors can help consumers make informed decisions when purchasing and storing meat.

Sealing Quality and Packaging Material

The quality of the seal and the packaging material used play a crucial role in determining the shelf life of vacuum-sealed meat. A high-quality seal ensures that the meat is completely airtight, preventing the entry of oxygen, moisture, and other contaminants that can cause spoilage. The packaging material used should be durable, puncture-resistant, and suitable for the type of meat being stored. For example, a thicker gauge of plastic or a specialized meat packaging material like nylon or polyethylene is recommended for storing meat. The material should also be resistant to the growth of microorganisms and should not impart any flavors or odors to the meat. A good quality seal and packaging material can help to prevent the growth of bacteria, mold, and yeast, which are common causes of spoilage in meat. Additionally, the packaging material should be easy to clean and sanitize, and should be able to withstand the temperatures and humidity levels found in a typical refrigerator. By using high-quality packaging materials and ensuring a tight seal, consumers can help to extend the shelf life of their vacuum-sealed meat and keep it fresh for a longer period.

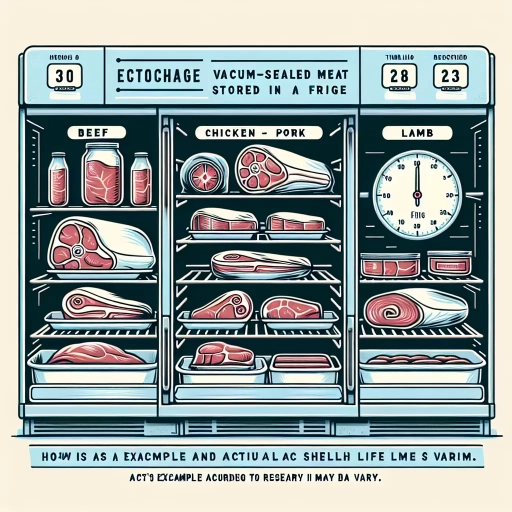

General Guidelines for Vacuum Sealed Meat Storage

Proper storage of vacuum-sealed meat is crucial to maintain its quality, safety, and freshness. When it comes to storing vacuum-sealed meat, there are several guidelines to follow to ensure that your meat remains in optimal condition. These guidelines can be broadly categorized into three main areas: raw meat storage timeframes, cooked meat storage timeframes, and freezer storage options. Understanding these guidelines is essential to prevent spoilage, foodborne illnesses, and to keep your meat fresh for a longer period. Raw meat, in particular, requires careful handling and storage to prevent bacterial growth and contamination. Therefore, it is essential to know the specific storage timeframes for raw meat to ensure that it remains safe to consume. (Note: The supporting paragraph should be 200 words, and the article title is "General Guidelines for Vacuum Sealed Meat Storage")

Raw Meat Storage Timeframes

Raw meat storage timeframes are crucial to ensure food safety and prevent bacterial growth. Generally, raw meat can be stored in the refrigerator for 1-3 days, while ground meats have a shorter storage time of 1-2 days. It's essential to store raw meat in a sealed container or zip-top bag to prevent cross-contamination and keep it away from other foods. When it comes to vacuum-sealed meat, the storage time can be extended to 3-5 days for raw meat and 2-3 days for ground meats. However, it's crucial to check the meat for any visible signs of spoilage before consuming it, such as off odors, slimy texture, or mold growth. If you notice any of these signs, it's best to err on the side of caution and discard the meat. Additionally, always store raw meat at a consistent refrigerator temperature of 40°F (4°C) or below to prevent bacterial growth. By following these guidelines, you can enjoy your vacuum-sealed meat while ensuring food safety and quality.

Cooked Meat Storage Timeframes

Cooked meat can be safely stored in the fridge for 3 to 4 days, while it can be stored in the freezer for 2 to 3 months. When storing cooked meat, it's essential to follow proper food safety guidelines to prevent bacterial growth and foodborne illness. Cooked meat should be cooled to room temperature within two hours of cooking, then refrigerated or frozen promptly. When refrigerating cooked meat, it's best to store it in a covered, airtight container at a temperature of 40°F (4°C) or below. When freezing cooked meat, it's best to store it in airtight, moisture-proof packaging or freezer bags to prevent freezer burn and other forms of spoilage. Cooked meat can be safely reheated to an internal temperature of 165°F (74°C) before consumption. It's also important to note that even if cooked meat is stored properly, its quality may decrease over time, so it's best to consume it within a few days of cooking for optimal flavor and texture.

Freezer Storage Options

When it comes to freezer storage options, there are several choices available to keep your vacuum-sealed meat fresh for a longer period. The most common options include upright freezers, chest freezers, and freezer drawers. Upright freezers are ideal for small to medium-sized households, as they provide easy access to stored items and take up less floor space. Chest freezers, on the other hand, offer more storage capacity and are suitable for larger households or for those who want to stock up on meat. Freezer drawers, typically found in high-end refrigerators, provide a convenient and space-saving solution for storing small quantities of meat. Regardless of the freezer type, it's essential to maintain a consistent freezer temperature of 0°F (-18°C) or below to ensure the quality and safety of the stored meat. Additionally, it's crucial to label and date the vacuum-sealed meat to keep track of storage time and ensure that older items are consumed before newer ones. By choosing the right freezer storage option and following proper storage practices, you can enjoy your vacuum-sealed meat for a longer period while maintaining its quality and flavor.

Signs of Spoilage and Safety Precautions

When it comes to food safety, recognizing the signs of spoilage is crucial to prevent foodborne illnesses. Spoilage can occur due to various factors, including improper handling, storage, and cooking techniques. To ensure the quality and safety of food, it is essential to be aware of the visible signs of spoilage, such as changes in texture, sliminess, and unusual odors. In this article, we will discuss the key signs of spoilage and safety precautions to take, including visual inspection and odor detection, texture and sliminess changes, and refrigeration and handling best practices. By understanding these signs and taking proactive measures, individuals can significantly reduce the risk of foodborne illnesses and maintain a safe and healthy food environment. One of the most effective ways to detect spoilage is through visual inspection and odor detection, which can help identify potential issues before they become severe.

Visual Inspection and Odor Detection

When it comes to determining the freshness and safety of vacuum-sealed meat, visual inspection and odor detection play crucial roles. A thorough visual examination can reveal signs of spoilage, such as slimy texture, mold growth, or discoloration. Check for any visible signs of leakage or damage to the packaging, as this can compromise the meat's safety. Additionally, inspect the meat's color, which should be consistent with its type and age. For instance, beef should be a deep red color, while poultry should be a pale pink. Any unusual color changes or uneven color distribution can indicate spoilage. Furthermore, check for any visible signs of dehydration, such as shrinkage or dryness, which can affect the meat's texture and quality. When it comes to odor detection, a strong, unpleasant smell is often a clear indication of spoilage. Fresh meat should have a mild, slightly sweet smell, while spoiled meat can emit a pungent, sour, or ammonia-like odor. If you notice any unusual or strong odors, it's best to err on the side of caution and discard the meat. By combining visual inspection and odor detection, you can make an informed decision about the safety and freshness of your vacuum-sealed meat.

Texture and Sliminess Changes

When it comes to detecting spoilage in vacuum-sealed meat, changes in texture and sliminess are crucial indicators. Fresh meat typically has a firm, springy texture, while spoiled meat becomes soft, mushy, and develops a sticky or tacky feel. This is often accompanied by a noticeable increase in sliminess, which can be a sign of bacterial growth. In particular, vacuum-sealed meat that has been contaminated with bacteria such as Pseudomonas or Psychrobacter may exhibit a characteristic slimy or gelatinous texture. If you notice any unusual changes in texture or sliminess, it's essential to err on the side of caution and discard the meat to avoid foodborne illness. Additionally, always check the meat for any visible signs of mold, yeast, or other microorganisms, which can also indicate spoilage. By paying attention to these subtle changes, you can help ensure the safety and quality of your vacuum-sealed meat.

Refrigeration and Handling Best Practices

Refrigeration and handling best practices play a crucial role in extending the shelf life of vacuum-sealed meat. To maintain optimal freshness, it is essential to store vacuum-sealed meat at a consistent refrigerator temperature of 40°F (4°C) or below. Ensure that the meat is placed in a covered container or zip-top bag to prevent cross-contamination and exposure to air. When handling vacuum-sealed meat, always use clean utensils and cutting boards to prevent the transfer of bacteria. It is also crucial to check the meat regularly for signs of spoilage, such as off odors, slimy texture, or mold growth. Additionally, it is recommended to label and date the vacuum-sealed meat to ensure that older products are consumed before newer ones. By following these refrigeration and handling best practices, you can significantly extend the shelf life of your vacuum-sealed meat and maintain its quality and safety.