How Is Gum Made

Here is the introduction paragraph: Gum, a ubiquitous product found in many cultures around the world, has a rich history that spans thousands of years. From its ancient origins to its modern-day manufacturing process, the production of gum has evolved significantly over time. But have you ever wondered how gum is made? What ingredients are used to create this chewy, flavorful treat? And how has the manufacturing process changed over the centuries? To answer these questions, we'll take a journey through the history of gum, exploring its origins and evolution over time. We'll also examine the ingredients that go into making gum, from natural waxes to artificial sweeteners. Finally, we'll delve into the manufacturing process, revealing the steps involved in transforming these ingredients into the gum we know and love. Let's start by taking a look at the history of gum, which dates back to ancient civilizations.

The History of Gum

The history of gum is a long and winding road that spans thousands of years, with its roots in ancient civilizations, its evolution during the Industrial Revolution, and its modern-day manifestations. From the earliest recorded use of chicle in ancient Mesoamerica to the mass-produced, sugar-coated sticks of today, gum has been a constant companion to humans, providing a quick fix of flavor, a stress-relieving habit, and a social bonding experience. In this article, we will explore the fascinating history of gum, from its ancient origins to its modern-day incarnations. We will delve into the ancient civilizations that first discovered the joys of gum, the Industrial Revolution that transformed the industry, and the modern era that has seen the rise of new flavors, textures, and uses for gum. Let's start our journey by exploring the ancient civilizations that first fell in love with gum.

The Ancient Civilizations of Gum

The ancient civilizations of gum date back thousands of years, with evidence of gum-like substances being used by various cultures around the world. One of the earliest recorded uses of gum was by the ancient Mayans and Aztecs in Central America, who used a substance called "chicle" to create a sticky, rubber-like material. Chicle was harvested from the sapodilla tree and was used not only for its adhesive properties but also for its medicinal and spiritual significance. The Mayans and Aztecs believed that chicle had healing properties and used it to treat a variety of ailments, including toothaches and skin irritations. In addition to its practical uses, chicle was also used in rituals and ceremonies, where it was believed to have spiritual significance. The use of chicle was not limited to the Mayans and Aztecs, as it was also used by other ancient civilizations in the region, including the Olmec and the Toltec. The ancient Greeks and Romans also used a type of gum, known as "mastiche," which was derived from the resin of the mastic tree. Mastiche was used for a variety of purposes, including as a breath freshener, a digestive aid, and a treatment for skin irritations. In ancient China, gum was used for medicinal purposes, including as a treatment for indigestion and diarrhea. The use of gum in ancient China dates back to the Han Dynasty, where it was used to treat a variety of ailments, including fever and rheumatism. In addition to its medicinal uses, gum was also used in ancient China for its adhesive properties, where it was used to bind papers and other materials together. Overall, the ancient civilizations of gum demonstrate the long history and versatility of gum-like substances, which have been used for a variety of purposes, including medicinal, spiritual, and practical uses.

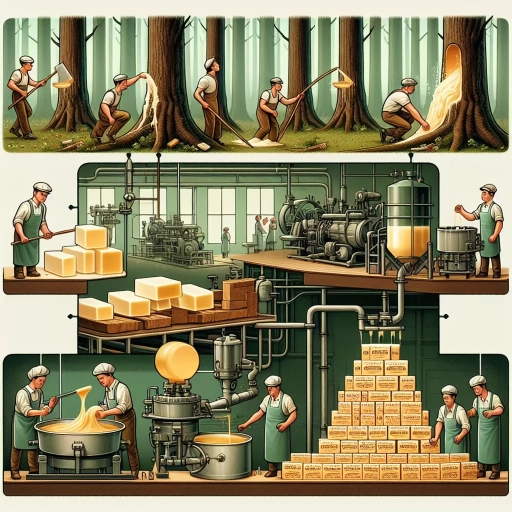

The Industrial Revolution of Gum

The Industrial Revolution of Gum was a transformative period in the history of chewing gum, marked by significant advancements in manufacturing technology and the introduction of new materials. Prior to this era, chewing gum was primarily made from natural substances such as chicle, a sap harvested from the sapodilla tree, and beeswax. However, with the advent of the Industrial Revolution, gum manufacturers began to experiment with synthetic materials like paraffin wax and petroleum-based products. This shift enabled mass production and made chewing gum more accessible and affordable for the general public. The introduction of the first commercial chewing gum, "State of Maine Pure Spruce Gum," in 1848, marked the beginning of the Industrial Revolution of Gum. This product was made from spruce tree resin and was marketed as a healthier alternative to traditional chewing tobacco. The late 19th and early 20th centuries saw the rise of iconic gum brands like Wrigley's and Juicy Fruit, which further popularized chewing gum and cemented its place in popular culture. The Industrial Revolution of Gum also led to the development of new gum textures and flavors, such as bubble gum and fruit-flavored gum, which have become staples of the industry. Today, the global chewing gum market is a multi-billion-dollar industry, with a wide range of products catering to diverse consumer preferences. The Industrial Revolution of Gum played a pivotal role in shaping the modern chewing gum industry, and its impact continues to be felt in the production and consumption of gum worldwide.

The Modern Era of Gum

The modern era of gum has seen significant advancements in terms of ingredients, manufacturing processes, and product offerings. One of the most notable developments is the introduction of sugar-free gum, which has become increasingly popular in recent years. This type of gum uses artificial sweeteners such as aspartame, sucralose, or xylitol, which provide sweetness without the calories. Sugar-free gum is particularly beneficial for individuals with dietary restrictions or preferences, such as those with diabetes or those who follow a low-carb diet. Additionally, sugar-free gum has been shown to have oral health benefits, as it can help prevent tooth decay and promote saliva production. Another significant development in the modern era of gum is the rise of functional gum, which is designed to provide specific health benefits beyond just freshening breath. Examples of functional gum include gum that contains vitamins, minerals, or antioxidants, as well as gum that is designed to help quit smoking or manage stress. These types of gum often use natural ingredients and are marketed as a healthier alternative to traditional gum. The modern era of gum has also seen the introduction of new textures and flavors, such as gummies, sours, and fruit flavors. These innovations have helped to keep the gum industry fresh and exciting, and have appealed to a new generation of consumers who are looking for unique and fun products. Overall, the modern era of gum has been marked by significant innovation and diversification, and it will be interesting to see how the industry continues to evolve in the future.

The Ingredients of Gum

Chewing gum is a ubiquitous product that has been a part of human culture for thousands of years. From its ancient origins as a natural resin to its modern forms as a mass-produced confectionery, gum has evolved significantly over time. Today, chewing gum is a complex mixture of various ingredients, each playing a crucial role in its texture, taste, and functionality. The ingredients of gum can be broadly categorized into three main groups: natural and synthetic rubbers, softeners and waxes, and flavorings and sweeteners. Natural and synthetic rubbers provide the chewy base of the gum, while softeners and waxes help to create a smooth and pliable texture. Flavorings and sweeteners, on the other hand, give gum its distinctive taste and aroma. In this article, we will delve into the world of gum ingredients, starting with the foundation of gum: natural and synthetic rubbers.

Natural and Synthetic Rubbers

Natural and synthetic rubbers are two types of elastomers used in the production of chewing gum. Natural rubber, also known as cis-1,4-polyisoprene, is derived from the sap of the rubber tree (Hevea brasiliensis). It is a biodegradable and renewable resource that has been used for centuries in various applications, including chewing gum. Natural rubber provides excellent elasticity and chewiness to gum, making it a popular choice for many manufacturers. On the other hand, synthetic rubber, such as polyisobutylene and polyvinyl acetate, is produced through chemical reactions involving petroleum-based materials. Synthetic rubber is more resistant to heat and oxidation than natural rubber, making it a better choice for gum products that require a longer shelf life. Additionally, synthetic rubber can be formulated to have specific properties, such as texture and color, which can enhance the overall gum experience. Both natural and synthetic rubbers play important roles in the production of chewing gum, and manufacturers often blend them together to achieve the desired texture and performance.

Softeners and Waxes

Softeners and waxes are essential components in the production of chewing gum, playing a crucial role in determining the final product's texture, consistency, and overall mouthfeel. Softeners, such as lanolin, mineral oil, and petroleum-based waxes, are added to the gum base to reduce its hardness and brittleness, making it more comfortable to chew. These softeners also help to improve the gum's flexibility and elasticity, allowing it to stretch and recover without breaking. On the other hand, waxes like paraffin, beeswax, and carnauba wax are used to provide a smooth, glossy finish to the gum, as well as to help control the release of flavors and sweeteners. The combination of softeners and waxes in the gum base enables manufacturers to achieve the perfect balance of texture and consistency, resulting in a product that is both enjoyable to chew and long-lasting. By carefully selecting and blending these ingredients, gum manufacturers can create a wide range of products with varying textures and properties, from soft and chewy to firm and crunchy. Ultimately, the strategic use of softeners and waxes is critical to producing high-quality chewing gum that meets the expectations of consumers.

Flavorings and Sweeteners

Flavorings and sweeteners are essential components of gum, as they provide the desired taste and aroma. Flavorings can be natural or artificial, and they come in a wide range of options, including spearmint, peppermint, fruit flavors, and spices. Natural flavorings are derived from plants, fruits, and herbs, while artificial flavorings are created in a laboratory. Sweeteners, on the other hand, are added to balance out the flavor and provide a pleasant taste experience. Common sweeteners used in gum include sugar, corn syrup, and artificial sweeteners like aspartame and sucralose. Some gum products may also contain sugar substitutes like xylitol or sorbitol, which are low in calories and do not contribute to tooth decay. The type and amount of flavorings and sweeteners used in gum can vary depending on the desired taste profile and the target market. For example, some gum products may be designed to be sugar-free or low-calorie, while others may be formulated to have a strong, intense flavor. Overall, flavorings and sweeteners play a crucial role in creating a gum product that is both enjoyable to chew and appealing to consumers.

The Manufacturing Process of Gum

The manufacturing process of gum is a complex and multi-step process that involves several stages, from compounding and mixing to shaping and forming, and finally, wrapping and packaging. The journey of creating a piece of gum begins with the combination of various ingredients, including gum base, elastomers, resins, fats, and waxes, which are mixed together to create a uniform blend. This blend is then heated and cooled to create a pliable mixture that can be shaped and formed into the desired shape. The shaped gum is then wrapped and packaged, ready for distribution and consumption. In this article, we will delve into the details of each stage of the gum manufacturing process, starting with the crucial step of compounding and mixing.

Compounding and Mixing

The manufacturing process of gum involves several stages, including compounding and mixing. Compounding is the process of combining the gum base with other ingredients, such as elastomers, resins, fats, and waxes, to create a uniform mixture. The gum base is the primary component of the gum, providing its chewy texture and durability. Elastomers, such as synthetic rubber, are added to improve the gum's elasticity and flexibility. Resins, like polyvinyl acetate, help to bind the ingredients together and provide a smooth texture. Fats and waxes, such as paraffin and beeswax, are added to give the gum its desired texture and mouthfeel. The compounding process involves heating and mixing the ingredients together in a specific order to create a uniform blend. The mixture is then cooled and formed into a sheet or block, which is then cut into small pieces. The compounding process is critical in determining the final texture and quality of the gum. Mixing is the process of combining the gum base with other ingredients, such as sweeteners, flavorings, and colorings, to create the final product. The mixing process involves blending the ingredients together in a specific order to create a uniform mixture. The mixture is then formed into the desired shape, such as a stick or a ball, and packaged for distribution. The mixing process is critical in determining the final flavor and texture of the gum. Overall, the compounding and mixing processes are crucial stages in the manufacturing process of gum, as they determine the final quality and texture of the product.

Shaping and Forming

The manufacturing process of gum involves several stages, including shaping and forming. After the gum base has been mixed with the desired ingredients, it is then shaped and formed into its desired shape. This can be done through various methods, including extrusion, rolling, and cutting. Extrusion involves forcing the gum base through a die to create a specific shape, such as a stick or a ball. Rolling involves using a series of rollers to shape the gum base into a sheet or a rope. Cutting involves using a machine to cut the gum base into specific shapes or sizes. The shaped gum is then wrapped in a wrapper or packaged in a container for distribution. The shaping and forming process is crucial in determining the final texture and appearance of the gum. For example, a gum that is extruded into a stick shape will have a smooth and uniform texture, while a gum that is rolled into a sheet will have a more irregular texture. The shaping and forming process also allows manufacturers to create a wide range of gum products, from traditional stick gum to more innovative products such as gum balls and gum strips. Overall, the shaping and forming process is an important step in the manufacturing process of gum, as it allows manufacturers to create a wide range of products with different textures and appearances.

Wrapping and Packaging

The manufacturing process of gum involves several stages, from the initial mixing of ingredients to the final packaging of the product. After the gum base has been mixed with the desired ingredients, such as sweeteners, flavorings, and colorings, it is then formed into its desired shape. This can be done through various methods, including extrusion, rolling, or cutting. Once the gum has been shaped, it is then wrapped and packaged for distribution. The wrapping and packaging process is a crucial step in the manufacturing process, as it helps to preserve the freshness and quality of the gum. There are several types of wrapping and packaging methods used in the gum industry, including individual wrapping, bulk packaging, and blister packaging. Individual wrapping involves wrapping each piece of gum in a separate wrapper, while bulk packaging involves packaging multiple pieces of gum in a single container. Blister packaging involves packaging the gum in a plastic blister pack, which is then sealed with a cardboard backing. The type of wrapping and packaging method used depends on the type of gum being produced, as well as the desired level of freshness and quality. For example, sugar-free gum may require individual wrapping to prevent moisture from entering the package, while bulk packaging may be more suitable for gum that is less sensitive to moisture. Overall, the wrapping and packaging process is an important step in the manufacturing process of gum, as it helps to ensure that the product remains fresh and of high quality until it reaches the consumer.