How To Cut Mirror

Cutting a mirror can be a daunting task, especially for those who are new to DIY projects or have never worked with glass before. However, with the right techniques and preparation, it can be a straightforward process that yields professional-looking results. To achieve a successful mirror-cutting experience, it's essential to understand the importance of preparation, the various cutting techniques for different types of mirrors, and the necessary post-cutting procedures to ensure a polished finish. In this article, we will delve into the world of mirror cutting, exploring the key steps to take before making the first cut, the most effective techniques for cutting different types of mirrors, and the crucial procedures to follow after cutting to achieve a professional finish. By the end of this article, you will be equipped with the knowledge and confidence to tackle your mirror-cutting project with ease. So, let's start with the foundation of a successful mirror-cutting experience: preparation is key.

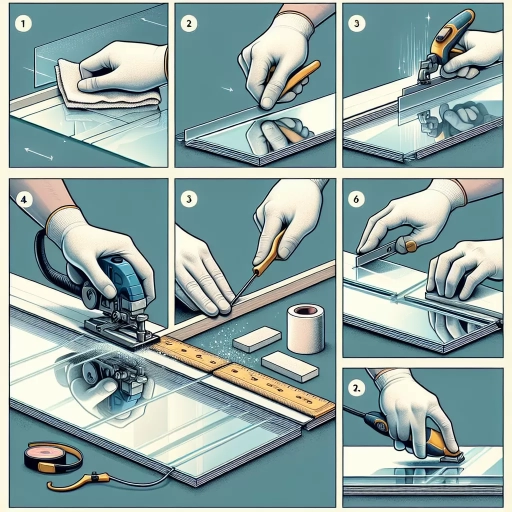

Preparation is Key

When it comes to hanging a mirror, many people assume it's a simple task that can be completed in a matter of minutes. However, this assumption can lead to a multitude of problems, from uneven hanging to damaged walls. To avoid these issues, preparation is key. Before you start hanging your mirror, it's essential to take the time to prepare properly. This includes choosing the right tools and materials for the job, measuring and marking the mirror accurately to ensure it's level and secure, and preparing a safe and stable workspace to prevent accidents. By taking these steps, you can ensure a successful and stress-free mirror-hanging experience. With the right preparation, you'll be able to hang your mirror with confidence and achieve professional-looking results. So, let's start with the first step: choosing the right tools and materials.

Choose the Right Tools and Materials

When it comes to cutting a mirror, having the right tools and materials is crucial for a successful outcome. A good quality glass cutter or a diamond blade saw is essential for making precise cuts. A glass cutter is a handheld tool with a small wheel that scores the glass, while a diamond blade saw is a power tool that uses a diamond-coated blade to cut through the glass. It's also important to have a straightedge or a template to guide the cutter and ensure straight cuts. Additionally, a pair of gloves and safety glasses should be worn to protect against cuts and flying glass particles. A work surface covered with a rubber mat or a non-slip material can also help prevent the mirror from slipping and breaking during the cutting process. Furthermore, a marker or a pencil can be used to mark the cutting line, and a ruler or a measuring tape can be used to measure and mark the dimensions of the cut. Having all these tools and materials ready and within reach can make the cutting process much easier and more efficient.

Measure and Mark the Mirror Accurately

When it comes to cutting a mirror, accuracy is crucial to achieve a precise fit and avoid costly mistakes. To measure and mark the mirror accurately, start by using a high-quality tape measure to take precise measurements of the area where the mirror will be installed. Record the measurements carefully, taking note of any obstructions, such as electrical outlets or windows. Next, transfer the measurements to the mirror using a pencil and a straightedge, ensuring that the marks are clear and visible. Use a ruler or a square to double-check the accuracy of the measurements and make any necessary adjustments. It's also essential to consider the bevel or edge of the mirror, as this can affect the overall size and fit. To account for this, measure the bevel and add it to the overall dimensions. Finally, use a marker or a piece of masking tape to mark the cutting line, making sure it is straight and even. By taking the time to measure and mark the mirror accurately, you can ensure a precise cut and a professional-looking finish.

Prepare a Safe and Stable Workspace

Preparing a safe and stable workspace is crucial when cutting a mirror. A dedicated workspace will help prevent accidents and ensure a successful cutting process. Start by clearing a large, flat surface, such as a table or countertop, of any clutter or obstructions. Cover the surface with a durable, heat-resistant material, such as a ceramic tile or a heat-resistant mat, to protect it from damage. Next, ensure the workspace is well-ventilated and free from any flammable materials. A stable and secure workspace will also help prevent the mirror from shifting or breaking during the cutting process. Additionally, consider using a mirror cutting mat or a specialized cutting surface, which can provide extra support and protection for the mirror. By taking the time to prepare a safe and stable workspace, you can minimize the risk of accidents and ensure a successful mirror cutting experience.

Cutting Techniques for Different Types of Mirrors

Cutting mirrors requires precision and the right techniques to avoid damage and ensure a clean finish. Different types of mirrors demand distinct cutting methods to achieve the desired results. For standard mirrors, a glass cutter is often the tool of choice, allowing for precise cuts and minimal waste. However, for thicker or tinted mirrors, a diamond blade may be necessary to effectively cut through the material. In more complex cases, such as large or intricately shaped mirrors, a wet saw can provide the necessary power and control. By understanding the specific cutting techniques required for each type of mirror, individuals can achieve professional-looking results and avoid costly mistakes. In this article, we will explore the various cutting techniques for different types of mirrors, starting with the use of a glass cutter for standard mirrors.

Using a Glass Cutter for Standard Mirrors

When it comes to cutting standard mirrors, a glass cutter is the most commonly used tool. A glass cutter is a handheld device with a small, rotating wheel that scores the glass, allowing it to be broken cleanly along the desired line. To use a glass cutter for standard mirrors, start by ensuring the mirror is clean and dry. Any dirt, dust, or moisture can interfere with the cutting process and lead to uneven breaks. Next, measure and mark the mirror where you want to make the cut, using a straightedge or ruler to draw a clear line. Place the glass cutter on the mark and apply gentle, consistent pressure, moving the cutter along the line in a smooth, continuous motion. Apply enough pressure to score the glass, but avoid applying too much pressure, which can cause the glass to shatter. Once you've scored the glass, use a pair of running pliers or a breaking plier to snap the glass along the score line. For larger mirrors, you may need to use a combination of a glass cutter and a straightedge or a specialized mirror cutting tool to ensure a clean, accurate cut. It's also important to wear protective gear, including gloves and safety glasses, when cutting mirrors to prevent injury from sharp edges or flying glass shards. By following these steps and using a glass cutter, you can achieve a clean, precise cut in your standard mirror.

Applying a Diamond Blade for Thick or Tinted Mirrors

When it comes to cutting thick or tinted mirrors, a diamond blade is the most effective tool to use. A diamond blade is a type of saw blade that is coated with diamond particles, which are extremely hard and abrasive. This makes it ideal for cutting through tough materials like thick glass or tinted mirrors. To apply a diamond blade for cutting thick or tinted mirrors, start by selecting the right blade for the job. Look for a blade that is specifically designed for cutting glass or mirrors, and make sure it is the correct size for your saw. Next, ensure that your saw is properly set up and calibrated for cutting glass. This may involve adjusting the saw's speed and pressure settings. Once your saw is set up, carefully place the mirror on a stable surface and align the blade with the cutting line. Slowly and carefully begin cutting the mirror, applying gentle to moderate pressure. It's essential to maintain a steady and consistent pace to avoid applying too much pressure, which can cause the blade to bind or the mirror to shatter. As you cut, keep the blade cool by periodically spraying it with water or using a coolant. This will help prevent the blade from overheating and extend its lifespan. Finally, once you have completed the cut, carefully remove the mirror from the saw and inspect the edge for any imperfections or chips. If necessary, use a glass grinder or sandpaper to smooth out the edge and remove any sharp edges. By following these steps and using a diamond blade, you can achieve a precise and clean cut on thick or tinted mirrors.

Utilizing a Wet Saw for Large or Complex Cuts

When tackling large or complex cuts in mirrors, a wet saw is often the most effective tool for the job. A wet saw, also known as a tile saw or glass saw, is a specialized power tool designed to make precise cuts in glass and other brittle materials. To utilize a wet saw for cutting mirrors, start by preparing the saw and the work area. Ensure the saw is properly assembled and the blade is securely in place. Next, don the necessary safety gear, including gloves, safety glasses, and a dust mask. Position the mirror on a stable, flat surface, and mark the desired cut line with a marker or pencil. Apply a small amount of water to the saw blade and the mirror, as this will help reduce friction and prevent the glass from shattering. With the saw turned on, slowly and steadily guide the mirror through the blade, maintaining a consistent pace and applying gentle pressure. For complex cuts, it may be necessary to use a combination of straight and curved cuts, or to make multiple passes with the saw. To achieve a smooth, chip-free edge, use a diamond blade or a specialized glass-cutting blade, and apply a steady stream of water to the cutting area throughout the process. By following these steps and taking the necessary precautions, you can successfully use a wet saw to make large or complex cuts in mirrors, achieving professional-looking results with ease.

Post-Cutting Procedures for a Professional Finish

To achieve a professional finish, post-cutting procedures are crucial in ensuring a high-quality outcome. After cutting a material, whether it's metal, wood, or plastic, the cut edge can be rough and uneven. To rectify this, it's essential to smooth the cut edge with a diamond stone, which helps to remove any imperfections and create a smooth surface. Additionally, removing any debris or residue from the cutting process is vital to prevent any damage or contamination. Finally, inspecting and polishing the cut area is necessary to ensure a flawless finish. By following these post-cutting procedures, individuals can achieve a professional finish that meets their standards. Smoothing the cut edge with a diamond stone is the first step in this process, and it's essential to get it right to set the foundation for a high-quality finish.

Smoothing the Cut Edge with a Diamond Stone

When cutting a mirror, one of the most crucial steps in achieving a professional finish is smoothing the cut edge with a diamond stone. This process is essential in removing any imperfections, such as chips or scratches, that may have occurred during the cutting process. To begin, select a diamond stone with a coarse grit, typically around 100-150, and place it on a flat surface. Next, position the mirror's cut edge on the stone, ensuring it is aligned with the stone's surface. With gentle to moderate pressure, move the mirror back and forth along the stone, maintaining consistent contact between the edge and the stone. This motion helps to wear down any rough spots and smooth out the edge. As you progress, inspect the edge regularly to check for any remaining imperfections. Once the edge appears smooth, switch to a finer grit stone, such as 220-240, and repeat the process. This will help to further refine the edge and remove any minor scratches. By smoothing the cut edge with a diamond stone, you can achieve a professional finish that is both safe and visually appealing.

Removing Any Debris or Residue

When it comes to removing any debris or residue after cutting a mirror, it's essential to take a meticulous approach to ensure a professional finish. Start by carefully inspecting the cut edge for any remaining glass particles or debris. Use a soft-bristled brush or a lint-free cloth to gently sweep away any loose particles. Next, dampen a clean, lint-free cloth with distilled water and wipe down the cut edge to remove any remaining residue or dust. Avoid using paper towels or other abrasive materials that can scratch the glass. For more stubborn residue, mix a solution of equal parts water and white vinegar, and apply it to the affected area using a soft cloth. Gently rub the area in a circular motion, then wipe clean with a damp cloth. If there are any remaining streaks or residue, use a glass cleaner and a lint-free cloth to remove them. Finally, use a dry, lint-free cloth to wipe down the entire mirror, removing any excess moisture or streaks. By following these steps, you can ensure a professional finish and a sparkling clean mirror that's free of debris and residue.

Inspecting and Polishing the Cut Area

Inspecting and polishing the cut area is a crucial step in achieving a professional finish when cutting mirrors. After cutting the mirror, it's essential to inspect the cut area for any imperfections, such as chips, cracks, or rough edges. This can be done using a magnifying glass or a jeweler's loupe to get a closer look. If any imperfections are found, they can be addressed by polishing the area using a series of progressively finer grits of polishing compound. Starting with a coarse grit, such as 120, and working up to a fine grit, such as 600, will help to remove any scratches or imperfections. It's also important to use a polishing wheel or felt wheel to help remove any scratches or imperfections, as these tools can be more effective than polishing by hand. Additionally, using a polishing compound specifically designed for glass, such as cerium oxide or aluminum oxide, will help to achieve a high-gloss finish. By taking the time to inspect and polish the cut area, you can ensure a professional finish that is free of imperfections and has a high-gloss shine.