How To Stud Tires

As the winter months approach, many drivers are preparing their vehicles for the harsh weather conditions that come with it. One of the most effective ways to improve traction and control on snowy and icy roads is to stud your tires. However, studding tires can be a daunting task, especially for those who are new to the process. In this article, we will provide a comprehensive guide on how to stud tires, covering the basics of studding, preparing your tires for studding, and the safe and effective techniques for studding. To get started, it's essential to understand the basics of studding tires, including the different types of studs, the benefits of studding, and the potential risks involved. By understanding the fundamentals, you'll be better equipped to prepare your tires for studding and ultimately, stud them safely and effectively. Understanding the Basics of Studding Tires is a crucial step in the process, and it's where we'll begin our journey to help you master the art of studding your tires.

Understanding the Basics of Studding Tires

As winter approaches, many drivers are faced with the daunting task of navigating icy and snowy roads. One effective way to improve traction and safety on these hazardous roads is by studding tires. But what exactly are studs, and how do they work? In this article, we will delve into the basics of studding tires, exploring the different types of studs available, and the importance of studding tires for winter driving. By understanding the fundamentals of studding tires, drivers can make informed decisions about their vehicle's safety and performance during the winter months. So, let's start by examining the basics of studs and how they work.

What are Studs and How Do They Work?

Studs are small, sharp metal protrusions that are inserted into the tread of a tire to provide additional traction on snow and ice. They work by digging into the surface of the road, creating a mechanical bond between the tire and the road that helps to improve acceleration, braking, and cornering. The studs are typically made of a hard, wear-resistant metal such as tungsten carbide, and are designed to be durable and long-lasting. When a studded tire rotates, the studs make contact with the road surface, creating a series of small, sharp points of contact that help to grip the road. This increased traction allows the vehicle to accelerate, brake, and corner more safely and effectively on snowy and icy roads. The studs are usually spaced at regular intervals around the circumference of the tire, and are typically 1-2 mm in length. The number and spacing of the studs can vary depending on the specific tire and the intended use, but the basic principle of how they work remains the same. Overall, studs are an effective way to improve traction on snowy and icy roads, and are a popular choice for drivers who live in areas with harsh winter conditions.

Types of Studs Available for Tires

There are several types of studs available for tires, each designed to provide optimal traction and performance in specific winter driving conditions. The most common types of studs are carbide studs, which are made from a combination of tungsten carbide and steel. These studs are extremely durable and provide excellent traction on ice and hard-packed snow. Another type of stud is the ceramic stud, which is made from a combination of ceramic and steel. Ceramic studs are designed to provide a quieter ride and are often used on passenger vehicles. Steel studs are also available and are a more affordable option, but they can be noisier and may not provide the same level of traction as carbide or ceramic studs. Some tire manufacturers also offer specialized studs, such as studs with a unique tread pattern or studs designed for specific types of vehicles, such as trucks or SUVs. Additionally, some studs are designed to be more environmentally friendly, such as studs made from recycled materials or studs that are designed to reduce noise pollution. Overall, the type of stud used will depend on the specific needs and preferences of the driver, as well as the type of vehicle and driving conditions.

Importance of Studding Tires for Winter Driving

Studding tires is a crucial aspect of winter driving, particularly in regions with harsh weather conditions. The primary importance of studding tires lies in their ability to provide enhanced traction and control on icy and snowy roads. The small metal studs embedded in the tire tread create a biting action that grips the road surface, allowing drivers to maintain speed and stability even on slippery surfaces. This is especially vital for vehicles that frequently travel on steep hills or mountainous terrain, where loss of traction can be catastrophic. Furthermore, studded tires can significantly reduce the risk of accidents caused by skidding or sliding on black ice or compacted snow. By providing a secure grip on the road, studded tires enable drivers to brake and accelerate with confidence, even in the most treacherous winter conditions. Additionally, studded tires can also improve the overall safety of winter driving by reducing the risk of hydroplaning, which occurs when a vehicle's tires lose contact with the road surface due to water or slush. Overall, studding tires is a simple yet effective way to enhance winter driving safety, and is an essential consideration for anyone who regularly drives in snowy or icy conditions.

Preparing Your Tires for Studding

Preparing your tires for studding is a crucial step in ensuring your vehicle's safety and performance during the winter months. Studding your tires can provide the necessary traction and control on icy and snowy roads, but it's essential to take the right steps before installing studs. To begin with, it's vital to choose the right tires for studding, as not all tires are compatible with studs. Additionally, checking the tire condition and tread depth is crucial to ensure that your tires can withstand the added stress of studding. Furthermore, ensuring proper tire pressure before studding is also essential to prevent uneven wear and damage to your tires. By taking these steps, you can ensure that your tires are properly prepared for studding and provide you with the necessary traction and control on winter roads. In this article, we will explore the first step in preparing your tires for studding: choosing the right tires for studding.

Choosing the Right Tires for Studding

When it comes to choosing the right tires for studding, there are several factors to consider. First and foremost, you'll want to select tires that are specifically designed for studding, as they will have the necessary features and materials to support the added weight and stress of the studs. Look for tires with a sturdy sidewall and a robust tread compound that can withstand the rigors of studding. Additionally, consider the size and type of studs you plan to use, as this will impact the type of tire you need. For example, if you plan to use large studs, you'll want a tire with a more aggressive tread pattern to accommodate them. It's also important to consider the terrain and conditions you'll be driving in, as this will impact the type of tire you need. For example, if you'll be driving in deep snow or ice, you'll want a tire with a more aggressive tread pattern and a softer compound to provide better traction. Finally, be sure to check the manufacturer's recommendations for studding, as some tires may not be suitable for studding at all. By considering these factors, you can choose the right tires for studding and ensure a safe and successful studding process.

Checking Tire Condition and Tread Depth

Checking tire condition and tread depth is a crucial step in preparing your tires for studding. Before installing studs, it's essential to ensure your tires are in good condition and have sufficient tread depth to support the studs. Start by visually inspecting your tires for any signs of wear, damage, or uneven wear patterns. Check for cracks, cuts, or bulges on the sidewalls and tread, as these can compromise the tire's integrity and make it unsafe for studding. Next, check the tread depth by inserting a penny into the tire groove with Lincoln's head facing down. If you can see the top of Lincoln's head, your tread depth is less than 2/32" and it's time to replace your tires. For studding, a minimum tread depth of 1/4" is recommended. Additionally, check the tire's age by looking for the date code on the sidewall, which indicates the week and year the tire was manufactured. If your tires are more than six years old, it's recommended to replace them, regardless of their condition. By checking your tire condition and tread depth, you can ensure your tires are safe and suitable for studding, and that you'll get the best performance and traction from your studs.

Ensuring Proper Tire Pressure Before Studding

Here is the paragraphy: Ensuring proper tire pressure before studding is a crucial step in the process. Proper tire pressure is essential for safe and effective studding, as it ensures the tire is inflated to the correct pressure for the studs to be installed correctly. Underinflated tires can lead to uneven stud wear, reduced traction, and increased risk of tire damage. On the other hand, overinflated tires can cause the studs to be installed too deeply, leading to reduced stud life and decreased traction. To ensure proper tire pressure, check the tire pressure at least 24 hours before studding, and adjust it according to the manufacturer's recommendations. It's also important to note that tire pressure may vary depending on the temperature, so it's essential to check the pressure at the same temperature as the studding process. Additionally, it's recommended to use a high-quality tire pressure gauge to ensure accurate readings. By ensuring proper tire pressure before studding, you can ensure a safe and effective studding process, and extend the life of your tires.

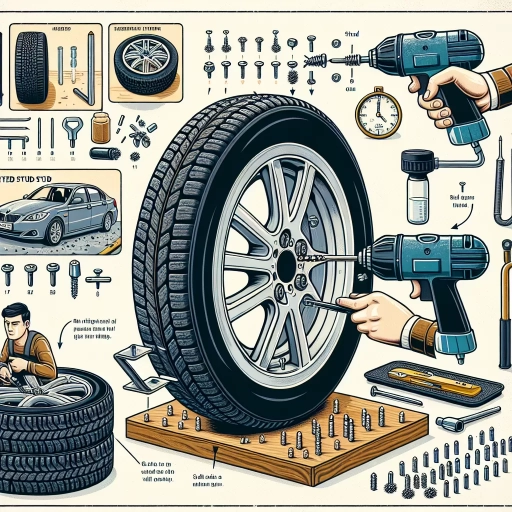

Studding Your Tires Safely and Effectively

When it comes to studding your tires safely and effectively, there are several key considerations to keep in mind. One of the most important factors is using the correct studding pattern for your vehicle, as this can greatly impact traction and stability on icy or snowy roads. Additionally, it's crucial to follow the manufacturer's instructions for studding, as they have specific guidelines for the type and number of studs that can be safely used on their tires. Finally, best practices for installing and maintaining studs are essential to ensure optimal performance and safety. By following these guidelines, you can help ensure that your studded tires are both effective and safe to use. In this article, we'll take a closer look at each of these considerations, starting with the importance of using the correct studding pattern for your vehicle.

Using the Correct Studding Pattern for Your Vehicle

Using the correct studding pattern for your vehicle is crucial to ensure optimal traction, safety, and durability of your tires. The studding pattern refers to the arrangement of studs on the tire, which can vary depending on the type of vehicle, driving conditions, and local regulations. A well-designed studding pattern can improve the tire's grip on snow and ice, reduce the risk of skidding, and minimize the impact on the road surface. On the other hand, an incorrect studding pattern can lead to reduced traction, uneven tire wear, and increased risk of accidents. To determine the correct studding pattern for your vehicle, consult your owner's manual or contact the manufacturer. Typically, studding patterns are categorized into three main types: symmetrical, asymmetrical, and directional. Symmetrical patterns are suitable for most passenger vehicles, while asymmetrical patterns are often used for trucks and SUVs. Directional patterns are designed for high-performance vehicles and provide improved traction on dry roads. When selecting a studding pattern, consider factors such as the type of driving you'll be doing, the climate, and the road conditions. It's also essential to ensure that the studding pattern complies with local regulations, as some areas may have specific requirements or restrictions on studded tires. By choosing the correct studding pattern for your vehicle, you can enjoy improved safety, performance, and peace of mind on the road.

Following Manufacturer Instructions for Studding

When it comes to studding your tires, following the manufacturer's instructions is crucial for safety and effectiveness. The manufacturer's instructions provide specific guidelines on the type of studs to use, the stud pattern, and the stud depth, all of which are critical for optimal performance. Using the wrong type of studs or installing them incorrectly can lead to reduced traction, uneven tire wear, and even damage to the tire or wheel. Furthermore, failing to follow the manufacturer's instructions can void the warranty on your tires, leaving you with costly repairs or replacements. By following the manufacturer's instructions, you can ensure that your studded tires are installed correctly, providing you with the best possible traction and control on snowy and icy roads. Additionally, following the manufacturer's instructions can also help you to avoid any potential safety hazards, such as studs coming loose or tires failing, which can be catastrophic on the road. Overall, following the manufacturer's instructions is essential for studding your tires safely and effectively, and it's a critical step that should not be overlooked.

Best Practices for Installing and Maintaining Studs

When it comes to installing and maintaining studs, there are several best practices to keep in mind to ensure optimal performance and safety. First and foremost, it's essential to choose the right type of studs for your tires, taking into account factors such as tire size, vehicle type, and driving conditions. Next, make sure to follow the manufacturer's instructions for installation, as improper installation can lead to reduced traction, uneven wear, and even tire failure. When installing studs, it's crucial to space them evenly and at the correct depth to ensure consistent traction and prevent damage to the tire. Additionally, it's recommended to use a stud installer tool to avoid damaging the tire or wheel. After installation, it's vital to check the studs regularly for wear and damage, and to replace them as needed to maintain optimal traction. Furthermore, it's essential to maintain proper tire pressure, as underinflated tires can lead to reduced traction and increased wear on the studs. Finally, it's recommended to have your tires professionally inspected and maintained by a qualified mechanic to ensure that your studs are installed and maintained correctly. By following these best practices, you can ensure that your studs are installed and maintained safely and effectively, providing you with optimal traction and control on snowy and icy roads.