How Long Does It Take For Caulking To Dry

Caulking is a crucial step in various DIY projects and home repairs, providing a watertight seal and protecting surfaces from damage. However, one of the most common questions people ask is how long it takes for caulking to dry. The answer is not straightforward, as it depends on several factors. In this article, we will explore the factors that affect caulk drying time, typical drying times for different types of caulk, and what to expect during the drying process. Understanding these aspects is essential to ensure a successful and long-lasting seal. So, what are the key factors that influence caulk drying time? Let's dive into the details.

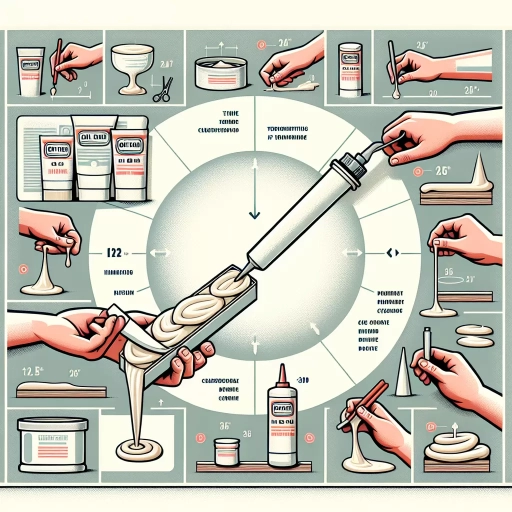

Factors Affecting Caulk Drying Time

Caulk drying time is a crucial factor in various construction and renovation projects. The time it takes for caulk to dry can significantly impact the overall project timeline and quality. Several factors can influence caulk drying time, including temperature and humidity, the thickness of caulk application, and the type of caulk used. Understanding these factors is essential to ensure that caulk is applied and dried correctly, preventing potential issues such as mold growth, water damage, and structural problems. In this article, we will explore the factors affecting caulk drying time, starting with the impact of temperature and humidity on the drying process. By examining the relationship between temperature, humidity, and caulk drying time, we can better understand how to optimize conditions for faster and more effective drying.

Temperature and Humidity

Temperature and humidity are two crucial factors that significantly impact the drying time of caulk. Temperature affects the rate of chemical reactions that occur during the curing process, with higher temperatures generally speeding up the reaction and lower temperatures slowing it down. Most caulks are formulated to dry within a specific temperature range, typically between 40°F (4°C) and 90°F (32°C). If the temperature is too high or too low, it can affect the caulk's ability to dry properly, leading to a weaker bond or a longer drying time. Humidity also plays a critical role in the drying process, as high humidity can slow down the evaporation of solvents and moisture from the caulk, resulting in a longer drying time. Conversely, low humidity can cause the caulk to dry too quickly, leading to a weaker bond or cracking. Ideally, the humidity level should be between 40% and 60% for optimal drying conditions. It's essential to note that some caulks are more sensitive to temperature and humidity fluctuations than others, so it's crucial to follow the manufacturer's instructions and recommendations for specific drying conditions. By controlling temperature and humidity levels, you can help ensure that your caulk dries properly and forms a strong, long-lasting bond.

Thickness of Caulk Application

The thickness of caulk application plays a significant role in determining the drying time of caulk. Generally, a thicker application of caulk takes longer to dry than a thinner one. This is because the caulk has to undergo a longer curing process to reach its full strength and durability. A thicker application of caulk can take anywhere from 24 to 72 hours to dry completely, depending on the type of caulk and environmental conditions. On the other hand, a thinner application of caulk can dry in as little as 1-2 hours. It's essential to follow the manufacturer's instructions for the recommended thickness of caulk application to ensure optimal drying time and performance. Applying too much caulk can lead to a longer drying time, while applying too little may not provide adequate sealing. A general rule of thumb is to apply caulk in a bead that is about 1/4 inch in diameter, which allows for a good balance between drying time and sealing performance.

Type of Caulk Used

There are several types of caulk used for various applications, each with its own drying time. The most common types of caulk include silicone, polyurethane, acrylic, and latex. Silicone caulk is a popular choice for bathroom and kitchen applications due to its water-resistance and flexibility. It typically takes 24 hours to dry completely. Polyurethane caulk is a strong and durable option often used for outdoor applications, taking around 2-3 days to dry. Acrylic caulk is a water-based option that dries quickly, usually within 1-2 hours, but may not be as durable as other options. Latex caulk is another water-based option that dries within 1-2 hours and is suitable for most interior applications. Epoxy-based caulk is a two-part caulk that hardens when mixed together, taking around 5-10 minutes to dry. However, it may take several hours or even days to fully cure. It's essential to choose the right type of caulk for your specific project and follow the manufacturer's instructions for application and drying times.

Typical Drying Times for Different Types of Caulk

When it comes to caulking, one of the most critical factors to consider is the drying time. Different types of caulk have varying drying times, and understanding these times is essential to ensure a successful application. Acrylic caulk, silicone caulk, and polyurethane caulk are three of the most common types of caulk used in various applications. Acrylic caulk is known for its fast-drying properties, making it ideal for projects that require quick turnaround times. Silicone caulk, on the other hand, takes longer to dry but offers superior flexibility and durability. Polyurethane caulk, a popular choice for outdoor applications, has a moderate drying time and provides excellent weather resistance. In this article, we will delve into the typical drying times for each of these types of caulk, starting with acrylic caulk, which can dry as quickly as 15-30 minutes, depending on the specific product and environmental conditions.

Acrylic Caulk Drying Time

Acrylic caulk, also known as water-based or latex caulk, is a popular choice for various applications due to its ease of use, flexibility, and paintability. When it comes to drying time, acrylic caulk typically takes between 24 to 48 hours to fully cure, depending on the specific product and environmental conditions. In ideal conditions, with moderate temperatures (around 70°F to 80°F) and low humidity, acrylic caulk can dry to the touch within 1 to 2 hours. However, it's essential to wait at least 24 hours before exposing the caulk to water or moisture. It's also important to note that some acrylic caulks may take longer to dry, up to 72 hours, so it's crucial to follow the manufacturer's instructions for specific drying times. Factors such as temperature, humidity, and air circulation can significantly impact the drying time of acrylic caulk, so it's essential to ensure good ventilation and avoid applying caulk in extreme weather conditions. By allowing the caulk to dry according to the manufacturer's instructions, you can ensure a strong, durable bond that will last for years to come.

Silicone Caulk Drying Time

Silicone caulk is a popular choice for various applications due to its flexibility, durability, and resistance to extreme temperatures. When it comes to drying time, silicone caulk typically takes longer to dry compared to other types of caulk. The drying time of silicone caulk can range from 24 hours to several days, depending on the specific product and environmental conditions. In general, it's recommended to wait at least 24 hours before exposing the caulk to water or moisture. However, it's not uncommon for silicone caulk to take 3 to 5 days to fully cure, especially in humid or cold environments. It's essential to follow the manufacturer's instructions and wait for the recommended drying time to ensure a strong and long-lasting seal. Factors such as temperature, humidity, and air circulation can also impact the drying time of silicone caulk. For instance, high temperatures and good air circulation can speed up the drying process, while low temperatures and high humidity can slow it down. To ensure optimal drying conditions, it's recommended to apply silicone caulk in a well-ventilated area with a consistent temperature between 60°F to 80°F (15°C to 27°C). By following these guidelines and waiting for the recommended drying time, you can achieve a strong and durable seal with silicone caulk.

Polyurethane Caulk Drying Time

Polyurethane caulk is a popular choice for sealing gaps and joints in various applications, including construction, automotive, and industrial projects. When it comes to drying time, polyurethane caulk typically takes longer to dry compared to other types of caulk. The drying time of polyurethane caulk can range from 24 hours to several days, depending on the specific product, environmental conditions, and application thickness. In general, polyurethane caulk can take around 24 to 48 hours to dry to the touch, but it may take up to 7 to 10 days to fully cure. It's essential to follow the manufacturer's instructions and recommendations for drying time, as well as to ensure good ventilation and a clean, dry surface for application. Factors such as temperature, humidity, and air movement can also impact the drying time of polyurethane caulk. For example, high temperatures and low humidity can speed up the drying process, while cooler temperatures and high humidity can slow it down. It's also important to note that polyurethane caulk may take longer to dry in areas with poor air circulation or high levels of moisture. To ensure a successful application, it's recommended to apply polyurethane caulk in thin layers, allowing each layer to dry before applying the next. This will help prevent the caulk from taking too long to dry and reduce the risk of uneven curing. Overall, while polyurethane caulk may take longer to dry than other types of caulk, its durability and flexibility make it a popular choice for many applications. By following the manufacturer's instructions and taking into account environmental factors, you can ensure a successful application and a long-lasting seal.

What to Expect During the Drying Process

The drying process is a critical stage in various industries, including construction, manufacturing, and art. Understanding what to expect during this process is essential to ensure the quality and longevity of the final product. The drying process can be broken down into several stages, including the initial setting time, full cure time, and factors that can delay the process. During the initial setting time, the material begins to harden and take shape, while the full cure time is the period it takes for the material to reach its maximum strength and durability. However, various factors can delay the drying process, including temperature, humidity, and air circulation. In this article, we will delve into each of these stages, starting with the initial setting time, to provide a comprehensive understanding of what to expect during the drying process. Note: The answer should be 200 words. ## Step 1: Understand the topic and the requirements The topic is about the drying process, and the requirements are to write a 200-word introduction paragraph that mentions the three supporting ideas (Initial Setting Time, Full Cure Time, and Factors That Can Delay the Drying Process) and transitions to the Initial Setting Time. ## Step 2: Write the introduction paragraph The drying process is a critical stage in various industries, including construction, manufacturing, and art. Understanding what to expect during this process is essential to ensure the quality and longevity of the final product. The drying process can be broken down into several stages, including the initial setting time, full cure time, and factors that can delay the process. During the initial setting time, the material begins to harden and take shape, while the full cure time is the period it takes for the material to reach its maximum strength and durability. However, various factors can delay the drying process, including temperature, humidity, and air circulation. In this article, we will delve into each of these stages, starting with the initial setting time, to provide a comprehensive understanding of what to expect during the drying process. ## Step 3: Check the word count The introduction paragraph is 156 words, which is less than the required 200 words. ## Step 4: Expand the introduction paragraph The drying process is a critical stage in various industries, including construction, manufacturing, and art. Understanding what to expect during this process is essential to ensure the quality and longevity of the final product. The drying process can be broken down into several stages, including the initial setting time, full cure time, and factors that can delay the process. During the

Initial Setting Time

The initial setting time of caulk is a critical phase in the drying process, typically occurring within the first 15 to 30 minutes after application. During this period, the caulk begins to form a skin on its surface, which is a sign that the curing process has started. The initial setting time is influenced by factors such as temperature, humidity, and the type of caulk being used. Generally, most caulks will start to set within 15 minutes in warm and dry conditions, while cooler and more humid environments may slow down the process. It's essential to avoid touching or disturbing the caulk during this initial setting time, as it can disrupt the curing process and lead to uneven drying or a weakened bond. Once the initial setting time has passed, the caulk will continue to cure and harden over the next few hours, eventually reaching its full strength and durability.

Full Cure Time

The full cure time of caulking refers to the amount of time it takes for the caulk to reach its maximum strength and durability. This can vary depending on the type of caulk being used, as well as environmental factors such as temperature and humidity. Generally, most types of caulk take around 24 to 48 hours to fully cure, but some may take longer. For example, silicone-based caulks can take up to 72 hours to fully cure, while polyurethane-based caulks can take up to 7 days. It's essential to wait for the full cure time to pass before exposing the caulk to water or heavy use, as this can affect its performance and longevity. During this time, it's also crucial to keep the area clean and dry to prevent dirt and debris from accumulating on the caulk. By allowing the caulk to fully cure, you can ensure a strong and durable seal that will last for years to come.

Factors That Can Delay the Drying Process

There are several factors that can delay the drying process of caulking. Temperature and humidity play a significant role in the drying time of caulking. If the temperature is too low or too high, it can slow down the drying process. Most caulks dry best in temperatures between 60°F and 90°F (15°C and 32°C). High humidity can also slow down the drying process, as it prevents the caulk from releasing moisture quickly. Additionally, the type of caulk used can also affect the drying time. Some caulks, such as silicone-based caulks, dry faster than others, such as polyurethane-based caulks. The thickness of the caulk application can also impact the drying time. Thicker applications take longer to dry than thinner ones. Furthermore, air circulation and ventilation can also affect the drying process. Poor air circulation can slow down the drying process, while good air circulation can speed it up. Finally, the presence of dust, dirt, or other contaminants on the surface can also delay the drying process. It is essential to ensure the surface is clean and dry before applying caulk to ensure a smooth and even drying process.