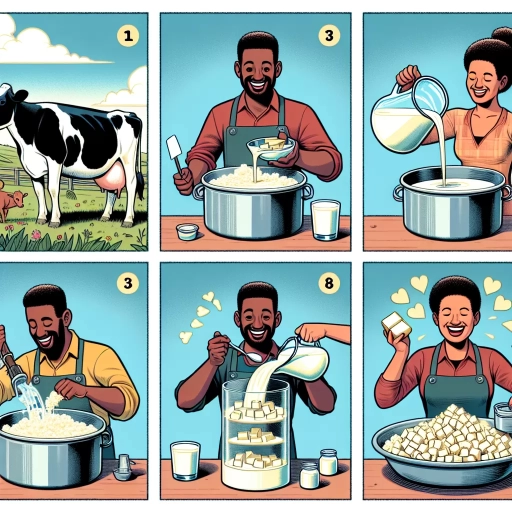

How To Make Cheese Curds

Here is the introduction paragraph: Making cheese curds is a fun and rewarding process that requires some basic knowledge and preparation. To get started, it's essential to understand the basics of cheese curds, including what they are, how they're made, and the different types of curds available. Once you have a solid grasp of the fundamentals, you can begin preparing the necessary ingredients and equipment, such as milk, cheese cultures, and a cheese mold. With your ingredients and equipment in hand, you can then move on to the cheese curd making process, which involves heating, coagulating, and shaping the curds. In this article, we'll take a closer look at each of these steps, starting with the basics of cheese curds.

Understanding the Basics of Cheese Curds

Cheese curds are a staple in many cuisines around the world, particularly in North America. These bite-sized morsels of cheese are often enjoyed on their own, used as an ingredient in various dishes, or served as a snack. But have you ever wondered what cheese curds are, how they're made, and what makes them so unique? To gain a deeper understanding of cheese curds, it's essential to explore their origins, the science behind their formation, and the different types that exist. By examining the history and production process of cheese curds, we can appreciate the craftsmanship and tradition that goes into creating these delicious treats. So, let's start by delving into the origins of cheese curds and uncovering the story behind their creation. What are Cheese Curds and Their Origins?

What are Cheese Curds and Their Origins

Cheese curds are small, bite-sized pieces of cheese that have been separated from the whey, a liquid byproduct of cheese production. They are typically made from cow's milk, but can also be produced from the milk of other animals such as goats, sheep, and buffalo. Cheese curds have a mild, slightly sweet flavor and a firm, springy texture. They are often served as a snack or appetizer, and are a popular ingredient in many dishes, including poutine, a classic Canadian dish made with French fries, cheese curds, and gravy. Cheese curds have a long history, dating back to the early days of cheese production in Europe. The process of making cheese curds involves heating the milk to a high temperature, adding a starter culture to convert the milk sugar into lactic acid, and then adding rennet, a natural enzyme that causes the milk to coagulate. The curds are then cut into small pieces and separated from the whey, which is drained off and used to make other dairy products. Cheese curds can be found in many different types of cheese, including cheddar, mozzarella, and feta. They are a versatile ingredient and can be used in a variety of dishes, from snacks and appetizers to main courses and desserts. In addition to their culinary uses, cheese curds are also a popular ingredient in many traditional dishes and are often served at social gatherings and celebrations. Overall, cheese curds are a delicious and versatile ingredient that can add flavor and texture to a wide range of dishes.

The Science Behind Cheese Curd Formation

The Science Behind Cheese Curd Formation Cheese curd formation is a complex process that involves the interaction of several factors, including milk composition, temperature, pH, and enzyme activity. It begins with the coagulation of milk, which is achieved by adding a coagulant, such as rennet, to the milk. Rennet is a complex of enzymes that helps to break down the casein proteins in milk, causing them to aggregate and form a gel-like substance. As the milk coagulates, the casein proteins begin to bond with each other, forming a network of protein fibers that gives the curd its strength and texture. The type and amount of coagulant used, as well as the temperature and pH of the milk, can all impact the final texture and flavor of the curd. For example, using a higher temperature or a stronger coagulant can result in a firmer, more crumbly curd, while using a lower temperature or a weaker coagulant can result in a softer, more gel-like curd. Additionally, the type of milk used can also impact the final product, with cow's milk producing a milder flavor and a more tender texture, while sheep's or goat's milk can produce a stronger, more tangy flavor. Overall, the science behind cheese curd formation is a delicate balance of factors that requires careful control to produce high-quality curds.

Types of Cheese Curds and Their Characteristics

Cheese curds are a delightful and versatile dairy product that can be enjoyed in various forms. There are several types of cheese curds, each with its unique characteristics, textures, and flavors. Fresh cheese curds are the most common type, typically made from cow's milk, and are known for their mild, slightly sweet flavor and firm, springy texture. They are often sold in their natural state, without any additional processing or aging, and are perfect for snacking, salads, or as a topping for poutine. Aged cheese curds, on the other hand, have been allowed to mature for a period of time, which develops a stronger, more pronounced flavor and a denser, creamier texture. They can range in color from white to golden yellow and are often used in recipes where a richer, more complex flavor is desired. Smoked cheese curds are another popular variety, which are made by exposing the curds to smoke, giving them a distinctive, savory flavor and a firm, chewy texture. They are often used as a topping for burgers, sandwiches, or as a snack on their own. Finally, flavored cheese curds are a type of curd that has been infused with additional ingredients, such as herbs, spices, or other seasonings, to create unique and exciting flavor profiles. These can range from garlic and herb to jalapeno and cheddar, and are perfect for adding a burst of flavor to any dish. Overall, the different types of cheese curds offer a wide range of possibilities for cooking, snacking, and exploring the world of cheese.

Preparing the Ingredients and Equipment

Preparing the ingredients and equipment is a crucial step in the cheese-making process. To produce high-quality cheese, it is essential to select the right type of milk, understand the role of cheese cultures and enzymes, and prepare the cheese-making equipment and workspace. The type of milk used can significantly impact the flavor, texture, and overall quality of the cheese. Cheese cultures and enzymes play a vital role in converting the milk into cheese, and their selection and application can affect the final product's characteristics. Furthermore, having the right equipment and a well-prepared workspace is necessary to ensure a smooth and efficient cheese-making process. In this article, we will explore these essential steps in more detail, starting with the selection of the right type of milk for cheese curds.

Selecting the Right Type of Milk for Cheese Curds

When it comes to selecting the right type of milk for cheese curds, there are several options to consider. Whole milk is a popular choice, as it contains a high percentage of fat, which contributes to the rich and creamy texture of cheese curds. However, it's worth noting that whole milk can be quite expensive, and some cheesemakers may prefer to use a combination of whole and skim milk to achieve a similar texture at a lower cost. Another option is to use low-fat or nonfat milk, which can produce a lighter and more crumbly texture. For those looking for a more premium product, grass-fed or organic milk can be used to create a more complex and nuanced flavor profile. Additionally, some cheesemakers may choose to use a combination of cow's milk and the milk of other animals, such as goats or sheep, to create a unique and distinctive flavor. Ultimately, the type of milk used will depend on personal preference, the desired texture and flavor of the cheese curds, and the budget of the cheesemaker.

Understanding the Role of Cheese Cultures and Enzymes

The role of cheese cultures and enzymes is crucial in the cheese-making process, particularly when it comes to creating cheese curds. Cheese cultures are a blend of microorganisms, such as bacteria, mold, or yeast, that are added to the milk to convert the milk sugar (lactose) into lactic acid. This process lowers the pH of the milk, causing it to curdle and separate into curds and whey. The type of cheese culture used will determine the flavor, texture, and overall characteristics of the final cheese product. For example, a mesophilic cheese culture is commonly used for soft cheeses like brie and feta, while a thermophilic cheese culture is used for hard cheeses like cheddar and mozzarella. Enzymes, on the other hand, are biological catalysts that help to break down the proteins and fats in the milk, making it easier for the cheese cultures to work their magic. Rennet, a complex of enzymes extracted from the stomach lining of young animals, is a common enzyme used in cheese production. It helps to coagulate the milk, creating a clean break between the curds and whey. By understanding the role of cheese cultures and enzymes, cheese makers can better control the cheese-making process, resulting in a higher quality and more consistent final product. In the context of making cheese curds, the right combination of cheese cultures and enzymes is essential for creating a smooth, creamy, and flavorful curd that will melt beautifully and add a delicious texture to any dish.

Preparing the Cheese Making Equipment and Workspace

Preparing the cheese making equipment and workspace is a crucial step in the cheese curd making process. To start, gather all the necessary equipment, including a large pot, a cheese mold or form, cheese cloth or butter muslin, a colander, and a thermometer. Ensure that all equipment is clean and sanitized to prevent contamination and spoilage. Next, prepare the workspace by covering the countertops and tables with a clean, sanitized surface, such as a plastic tablecloth or a stainless steel sheet. This will prevent any bacteria or other contaminants from coming into contact with the cheese. Additionally, make sure the workspace is well-ventilated and at a comfortable temperature, between 70°F and 75°F (21°C and 24°C), to promote optimal cheese making conditions. It's also essential to have a sink nearby for easy cleaning and sanitizing of equipment. Once the equipment and workspace are prepared, it's time to move on to the next step in the cheese curd making process.

The Cheese Curd Making Process

The art of cheese curd making is a fascinating process that requires precision, patience, and a deep understanding of the intricacies involved. From the initial heating and acidifying of the milk to the final shaping of the curds, each step plays a crucial role in determining the quality and flavor of the end product. The process begins with heating and acidifying the milk, a critical step that sets the stage for the entire cheese-making process. This initial step is followed by the cutting and stirring of the curds, a delicate process that requires great care to avoid damaging the curds. Finally, the curds are drained and shaped, a step that gives the cheese its characteristic texture and form. In this article, we will delve into the intricacies of the cheese curd making process, starting with the crucial step of heating and acidifying the milk.

Heating and Acidifying the Milk

The cheese curd making process begins with heating and acidifying the milk. This step is crucial in creating an environment that fosters the growth of beneficial bacteria and enzymes, which ultimately leads to the formation of curds. To start, the milk is heated to a temperature of around 86°F (30°C) to create an ideal environment for the bacteria to thrive. Next, a starter culture is added to the milk, which contains the necessary bacteria, such as Lactococcus lactis subsp. lactis and Lactococcus lactis subsp. cremoris, to convert the milk sugar (lactose) into lactic acid. The acidification process lowers the pH of the milk, causing the casein proteins to coagulate and form a gel-like substance. Rennet, a natural enzyme extracted from the stomach lining of young animals, is then added to the milk to help strengthen the curds and create a clean break. The combination of heat, acid, and rennet works together to create a strong and stable curd that will eventually become the cheese curds. As the milk continues to sit, the curds will firm up and separate from the whey, making it easier to cut and shape them into their desired form. By carefully controlling the temperature, acidity, and enzyme activity, cheese makers can create a wide range of cheese curds with unique flavors and textures.

Cutting and Stirring the Curds

Cutting and stirring the curds is a crucial step in the cheese curd making process. After the coagulant has been added and the milk has been left to sit for a period of time, the curds will have firmed up and separated from the whey. The next step is to cut the curds into small pieces, typically around 1/2 inch in size, to release more whey and create a smooth, even texture. This process, known as cutting, helps to break down the curds and release any trapped whey, resulting in a more consistent and better-tasting final product. Following cutting, the curds are stirred gently to separate them further and prevent them from matting together. Stirring also helps to distribute heat evenly throughout the mixture, which is important for developing the desired flavor and texture. The stirring process should be done carefully, as over-stirring can cause the curds to become tough and rubbery. The ideal stirring motion is gentle and smooth, with a focus on separating the curds rather than breaking them down further. By cutting and stirring the curds correctly, cheese makers can create a smooth, creamy, and delicious final product that is perfect for snacking, cooking, or using in a variety of recipes.

Draining and Shaping the Cheese Curds

The process of draining and shaping the cheese curds is a crucial step in the cheese curd making process. After the curdling process, the mixture is left to sit for a period of time, allowing the curds to firm up and separate from the whey. The curds are then cut into small pieces to release more whey and create a smooth, even texture. The mixture is then stirred gently to separate the curds and whey further, and the curds are allowed to settle at the bottom of the container. The whey is then drained off, and the curds are transferred to a cheesecloth or a butter muslin, where they are allowed to drain for a period of time. The curds are then gathered up and shaped into their desired form, such as a ball, a block, or a wheel. The shaping process helps to remove any excess liquid and gives the cheese its final texture and appearance. The cheese curds are then ready to be aged, packaged, and distributed to stores.