How Is Ink Made

Ink, a ubiquitous substance used in writing, printing, and art, has a rich history that spans thousands of years. From ancient civilizations to modern times, ink has played a vital role in human communication and expression. But have you ever wondered how ink is made? The process of creating ink involves a combination of traditional techniques and modern technology. To understand the intricacies of ink production, it's essential to delve into its history, explore the ingredients and composition of ink, and examine the modern manufacturing process. By tracing the evolution of ink production, we can gain a deeper appreciation for the craftsmanship and innovation that goes into creating this essential substance. Let's begin by exploring the history of ink production, which dates back to ancient Egypt and China, where ink was first used for writing and art.

The History of Ink Production

The history of ink production is a rich and fascinating tale that spans thousands of years, with various civilizations contributing to its development. From ancient natural substances to modern synthetic formulas, ink has played a crucial role in human communication and artistic expression. This article will explore the evolution of ink production, highlighting three significant periods: the use of natural substances by ancient civilizations, the development of iron gall ink in the Middle Ages, and the impact of the Industrial Revolution on ink production. We will begin by examining how ancient civilizations harnessed the power of natural substances to create the first inks, laying the foundation for the sophisticated writing materials we use today.

The Ancient Civilizations' Use of Natural Substances

The ancient civilizations were known to utilize natural substances in their daily lives, and this was also reflected in their writing practices. The earliest known writing materials were derived from plants, animals, and minerals. The ancient Sumerians, for example, used a mixture of soot and beeswax to create a crude form of ink, which they applied to clay tablets using reeds. The ancient Egyptians, on the other hand, used a combination of soot, gum, and beeswax to create a more durable and water-resistant ink, which they used to write on papyrus. The ancient Chinese also used natural substances, such as plant dyes, soot, and animal products, to create a range of ink colors. The use of natural substances in ink production continued well into the Middle Ages, with the addition of new ingredients such as iron gall and logwood. These natural substances played a crucial role in the development of writing and communication, and their use laid the foundation for the modern ink production techniques used today.

The Development of Iron Gall Ink in the Middle Ages

The development of iron gall ink in the Middle Ages marked a significant milestone in the history of ink production. This type of ink, also known as iron gall nut ink, was made from a combination of iron salts and tannins extracted from the galls of oak trees. The production of iron gall ink involved a labor-intensive process, where the galls were collected, crushed, and mixed with water to create a solution. The solution was then mixed with iron salts, such as iron sulfate or iron chloride, to create the ink. The resulting ink was a dark blue-black color and was highly valued for its durability and water resistance. Iron gall ink was widely used by scribes and artists throughout the Middle Ages, and its use continued well into the Renaissance period. The development of iron gall ink had a significant impact on the spread of knowledge and literature during this time, as it allowed for the mass production of written materials. Despite its many advantages, iron gall ink had some drawbacks, including its tendency to corrode metal nibs and its potential to damage certain types of paper. Nevertheless, iron gall ink remained a popular choice for many centuries, and its legacy can still be seen in the many historical documents and artworks that were created with it.

The Industrial Revolution's Impact on Ink Production

The Industrial Revolution had a profound impact on ink production, transforming it from a labor-intensive, small-scale process to a mechanized, mass-produced industry. With the introduction of new machinery and manufacturing techniques, ink production became faster, cheaper, and more efficient. The development of the steam engine and the rotary printing press enabled the mass production of printed materials, creating a huge demand for ink. To meet this demand, ink manufacturers began to use new raw materials, such as coal tar and synthetic dyes, which were more readily available and cheaper than traditional ingredients like soot and plant-based dyes. The introduction of the ballpoint pen in the mid-20th century further increased the demand for ink, leading to the development of new types of ink, such as quick-drying and waterproof inks. The Industrial Revolution also led to the establishment of large-scale ink manufacturing companies, which were able to produce ink on a massive scale and distribute it globally. Today, the ink industry is a multi-billion-dollar market, with a wide range of ink products available for various applications, from printing and writing to art and design. Overall, the Industrial Revolution played a crucial role in transforming the ink production process, making it more efficient, cost-effective, and widely available.

The Ingredients and Composition of Ink

Ink is a complex mixture of various ingredients, each playing a crucial role in its composition and performance. The ingredients and composition of ink are carefully formulated to achieve specific properties, such as color, flow, and durability. At the heart of ink formulation are dyes and pigments, which provide the color and vibrancy that inks are known for. However, dyes and pigments are not the only essential components of ink. Surfactants and wetting agents are also critical, as they enable the ink to flow smoothly and consistently through printing devices. Additionally, viscosity modifiers are used to adjust the ink's thickness and flow characteristics, ensuring optimal performance in various applications. In this article, we will delve into the role of dyes and pigments in ink formulation, exploring their functions, types, and importance in creating high-quality inks. Note: The answer should be 200 words. Here is the answer: Ink is a complex mixture of various ingredients, each playing a crucial role in its composition and performance. The ingredients and composition of ink are carefully formulated to achieve specific properties, such as color, flow, and durability. At the heart of ink formulation are dyes and pigments, which provide the color and vibrancy that inks are known for. However, dyes and pigments are not the only essential components of ink. Surfactants and wetting agents are also critical, as they enable the ink to flow smoothly and consistently through printing devices. Additionally, viscosity modifiers are used to adjust the ink's thickness and flow characteristics, ensuring optimal performance in various applications. The combination of these ingredients is crucial in creating high-quality inks that meet the demands of various printing technologies. The role of dyes and pigments in ink formulation is particularly significant, as they determine the color strength, lightfastness, and overall appearance of the ink. Understanding the functions, types, and importance of dyes and pigments is essential in creating high-quality inks that meet the demands of various printing applications. By examining the role of dyes and pigments, we can gain a deeper understanding of the complex composition of ink.

The Role of Dyes and Pigments in Ink Formulation

The role of dyes and pigments in ink formulation is crucial as they provide the color and writing performance of the ink. Dyes are dissolved in the ink vehicle, which is typically a mixture of water and glycerin, and are used to create a range of colors. However, dyes have some limitations, such as being prone to fading and bleeding, which can affect the overall appearance of the written text. On the other hand, pigments are finely ground particles that are suspended in the ink vehicle and provide more lightfastness and durability than dyes. Pigments are often used in combination with dyes to create a wider range of colors and to improve the overall performance of the ink. The type and amount of dye or pigment used in ink formulation can vary depending on the intended use of the ink, such as writing, printing, or artistic applications. In general, dyes are used in ballpoint pens and rollerball pens, while pigments are used in fountain pens and some types of printing inks. The choice of dye or pigment also depends on the desired color strength, lightfastness, and durability of the ink. Overall, the selection of dyes and pigments is a critical step in ink formulation, as it directly affects the color, writing performance, and overall quality of the ink.

The Use of Surfactants and Wetting Agents in Ink

The use of surfactants and wetting agents in ink is crucial for achieving optimal printing performance and image quality. Surfactants, also known as surface-active agents, are chemical compounds that reduce the surface tension of the ink, allowing it to flow smoothly and evenly onto the printing surface. This is particularly important for inkjet printing, where the ink is sprayed onto the paper through tiny nozzles. By reducing the surface tension, surfactants enable the ink to penetrate the paper more easily, resulting in sharper images and reduced bleeding. Wetting agents, on the other hand, are additives that improve the ink's ability to wet the printing surface, ensuring that the ink spreads evenly and consistently. This is especially important for printing on non-porous surfaces, such as plastics or metals, where the ink may not naturally adhere. By incorporating surfactants and wetting agents into the ink formulation, manufacturers can improve the overall print quality, increase the ink's flowability, and reduce the risk of printing defects. Additionally, these additives can also help to improve the ink's stability and shelf life, making it easier to store and transport. Overall, the use of surfactants and wetting agents is a critical component of ink formulation, and their selection and optimization are essential for achieving high-quality printing results.

The Importance of Viscosity Modifiers in Ink Composition

The viscosity modifiers in ink composition play a crucial role in determining the overall performance and quality of the ink. Viscosity modifiers are additives that adjust the flow characteristics of the ink, ensuring it flows smoothly and consistently through the printing process. The primary function of viscosity modifiers is to maintain the optimal viscosity of the ink, which is essential for achieving high-quality prints. If the ink is too thick, it may not flow properly, resulting in poor print quality, while ink that is too thin may lead to bleeding or feathering. Viscosity modifiers help to strike a balance between these two extremes, allowing the ink to flow smoothly and consistently, even at high printing speeds. Additionally, viscosity modifiers can also help to improve the ink's stability and shelf life, reducing the risk of settling or separation over time. By incorporating viscosity modifiers into the ink composition, manufacturers can ensure that their inks meet the required standards for print quality, consistency, and reliability. Overall, the importance of viscosity modifiers in ink composition cannot be overstated, as they play a critical role in determining the final print quality and overall performance of the ink.

The Modern Ink Manufacturing Process

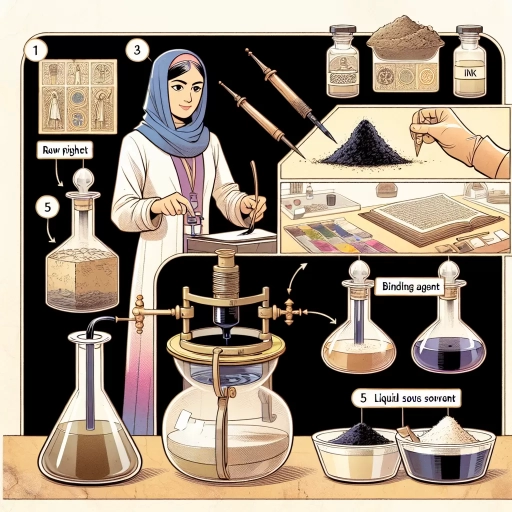

The modern ink manufacturing process is a complex and multi-step procedure that involves the combination of various raw materials to produce high-quality ink products. The process begins with the grinding and milling of pigments and dyes, which are the primary colorants used in ink. This step is crucial in determining the final color strength and consistency of the ink. Following the grinding and milling process, the mixing and blending of ink ingredients takes place, where the ground pigments and dyes are combined with other additives such as resins, solvents, and surfactants. Finally, the quality control and testing of ink products is conducted to ensure that the final product meets the required standards. In this article, we will delve into the details of each of these steps, starting with the grinding and milling of pigments and dyes, which is the foundation of the ink manufacturing process.

The Grinding and Milling of Pigments and Dyes

The grinding and milling of pigments and dyes is a crucial step in the ink manufacturing process. This process involves reducing the particle size of the pigments and dyes to a uniform size, typically in the range of 1-10 microns, to ensure optimal dispersion and stability in the final ink product. The grinding and milling process can be achieved through various methods, including ball milling, bead milling, and high-speed grinding. Ball milling is a traditional method that uses steel balls to grind the pigments and dyes, while bead milling uses small ceramic or glass beads to achieve a finer particle size. High-speed grinding, on the other hand, uses a high-speed rotor to grind the pigments and dyes, resulting in a more uniform particle size distribution. The choice of grinding and milling method depends on the type of pigment or dye being used, as well as the desired particle size and distribution. The grinding and milling process is typically carried out in a controlled environment, with careful monitoring of temperature, humidity, and particle size to ensure optimal results. The resulting ground pigments and dyes are then mixed with other ingredients, such as binders, solvents, and additives, to create the final ink product. The grinding and milling of pigments and dyes is a critical step in the ink manufacturing process, as it directly affects the final product's color strength, stability, and overall performance.

The Mixing and Blending of Ink Ingredients

The mixing and blending of ink ingredients is a critical step in the modern ink manufacturing process. This stage involves combining the various components, including pigments, dyes, resins, solvents, and additives, in a specific order and ratio to achieve the desired ink properties. The process typically begins with the dispersion of pigments or dyes in a solvent, followed by the addition of resins and other additives. The mixture is then blended and stirred to ensure uniform distribution of the ingredients. The blending process can be done using various techniques, including high-speed mixing, grinding, and milling, depending on the type of ink being produced. The goal of this stage is to create a consistent and stable ink formula that meets the required specifications for color strength, viscosity, and flow characteristics. The mixing and blending process can be done in batches or continuously, depending on the production volume and equipment used. In some cases, the ink mixture may undergo additional processing, such as filtration or centrifugation, to remove impurities and improve its overall quality. The final product is then filled into containers, such as drums or pails, and prepared for shipping to customers. Throughout the mixing and blending process, quality control measures are in place to ensure that the ink meets the required standards and specifications. This includes testing for color consistency, viscosity, and other physical properties, as well as evaluating the ink's performance in various printing applications. By carefully controlling the mixing and blending of ink ingredients, manufacturers can produce high-quality inks that meet the demands of various printing industries, from commercial printing to packaging and digital printing.

The Quality Control and Testing of Ink Products

The quality control and testing of ink products is a critical step in the ink manufacturing process. Ink manufacturers conduct rigorous testing to ensure that their products meet the required standards of quality, performance, and safety. The testing process typically involves a series of physical, chemical, and performance tests to evaluate the ink's properties, such as its color strength, viscosity, surface tension, and pH level. Additionally, ink manufacturers also conduct tests to assess the ink's compatibility with different printing surfaces, such as paper, plastic, and fabric, as well as its resistance to fading, bleeding, and smudging. Furthermore, ink manufacturers may also conduct tests to evaluate the ink's environmental impact, such as its toxicity and biodegradability. The results of these tests are used to make any necessary adjustments to the ink formulation and manufacturing process to ensure that the final product meets the required standards. By conducting thorough quality control and testing, ink manufacturers can ensure that their products are of high quality, reliable, and safe for use in various applications.