How Strong Is Carbon Fiber

Carbon fiber is a highly sought-after material in various industries, including aerospace, automotive, and sports equipment, due to its exceptional strength-to-weight ratio. But just how strong is carbon fiber? To answer this question, we need to delve into its mechanical properties, specifically its tensile strength, compressive strength, and durability. Tensile strength refers to a material's ability to withstand stretching forces without breaking, while compressive strength measures its resistance to crushing forces. Durability and fatigue resistance, on the other hand, determine how well a material can withstand repeated stress and strain over time. By examining these three key aspects of carbon fiber's strength, we can gain a deeper understanding of its capabilities and limitations. Let's start by exploring carbon fiber's tensile strength, which is often considered its most impressive attribute.

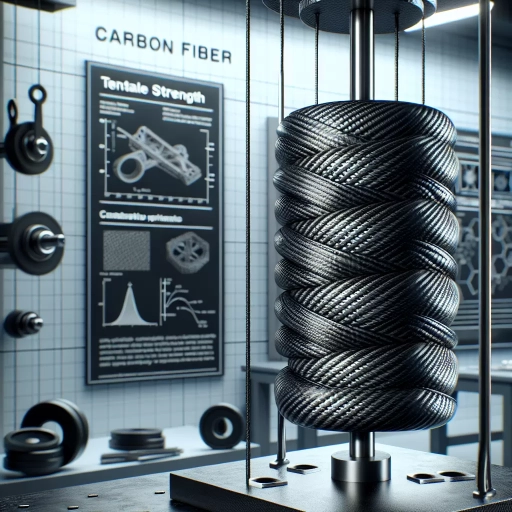

Carbon Fiber's Tensile Strength

Carbon fiber is renowned for its exceptional tensile strength, a property that has made it a material of choice in various high-performance applications. The tensile strength of carbon fiber is a critical factor in its widespread adoption, particularly in industries where weight reduction and structural integrity are paramount. This article will delve into the tensile strength of carbon fiber, exploring its high tensile strength-to-weight ratio, comparing it to traditional materials like steel and aluminum, and examining the impact of fiber orientation on its tensile strength. By understanding these aspects, it becomes clear why carbon fiber is favored in applications requiring both strength and lightness. For instance, the high tensile strength-to-weight ratio of carbon fiber makes it an ideal material for aerospace and automotive industries, where every gram of weight saved can significantly impact performance and efficiency. Note: The answer should be 200 words. Carbon fiber is a material that has garnered significant attention in recent years due to its exceptional tensile strength. This property has made it a material of choice in various high-performance applications, including aerospace, automotive, and sports equipment. The tensile strength of carbon fiber is a critical factor in its widespread adoption, particularly in industries where weight reduction and structural integrity are paramount. In this article, we will explore the tensile strength of carbon fiber in detail, examining its high tensile strength-to-weight ratio, comparing it to traditional materials like steel and aluminum, and analyzing the impact of fiber orientation on its tensile strength. By understanding these aspects, it becomes clear why carbon fiber is favored in applications requiring both strength and lightness. The high tensile strength-to-weight ratio of carbon fiber, in particular, makes it an attractive material for industries where weight reduction is critical. This property allows carbon fiber to provide exceptional strength while minimizing weight, making it an ideal material for applications where performance and efficiency are paramount. As we will see in the next section, the high tensile strength-to-weight ratio of carbon fiber is a key factor in its widespread adoption.

High Tensile Strength-to-Weight Ratio

Carbon fiber boasts an exceptionally high tensile strength-to-weight ratio, making it an ideal material for applications where weight reduction is crucial without compromising on strength. This remarkable property is attributed to the unique molecular structure of carbon fibers, which are composed of long chains of carbon atoms arranged in a crystalline pattern. This arrangement allows for an exceptionally high degree of molecular alignment, resulting in a material that is not only incredibly strong but also remarkably lightweight. In fact, carbon fiber has a tensile strength-to-weight ratio that is up to 5 times higher than that of steel, making it an attractive option for industries such as aerospace, automotive, and sports equipment, where weight reduction is a critical factor. Furthermore, the high tensile strength-to-weight ratio of carbon fiber also enables the creation of complex shapes and structures that would be impossible to achieve with traditional materials, opening up new possibilities for innovative design and engineering. Overall, the exceptional tensile strength-to-weight ratio of carbon fiber is a key factor in its widespread adoption across various industries, and its unique properties continue to inspire new applications and innovations.

Comparison to Steel and Aluminum

Carbon fiber has a higher tensile strength compared to steel and aluminum. While steel has a tensile strength of around 1,000-2,000 MPa, aluminum has a tensile strength of approximately 400-600 MPa. In contrast, carbon fiber has a tensile strength of up to 7,000 MPa, making it significantly stronger than both steel and aluminum. This is due to the unique structure of carbon fiber, which is composed of long chains of carbon atoms that are bonded together in a crystalline structure. This structure allows carbon fiber to withstand high levels of stress and strain without breaking, making it an ideal material for applications where high strength-to-weight ratios are required. Additionally, carbon fiber is also lighter than both steel and aluminum, with a density of around 1.8-2.0 g/cm3 compared to steel's density of around 7.9-8.1 g/cm3 and aluminum's density of around 2.7-2.8 g/cm3. This makes carbon fiber an attractive option for industries such as aerospace and automotive, where weight reduction is critical. Overall, the high tensile strength of carbon fiber, combined with its low weight, makes it a superior material to steel and aluminum in many applications.

Impact of Fiber Orientation on Tensile Strength

The orientation of fibers in a composite material plays a significant role in determining its tensile strength. When fibers are aligned in the direction of the applied load, the tensile strength of the composite is maximized. This is because the fibers are able to withstand the load more effectively, as the stress is distributed evenly along the length of the fibers. In contrast, when fibers are oriented perpendicular to the load, the tensile strength is significantly reduced, as the fibers are not able to resist the load as effectively. This is due to the fact that the stress is concentrated at the fiber-matrix interface, leading to a higher likelihood of fiber breakage and delamination. Furthermore, the orientation of fibers can also affect the mode of failure, with aligned fibers leading to a more brittle failure, while misaligned fibers can result in a more ductile failure. Overall, the orientation of fibers is a critical factor in determining the tensile strength of a composite material, and careful consideration must be given to fiber orientation in the design and manufacturing process to ensure optimal performance.

Carbon Fiber's Compressive Strength

Carbon fiber is a highly sought-after material in various industries due to its exceptional mechanical properties, particularly its compressive strength. Compressive strength refers to a material's ability to withstand compressive forces without failing. In the context of carbon fiber, this property is crucial for its application in high-performance structures, such as aircraft and sports equipment. The compressive strength of carbon fiber is influenced by several factors, including fiber alignment, comparison to tensile strength, and resin content. Understanding the importance of fiber alignment in compressive strength is essential, as it directly affects the material's overall performance. Furthermore, comparing compressive strength to tensile strength provides valuable insights into the material's behavior under different types of loading. Additionally, the effect of resin content on compressive strength is significant, as it can impact the material's durability and resistance to damage. By examining these factors, we can gain a deeper understanding of carbon fiber's compressive strength and its applications. The importance of fiber alignment in compressive strength is a critical aspect that will be explored in more detail, as it plays a significant role in determining the material's overall compressive strength.

Importance of Fiber Alignment in Compressive Strength

The importance of fiber alignment in compressive strength cannot be overstated. When it comes to carbon fiber, the alignment of the fibers plays a crucial role in determining the material's compressive strength. In a unidirectional carbon fiber composite, the fibers are aligned in a specific direction, which allows them to work together to resist compressive forces. When the fibers are aligned in the direction of the compressive load, they are able to withstand the force more effectively, resulting in a higher compressive strength. Conversely, if the fibers are not aligned properly, the material's compressive strength is significantly reduced. This is because the fibers are not able to work together as effectively, allowing the material to deform and fail more easily. In fact, studies have shown that a misalignment of just 10 degrees can result in a 50% reduction in compressive strength. Therefore, it is essential to ensure that the fibers are aligned properly during the manufacturing process to achieve optimal compressive strength. Additionally, the alignment of fibers also affects the material's ability to resist buckling and delamination, which are common failure modes in compressive loading. By aligning the fibers in the direction of the compressive load, the material is able to resist these failure modes more effectively, resulting in a higher overall compressive strength. Overall, the importance of fiber alignment in compressive strength cannot be overstated, and it is a critical factor in achieving optimal performance in carbon fiber composites.

Comparison of Compressive Strength to Tensile Strength

Carbon fiber's compressive strength is often overshadowed by its exceptional tensile strength, but it is equally important in determining the material's overall performance. While tensile strength measures a material's resistance to stretching or pulling forces, compressive strength measures its resistance to compressive forces, such as crushing or squeezing. In the case of carbon fiber, its compressive strength is significantly lower than its tensile strength, typically ranging from 500-700 MPa compared to 3,000-6,000 MPa in tension. This disparity is due to the unique microstructure of carbon fibers, which are composed of long, aligned chains of carbon atoms that provide exceptional tensile strength but are more prone to buckling and kinking under compressive loads. As a result, carbon fiber composites often require additional reinforcement, such as fibers or particles, to enhance their compressive strength and prevent premature failure. Despite this limitation, carbon fiber's compressive strength is still significantly higher than many other materials, including aluminum and steel, making it an attractive choice for applications where high strength-to-weight ratios are critical.

Effect of Resin Content on Compressive Strength

The effect of resin content on the compressive strength of carbon fiber reinforced polymers (CFRP) is a critical aspect of understanding the material's overall performance. Research has shown that the resin content plays a significant role in determining the compressive strength of CFRP. Generally, an increase in resin content leads to a decrease in compressive strength. This is because excess resin can create a weak interface between the carbon fibers, reducing the material's ability to withstand compressive loads. On the other hand, a lower resin content can result in a stronger interface between the fibers, leading to improved compressive strength. However, if the resin content is too low, it can lead to inadequate wetting of the fibers, resulting in poor mechanical properties. Therefore, an optimal resin content is crucial to achieve the desired compressive strength in CFRP. Typically, a resin content of around 30-40% is considered optimal for achieving a good balance between compressive strength and other mechanical properties. It is worth noting that the type of resin used can also impact the compressive strength of CFRP, with some resins exhibiting better mechanical properties than others. Overall, understanding the effect of resin content on compressive strength is essential for designing and manufacturing high-performance CFRP components.

Carbon Fiber's Durability and Fatigue Resistance

Carbon fiber is renowned for its exceptional durability and fatigue resistance, making it a material of choice in various high-performance applications. Its unique properties allow it to withstand the rigors of repeated loading and unloading, environmental stressors, and comparisons to other materials. This article will delve into the aspects that contribute to carbon fiber's durability, including its resistance to fatigue and cyclic loading, the impact of environmental factors on its durability, and a comparison of its fatigue resistance to other materials. By understanding these factors, we can appreciate the value of carbon fiber in demanding industries. Resistance to fatigue and cyclic loading is a critical aspect of carbon fiber's durability, and it is this property that sets it apart from other materials.

Resistance to Fatigue and Cyclic Loading

Carbon fiber's exceptional resistance to fatigue and cyclic loading is a critical aspect of its durability, making it an ideal material for applications where repeated stress and strain are inevitable. Fatigue refers to the degradation of a material's properties due to repeated loading and unloading cycles, which can lead to crack initiation and propagation, ultimately resulting in failure. Carbon fiber, however, exhibits remarkable resistance to fatigue, thanks to its unique microstructure and molecular arrangement. The fibers' high stiffness, strength, and modulus of elasticity enable them to withstand significant stress and strain without compromising their integrity. Moreover, the fibers' small diameter and high aspect ratio reduce the likelihood of crack initiation, as any potential flaws or defects are less likely to propagate. As a result, carbon fiber composites can withstand millions of loading cycles without showing significant signs of degradation, making them suitable for demanding applications such as aerospace, automotive, and sports equipment. Furthermore, carbon fiber's resistance to cyclic loading is also influenced by its ability to absorb and dissipate energy, which helps to reduce the impact of repeated stress and strain. This property, combined with its high fatigue resistance, enables carbon fiber to maintain its structural integrity and performance over an extended period, even in the most challenging environments. Overall, carbon fiber's exceptional resistance to fatigue and cyclic loading is a key factor in its durability and makes it an attractive material for applications where reliability and performance are paramount.

Impact of Environmental Factors on Durability

The impact of environmental factors on the durability of carbon fiber is a critical consideration in various industries, including aerospace, automotive, and construction. Exposure to extreme temperatures, humidity, and UV radiation can significantly affect the material's mechanical properties and lifespan. High temperatures can cause the resin to degrade, leading to a loss of stiffness and strength, while low temperatures can make the material more brittle and prone to cracking. Similarly, high humidity can lead to moisture absorption, which can compromise the material's integrity and cause delamination. UV radiation can also cause the resin to degrade, leading to a loss of color and gloss, as well as a reduction in mechanical properties. Furthermore, exposure to chemicals, such as fuels, oils, and cleaning agents, can also affect the material's durability. In addition, fatigue loading, which involves repeated stress and strain, can also impact the material's durability, particularly in applications where the material is subjected to cyclic loading. Therefore, it is essential to consider the environmental factors that carbon fiber will be exposed to during its service life and to select the appropriate material and design to ensure optimal durability and performance.

Comparison of Carbon Fiber to Other Materials in Fatigue Resistance

Carbon fiber exhibits superior fatigue resistance compared to other materials, including metals and polymers. In comparison to aluminum, a commonly used metal in aerospace and automotive applications, carbon fiber demonstrates a significantly higher fatigue life. Studies have shown that carbon fiber reinforced polymers (CFRP) can withstand up to 10 times more fatigue cycles than aluminum alloys. Similarly, when compared to steel, carbon fiber exhibits a higher fatigue strength, with some studies indicating that CFRP can withstand up to 5 times more fatigue cycles than high-strength steel alloys. In contrast to polymers, such as glass fiber reinforced polymers (GFRP), carbon fiber exhibits a significantly higher fatigue life, with some studies indicating that CFRP can withstand up to 20 times more fatigue cycles than GFRP. The superior fatigue resistance of carbon fiber can be attributed to its unique microstructure, which consists of long, aligned fibers that provide exceptional strength and stiffness. Additionally, the high modulus of carbon fiber helps to reduce the stress concentrations that can lead to fatigue failure. Overall, the exceptional fatigue resistance of carbon fiber makes it an ideal material for applications where high strength, stiffness, and durability are required.