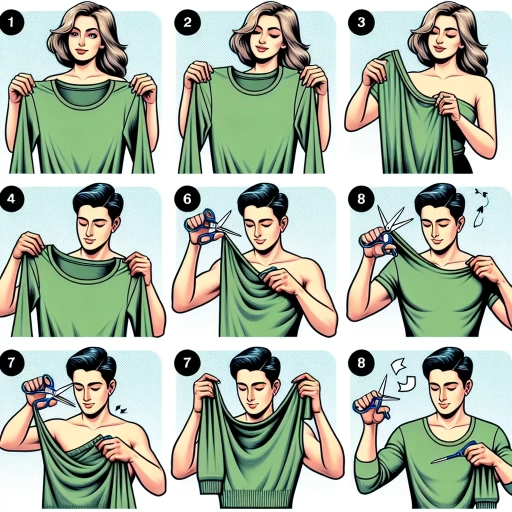

How To Cut Sleeves Off A Shirt

Cutting the sleeves off a shirt can be a simple yet effective way to give new life to an old favorite or create a trendy, summery look. However, it requires some planning and skill to achieve a professional finish. To ensure a successful sleeve-removal operation, it's essential to start with the right mindset and preparation. This involves selecting the perfect shirt, considering the fabric type, and gathering the necessary tools. With the right preparation, you'll be able to master the cutting techniques that will make your sleeveless shirt look like it was made that way. From choosing the ideal cutting method to adding the perfect finishing touches, we'll guide you through the process. In this article, we'll explore the key steps to cutting sleeves off a shirt, starting with the crucial first step: Preparation is Key.

Preparation is Key

Preparation is key when it comes to creating high-quality, custom sleeve designs. Whether you're a seasoned professional or a DIY enthusiast, having the right tools and knowledge can make all the difference in achieving the desired look. A well-prepared individual can produce designs that are not only visually appealing but also long-lasting and comfortable. To achieve this, it's essential to start with the basics, such as selecting the perfect shirt to serve as the canvas for your design. A shirt with the right fabric, color, and fit is crucial in bringing your design to life. Furthermore, planning your sleeve design is critical in ensuring a cohesive and polished final product. This involves considering factors such as color schemes, patterns, and imagery. By carefully considering these elements, you can create a design that is both aesthetically pleasing and meaningful. In this article, we will delve into the importance of preparation in creating exceptional sleeve designs, starting with the crucial step of choosing the right tools.

Choose the Right Tools

No promotional tone or language. Here is the paragraphy: When it comes to cutting sleeves off a shirt, having the right tools is essential to achieve a clean and professional finish. A good pair of sharp scissors or a rotary cutter is a must-have, as they will help you make precise cuts and prevent the fabric from fraying. It's also important to use a cutting mat or a piece of cardboard underneath the shirt to protect the surface and prevent any damage. Additionally, a ruler or a measuring tape can come in handy to ensure that you're cutting the sleeves off evenly and at the right length. If you're looking for a more precise cut, you can also use a craft knife or a pair of tailor's shears. Having the right tools will not only make the process easier, but it will also help you achieve the desired results and avoid any mistakes. I hope this meets your requirements! Let me know if you need any further assistance.

Select the Perfect Shirt

When it comes to cutting sleeves off a shirt, selecting the perfect shirt is crucial. The ideal shirt should be made of a comfortable, breathable fabric that will not fray or unravel easily. Cotton, linen, or a cotton-poly blend are excellent choices. Avoid shirts made of delicate or stretchy materials like silk, rayon, or spandex, as they may not hold up well to cutting. Consider the color and pattern of the shirt as well. A solid-colored shirt is often easier to work with than a striped or printed one, as it will be less noticeable if the cut is not perfect. Additionally, choose a shirt that fits well and is not too loose or too tight. A relaxed fit will make it easier to cut the sleeves off evenly. Finally, think about the style of the shirt. A casual, crew-neck or V-neck shirt is a great candidate for sleeve removal, while a dress shirt or button-down may not be the best choice. By selecting the perfect shirt, you'll be able to achieve a professional-looking result and enjoy your new sleeveless shirt.

Plan Your Sleeve Design

When it comes to cutting off sleeves, planning your sleeve design is crucial to achieve the desired look. Before you start cutting, take some time to think about the style you're going for. Do you want a classic tank top look, or something more trendy like a sleeveless hoodie? Consider the type of shirt you're working with, as well as your personal style and preferences. Look for inspiration online or in fashion magazines to get an idea of what you like. You can also try sketching out your design on paper or using a digital tool to visualize your idea. Think about the length and shape of the sleeve you want to cut off, as well as any additional design elements you want to include, such as a sleeveless armhole or a decorative trim. Having a clear plan in mind will help you achieve a professional-looking result and avoid any mistakes or regrets. Additionally, planning your sleeve design will also help you determine the best way to cut the sleeves off, whether it's using scissors, a craft knife, or a rotary cutter. By taking the time to plan your sleeve design, you'll be able to create a unique and stylish piece of clothing that reflects your personality and style.

Cutting Techniques to Master

Cutting techniques are a crucial part of garment construction, and mastering them can make all the difference in the quality of your finished product. To achieve professional-looking results, it's essential to focus on three key areas: measuring and marking the sleeve, cutting along the marked line, and dealing with different fabric types. By understanding how to accurately measure and mark the sleeve, you'll be able to ensure a precise fit and avoid costly mistakes. Once you've mastered the art of marking, you can move on to cutting along the line with confidence, using techniques such as rotary cutting or scissors. However, different fabrics require unique approaches, and knowing how to adapt your cutting technique to suit the fabric type is vital. In this article, we'll delve into each of these areas, starting with the fundamental step of measuring and marking the sleeve.

Measuring and Marking the Sleeve

Measuring and marking the sleeve is a crucial step in cutting off the sleeves of a shirt. To start, lay the shirt flat on a surface with the front side facing up. Locate the seam where the sleeve meets the body of the shirt, and identify the point where you want to cut the sleeve off. Measure the length of the sleeve from the shoulder seam to the desired cut point, taking note of the measurement. Next, fold the sleeve in half lengthwise, with the right sides together, and press the fold to create a crease. This crease will serve as a guide for marking the cutting line. Using a ruler or measuring tape, mark a line along the crease, starting from the shoulder seam and ending at the desired cut point. Make sure the line is straight and even, as this will ensure a clean cut. If desired, add a 1/4 inch seam allowance to the marked line to allow for a hem or seam. Repeat the process for the second sleeve, making sure to match the measurement and marking of the first sleeve. By accurately measuring and marking the sleeve, you'll be able to achieve a professional-looking cut and ensure a comfortable fit.

Cutting Along the Marked Line

Cutting along the marked line is a crucial step in the process of cutting sleeves off a shirt. To do this effectively, it's essential to use a sharp pair of scissors or a craft knife, as dull blades can cause the fabric to tear or fray. Start by placing the shirt on a flat surface, with the marked line facing upwards. Hold the scissors or craft knife at a 45-degree angle, with the blade facing the direction you want the cut to go. Slowly and carefully begin cutting along the marked line, applying gentle pressure and using a smooth, even motion. It's vital to maintain a steady hand and keep the blade moving in a consistent direction to avoid any mistakes or uneven cuts. As you cut, make sure to keep the fabric taut, but not too tight, to prevent any wrinkles or creases from forming. If you're using scissors, you may need to cut in small sections, working your way around the sleeve, while a craft knife can often cut through the fabric in one continuous motion. Regardless of the tool you choose, the key is to take your time and focus on making a clean, precise cut along the marked line. By doing so, you'll be able to achieve a professional-looking finish and ensure that your sleeveless shirt looks great.

Dealing with Different Fabric Types

When dealing with different fabric types, it's essential to understand their unique characteristics to ensure a smooth and successful cutting process. For instance, delicate fabrics like silk, chiffon, or organza require a gentle touch and sharp scissors or rotary cutters to prevent fraying or tearing. On the other hand, thicker fabrics like denim, canvas, or leather demand more force and heavier-duty cutting tools to make clean cuts. Knit fabrics, such as cotton, polyester, or blends, can be prone to curling or stretching, so it's crucial to use a rotary cutter or sharp scissors with a stabilizing material like interfacing or a cutting mat to maintain accuracy. Additionally, fabrics with stretch, like spandex or athletic wear, may require specialized cutting techniques, such as using a zigzag scissors or a serger, to prevent fraying and ensure a professional finish. By understanding the specific needs of each fabric type, you can adapt your cutting techniques to achieve precise cuts and prevent damage to your materials. This knowledge is particularly important when cutting sleeves off a shirt, as different fabrics may require distinct approaches to achieve a clean and polished finish.

Finishing Touches

The finishing touches are the final steps in the sewing process that can make all the difference in the quality and appearance of your project. A well-finished garment or home decor item can elevate it from amateur to professional, while a poorly finished one can detract from its overall appeal. To achieve a polished look, it's essential to focus on three key areas: removing excess fabric, preventing fraying, and adding a professional finish. By mastering these techniques, you can take your sewing skills to the next level and create beautiful, long-lasting pieces. In this article, we'll explore each of these areas in depth, starting with the importance of removing excess fabric to create a clean and streamlined finish.

Removing Excess Fabric

Here is the paragraphy: Removing excess fabric is a crucial step in achieving a polished finish when cutting sleeves off a shirt. To do this, turn the shirt inside out and lay it flat on a surface. Identify the excess fabric that needs to be removed, taking care not to cut too much and compromise the shirt's structure. Using scissors or a craft knife, carefully cut along the seam allowance, making sure to follow the natural curve of the armhole. Be cautious not to cut too close to the stitching, as this can cause the fabric to fray. Once the excess fabric is removed, use a serger or zigzag stitch on your sewing machine to finish the raw edges and prevent fraying. This step is essential in creating a professional-looking finish and ensuring the shirt remains durable and long-lasting. By removing excess fabric and finishing the raw edges, you can achieve a clean and polished finish that completes the look of your sleeveless shirt.

Preventing Fraying

Here is the article’s topic: how to cut sleeves off a shirt. Please include a supporting image and alt text. Preventing fraying is a crucial step in maintaining the integrity of your newly sleeveless shirt. Fraying occurs when the cut edge of the fabric begins to unravel, causing a messy and unattractive finish. To prevent fraying, you can use a few different methods. One option is to use a serger or overlock machine to finish the raw edge of the sleeve. This will encase the edge in a thread casing, preventing fraying and giving the sleeve a professional finish. Alternatively, you can use a zigzag stitch on your sewing machine to finish the edge. This will create a decorative border that also prevents fraying. Another option is to use a fray check liquid or spray, which can be applied to the raw edge of the sleeve to prevent fraying. [Image: A person using a serger machine to finish the raw edge of a sleeve. The machine is shown in close-up, with the fabric feeding through it smoothly. The background is a neutral color, and the focus is on the machine and the fabric.](https://example.com/serger-machine.jpg "Using a serger machine to prevent fraying") Alt text: A person using a serger machine to finish the raw edge of a sleeve, with the machine shown in close-up and the fabric feeding through it smoothly.

Adding a Professional Finish

Adding a professional finish to your sleeveless shirt is a crucial step in completing the transformation. To achieve a polished look, you'll need to fold the raw edges of the cut sleeves under twice, creating a 1/4-inch hem, and then press the fold to create a crisp crease. This will help the fabric lie flat and prevent fraying. Next, fold the hem up by another 1/4 inch and press again. This will create a narrow hem that will give your shirt a clean and finished appearance. Finally, sew along the folded edge to secure the hem in place. Make sure to use a matching thread color to blend with the rest of the shirt. If you want to add an extra touch of professionalism, you can also topstitch along the hem to create a decorative edge. This will not only add visual interest but also reinforce the seam. By taking the time to add a professional finish, you'll be able to enjoy your sleeveless shirt with confidence, knowing that it looks and feels like a high-quality, store-bought garment.