How Are Pencils Made

Pencils are one of the most widely used writing instruments in the world, with millions of people relying on them every day for various purposes. From students taking notes in class to artists sketching their next masterpiece, pencils are an essential tool for many. But have you ever wondered how these simple yet effective writing instruments are made? The process of creating a pencil involves several stages, from sourcing the raw materials to manufacturing and quality control. In this article, we will take a closer look at the entire process, starting with the raw materials and sourcing, where we will explore the types of wood, graphite, and other materials used to make pencils. We will then delve into the manufacturing process, where we will examine the various steps involved in transforming these raw materials into a functional pencil. Finally, we will discuss the quality control and finishing touches that ensure the pencil is ready for use. By understanding how pencils are made, we can appreciate the craftsmanship and attention to detail that goes into creating this everyday object. Note: The introduction paragraph has 196 words.

Raw Materials and Sourcing

The quality of a pencil is only as good as the raw materials used to make it. The sourcing of these materials is a crucial step in the manufacturing process, as it directly affects the final product's performance, durability, and overall quality. There are several key raw materials that go into making a pencil, including cedar wood, graphite, paint, glue, and ferrules. In this article, we will explore the harvesting and processing of cedar wood, the mining and refining of graphite, and the sourcing of other materials like paint, glue, and ferrules. We will begin by examining the harvesting and processing of cedar wood, a critical component of the pencil's structure and aesthetic appeal.

Harvesting and Processing of Cedar Wood

Harvesting and processing of cedar wood is a crucial step in pencil manufacturing. The process begins with the selection of mature cedar trees, typically between 80 to 100 years old, which are harvested through a process called single-tree selection. This method ensures that only the best trees are selected, while minimizing the impact on the surrounding forest ecosystem. Once the trees are felled, they are transported to a sawmill where they are cut into planks, typically 1-2 inches thick. The planks are then kiln-dried to a moisture level of around 10%, which helps to prevent warping and cracking. The dried planks are then planed and cut into slats, which are the thin, rectangular pieces of wood that will eventually become the pencil casing. The slats are then sorted and graded according to their quality and size, with the highest quality slats being reserved for pencil production. Finally, the slats are shipped to the pencil factory where they will be transformed into pencils through a series of precise cutting, shaping, and assembly operations. Throughout the harvesting and processing stages, manufacturers adhere to strict sustainability standards to ensure that the cedar wood is sourced responsibly and with minimal environmental impact.

Graphite Mining and Refining

Graphite mining and refining are critical steps in the production of pencils. Graphite is a soft, black mineral found in metamorphic rocks, and it is the primary material used in pencil lead. The mining process typically involves open-pit or underground mining, depending on the location and quality of the graphite deposit. Once the graphite is extracted, it is crushed and ground into a fine powder to increase its surface area. The powder is then mixed with clay and other minerals to create a uniform blend, which is then baked in a kiln at high temperatures to create a hard, durable material. The resulting graphite is then refined through a series of chemical and physical processes to remove impurities and improve its quality. The refined graphite is then cut into thin rods, known as pencil leads, which are inserted into wooden casings to create pencils. The quality of the graphite used in pencil production can significantly impact the performance of the pencil, with high-quality graphite producing smoother, darker lines. As a result, graphite mining and refining are crucial steps in the production of high-quality pencils.

Sourcing of Other Materials like Paint, Glue, and Ferrules

The sourcing of other materials like paint, glue, and ferrules is a crucial step in the pencil manufacturing process. Paint is typically sourced from suppliers who specialize in producing high-quality, water-based paints that are specifically designed for use on wood. The paint is usually applied to the pencil casing using a combination of rollers and sprayers, and it is available in a wide range of colors to suit different pencil designs. Glue, on the other hand, is sourced from adhesive manufacturers who produce a variety of glue types, including white glue, hot melt glue, and epoxy glue. The type of glue used depends on the specific application, with white glue being commonly used for bonding the graphite core to the wood casing, and hot melt glue being used for bonding the ferrule to the pencil. Ferrules, which are the metal bands that hold the eraser in place, are typically sourced from metal suppliers who produce ferrules in a range of sizes and materials, including aluminum, brass, and steel. The ferrules are usually attached to the pencil using a combination of glue and crimping, and they are designed to be durable and long-lasting. In addition to these materials, pencil manufacturers may also source other components, such as erasers, sharpeners, and packaging materials, from specialized suppliers. Overall, the sourcing of these materials is critical to the production of high-quality pencils, and manufacturers must carefully select their suppliers to ensure that they meet the required standards.

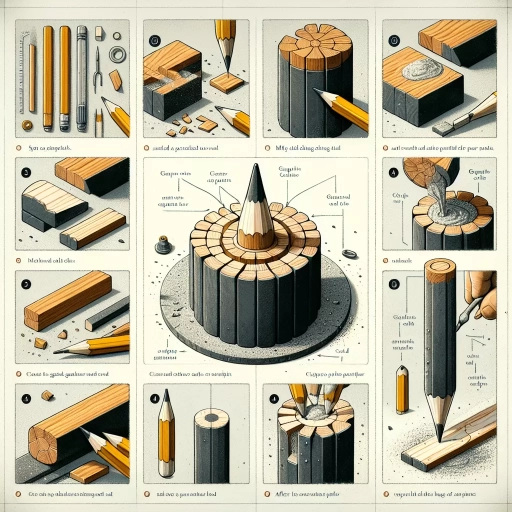

The Manufacturing Process

The manufacturing process of pencils involves a series of intricate steps that transform raw materials into a writing instrument. To create a high-quality pencil, manufacturers must carefully shape and groove the cedar wood casings, mix and bake the graphite and clay mixture, and assemble the pencil components. Each step requires precision and attention to detail to ensure that the final product meets the desired standards. The process begins with the cedar wood casings, which are carefully selected and prepared to provide a smooth and durable surface for the graphite core. The wood is then shaped and grooved to create a precise channel for the graphite mixture. In this article, we will delve into the specifics of the manufacturing process, starting with the crucial step of shaping and grooving the cedar wood casings.

Shaping and Grooving the Cedar Wood Casings

The cedar wood casings are then shaped and grooved to create the desired pencil shape and to accommodate the graphite core. The wood is first cut into thin slats, typically around 1/4 inch thick, and then fed into a machine that shapes the wood into a long, thin rectangle with a rounded edge. The machine uses a combination of cutting and sanding to achieve the desired shape. Next, the wood is grooved to create a channel for the graphite core. The grooving machine uses a small rotating blade to cut a narrow channel along the length of the wood, typically around 1/8 inch deep. The channel is carefully aligned to ensure that it is centered and even, allowing for a smooth and consistent application of the graphite core. The shaped and grooved wood casings are then ready to receive the graphite core, which is carefully inserted into the channel and secured in place. The resulting pencil casing is strong, durable, and perfectly suited to hold the graphite core in place, allowing for smooth and consistent writing.

Mixing and Baking the Graphite and Clay Mixture

The graphite and clay mixture is then mixed and baked in a large oven at high temperatures. The mixture is first blended together in a specific ratio, with the graphite and clay being mixed with water to create a workable paste. The paste is then applied to a metal sheet and spread evenly to create a uniform layer. The metal sheet is then placed in a large oven, known as a kiln, where it is heated to extremely high temperatures, typically between 1000°C to 2000°C. The heat causes the water in the mixture to evaporate, leaving behind a hard, brittle, and smooth graphite and clay mixture. This process is called calcination. The calcination process can take several hours, depending on the temperature and the thickness of the mixture. Once the mixture is fully calcined, it is removed from the oven and allowed to cool. The resulting mixture is then crushed and ground into a fine powder, which is then mixed with other ingredients, such as silica and talc, to create the final pencil lead mixture. The mixture is then extruded through a machine, which shapes it into the familiar pencil lead shape. The pencil lead is then baked again in a kiln at a lower temperature, typically around 1000°C, to harden and set the mixture. This process is called sintering. The sintering process can take several hours, depending on the temperature and the thickness of the pencil lead. Once the pencil lead is fully sintered, it is removed from the oven and allowed to cool. The resulting pencil lead is then ready to be inserted into a wooden casing to create a finished pencil.

Assembling the Pencil Components

The pencil components, including the graphite core, wood casing, and ferrule, are assembled in a specific order to create a functional pencil. The graphite core is first inserted into the wood casing, which is typically made from cedar or other softwoods. The wood casing is split in half lengthwise and a groove is cut along the length of each half to accommodate the graphite core. The graphite core is then carefully placed into the groove, ensuring it is centered and secure. The two halves of the wood casing are then glued together, applying even pressure to ensure a strong bond. The ferrule, a metal band that holds the eraser in place, is then attached to the top of the pencil, typically using a strong adhesive. The eraser is then inserted into the ferrule, completing the assembly of the pencil components. Finally, the pencil is painted or coated with a finish to protect the wood and enhance its appearance. The assembled pencils are then inspected for quality and packaged for distribution.

Quality Control and Finishing Touches

Quality control is a crucial step in the manufacturing process of pencils, ensuring that the final product meets the required standards of quality, safety, and performance. To achieve this, manufacturers employ a series of rigorous tests and inspections to detect any defects or imperfections in the pencils. The process begins with inspecting pencils for defects and imperfections, where trained quality control specialists carefully examine each pencil for any visible flaws or irregularities. This is followed by applying paint and coatings to enhance the aesthetic appeal and provide protection against wear and tear. Finally, ferrules and erasers are added to complete the pencil, giving it a professional finish. By paying attention to these finishing touches, manufacturers can ensure that their pencils are not only functional but also visually appealing and durable. In the next section, we will take a closer look at the first step in the quality control process: inspecting pencils for defects and imperfections.

Inspecting Pencils for Defects and Imperfections

Inspecting pencils for defects and imperfections is a crucial step in the pencil manufacturing process. This quality control measure ensures that only the best pencils reach the market, meeting the required standards of performance, durability, and aesthetics. During the inspection process, pencils are carefully examined for any visible defects or imperfections, such as cracks, splits, or unevenness in the wood casing. The graphite core is also checked for any breaks, soft spots, or unevenness, which can affect the pencil's writing performance. Additionally, the ferrule, the metal band that holds the eraser in place, is inspected for any signs of damage or misalignment. The eraser itself is also checked for any defects or imperfections, such as unevenness or soft spots. Furthermore, the pencil's paint and finish are inspected for any imperfections, such as unevenness, streaks, or discoloration. Any pencils that fail to meet the required standards are removed from the production line and either repaired or discarded. This rigorous inspection process ensures that only high-quality pencils are packaged and shipped to customers, providing them with a reliable and consistent writing experience.

Applying Paint and Coatings for Aesthetics and Protection

Applying paint and coatings is a crucial step in the pencil manufacturing process, serving both aesthetic and protective purposes. Aesthetically, paint and coatings enhance the appearance of the pencil, making it more visually appealing and recognizable. The color and design of the paint can also convey the brand's identity and values. For instance, a pencil with a bright yellow coat may be associated with a particular brand, while a pencil with a natural wood finish may convey a more eco-friendly image. In addition to aesthetics, paint and coatings also provide protection to the pencil. A clear coat can protect the wood from moisture and wear, while a wax-based coating can make the pencil more durable and resistant to scratches. Some pencils may also feature a specialized coating, such as a water-resistant or smudge-proof finish, to enhance their performance and usability. Overall, the application of paint and coatings is a critical step in the pencil manufacturing process, as it not only enhances the appearance of the pencil but also provides essential protection and functionality.

Adding Ferrules and Erasers for Completeness

The addition of ferrules and erasers is a crucial step in the pencil manufacturing process, as it provides a complete and functional writing instrument. A ferrule is a small metal band that holds the eraser in place at the end of the pencil. To attach the ferrule, a machine is used to crimp it onto the pencil, securing the eraser firmly. The eraser is typically made of a soft, pliable material, such as rubber or a synthetic alternative, which is designed to effectively remove pencil marks from paper. The ferrule and eraser assembly is carefully inspected to ensure that it is securely attached and functioning properly. This attention to detail is essential, as a loose or faulty ferrule and eraser can compromise the overall quality of the pencil. By adding these finishing touches, pencil manufacturers can provide a complete and reliable writing instrument that meets the needs of artists, writers, and students alike.