How To Measure A Box

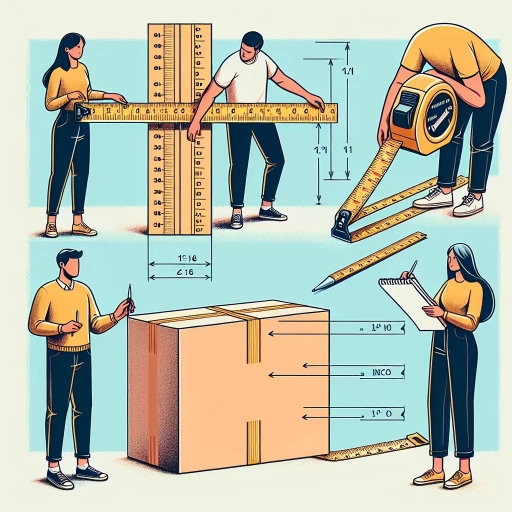

Measuring a box accurately is a crucial task in various industries, including shipping, logistics, and construction. Whether you're a professional or a DIY enthusiast, knowing how to measure a box correctly can save you time, money, and frustration. In this article, we will guide you through the process of measuring a box, covering the essential basics, the step-by-step process of measuring the dimensions, and how to record and apply the measurements effectively. To start, it's essential to understand the basics of measuring a box, including the types of measurements, the tools required, and the common mistakes to avoid. By grasping these fundamentals, you'll be able to move on to measuring the dimensions of a box with confidence, and ultimately, record and apply the measurements accurately. So, let's begin by understanding the basics of measuring a box.

Understanding the Basics of Measuring a Box

Measuring a box may seem like a straightforward task, but it requires attention to detail and a clear understanding of the basics. To accurately measure a box, one must first define the dimensions of the box, including its length, width, and height. This involves identifying the units of measurement, such as inches or centimeters, and choosing the right measuring tools, such as a ruler or tape measure. By understanding these fundamental concepts, individuals can ensure accurate measurements and avoid costly mistakes. In this article, we will explore the basics of measuring a box, starting with defining the dimensions of a box.

Defining the Dimensions of a Box

When measuring a box, it's essential to understand the three dimensions that define its size: length, width, and height. The length is the longest side of the box, typically the side that runs from one end to the other. The width is the shorter side that runs perpendicular to the length, while the height is the vertical distance from the base of the box to its top. To accurately measure these dimensions, use a ruler or measuring tape and take note of the units of measurement, such as inches or centimeters. It's also crucial to consider the orientation of the box, as the dimensions may vary depending on how it's positioned. For example, a box that is taller than it is wide may have different dimensions when measured from a different angle. By understanding and accurately measuring the length, width, and height of a box, you can ensure that it fits in a specific space or meets specific shipping requirements.

Identifying the Units of Measurement

When measuring a box, it's essential to identify the units of measurement to ensure accuracy. The most common units of measurement used in measuring boxes are inches (in) and feet (ft) for length, width, and height. However, it's also possible to use centimeters (cm) and meters (m) for international shipping or storage purposes. To identify the units of measurement, look for the following abbreviations: in, ft, cm, or m. For example, if a box is labeled as 12 in x 8 in x 6 in, it means the box is 12 inches long, 8 inches wide, and 6 inches high. Similarly, if a box is labeled as 30 cm x 20 cm x 15 cm, it means the box is 30 centimeters long, 20 centimeters wide, and 15 centimeters high. It's crucial to note that some boxes may have both imperial and metric units of measurement, so it's essential to check the label carefully to avoid confusion. Additionally, some boxes may have a unit of measurement symbol, such as ″ for inches or ′ for feet, so it's essential to be familiar with these symbols to ensure accurate measurement. By identifying the units of measurement correctly, you can ensure that your box is measured accurately and efficiently.

Choosing the Right Measuring Tools

When it comes to measuring a box, having the right tools is essential to ensure accuracy and efficiency. The most common measuring tools used for measuring boxes are rulers, tape measures, and calipers. Rulers are ideal for measuring small boxes or boxes with simple dimensions, while tape measures are better suited for larger boxes or boxes with complex shapes. Calipers, on the other hand, are perfect for measuring precise dimensions, such as the thickness of a box's walls or the diameter of a circular opening. Additionally, digital calipers are available, which can provide even more accurate measurements. It's also important to consider the unit of measurement, with options including inches, centimeters, or millimeters. When choosing a measuring tool, consider the size and complexity of the box, as well as the level of precision required. By selecting the right tool, you can ensure accurate measurements and avoid errors. Furthermore, it's also a good idea to have multiple measuring tools on hand, as this can help to verify measurements and increase confidence in the accuracy of the results. By investing in a set of high-quality measuring tools, you can ensure that your box measurements are accurate and reliable, making it easier to pack, ship, and store your boxes with confidence.

Measuring the Dimensions of a Box

Measuring the dimensions of a box is a crucial task in various fields, including shipping, engineering, and architecture. To accurately determine the size of a box, it is essential to measure its length, width, and height. These three dimensions are vital in calculating the volume, surface area, and weight of the box. In this article, we will explore the methods and techniques for measuring the dimensions of a box, starting with the length, which is the longest side of the box. We will then discuss how to measure the width, which is the shorter side perpendicular to the length, and finally, the height, which is the vertical distance from the base to the top of the box. By understanding how to measure these three dimensions, you will be able to accurately determine the size of a box and make informed decisions in your field. First, let's start with measuring the length of a box.

Measuring the Length of a Box

Measuring the length of a box is a straightforward process that requires a tape measure or ruler. To start, place the box on a flat surface and locate the longest side, which is typically the side that runs from one end of the box to the other. This side is usually the length of the box. Next, position the tape measure or ruler along the length of the box, ensuring that it is parallel to the surface and aligned with the edges of the box. Take note of the measurement in inches or centimeters, depending on the unit of measurement you prefer. It's essential to record the measurement accurately, as it will be used to calculate the box's volume and other dimensions. If the box has a lid or a removable top, make sure to measure the length of the box itself, excluding the lid or top. Additionally, if the box has any obstructions, such as handles or protrusions, take them into account when measuring the length to ensure an accurate reading. By following these simple steps, you can quickly and easily measure the length of a box.

Measuring the Width of a Box

Measuring the width of a box is a straightforward process that requires a flexible tape measure or a ruler. To start, place the box on a flat surface and ensure it is standing upright on its base. Locate the two parallel sides of the box that you want to measure, which are typically the left and right sides. Open your tape measure or extend your ruler to its full length, and place one end of the measuring tool against the edge of one of the parallel sides. Make sure the tape measure or ruler is aligned with the edge of the box and is not at an angle. Then, read the measurement on the tape measure or ruler where it meets the edge of the other parallel side. Take note of this measurement, which represents the width of the box. It's essential to record the measurement accurately, as it will be used to calculate the box's volume and to determine the correct size of packaging materials. If you're using a tape measure, you can also use the locking mechanism to hold the measurement in place, making it easier to read and record the width. By following these simple steps, you can quickly and accurately measure the width of a box, which is a crucial dimension in various applications, such as shipping, storage, and design.

Measuring the Height of a Box

Measuring the height of a box is a straightforward process that requires a ruler or measuring tape. To start, place the box on a flat surface and ensure it is standing upright. Next, locate the top and bottom edges of the box, which are usually the horizontal edges that run along the length and width of the box. Place the ruler or measuring tape along the vertical edge of the box, aligning it with the top and bottom edges. Take note of the measurement in inches or centimeters, making sure to record the exact height of the box. It's essential to measure the height of the box accurately, as this dimension is crucial in determining the overall size and volume of the box. Additionally, measuring the height of the box can help you determine if it will fit in a specific space or if it can be stacked on top of other boxes. By following these simple steps, you can quickly and easily measure the height of a box and ensure that you have an accurate measurement for your needs.

Recording and Applying the Measurements

When it comes to recording and applying measurements, accuracy is key. Whether you're a business owner shipping products, a homeowner storing furniture, or a professional in a field that requires precise calculations, having reliable measurements is crucial. In this article, we'll explore the importance of recording measurements accurately, converting them to different units when necessary, and using them for shipping or storage purposes. We'll start by discussing the best practices for recording measurements accurately, including the tools and techniques you can use to ensure precision. By following these guidelines, you'll be able to take accurate measurements that can be used for a variety of purposes, from calculating shipping costs to determining storage space requirements. In the following sections, we'll delve into the specifics of converting measurements to different units and using them for shipping or storage, but first, let's take a closer look at the importance of recording measurements accurately.

Recording the Measurements Accurately

When recording the measurements, it is crucial to be as accurate as possible to ensure that the box is measured correctly. To achieve this, use a ruler or measuring tape that is calibrated and in good condition. Take multiple measurements of each dimension to confirm accuracy, and record the measurements in a clear and concise manner. It is also essential to specify the unit of measurement, such as inches or centimeters, to avoid confusion. Additionally, consider using a digital measuring tool, such as a laser distance measurer, for increased accuracy and efficiency. When recording the measurements, it is also important to note any irregularities or obstructions, such as protrusions or recesses, that may affect the box's dimensions. By being meticulous and thorough in recording the measurements, you can ensure that the box is measured accurately and that any subsequent calculations or applications are reliable.

Converting Measurements to Different Units

Converting measurements to different units is a crucial step in recording and applying measurements accurately. When measuring a box, it's essential to ensure that all measurements are in the same unit to avoid errors and inconsistencies. To convert measurements to different units, you can use conversion factors or formulas. For example, to convert inches to feet, you can divide the measurement in inches by 12, as there are 12 inches in a foot. Similarly, to convert pounds to kilograms, you can multiply the measurement in pounds by 0.45, as 1 pound is equal to 0.45 kilograms. It's also important to consider the level of precision required for the measurement, as converting between units can sometimes result in rounding errors. By converting measurements to different units accurately, you can ensure that your measurements are reliable and consistent, which is critical in various applications, such as shipping, construction, and engineering. Additionally, using conversion charts or online tools can also help simplify the process and reduce errors. By mastering the art of converting measurements to different units, you can become more efficient and accurate in your measurement tasks, and make informed decisions based on reliable data.

Using the Measurements for Shipping or Storage

When it comes to shipping or storing a box, accurate measurements are crucial to ensure a smooth and cost-effective process. Using the measurements you've recorded, you can determine the best way to pack and ship your box, as well as calculate the costs involved. For shipping, you'll need to provide the length, width, height, and weight of the box to the shipping carrier, who will use this information to calculate the shipping cost and determine the best shipping method. If you're storing the box, you'll need to consider the dimensions to ensure it fits in the storage space and to calculate the storage costs. Additionally, having accurate measurements can help you avoid any potential issues during transit, such as the box being too large for a particular shipping method or storage space. By using the measurements you've recorded, you can make informed decisions about shipping and storage, and avoid any costly mistakes. Furthermore, accurate measurements can also help you to optimize your packaging, by choosing the right size of box and packing materials, which can lead to cost savings and reduced waste. Overall, using the measurements for shipping or storage is an essential step in ensuring a successful and efficient process.