How To Make A Mold

Here is the introduction paragraph: Mold making is a fascinating process that requires attention to detail, creativity, and technical skills. Whether you're a hobbyist, artist, or manufacturer, creating a mold can be a rewarding experience that allows you to replicate objects with precision and accuracy. To get started, it's essential to understand the basics of mold making, including the different types of molds, materials, and techniques involved. Before diving into the process, it's crucial to prepare a well-designed pattern and plan the mold's structure. Once you have a solid foundation, you can begin creating the mold and casting process, which involves mixing and applying materials, allowing them to set, and finally, removing the finished product from the mold. In this article, we'll explore the world of mold making, starting with the fundamentals. Let's begin by understanding the basics of mold making.

Understanding the Basics of Mold Making

Mold making is a crucial process in various industries, including manufacturing, art, and construction. It involves creating a hollowed-out block, known as a mold, which is used to shape and form materials into specific designs and patterns. To understand the basics of mold making, it's essential to grasp the fundamental concepts, including the purpose and types of molds, as well as the materials needed for the process. In this article, we will delve into the world of mold making, exploring what a mold is and its purpose, the different types of molds and their applications, and the materials required for mold making. By understanding these basics, individuals can gain a deeper appreciation for the art and science of mold making, and how it contributes to the creation of various products and structures. So, let's start by examining what a mold is and its purpose.

What is a Mold and Its Purpose

A mold is a hollowed-out block that is used to shape a liquid material, such as plastic, metal, or glass, into a specific form. The purpose of a mold is to create a cavity that the liquid material can flow into and take the shape of, allowing it to cool and harden into the desired form. Molds can be made from a variety of materials, including metal, plastic, and silicone, and can be used to create a wide range of objects, from small toys and trinkets to large industrial parts. The mold is typically designed to be reusable, allowing it to be used multiple times to create multiple copies of the same object. In addition to shaping the material, molds can also be used to add texture, patterns, and other details to the finished product. Overall, the purpose of a mold is to provide a precise and efficient way to create complex shapes and designs, making it an essential tool in a wide range of industries, from manufacturing and engineering to art and craft.

Types of Molds and Their Applications

Molds are versatile tools used in various industries, including manufacturing, construction, and art. There are several types of molds, each with its unique characteristics and applications. One common type is the silicone mold, known for its flexibility and durability. It is often used in casting, prototyping, and creating replicas of intricate designs. Another type is the polyurethane mold, which is resistant to abrasion and chemicals, making it ideal for producing parts with complex geometries. The epoxy mold is a popular choice for creating molds with high dimensional accuracy and surface finish. It is commonly used in the aerospace and automotive industries. The aluminum mold is a cost-effective option for producing large quantities of parts with simple geometries. It is often used in the production of consumer goods, such as plastic containers and packaging materials. The steel mold is a durable and long-lasting option, commonly used in the production of high-volume parts, such as automotive components and medical devices. The 3D printed mold is a relatively new type of mold that offers rapid prototyping and production capabilities. It is often used in the production of complex parts with intricate geometries. The plaster mold is a traditional type of mold that is still widely used in art and craft applications. It is often used to create decorative items, such as vases and sculptures. The fiberglass mold is a lightweight and corrosion-resistant option, commonly used in the production of boat hulls and other marine components. The carbon fiber mold is a high-performance option, often used in the production of aerospace and automotive components. Each type of mold has its unique advantages and disadvantages, and the choice of mold depends on the specific application, material, and production requirements.

Materials Needed for Mold Making

To create a mold, you'll need a variety of materials, depending on the type of mold you're making and the object you're trying to replicate. For a basic mold, you'll need a mold-making material, such as silicone, polyurethane, or alginate, which can be purchased at a craft store or online. You'll also need a mold release agent, such as petroleum jelly or cooking spray, to prevent the mold from sticking to the object being molded. A mixing container, stir stick, and scale or measuring cups are also necessary for accurately measuring and mixing the mold-making material. If you're creating a more complex mold, you may also need additional materials, such as a mold box or frame, to contain the mold-making material and provide support for the mold. Other materials, such as a vacuum chamber or pressure pot, may be necessary for creating a mold with intricate details or a high level of accuracy. Additionally, you may need a mold-making kit, which usually includes a mold-making material, mold release agent, and other necessary materials, or a mold-making machine, which can automate the mold-making process. It's also important to have a clean and well-ventilated workspace, as well as protective gear, such as gloves and goggles, to ensure a safe and successful mold-making process.

Preparing the Mold Design and Pattern

Preparing the mold design and pattern is a crucial step in the manufacturing process, as it directly affects the quality and efficiency of the final product. To ensure a successful mold design, several key considerations must be taken into account. First, designing the mold pattern and layout is essential to determine the optimal configuration of the mold components and ensure proper material flow. Additionally, creating a prototype or model of the mold design allows for testing and validation of the design before investing in the actual mold. Finally, refining the design for mold making involves making any necessary adjustments to the design to ensure it meets the required specifications and tolerances. By carefully considering these factors, manufacturers can create a high-quality mold design that meets their needs and produces consistent results. With a well-designed mold pattern and layout, manufacturers can set themselves up for success and ensure a smooth production process, which is why designing the mold pattern and layout is the first step in preparing the mold design and pattern.

Designing the Mold Pattern and Layout

Designing the mold pattern and layout is a critical step in the mold-making process. It involves creating a detailed plan for the mold's shape, size, and configuration to ensure that it can produce the desired part with the required quality and precision. The first step in designing the mold pattern and layout is to review the part design and identify the key features that need to be replicated in the mold. This includes the part's shape, size, material, and any critical dimensions or tolerances. Next, the mold designer must consider the type of mold being created, such as a injection mold, blow mold, or compression mold, and the specific requirements for each type. The designer must also consider the mold's material, such as steel or aluminum, and the manufacturing process that will be used to create the mold. With this information, the designer can begin to create a detailed layout of the mold, including the location of the parting line, the position of the ejector pins, and the configuration of the cooling system. The designer must also ensure that the mold is designed to withstand the stresses and pressures of the molding process, and that it can be easily maintained and repaired. Finally, the designer must create a detailed drawing or model of the mold design, which can be used to create the mold pattern and layout. This drawing or model should include all of the critical dimensions and features of the mold, as well as any necessary tolerances or specifications. By carefully designing the mold pattern and layout, mold makers can ensure that their molds produce high-quality parts with the required precision and accuracy.

Creating a Prototype or Model

Creating a prototype or model is a crucial step in the mold-making process. It allows you to test and refine your design before investing time and resources into creating the final mold. A prototype can be a simple representation of the final product, or it can be a highly detailed and functional model. The type of prototype you create will depend on the complexity of your design and the materials you plan to use. For example, if you're creating a mold for a plastic part, you may want to create a 3D printed prototype to test the shape and functionality of the part. On the other hand, if you're creating a mold for a metal part, you may want to create a machined prototype to test the strength and durability of the part. Regardless of the type of prototype you create, it's essential to ensure that it accurately represents the final product. This will help you identify any design flaws or issues that need to be addressed before creating the final mold. By creating a prototype, you can save time and money in the long run by avoiding costly mistakes and ensuring that your final product meets your requirements. Additionally, a prototype can also be used to test the mold-making process itself, allowing you to refine your techniques and make any necessary adjustments before creating the final mold. Overall, creating a prototype or model is an essential step in the mold-making process, and it can help you create a high-quality mold that produces accurate and reliable results.

Refining the Design for Mold Making

Refining the design for mold making involves several key considerations to ensure the final product meets the desired specifications and is manufactured efficiently. One crucial aspect is to analyze the part's geometry and identify any potential issues that could affect moldability, such as undercuts, thin walls, or complex features. This analysis helps to determine the most suitable mold design and material selection. Additionally, designers should consider the mold's gating system, which is responsible for directing molten material into the mold cavity. A well-designed gating system can significantly impact the quality of the final product, reducing defects and improving overall efficiency. Furthermore, refining the design also involves optimizing the mold's cooling system, which is critical for controlling the solidification process and preventing warping or distortion. By carefully considering these factors, designers can create a refined mold design that produces high-quality parts with minimal waste and reduced production costs. Effective communication with the mold maker and manufacturer is also essential to ensure that the design is feasible and meets the required specifications. By working together, designers and manufacturers can refine the design to achieve optimal results and produce a successful mold.

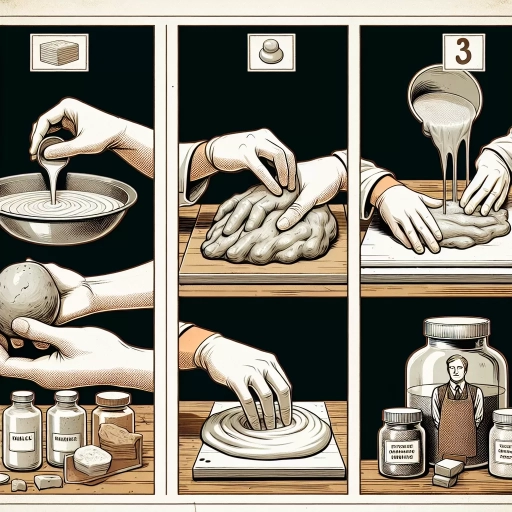

Creating the Mold and Casting Process

The mold and casting process is a crucial step in creating a wide range of products, from industrial parts to artistic sculptures. This process involves creating a mold, filling it with a material, and then removing the material from the mold to reveal the final product. To achieve a successful mold and casting process, it is essential to follow a series of steps, including choosing the right mold material and technique, building and assembling the mold, and casting the final product and post-mold processing. By carefully selecting the mold material and technique, manufacturers can ensure that their mold is durable, accurate, and able to produce high-quality products. In the next section, we will explore the importance of choosing the right mold material and technique, and how it sets the stage for a successful mold and casting process.

Choosing the Right Mold Material and Technique

When it comes to creating a mold, selecting the right material and technique is crucial for achieving the desired outcome. The choice of mold material depends on the type of object being cast, the desired level of detail, and the intended use of the final product. For example, silicone molds are ideal for casting delicate or intricate objects, such as jewelry or miniatures, due to their flexibility and high level of detail reproduction. On the other hand, polyurethane molds are better suited for casting larger objects, such as furniture or decorative items, due to their durability and resistance to wear and tear. Other popular mold materials include plaster, resin, and metal, each with its own unique characteristics and applications. In addition to selecting the right material, the technique used to create the mold is also important. Techniques such as hand-building, casting, and 3D printing can be used to create molds, each with its own advantages and disadvantages. For instance, hand-building allows for a high level of control and customization, while casting is often faster and more cost-effective. Ultimately, the choice of mold material and technique will depend on the specific needs and goals of the project, and it is essential to carefully consider these factors to ensure a successful outcome.

Building and Assembling the Mold

When building and assembling the mold, it's essential to ensure that all the parts fit together seamlessly to prevent any leaks or defects in the final product. Start by preparing the mold components, including the mold base, sides, and top, according to the design specifications. Apply a release agent to the mold surfaces to prevent the casting material from sticking to the mold. Next, assemble the mold parts, making sure they are properly aligned and securely fastened together using screws, clips, or adhesives. If using a silicone mold, apply a thin layer of mold release spray to the mold surfaces to ensure easy demolding. For a more complex mold design, consider using a mold assembly jig or fixture to ensure accurate alignment and positioning of the mold parts. Once the mold is assembled, inspect it carefully for any defects or irregularities, and make any necessary adjustments before proceeding with the casting process. By taking the time to carefully build and assemble the mold, you can ensure a successful casting process and achieve high-quality results.

Casting the Final Product and Post-Mold Processing

Casting the final product and post-mold processing are crucial steps in the mold-making process. Once the mold is created, the next step is to cast the final product. This involves pouring the desired material, such as resin, metal, or plastic, into the mold and allowing it to cure or solidify. The material is then removed from the mold, and the final product is revealed. However, the process doesn't end there. Post-mold processing involves refining the final product to achieve the desired finish and quality. This may include sanding, polishing, or applying a coating to the product. In some cases, additional features or details may need to be added, such as paint or decals. The goal of post-mold processing is to enhance the appearance and functionality of the final product, making it ready for use or distribution. By carefully executing these steps, manufacturers can produce high-quality products that meet their specifications and exceed customer expectations.