How To Use Teflon Tape

Teflon tape, also known as plumber's tape or thread seal tape, is a versatile and essential tool in various industries, including plumbing, HVAC, and automotive. Its primary function is to create a watertight or airtight seal on threaded connections, preventing leaks and ensuring the integrity of the system. However, using Teflon tape effectively requires some knowledge and technique. In this article, we will explore the key aspects of working with Teflon tape, including choosing the right type for your specific application, applying it correctly to achieve a reliable seal, and troubleshooting common issues that may arise. By understanding these fundamental principles, you'll be able to use Teflon tape with confidence and achieve professional-grade results. So, let's start by examining the different types of Teflon tape available and how to select the right one for your needs.

Choosing the Right Teflon Tape

When it comes to choosing the right Teflon tape for your specific needs, there are several factors to consider. With so many different types of Teflon tape available on the market, it can be overwhelming to determine which one is best for your application. To make an informed decision, it's essential to understand the different types of Teflon tape, consider the thread size and material, and look for the correct thickness and density. By taking these factors into account, you can ensure that you choose a Teflon tape that meets your specific requirements and provides a reliable seal. In this article, we'll explore these key considerations in more detail, starting with understanding the different types of Teflon tape.

Understanding the Different Types of Teflon Tape

Teflon tape, also known as PTFE tape, is a versatile and widely used product in various industries, including plumbing, HVAC, and automotive. However, not all Teflon tapes are created equal, and understanding the different types is crucial to ensure the right application and optimal performance. The main types of Teflon tape are differentiated by their thickness, density, and temperature rating. The most common types include standard Teflon tape, which is suitable for general-purpose applications, and high-density Teflon tape, which is designed for high-pressure and high-temperature applications. There is also a specialized type of Teflon tape, known as gas-rated Teflon tape, which is specifically designed for use in gas lines and applications where a high level of seal integrity is required. Additionally, some Teflon tapes are designed with specialized coatings or additives, such as silicone or ceramic, which provide enhanced performance in specific applications. Understanding the different types of Teflon tape and their characteristics is essential to ensure the right product is selected for the job, and to prevent costly mistakes or failures. By choosing the correct type of Teflon tape, users can ensure a reliable seal, prevent leaks, and maintain the integrity of their systems.

Considering the Thread Size and Material

When choosing the right Teflon tape, it's essential to consider the thread size and material of the pipe or fitting you're working with. The thread size will determine the width of the tape you need, as a tape that's too narrow may not provide a sufficient seal, while one that's too wide may be difficult to apply and may leave excess tape that can compromise the seal. The material of the pipe or fitting is also crucial, as different materials have different thread types and sizes. For example, NPT (National Pipe Taper) threads are commonly used in the United States, while BSP (British Standard Pipe) threads are used in the UK. Using the wrong type of tape for the thread material can lead to a poor seal or even damage to the threads. Additionally, some materials, such as PVC or ABS, may require a specialized tape that's designed specifically for those materials. By considering the thread size and material, you can ensure that you choose a Teflon tape that will provide a reliable and long-lasting seal.

Looking for the Correct Thickness and Density

When selecting the right Teflon tape, it's crucial to consider the correct thickness and density for your specific application. The thickness of Teflon tape is usually measured in mils (thousandths of an inch), and it can range from 0.002 to 0.010 inches. The density of the tape, on the other hand, is measured in pounds per cubic foot (pcf) and can vary from 1.5 to 2.5 pcf. A higher density tape is generally more durable and resistant to wear and tear, but it may be more difficult to apply and remove. A lower density tape, while easier to apply and remove, may not provide the same level of durability. The correct thickness and density of Teflon tape will depend on the specific application, including the type of pipe or fitting, the operating pressure and temperature, and the desired level of seal. For example, a thicker tape with a higher density may be required for high-pressure applications, while a thinner tape with a lower density may be sufficient for low-pressure applications. It's essential to consult the manufacturer's recommendations and industry standards to ensure the correct thickness and density of Teflon tape is used for your specific application.

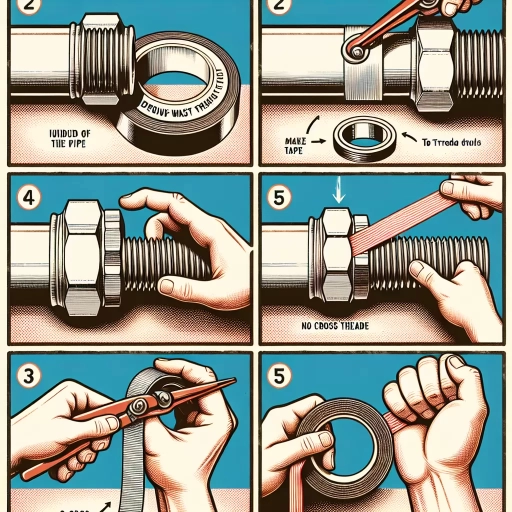

Applying Teflon Tape Correctly

Applying Teflon tape correctly is crucial to ensure a secure and leak-free connection in various applications, including plumbing, HVAC, and industrial processes. To achieve this, it is essential to follow the correct techniques and guidelines. Three key aspects to focus on are wrapping the tape in the correct direction, applying the right amount of tension, and ensuring a smooth and even surface. By mastering these techniques, individuals can guarantee a reliable and long-lasting seal. In this article, we will delve into the specifics of each of these critical steps, starting with the importance of wrapping the tape in the correct direction.

Wrapping the Tape in the Correct Direction

When wrapping the tape in the correct direction, it's essential to follow a few simple guidelines to ensure a secure and leak-free seal. The tape should always be wrapped in a clockwise direction, which helps to prevent the tape from unraveling and ensures that the threads are sealed properly. To begin, start by wrapping the tape around the male thread, overlapping the tape as you go to create a solid seal. Apply gentle to moderate pressure to ensure the tape adheres properly to the threads. As you wrap the tape, make sure to maintain a consistent tension to avoid any wrinkles or air pockets that could compromise the seal. It's also crucial to avoid stretching or pulling the tape too tightly, as this can cause it to tear or become misshapen. By wrapping the tape in the correct direction and following these simple guidelines, you can create a reliable and long-lasting seal that will withstand the rigors of daily use.

Applying the Right Amount of Tension

Applying the right amount of tension is crucial when using Teflon tape to create a watertight seal. If the tape is applied too loosely, it may not provide a sufficient seal, leading to leaks and other issues. On the other hand, applying too much tension can cause the tape to become over-compressed, which can also compromise its sealing ability. The ideal amount of tension will depend on the specific application and the type of Teflon tape being used. As a general rule, the tape should be applied with a moderate amount of tension, just enough to ensure that it is snug against the threads. This will help to create a strong, watertight seal that will last for a long time. It's also important to note that the tape should be applied in a consistent, even manner, with no wrinkles or creases that could compromise the seal. By applying the right amount of tension and using the correct technique, you can ensure that your Teflon tape is applied correctly and will provide a reliable seal.

Ensuring a Smooth and Even Surface

Ensuring a smooth and even surface is crucial when applying Teflon tape to achieve a secure and leak-free connection. Any imperfections, such as scratches, dirt, or corrosion, can compromise the tape's ability to create a tight seal. To guarantee a smooth surface, start by cleaning the area thoroughly with a soft cloth and a mild detergent. Remove any dirt, grime, or old tape residue, and dry the surface completely with a clean towel. Next, inspect the surface for any scratches or corrosion and address these issues before applying the tape. If necessary, use a fine-grit sandpaper to smooth out any rough spots, and then wipe the area clean with a soft cloth. By taking the time to prepare the surface properly, you can ensure that the Teflon tape adheres evenly and effectively, creating a reliable and long-lasting seal.

Troubleshooting Common Issues with Teflon Tape

Teflon tape, also known as plumber's tape, is a versatile and widely used tool for creating watertight seals in pipes and fittings. However, like any other material, it can sometimes fail to perform as expected, leading to frustrating issues such as leaks, seepage, and difficulties with tape removal. To address these common problems, it's essential to understand the root causes and apply the right troubleshooting techniques. In this article, we'll explore three key areas of troubleshooting: dealing with leaks and seepage, addressing tape that is too loose or too tight, and removing old or damaged Teflon tape. By understanding these common issues and their solutions, you'll be better equipped to tackle Teflon tape problems and ensure a secure, leak-free connection. Let's start by examining one of the most common issues: dealing with leaks and seepage.

Dealing with Leaks and Seepage

Dealing with leaks and seepage is a common issue when using Teflon tape, but there are several steps you can take to address the problem. First, inspect the threaded connection to ensure that the tape is applied correctly and that there are no gaps or wrinkles in the tape. If the tape is not applied evenly, it may not provide a proper seal, leading to leaks. Next, check the type of Teflon tape being used and ensure that it is suitable for the specific application. Some Teflon tapes are designed for specific uses, such as high-pressure or high-temperature applications, and using the wrong type of tape can lead to leaks. If the leak persists, try re-taping the connection, making sure to apply the tape in a consistent and even manner. It's also a good idea to use a pipe dope or sealant in addition to the Teflon tape to provide an extra layer of protection against leaks. In some cases, leaks may be caused by over-tightening the connection, which can damage the threads and create a gap for fluid to escape. To avoid this, make sure to tighten the connection in a star pattern, rather than tightening it in a circular motion. By following these steps, you should be able to effectively deal with leaks and seepage when using Teflon tape.

Addressing Tape that is Too Loose or Too Tight

When addressing tape that is too loose or too tight, it's essential to understand the consequences of improper application. If the tape is too loose, it may not provide a sufficient seal, leading to leaks and reduced performance. On the other hand, if the tape is too tight, it can damage the threads or even strip them, causing more harm than good. To resolve this issue, start by inspecting the tape for any visible signs of damage or wear. If the tape is damaged, replace it with a new one. If the tape is still in good condition, try adjusting the tension by unwinding or rewinding the tape. For loose tape, try wrapping it around the threads a few more times to increase the tension. For tight tape, try unwinding it slightly to reduce the pressure. It's also crucial to ensure that the tape is applied in the correct direction, following the manufacturer's instructions. Additionally, consider using a tape with a built-in tension indicator or a torque wrench to help achieve the optimal tension. By taking these steps, you can ensure that your Teflon tape is applied correctly, providing a reliable seal and preventing potential issues.

Removing Old or Damaged Teflon Tape

When dealing with old or damaged Teflon tape, it's essential to remove it properly to ensure a clean and secure connection. Start by identifying the type of Teflon tape used, as some may be more challenging to remove than others. For most standard Teflon tapes, you can use a combination of heat and solvents to loosen the adhesive. Apply a small amount of heat using a hair dryer or heat gun to the affected area, taking care not to apply too much heat, which can damage the surrounding material. Next, use a solvent such as acetone, mineral spirits, or a specialized adhesive remover to dissolve the adhesive. Gently scrape off the old tape using a plastic scraper or a credit card, working from one edge to the other. Be cautious not to scratch the surface or push the old adhesive further into the threads. If the old tape is particularly stubborn, you can use a Teflon tape remover tool, which is specifically designed to safely remove old tape without damaging the surface. Once the old tape is removed, inspect the area for any remaining adhesive or debris and clean it thoroughly with a soft cloth and a mild solvent. Finally, apply a new layer of Teflon tape, following the manufacturer's instructions and taking care to apply the correct amount to ensure a secure and leak-free connection.