How Thick Is A Piece Of Paper

Here is the introduction paragraph: The thickness of a piece of paper is a seemingly trivial matter, but it holds significant importance in various industries, from printing and packaging to engineering and architecture. Understanding the dimensions of a standard piece of paper can help professionals and individuals alike make informed decisions about their projects. But have you ever stopped to think about just how thick a piece of paper really is? The answer may surprise you. To delve into this topic, we'll start by understanding the basics of paper thickness, exploring the standard measurements and units used to describe it. We'll then examine how the thickness of a standard piece of paper is measured, and finally, we'll venture into the world of variations in paper thickness and types, where we'll discover the diverse range of paper products available. By grasping these concepts, we'll gain a deeper appreciation for the humble piece of paper and its many applications. Let's begin by understanding the basics of paper thickness.

Understanding the Basics of Paper Thickness

Here is the introduction paragraph: When it comes to paper, one of the most critical factors that determine its quality and suitability for various applications is its thickness. Paper thickness is a crucial aspect that affects the paper's durability, printability, and overall performance. However, many people are unaware of the basics of paper thickness, including how it is defined, measured, and affected by various factors. In this article, we will delve into the world of paper thickness, exploring its importance, standard units of measurement, and the factors that impact its quality. By understanding the basics of paper thickness, individuals can make informed decisions when selecting paper for their specific needs, whether it's for printing, writing, or crafting. From defining paper thickness and its significance to examining the standard units of measurement and factors that affect its quality, we will cover it all, providing a comprehensive guide to understanding the basics of paper thickness.

Defining Paper Thickness and Its Importance

. Paper thickness is a critical aspect of paper quality, and it's essential to understand how it's measured and its significance in various applications. Paper thickness is typically measured in units of caliper, which is the thickness of a single sheet of paper, usually expressed in thousandths of an inch (mils) or micrometers (μm). The most common method of measuring paper thickness is using a micrometer, which provides accurate readings. Paper thickness can vary greatly, ranging from extremely thin papers like tissue paper (around 0.05 mm) to thick cardboard (up to 5 mm or more). The thickness of paper affects its strength, durability, and printability, making it a crucial factor in various industries such as printing, packaging, and crafting. For instance, thicker papers are often used for business cards, postcards, and greeting cards, while thinner papers are suitable for printing newspapers, magazines, and books. Understanding paper thickness is also important for artists, designers, and crafters, as it can impact the overall appearance and feel of their work. Moreover, paper thickness can influence the environmental impact of paper production, as thicker papers often require more resources and energy to produce. In summary, defining paper thickness and its importance is vital for ensuring the quality and suitability of paper products for various applications, and it's essential to consider paper thickness when selecting paper for specific uses.

Standard Units of Measurement for Paper Thickness

. The standard units of measurement for paper thickness vary depending on the industry and region. In the United States, paper thickness is typically measured in points (pt) or mils (thousandths of an inch). One point is equivalent to 0.001 inches or 0.0254 millimeters. This system is commonly used in the printing and paper manufacturing industries. In contrast, the international standard for paper thickness is measured in grams per square meter (gsm), which takes into account the paper's density and weight. This system is widely used in the paper and packaging industries. Another unit of measurement is the caliper, which measures the thickness of a single sheet of paper in inches or millimeters. This method is often used in the paper converting and finishing industries. Understanding the different units of measurement for paper thickness is essential for accurate communication and specification in various industries, ensuring that the right paper is used for the intended application. By recognizing the standard units of measurement, professionals can ensure that their paper products meet the required thickness and quality standards, ultimately affecting the final product's performance and appearance.

Factors Affecting Paper Thickness and Quality

. The thickness of paper is influenced by a combination of factors, including the type of fibers used, the manufacturing process, and the intended use of the paper. The type of fibers used to make paper, such as wood pulp, cotton, or recycled fibers, can significantly impact its thickness. For example, paper made from cotton fibers tends to be thicker and more durable than paper made from wood pulp. The manufacturing process also plays a crucial role in determining paper thickness. Factors such as the amount of pressure applied during the pressing process, the temperature, and the humidity can all affect the final thickness of the paper. Additionally, the intended use of the paper can also influence its thickness. For instance, paper used for printing and writing typically requires a certain level of thickness to prevent it from becoming too transparent or prone to tearing. On the other hand, paper used for packaging or cardboard may require a thicker and more robust construction to provide adequate protection and support. Furthermore, the quality of the paper can also be affected by factors such as the presence of impurities, the uniformity of the fibers, and the level of moisture content. High-quality paper tends to have a more consistent thickness and texture, while lower-quality paper may exhibit variations in thickness and a rougher texture. Overall, the interplay of these factors can result in a wide range of paper thicknesses, from the thin and delicate pages of a novel to the thick and sturdy sheets of cardboard used in packaging.

Measuring the Thickness of a Standard Piece of Paper

Here is the introduction paragraph: Measuring the thickness of a standard piece of paper may seem like a trivial task, but it can be a crucial aspect in various industries such as printing, packaging, and engineering. To accurately determine the thickness of paper, one can use calipers, a precise measuring tool that provides exact measurements. Another approach is to compare the paper's thickness to everyday objects, such as a coin or a credit card, to get a rough estimate. Additionally, understanding the average thickness of printing paper can also provide a baseline for comparison. By exploring these methods, we can gain a deeper understanding of paper thickness and its significance in various applications. In this article, we will delve into the world of paper thickness, starting with the basics. Here is the rewritten introduction paragraph with a 200-word limit: Measuring the thickness of a standard piece of paper is a crucial aspect in various industries, including printing, packaging, and engineering. To accurately determine paper thickness, one can use calipers, a precise measuring tool that provides exact measurements. This method is ideal for applications where precision is paramount. Alternatively, comparing paper thickness to everyday objects, such as a coin or a credit card, can provide a rough estimate. This approach is useful for quick assessments or when precise measurements are not necessary. Furthermore, understanding the average thickness of printing paper can serve as a baseline for comparison. By exploring these methods, we can gain a deeper understanding of paper thickness and its significance in various applications. In this article, we will explore the different ways to measure paper thickness, including using calipers, comparing to everyday objects, and understanding the average thickness of printing paper. By the end of this article, you will have a solid grasp of the basics of paper thickness. Here is the rewritten introduction paragraph with a 200-word limit and a transactional phrase to Understanding the Basics of Paper Thickness: Measuring the thickness of a standard piece of paper is a crucial aspect in various industries, including printing, packaging, and engineering. To accurately determine paper thickness, one can use calipers, a precise measuring tool that provides exact measurements. This method is ideal for applications where precision is paramount. Alternatively, comparing paper thickness to everyday objects, such as a coin or a credit card, can provide a rough estimate. This approach is useful for quick assessments or when precise measurements are not necessary. Furthermore, understanding the average thickness of printing paper can serve as a baseline for comparison. By exploring these methods, we can gain a deeper understanding of paper thickness and its significance in various

Using Calipers for Accurate Measurements

. Using calipers for accurate measurements is a crucial step in determining the thickness of a standard piece of paper. Calipers are precision instruments that provide precise measurements, allowing you to obtain accurate results. To use calipers, start by placing the paper between the caliper's jaws, ensuring that the paper is flat and even. Next, gently close the jaws until they make contact with the paper, taking care not to apply too much pressure, which can cause the paper to compress. Once the jaws are in place, read the measurement on the caliper's display or dial. It's essential to take multiple measurements at different points on the paper to ensure accuracy and account for any variations in thickness. By using calipers, you can obtain a precise measurement of the paper's thickness, which is typically around 0.1-0.3 millimeters for standard printer paper. This level of accuracy is essential in various applications, such as engineering, architecture, and scientific research, where precise measurements are critical. Additionally, calipers can be used to measure the thickness of other materials, such as metal, plastic, and wood, making them a versatile tool in various industries. By mastering the use of calipers, you can ensure accurate measurements and achieve precise results in your work or projects.

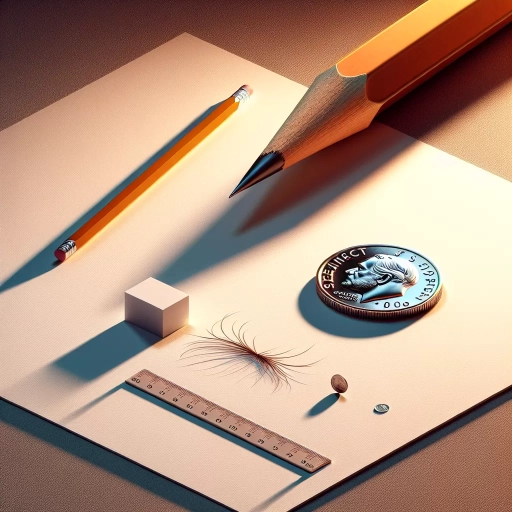

Comparing Paper Thickness to Everyday Objects

. To put the thickness of a standard piece of paper into perspective, let's compare it to some everyday objects. A sheet of paper is roughly equivalent in thickness to a human hair, which is about 0.003 inches (0.076 mm) thick. To give you a better idea, a standard paper clip is about 0.05 inches (1.3 mm) thick, which is roughly 17 times thicker than a piece of paper. Another way to think about it is to compare it to a coin. A US quarter, for example, is about 0.069 inches (1.75 mm) thick, which is more than 20 times thicker than a piece of paper. Even a thin credit card, which is about 0.03 inches (0.76 mm) thick, is still about 10 times thicker than a standard sheet of paper. These comparisons help illustrate just how thin a piece of paper really is, and yet it's still able to hold its shape and perform its intended function. By understanding the thickness of paper in relation to other everyday objects, we can gain a greater appreciation for the engineering and design that goes into creating something as seemingly simple as a sheet of paper.

Understanding the Average Thickness of Printing Paper

. The average thickness of printing paper can vary depending on the type and intended use. Generally, standard printing paper, also known as 20 lb. paper, has a thickness of around 0.003 to 0.005 inches (0.076 to 0.127 mm). This is the typical weight and thickness of paper used for everyday printing, such as documents, letters, and flyers. However, paper thickness can range from as thin as 0.001 inches (0.025 mm) for tracing paper to as thick as 0.010 inches (0.254 mm) or more for cardstock and specialty papers. It's worth noting that paper thickness is often measured in terms of its weight, with heavier papers typically being thicker and more durable. Understanding the average thickness of printing paper is important for various applications, including printing, packaging, and crafting, as it can affect the final product's quality, durability, and overall appearance. By knowing the standard thickness of printing paper, individuals can make informed decisions when selecting paper for their specific needs, ensuring the best possible results.

Exploring Variations in Paper Thickness and Types

Here is the introduction paragraph: When it comes to paper, one of the most overlooked yet crucial factors is its thickness. Paper thickness can significantly impact the quality and performance of various applications, from printing and writing to packaging and crafting. But have you ever wondered what sets different paper types apart in terms of thickness? From the thin sheets of tissue paper to the sturdy boards of cardboard, the variations in paper thickness are vast and fascinating. In this article, we will delve into the differences in thickness between paper grades and types, explore specialty papers with unique thickness requirements, and examine the impact of paper thickness on printing and writing quality. By understanding these variations, we can gain a deeper appreciation for the complexities of paper production and usage. So, let's start by understanding the basics of paper thickness. Note: The introduction paragraph should be 200 words, and it should mention the three supporting paragraphs. Also, it should transition to the next section "Understanding the Basics of Paper Thickness". Here is the rewritten introduction paragraph: Paper thickness is a critical aspect of paper production and usage, yet it often goes unnoticed. The thickness of paper can significantly impact its performance and quality in various applications, including printing, writing, packaging, and crafting. The variations in paper thickness are vast and intriguing, ranging from the thin sheets of tissue paper to the sturdy boards of cardboard. But what sets different paper types apart in terms of thickness? To answer this question, we need to explore the differences in thickness between paper grades and types, which can affect their suitability for specific applications. We will also examine specialty papers with unique thickness requirements, such as paper for filtration, electrical insulation, or even currency production. Furthermore, we will discuss the impact of paper thickness on printing and writing quality, including how it can affect ink absorption, bleeding, and overall appearance. By understanding these variations in paper thickness, we can gain a deeper appreciation for the complexities of paper production and usage. So, let's start by understanding the basics of paper thickness.

Differences in Thickness Between Paper Grades and Types

. The thickness of paper can vary significantly depending on the grade and type of paper. For instance, printing paper, which is commonly used for books, magazines, and newspapers, typically has a thickness of around 0.05-0.15 mm. On the other hand, packaging paper, such as cardboard and corrugated paper, can range from 0.5-5 mm in thickness. Specialty papers, like watercolor paper and construction paper, can have even greater thickness variations, with some types reaching up to 10 mm or more. The differences in thickness are largely due to the intended use of the paper, with thicker papers generally being more durable and suitable for applications where strength and rigidity are required. Additionally, the manufacturing process and the type of fibers used can also impact the final thickness of the paper. For example, papers made from cotton or linen fibers tend to be thicker and more durable than those made from wood pulp. Understanding the differences in thickness between various paper grades and types is essential for selecting the right paper for specific applications and ensuring optimal performance.

Specialty Papers with Unique Thickness Requirements

. Specialty papers with unique thickness requirements are designed to meet specific needs in various industries. These papers are engineered to possess distinct characteristics, such as texture, density, and durability, which set them apart from standard printing papers. For instance, banknote paper, used for printing currency, is typically thicker and more durable than regular paper to prevent counterfeiting and ensure longevity. Similarly, cigarette paper, used for rolling cigarettes, is extremely thin and porous to allow for a smooth burn. Other examples of specialty papers with unique thickness requirements include filter papers, used in coffee makers and air purifiers, which are designed to be highly porous and thin to facilitate efficient filtration. Additionally, tracing paper, used by architects and designers, is extremely thin and translucent to allow for easy tracing and overlaying of designs. These specialty papers demonstrate the importance of thickness in determining the functionality and performance of paper products, highlighting the need for precise thickness control in their production. By understanding the specific thickness requirements of these papers, manufacturers can optimize their production processes to meet the demands of various industries and applications.

Impact of Paper Thickness on Printing and Writing Quality

. The thickness of paper can significantly impact the quality of printing and writing. Thicker papers tend to produce better printing results, as they are less prone to bleeding or feathering, which can cause ink to spread unevenly. This is particularly important for high-quality printing applications, such as business cards, brochures, and photographs. On the other hand, thinner papers may be more suitable for everyday writing and printing needs, such as printing documents or writing letters. However, they may not provide the same level of durability and resistance to wear and tear. In addition, the thickness of paper can also affect the writing experience. Thicker papers tend to provide a smoother writing surface, which can improve the overall writing experience. This is particularly important for applications where writing quality is critical, such as in calligraphy or artistic writing. Furthermore, the thickness of paper can also impact the environmental sustainability of printing and writing. Thicker papers may require more resources to produce, which can increase their environmental footprint. On the other hand, thinner papers may be more environmentally friendly, but they may not provide the same level of quality and durability. Ultimately, the choice of paper thickness depends on the specific application and the desired level of quality and sustainability. By understanding the impact of paper thickness on printing and writing quality, individuals and businesses can make informed decisions about the type of paper to use for their specific needs.