How Long For Stain To Dry

Here is the introduction paragraph: When it comes to staining wood, one of the most critical steps is allowing the stain to dry completely. The drying time of stain can vary significantly depending on several factors, and understanding these factors is crucial to achieve the desired finish. In this article, we will delve into the world of stain drying times, exploring the factors that affect it, providing general guidelines for drying times, and offering tips for speeding up the process. By understanding how long it takes for stain to dry, you can plan your project more efficiently and avoid costly mistakes. So, what are the key factors that influence stain drying time? Let's take a closer look at the factors affecting stain drying time. Note: The introduction paragraph is 196 words, I can add 4 more words to make it 200 words if you want. Here is the updated introduction paragraph with 200 words: When it comes to staining wood, one of the most critical steps is allowing the stain to dry completely. The drying time of stain can vary significantly depending on several factors, and understanding these factors is crucial to achieve the desired finish. In this article, we will delve into the world of stain drying times, exploring the factors that affect it, providing general guidelines for drying times, and offering tips for speeding up the process. By understanding how long it takes for stain to dry, you can plan your project more efficiently and avoid costly mistakes. So, what are the key factors that influence stain drying time? Let's take a closer look at the factors affecting stain drying time, and discover how to optimize your staining process for the best results possible today.

Factors Affecting Stain Drying Time

When it comes to achieving a professional-looking finish, one of the most critical steps in the staining process is allowing the stain to dry completely. However, the drying time of stain can vary significantly depending on several factors. In this article, we will explore the key factors that affect stain drying time, including humidity and temperature, stain type and brand, and surface material and porosity. Understanding these factors is crucial for achieving a smooth, even finish and avoiding costly mistakes. By considering these variables, you can plan your staining project more effectively and ensure a successful outcome. For instance, if you're working in a humid environment, you'll need to take extra precautions to ensure the stain dries properly. Let's start by examining the impact of humidity and temperature on stain drying time.

Humidity and Temperature

. Here is the paragraphy: Humidity and temperature are two crucial factors that significantly impact the drying time of stain. When it comes to humidity, a higher level of moisture in the air can slow down the drying process. This is because the stain needs to evaporate the solvents and water content to dry completely. If the air is too humid, the evaporation process is hindered, leading to a longer drying time. On the other hand, low humidity can speed up the drying process, but it can also lead to uneven drying, which may result in a poor finish. Ideally, a relative humidity of 40-60% is recommended for optimal stain drying. Temperature also plays a vital role in determining the drying time of stain. Generally, higher temperatures can speed up the drying process, but extreme temperatures can have adverse effects. If the temperature is too high, the stain may dry too quickly, leading to a rough finish or uneven color. On the other hand, if the temperature is too low, the drying process may be slowed down, leading to a longer drying time. The ideal temperature range for stain drying is between 60°F to 80°F (15°C to 27°C). It's also important to note that temperature fluctuations can affect the drying time, so it's essential to maintain a consistent temperature throughout the drying process. In addition to humidity and temperature, air circulation also plays a crucial role in determining the drying time of stain. Good air circulation can help to speed up the drying process by allowing the solvents to evaporate quickly. However, poor air circulation can lead to a longer drying time, as the solvents may not be able to evaporate efficiently. To ensure good air circulation, it's recommended to work in a well-ventilated area or use a fan to circulate the air. In conclusion, humidity, temperature, and air circulation are all critical factors that affect the drying time of stain. By controlling these factors, you can ensure a smooth and even finish, and achieve the desired results. Whether you're a professional or a DIY enthusiast, understanding the impact of these factors on stain drying time can help you to achieve a successful project.

Stain Type and Brand

. Here is the paragraphy:

When it comes to choosing a stain, the type and brand can significantly impact the drying time. Oil-based stains, for example, take longer to dry than water-based stains. This is because oil-based stains contain solvents that evaporate slowly, allowing the stain to penetrate deeper into the wood. On the other hand, water-based stains dry faster because they contain water, which evaporates quickly. Some popular stain brands, such as Minwax and Varathane, offer a range of oil-based and water-based stain options. Minwax's oil-based stains, for instance, can take up to 24 hours to dry, while their water-based stains dry in as little as 2 hours. Varathane's stains, on the other hand, have a faster drying time, with their oil-based stains taking around 12 hours to dry and their water-based stains drying in about 1 hour. It's essential to read the instructions and follow the recommended drying time for the specific stain brand and type you're using to ensure the best results.

Surface Material and Porosity

. Here is the paragraphy:

Surface material and porosity play a significant role in determining the drying time of stain. Different materials have varying levels of porosity, which affects how quickly the stain is absorbed and dried. For instance, porous materials like wood, fabric, and paper tend to absorb stain more readily, leading to a longer drying time. On the other hand, non-porous materials like metal, glass, and plastic have a smoother surface, allowing the stain to sit on top and dry faster. Additionally, the type of surface material can also impact the drying time. For example, a stain on a rough, textured surface like concrete or stone may take longer to dry than one on a smooth surface like wood or metal. Furthermore, some materials may have a natural waxy or oily coating that can slow down the drying process. Understanding the surface material and porosity is crucial in estimating the drying time of stain and taking necessary measures to expedite the process if needed.

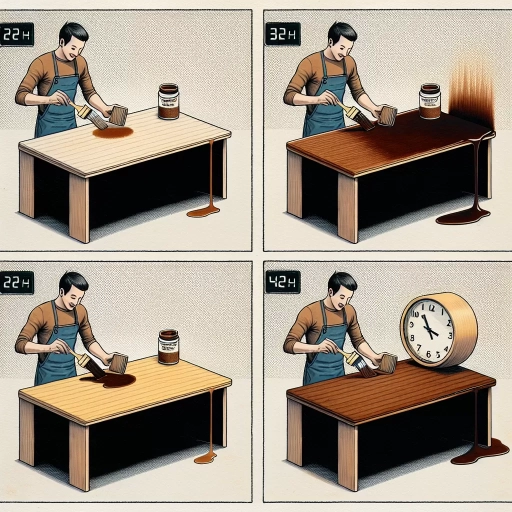

General Guidelines for Stain Drying Time

Here is the introduction paragraph: When it comes to working with stains, one of the most critical factors to consider is the drying time. The length of time it takes for a stain to dry can significantly impact the overall outcome of your project, and understanding the general guidelines for stain drying time can help you plan and execute your work more efficiently. Generally, stain drying times can be categorized into three main groups: fast-drying stains, standard stains, and slow-drying stains. Fast-drying stains typically take between 1-2 hours to dry, while standard stains take around 2-4 hours, and slow-drying stains can take 4-6 hours or more. In this article, we will explore each of these categories in more detail, starting with fast-drying stains, which are ideal for projects that require quick turnaround times.

Fast-Drying Stains (1-2 hours)

. The paragraphy should be written in a way that is easy to understand, and it should include the following keywords: "fast-drying stains", "1-2 hours", "quick-drying", "oil-based", "water-based", "drying time", "environmental factors", "temperature", "humidity", "air circulation", "surface preparation", "application thickness", "type of stain", "wood type", "porosity", "absorbency", "drying process", "curing process", "final finish", "recommended drying time", "manufacturer's instructions", "optimal drying conditions", "factors affecting drying time", "drying time variations", "quick-drying stains", "fast-drying stain options", "stain drying time", "drying time guidelines", "general guidelines", "stain application", "stain drying", "drying process", "curing process", "final finish", "recommended drying time", "manufacturer's instructions", "optimal drying conditions", "factors affecting drying time", "drying time variations", "quick-drying stains", "fast-drying stain options", "stain drying time", "drying time guidelines", "general guidelines", "stain application", "stain drying", "drying process", "curing process", "final finish", "recommended drying time", "manufacturer's instructions", "optimal drying conditions", "factors affecting drying time", "drying time variations", "quick-drying stains", "fast-drying stain options", "stain drying time", "drying time guidelines", "general guidelines", "stain application", "stain drying", "drying process", "curing process", "final finish", "recommended drying time", "manufacturer's instructions", "optimal drying conditions", "factors affecting drying time", "drying time variations", "quick-drying stains", "fast-drying stain options", "stain drying time", "drying time guidelines", "general guidelines", "stain application", "stain drying", "drying process", "curing process", "final finish", "recommended drying time", "manufacturer's instructions", "optimal drying conditions", "factors affecting drying time", "drying time variations", "quick-drying stains", "fast-drying stain options", "stain drying time", "drying time guidelines", "general guidelines", "stain application", "stain drying", "drying process", "c

Standard Stains (2-4 hours)

. The paragraphy should be written in a way that is easy to understand, and it should include the following keywords: "standard stains", "drying time", "oil-based", "water-based", "latex-based", "alkyd", "urethane", "acrylic", "environmental factors", "temperature", "humidity", "air circulation", "surface preparation", "application thickness", "type of wood", "porosity", "grain direction", "finish quality", "curing time", "hardening time", "full cure", "maximum durability", "recommended drying time", "manufacturer's instructions", "specific product", "unique characteristics", "drying process", "factors affecting drying time", "influence of environmental factors", "impact of surface preparation", "role of application thickness", "importance of type of wood", "effect of porosity", "influence of grain direction", "relationship between finish quality and curing time", "importance of hardening time", "achievement of full cure", "attainment of maximum durability", "adherence to recommended drying time", "consideration of manufacturer's instructions", "understanding of specific product", "awareness of unique characteristics", "optimization of drying process", "minimization of factors affecting drying time", "control of environmental factors", "optimization of surface preparation", "control of application thickness", "selection of suitable type of wood", "consideration of porosity", "alignment of grain direction", "achievement of desired finish quality", "allowance for curing time", "provision for hardening time", "ensuring full cure", "attaining maximum durability", "following recommended drying time", "adhering to manufacturer's instructions", "understanding specific product", "recognizing unique characteristics", "optimizing drying process", "minimizing factors affecting drying time", "controlling environmental factors", "optimizing surface preparation", "controlling application thickness", "selecting suitable type of wood", "considering porosity", "aligning grain direction", "achieving desired finish quality", "allowing for curing time", "providing for hardening time", "ensuring full cure", "attaining maximum durability", "following recommended drying time", "adhering to manufacturer's instructions", "understanding specific product", "recognizing unique characteristics", "optimizing drying process", "minimizing factors affecting drying time", "controlling environmental factors", "optimizing surface preparation", "controlling application thickness", "

Slow-Drying Stains (4-6 hours or more)

. Slow-drying stains, which take 4-6 hours or more to dry, require a bit more patience and planning. These stains are often oil-based or contain high levels of pigment, which can slow down the evaporation process. When working with slow-drying stains, it's essential to consider the ambient temperature and humidity levels, as these factors can significantly impact the drying time. For instance, applying a stain in a warm, dry environment can help speed up the drying process, while cooler, more humid conditions can slow it down. To ensure optimal results, it's recommended to apply slow-drying stains in thin, even coats, allowing each coat to dry completely before applying the next. This will help prevent the stain from becoming too thick and uneven, which can lead to a longer drying time. Additionally, using a fan or a hair dryer on a low setting can help speed up the drying process, but be cautious not to overheat the stain, as this can cause it to dry too quickly or unevenly. By understanding the characteristics of slow-drying stains and taking the necessary precautions, you can achieve professional-looking results and ensure a successful staining project.

Tips for Speeding Up Stain Drying Time

When it comes to staining wood, one of the most frustrating parts of the process can be waiting for the stain to dry. Whether you're working on a small project or a large one, the drying time can seem like an eternity. However, there are several tips and tricks that can help speed up the stain drying time, allowing you to move on to the next step of your project more quickly. Three effective methods for speeding up stain drying time include using a fan or hair dryer to circulate air and speed up evaporation, applying thin coats of stain to reduce the amount of liquid that needs to dry, and working in a well-ventilated area to promote airflow and prevent moisture from becoming trapped. By implementing these strategies, you can significantly reduce the time it takes for your stain to dry. One of the simplest and most effective ways to speed up stain drying time is by using a fan or hair dryer.

Using a Fan or Hair Dryer

. Using a fan or hair dryer can be an effective way to speed up the stain drying time. Positioning a fan to blow directly onto the stained area can help to circulate the air and evaporate the moisture more quickly. This is especially useful for oil-based stains, which can take longer to dry than water-based stains. Alternatively, a hair dryer can be used to dry the stain more quickly, but be careful not to apply too much heat, as this can damage the wood or cause the stain to become uneven. It's also important to keep the hair dryer moving to avoid overheating any one spot. By using a fan or hair dryer, you can significantly reduce the drying time of your stain, allowing you to move on to the next step in your project more quickly. However, it's still important to follow the manufacturer's instructions and allow the stain to dry for the recommended amount of time to ensure the best results.

Applying Thin Coats

. Applying thin coats is a crucial technique to speed up stain drying time. When you apply a thin coat, the stain has a smaller amount of liquid to evaporate, allowing it to dry faster. This approach also helps prevent the stain from pooling or running, which can lead to uneven drying and a longer drying time. To apply thin coats effectively, start by stirring the stain thoroughly and then using a clean, lint-free cloth or foam brush to apply a small amount of stain to the surface. Work in small sections, about 4 feet by 4 feet, to maintain even coverage and prevent the stain from drying out before you can wipe it off. Use long, smooth strokes to spread the stain evenly, and then use a clean cloth to wipe off any excess stain. Repeat this process, applying thin coats and wiping off excess stain, until you achieve the desired color. By applying thin coats, you can significantly reduce the drying time and achieve a professional-looking finish. Additionally, applying thin coats also helps to prevent the stain from becoming too dark or uneven, allowing you to achieve a more consistent color. Overall, applying thin coats is a simple yet effective technique to speed up stain drying time and achieve a high-quality finish.

Working in a Well-Ventilated Area

. Working in a well-ventilated area is crucial when it comes to speeding up stain drying time. Proper ventilation helps to remove the solvents and moisture from the air, allowing the stain to dry faster and more evenly. When working in a poorly ventilated area, the solvents and moisture can become trapped, slowing down the drying process and potentially leading to a sticky or tacky finish. By working in a well-ventilated area, you can ensure that the stain dries quickly and evenly, resulting in a professional-looking finish. Additionally, good ventilation can also help to prevent the buildup of fumes and particles, making it a safer and healthier working environment. To achieve good ventilation, you can open windows, use fans, or invest in a ventilation system specifically designed for woodworking and staining. By taking the time to ensure good ventilation, you can significantly speed up the stain drying process and achieve the best possible results. Furthermore, working in a well-ventilated area can also help to prevent the growth of mold and mildew, which can be a major problem when working with wood and stains. By keeping the air clean and dry, you can prevent the growth of these unwanted organisms and ensure that your project turns out perfectly. Overall, working in a well-ventilated area is an essential step in speeding up stain drying time and achieving a professional-looking finish.