How Does Vinyl Work

The introduction paragraph should be 200 words and should include the following information: * Briefly introduce the topic of vinyl records and their resurgence in popularity * Mention the three main points that will be covered in the article: what vinyl is and how it stores music, how a record player reads vinyl records, and what makes vinyl sound unique and warm * Transition to the first supporting paragraph, "What is Vinyl and How Does it Store Music?" Here is the introduction paragraph: In recent years, vinyl records have experienced a significant resurgence in popularity, with many music enthusiasts seeking out the unique sound and tactile experience that they offer. But have you ever stopped to think about how vinyl records actually work? From the physical properties of the vinyl itself to the way that record players read the grooves, there's a lot of fascinating technology at play. In this article, we'll delve into the world of vinyl and explore three key aspects of how it works. First, we'll take a closer look at what vinyl is and how it stores music, examining the physical properties of the material and how it's used to capture sound. We'll also explore how a record player reads vinyl records, including the mechanics of the stylus and the role of the cartridge. Finally, we'll discuss what makes vinyl sound unique and warm, including the impact of surface noise and the way that vinyl responds to different playback systems. So, let's start by taking a closer look at the basics: what is vinyl, and how does it store music?

What is Vinyl and How Does it Store Music?

Vinyl records have been a popular medium for music storage and playback for decades, with a resurgence in popularity in recent years. But have you ever wondered what vinyl is and how it stores music? Vinyl is a type of plastic material that is used to make records, which are played on a turntable to produce sound. The process of creating a vinyl record involves several steps, from manufacturing the physical record to encoding the audio information onto it. In this article, we will explore the physical structure of vinyl records, the process of vinyl record manufacturing, and how vinyl records store audio information. By understanding these aspects, we can appreciate the complexity and beauty of vinyl records. The physical structure of vinyl records is the foundation of how they store music, so let's start by examining the anatomy of a vinyl record.

The Physical Structure of Vinyl Records

The physical structure of vinyl records is a marvel of engineering and design. At its core, a vinyl record consists of a thin, flexible disc made of polyvinyl chloride (PVC) with a spiral groove etched into its surface. The groove starts from the outer edge of the record and spirals inward, containing the audio information that is read by a stylus as it tracks the groove. The record is typically 12 inches in diameter and 1.5 mm thick, with a hole in the center for mounting on a turntable. The surface of the record is coated with a thin layer of material, usually a metal or ceramic compound, to reduce wear and tear on the stylus. The label, which contains the album artwork and track information, is applied to the center of the record. The vinyl itself is a complex mixture of PVC, plasticizers, and other additives that provide the necessary flexibility, durability, and sound quality. The record's physical structure is designed to withstand the mechanical stress of being played, with the vinyl material able to absorb and distribute the forces exerted by the stylus as it tracks the groove. Overall, the physical structure of vinyl records is a remarkable example of how materials science and engineering can come together to create a durable and high-quality music playback format.

The Process of Vinyl Record Manufacturing

The process of vinyl record manufacturing involves several stages, from mastering to pressing. It begins with the creation of a master recording, which is typically done in a professional recording studio. The master recording is then used to create a lacquer, a thin, flexible disc coated with a layer of nitrocellulose. The lacquer is then cut with a stylus, which etches the grooves that contain the music into the surface of the disc. The lacquer is then coated with a thin layer of metal, usually silver or gold, to create a negative image of the grooves. This negative image is called a "father" and is used to create multiple positive copies, known as "stampers." The stampers are then used to press the vinyl records, which are made from a mixture of polyvinyl chloride (PVC) and other additives. The vinyl mixture is melted and formed into a puck, which is then pressed between the stampers to create the record. The record is then cooled, removed from the mold, and excess vinyl is trimmed from the edges. Finally, the record is packaged and shipped to stores. Throughout the process, quality control measures are taken to ensure that the records are free from defects and sound their best.

How Vinyl Records Store Audio Information

Vinyl records store audio information through a physical process that involves the manipulation of grooves on the record's surface. The grooves are etched into the vinyl material in a spiral pattern, starting from the outer edge and moving inward. As the record rotates, a stylus, also known as a needle, tracks the grooves and vibrates in response to the undulations in the groove walls. These vibrations are then converted into electrical signals, which are sent to a phono amplifier and eventually to a speaker, where they are converted back into sound waves. The audio information is encoded in the shape and size of the grooves, with the undulations in the groove walls corresponding to the amplitude and frequency of the sound waves. The grooves are typically between 0.5 and 1.5 microns in width, and the stylus is designed to track these tiny undulations with precision. The vinyl record's ability to store audio information is based on the physical properties of the material, including its density and elasticity, which allow it to maintain the shape of the grooves over time. The quality of the audio information stored on a vinyl record is dependent on a number of factors, including the quality of the mastering process, the condition of the record, and the quality of the playback equipment. Overall, the physical process of storing audio information on vinyl records is a remarkable example of how a simple, analog technology can be used to capture and reproduce high-quality sound.

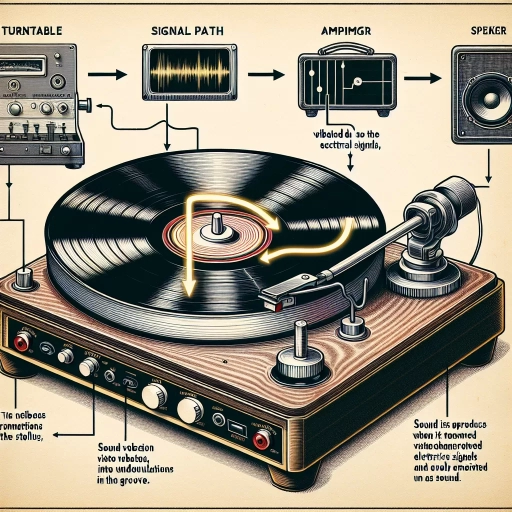

How Does a Record Player Read Vinyl Records?

A record player, also known as a turntable, is a device that plays sound recordings on vinyl records. But have you ever wondered how it actually reads the information stored on those vinyl records? The process involves a combination of mechanical and electrical components working together in harmony. To understand how a record player reads vinyl records, we need to break down the components that make up the device, including the motor, platter, tonearm, and cartridge. We also need to explore the process of how the record player reads the information stored on the vinyl record, including how the stylus tracks the grooves on the record. By understanding these components and processes, we can gain a deeper appreciation for the technology that brings music to our ears. In this article, we will delve into the components of a record player, the process of reading vinyl records, and how the stylus tracks the grooves on a vinyl record, starting with the components that make up the device.

The Components of a Record Player

The components of a record player are crucial in enabling it to read vinyl records. The main components include the turntable, tonearm, cartridge, stylus, motor, and platter. The turntable is the rotating platform that spins the record, while the tonearm is the long, thin arm that holds the cartridge and stylus. The cartridge is a small device that converts the vibrations from the stylus into electrical signals, which are then sent to a speaker or amplifier. The stylus, also known as the needle, is a small metal tip that tracks the grooves on the record, reading the undulations and vibrations. The motor is responsible for rotating the turntable at a constant speed, usually 33 1/3 or 45 revolutions per minute. The platter is the flat disc that the record sits on, and it is typically made of a heavy, non-resonant material to minimize vibrations. Additionally, some record players may also have features such as a phono preamp, which amplifies the low-level signal from the cartridge, and a counterweight, which helps to balance the tonearm. Overall, the combination of these components allows a record player to accurately read the information stored on a vinyl record and produce high-quality sound.

The Process of Reading Vinyl Records

The process of reading vinyl records involves a series of intricate steps that work together to produce high-quality sound. It begins with the record player's motor, which rotates the record at a precise speed, typically 33 1/3 or 45 revolutions per minute. As the record spins, the tonearm, also known as the arm, is gently placed on the outer edge of the record, where the grooves are widest. The tonearm is equipped with a cartridge, which contains a tiny needle, or stylus, that tracks the undulations in the record's grooves. As the record rotates, the stylus vibrates in response to the changes in the groove's shape, causing the cartridge to generate a tiny electrical signal. This signal is then sent to a phono preamplifier, which boosts the signal to a level strong enough to drive a speaker. The amplified signal is then sent to a speaker, where it is converted back into sound waves, allowing the listener to hear the music or other audio content stored on the record. Throughout the process, the record player's mechanical components work together to ensure that the stylus tracks the grooves accurately, and that the signal is transmitted with minimal distortion or loss of quality. The result is a warm, rich, and immersive listening experience that many music enthusiasts swear by.

How the Stylus Tracks the Grooves on a Vinyl Record

The stylus, also known as the needle, is a crucial component of a record player that tracks the grooves on a vinyl record. As the record rotates, the stylus is placed in the starting groove and begins to vibrate in response to the undulations in the groove walls. These vibrations are caused by the physical interaction between the stylus and the record's surface, where the stylus is pushed and pulled by the varying depths and widths of the grooves. The stylus is designed to be extremely sensitive, allowing it to detect even the slightest changes in the groove's shape and size. As the stylus tracks the grooves, it converts the physical vibrations into electrical signals, which are then sent to a phono amplifier and eventually to a speaker, where they are converted back into sound waves. The stylus's ability to accurately track the grooves is dependent on its shape, size, and material, as well as the quality of the record itself. A well-designed stylus and a high-quality record can result in a highly accurate and detailed sound reproduction, while a poorly designed stylus or a low-quality record can lead to distortion and a loss of sound quality. Overall, the stylus plays a vital role in the process of reading vinyl records, and its ability to track the grooves with precision is essential for producing high-quality sound.

What Makes Vinyl Sound Unique and Warm?

The unique sound quality of vinyl records has captivated music enthusiasts for decades. While digital music formats have become increasingly popular, many audiophiles swear by the warm, rich sound of vinyl. But what makes vinyl sound so unique and warm? The answer lies in a combination of factors, including the physical interaction between the stylus and vinyl, the analog nature of vinyl records, and the role of surface noise in vinyl sound quality. As we delve into the world of vinyl, it becomes clear that the physical interaction between the stylus and vinyl is a crucial aspect of the vinyl sound. The way the stylus tracks the grooves on the record, reading the undulations and vibrations, is a key factor in producing the distinctive sound of vinyl. In this article, we will explore the physical interaction between the stylus and vinyl, and how it contributes to the unique sound quality of vinyl records.

The Physical Interaction Between the Stylus and Vinyl

The physical interaction between the stylus and vinyl is a crucial aspect of the vinyl playback process. When a record is played, the stylus, also known as the needle, tracks the grooves on the vinyl surface, reading the undulations and vibrations encoded in the grooves. The stylus is typically made of a hard, durable material such as sapphire or diamond, which is designed to withstand the friction and wear generated by the interaction with the vinyl. As the stylus moves along the grooves, it vibrates in response to the changes in the groove shape and size, these vibrations are then transmitted to a coil or magnet, which converts them into an electrical signal. This signal is then sent to a phono preamplifier, which amplifies and equalizes the signal, preparing it for playback through a speaker. The physical interaction between the stylus and vinyl is what allows the vinyl to convey the unique warmth and character that is often associated with vinyl sound. The imperfections and irregularities in the vinyl surface, such as surface noise and crackle, are also picked up by the stylus and contribute to the distinctive sound of vinyl. Additionally, the mechanical nature of the stylus-vinyl interaction introduces a degree of randomness and unpredictability, which can add to the sense of warmth and humanity in the sound. Overall, the physical interaction between the stylus and vinyl is a key factor in what makes vinyl sound unique and warm.

The Analog Nature of Vinyl Records

The analog nature of vinyl records is a key factor in their unique sound quality. Unlike digital music formats, which convert sound waves into a series of 1s and 0s, vinyl records store music in an analog format, where the sound waves are represented by physical grooves on the record. This analog format allows for a more nuanced and detailed representation of sound, with a wider range of tonal frequencies and a more natural dynamic range. As the stylus tracks the grooves on the record, it reads the physical undulations and translates them into sound waves, creating a warm and rich sound that is often described as more "organic" and "human" than digital music. The analog nature of vinyl also allows for a more tactile and immersive listening experience, as the listener can see the physical grooves on the record and feel the weight of the vinyl in their hands. Overall, the analog nature of vinyl records is a key part of their enduring appeal and unique sound quality.

The Role of Surface Noise in Vinyl Sound Quality

The role of surface noise in vinyl sound quality is a topic of ongoing debate among audiophiles and music enthusiasts. Surface noise, also known as crackle or hiss, refers to the unwanted sounds that can be heard when a vinyl record is played, such as pops, crackles, and hisses. These sounds are caused by imperfections in the vinyl surface, such as dust, dirt, and scratches, as well as the physical interaction between the stylus and the record groove. While some listeners may find surface noise to be a distraction or a nuisance, others argue that it is an integral part of the vinyl listening experience and can even contribute to the unique warmth and character of vinyl sound. In fact, many audiophiles believe that surface noise can add a sense of authenticity and humanity to music, making it sound more organic and less polished than digital formats. Furthermore, surface noise can also serve as a reminder of the physicality of vinyl records and the tactile experience of listening to music on a tangible medium. Overall, the role of surface noise in vinyl sound quality is complex and multifaceted, and its impact on the listening experience can vary greatly depending on individual preferences and expectations.