How To Cut Styrofoam

Styrofoam is a versatile material used in various applications, from packaging and insulation to crafting and modeling. However, cutting it can be a daunting task, especially for those who are new to working with this material. To achieve a clean and precise cut, it's essential to understand the different techniques and tools required for the job. In this article, we'll explore the best practices for cutting styrofoam, including the importance of preparation, the various cutting techniques for different types of styrofoam, and valuable tips for a smooth and safe cutting experience. By following these guidelines, you'll be able to cut styrofoam with confidence and accuracy. So, let's start by emphasizing the crucial first step: preparation is key.

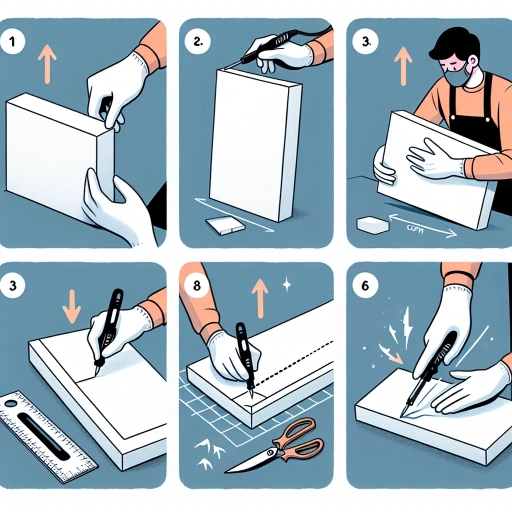

Preparation is Key

When it comes to working with Styrofoam, preparation is key to achieving professional-looking results and ensuring a safe working experience. To get started, it's essential to choose the right tool for the job, as different tools are designed for specific tasks and can greatly impact the outcome. Additionally, selecting the correct type of Styrofoam is crucial, as it can affect the durability and stability of the final product. Furthermore, preparing a safe workspace is vital to prevent accidents and injuries. By taking the time to prepare properly, you can avoid costly mistakes and achieve the desired results. In this article, we will explore the importance of preparation when working with Styrofoam, starting with the first crucial step: choosing the right tool.

Choose the Right Tool

When it comes to cutting Styrofoam, having the right tool for the job is crucial. The type of tool you choose will depend on the thickness and density of the Styrofoam, as well as the desired level of precision and finish. For thin sheets of Styrofoam, a craft knife or a utility knife with a sharp blade is often sufficient. These knives are easy to maneuver and can make clean cuts, but they may not be suitable for thicker or denser Styrofoam. For thicker sheets, a hot wire cutter or a foam saw is a better option. Hot wire cutters use a heated wire to melt the Styrofoam, creating a smooth and precise cut. Foam saws, on the other hand, use a serrated blade to cut through the Styrofoam, and are often used for more intricate cuts. For very thick or dense Styrofoam, a power saw or a band saw may be necessary. These saws are more aggressive and can make quick work of even the toughest Styrofoam, but they require more skill and caution to use safely. Ultimately, the right tool for the job will depend on the specific requirements of your project, and it's essential to choose a tool that is suitable for the task at hand.

Select the Correct Styrofoam Type

When it comes to cutting Styrofoam, selecting the correct type is crucial for a successful project. There are several types of Styrofoam, each with its own unique characteristics, and choosing the right one can make all the difference. The most common types of Styrofoam are Expanded Polystyrene (EPS), Extruded Polystyrene (XPS), and Styrofoam Brand Foam. EPS is the most widely used type and is ideal for crafts, packaging, and insulation. It is lightweight, easy to cut, and can be molded into various shapes. XPS, on the other hand, is denser and more rigid than EPS, making it perfect for applications that require more strength and durability, such as construction and building insulation. Styrofoam Brand Foam is a type of XPS that is specifically designed for crafts and is known for its smooth, even texture. When selecting the correct type of Styrofoam, consider the project's requirements, such as the level of density, strength, and texture needed. By choosing the right type of Styrofoam, you can ensure a successful project and achieve the desired results.

Prepare a Safe Workspace

When it comes to cutting Styrofoam, having a safe workspace is crucial to avoid accidents and ensure a smooth process. To prepare a safe workspace, start by clearing a large, flat area of any clutter, tripping hazards, or flammable materials. Cover the work surface with a heat-resistant material, such as a ceramic tile or a heat-resistant mat, to prevent damage from heat tools or accidental sparks. If you're using a hot wire cutter or a heat gun, make sure the area is well-ventilated to prevent inhaling fumes or particles. Wear protective gear, including safety glasses, a dust mask, and gloves, to shield yourself from debris and potential chemical reactions. Additionally, keep a fire extinguisher nearby and ensure that your workspace is away from any open flames or sparks. By taking these precautions, you can minimize the risk of accidents and create a safe environment for cutting Styrofoam.

Cutting Techniques for Different Styrofoam Types

Styrofoam is a versatile material used in various applications, from packaging and crafts to construction and insulation. When working with Styrofoam, having the right cutting techniques is essential to achieve the desired shape and size. Different types of Styrofoam require different cutting methods to ensure a clean and precise cut. In this article, we will explore three effective cutting techniques for different types of Styrofoam. For thick Styrofoam, hot wire cutting is a popular method that produces a smooth finish. For thinner Styrofoam, a serrated utility knife is a great option that provides a high level of control. Meanwhile, for detailed cuts, a craft knife is the way to go. By understanding the best cutting techniques for each type of Styrofoam, you can achieve professional-looking results and take your projects to the next level. Let's start by exploring hot wire cutting for thick Styrofoam.

Hot Wire Cutting for Thick Styrofoam

Hot wire cutting is a popular method for cutting thick Styrofoam, particularly for applications that require high precision and smooth edges. This technique involves using a heated wire, typically made of nichrome or stainless steel, to melt and vaporize the Styrofoam, creating a clean cut. The wire is usually suspended between two metal arms or a frame, and the Styrofoam is passed through the wire to achieve the desired cut. Hot wire cutting is ideal for thick Styrofoam sheets, as it can cut through materials up to 12 inches thick with ease. The process is also relatively fast, with cutting speeds ranging from 1-10 inches per second, depending on the thickness of the material and the desired level of precision. One of the key benefits of hot wire cutting is its ability to produce smooth, beveled edges, which are ideal for applications such as architectural modeling, product design, and packaging. Additionally, hot wire cutting generates minimal waste and produces no dust or debris, making it a clean and efficient cutting method. However, it does require a significant amount of heat, which can be a safety concern if not handled properly. Overall, hot wire cutting is a versatile and effective technique for cutting thick Styrofoam, offering high precision, smooth edges, and fast cutting speeds.

Serrated Utility Knife for Thin Styrofoam

A serrated utility knife is an excellent tool for cutting thin Styrofoam, offering a smooth and efficient cutting experience. The serrated edge of the knife allows for a gentle sawing motion, which helps to prevent the Styrofoam from tearing or crumbling. This is particularly useful when working with thin sheets of Styrofoam, as it enables you to make precise cuts without applying too much pressure. To achieve the best results, it's essential to use a sharp serrated utility knife, as a dull blade can cause the Styrofoam to tear or become uneven. When cutting thin Styrofoam, it's also recommended to use a gentle, back-and-forth motion, applying moderate pressure. This will help to maintain control and prevent the knife from slipping or digging into the Styrofoam. By using a serrated utility knife and employing the right cutting technique, you can achieve clean, precise cuts in thin Styrofoam, making it an ideal tool for a variety of applications, from crafting to packaging.

Craft Knife for Detailed Styrofoam Cuts

A craft knife is an essential tool for making detailed cuts in styrofoam, offering precision and control that is hard to achieve with other cutting tools. When choosing a craft knife for cutting styrofoam, look for one with a sharp, pointed blade that is specifically designed for detailed work. A knife with a flexible blade is also beneficial, as it allows for smooth, curved cuts. To make detailed cuts, start by marking the styrofoam with a pencil or marker, using a ruler or template to ensure accuracy. Hold the knife at a 45-degree angle and gently press the blade into the styrofoam, using a gentle sawing motion to make the cut. Apply gentle pressure, increasing as needed, and use a steady hand to maintain control. For intricate cuts, use a craft knife with a small, pointed blade, and make small, gentle cuts, gradually building up to the desired shape. To avoid mistakes, work slowly and carefully, and use a cutting mat or other protective surface to prevent damage to your work surface. With practice and patience, a craft knife can be used to make precise, detailed cuts in styrofoam, allowing you to create complex shapes and designs with ease.

Tips for a Smooth and Safe Cutting Experience

When it comes to cutting various materials, whether it's wood, metal, or plastic, having a smooth and safe experience is crucial. To achieve this, there are several tips that can make all the difference. Firstly, using a ruler or straightedge can help ensure straight cuts, which is especially important when working with precise measurements. Additionally, applying gentle pressure can help maintain control over the cutting tool, reducing the risk of accidents. Furthermore, working in a well-ventilated area is essential to avoid inhaling harmful fumes that can be emitted during the cutting process. By following these simple yet effective tips, you can significantly improve your cutting experience. In this article, we will explore each of these tips in more detail, starting with the importance of using a ruler or straightedge for straight cuts.

Use a Ruler or Straightedge for Straight Cuts

When it comes to making straight cuts in Styrofoam, using a ruler or straightedge is an essential tool to achieve clean and precise cuts. A ruler or straightedge provides a stable guide for your cutting tool, allowing you to make smooth and even cuts. To use a ruler or straightedge effectively, place it along the line where you want to make the cut, ensuring it is securely positioned and won't move during the cutting process. Hold the cutting tool, such as a craft knife or hot wire cutter, firmly against the ruler or straightedge, and slowly begin to make the cut. Apply gentle to moderate pressure, depending on the thickness of the Styrofoam, and maintain a steady motion to achieve a smooth cut. By using a ruler or straightedge, you can prevent wobbly or uneven cuts, and achieve professional-looking results. Additionally, using a ruler or straightedge can also help prevent accidents, as it provides a clear guide for your cutting tool, reducing the risk of slips or mistakes. Overall, incorporating a ruler or straightedge into your cutting process is a simple yet effective way to ensure straight cuts and a smooth cutting experience.

Apply Gentle Pressure for Controlled Cuts

Applying gentle pressure is crucial for making controlled cuts in Styrofoam. This technique allows you to maintain precision and avoid applying too much pressure, which can cause the material to tear or crumble. To apply gentle pressure, start by holding your cutting tool, such as a craft knife or hot wire cutter, at a 45-degree angle to the Styrofoam surface. Slowly and steadily apply gentle pressure, using your wrist and forearm to guide the tool rather than your fingers. This will help you maintain control and prevent the tool from slipping or digging too deeply into the material. As you cut, pay attention to the pressure you're applying and adjust it as needed to achieve a smooth, even cut. By applying gentle pressure, you can make precise cuts and achieve professional-looking results, even when working with intricate designs or complex shapes. Additionally, gentle pressure helps to reduce the risk of accidents and injuries, as it allows you to maintain control of the cutting tool at all times. By mastering the technique of applying gentle pressure, you can take your Styrofoam cutting skills to the next level and achieve smooth, safe, and precise cuts every time.

Work in a Well-Ventilated Area to Avoid Fumes

When cutting Styrofoam, it's essential to work in a well-ventilated area to avoid inhaling fumes. Styrofoam is made from a type of plastic called polystyrene, which can release toxic fumes when cut or heated. These fumes can cause respiratory problems, headaches, and dizziness. To minimize exposure, open windows and doors to provide good airflow, and consider using a fan to circulate the air. If possible, work outdoors or in a garage with the door open. Additionally, wear a mask or respirator to filter out any remaining fumes. By taking these precautions, you can ensure a safe and healthy cutting experience.