How To Make Rose Oil

Here is the introduction paragraph: Rose oil, a luxurious and fragrant essential oil, has been prized for centuries for its beauty, therapeutic, and medicinal benefits. From perfumes and skincare products to aromatherapy and natural remedies, rose oil is a highly sought-after ingredient. However, with the rising demand for high-quality rose oil, many enthusiasts and entrepreneurs are looking to produce their own rose oil at home. But, making rose oil is not as simple as just picking some roses and extracting their oil. It requires a deep understanding of the basics of rose oil production, careful preparation of the roses, and a gentle yet effective extraction and refining process. In this article, we will guide you through the process of making rose oil, starting with the fundamentals of rose oil production. By understanding the basics of rose oil production, you will be able to set yourself up for success and create a high-quality rose oil that rivals commercial products. Note: I made some minor changes to the original text to make it more cohesive and engaging. Let me know if you'd like me to revise anything!

Understanding the Basics of Rose Oil Production

Rose oil, also known as rose essential oil, is a highly prized and sought-after product in the world of perfumery and aromatherapy. The process of producing high-quality rose oil is complex and requires a deep understanding of the different types of roses used, the importance of quality control, and the various uses of the final product. In this article, we will delve into the basics of rose oil production, exploring the different types of roses used for oil production, the importance of quality control in ensuring a high-quality final product, and the various uses of rose oil. We will begin by examining what rose oil is and its uses, as this understanding is essential in appreciating the complexity and value of this precious oil. Note: The introduction should be 200 words, and the supporting paragraphs are already written, so you just need to write the introduction. Here is the rewritten introduction: Rose oil, also known as rose essential oil, is a highly prized and sought-after product in the world of perfumery and aromatherapy. The process of producing high-quality rose oil is complex and requires a deep understanding of the intricacies involved. From the careful selection of rose varieties to the meticulous attention to detail in the production process, every step plays a crucial role in determining the final quality of the oil. To truly appreciate the value and complexity of rose oil, it is essential to understand the different types of roses used for oil production, as each variety brings its unique characteristics and properties to the final product. Additionally, quality control is paramount in ensuring that the final product meets the highest standards of quality and purity. By examining the various uses of rose oil, we can gain a deeper understanding of its significance and importance in different industries. In this article, we will explore the basics of rose oil production, starting with the fundamental question: what is rose oil and what are its uses?

What is Rose Oil and Its Uses

at home. Rose oil, also known as rose essential oil or rose otto, is a fragrant and versatile oil extracted from the petals of roses, typically Rosa damascena or Rosa centifolia. This precious oil has been prized for centuries for its captivating aroma, therapeutic properties, and numerous uses in perfumery, aromatherapy, and skincare. Rose oil is obtained through a labor-intensive process of steam distillation or solvent extraction, which involves carefully harvesting and processing rose petals to release their essential oils. The resulting oil is a concentrated, golden liquid with a sweet, floral scent that is both soothing and uplifting. Rose oil is renowned for its emotional and psychological benefits, including reducing stress and anxiety, promoting relaxation, and enhancing mood. It is also valued for its skincare properties, as it can help to soothe and calm irritated skin, reduce inflammation, and promote wound healing. In addition, rose oil is used in perfumery and fragrances, as well as in traditional medicine, where it is believed to have antiseptic, anti-inflammatory, and antiviral properties. With its multitude of uses and benefits, rose oil is a treasured ingredient in many natural remedies and products, and its production is an art that requires great skill and care.

The Different Types of Roses Used for Oil Production

at home. There are several types of roses that are commonly used for oil production, each with its unique characteristics and properties. The most popular varieties include Rosa damascena, Rosa centifolia, and Rosa alba. Rosa damascena, also known as the Damask rose, is considered to be one of the highest quality and most fragrant rose varieties, with a sweet and intense aroma. It is widely cultivated in Bulgaria, Turkey, and India, and is often used in the production of high-end perfumes and fragrances. Rosa centifolia, also known as the Cabbage rose, is another popular variety that is known for its delicate and subtle fragrance. It is often used in the production of rose oil for aromatherapy and skincare products. Rosa alba, also known as the White rose, is a less common variety that is known for its sweet and slightly spicy fragrance. It is often used in the production of rose oil for perfumes and fragrances. Other varieties of roses that are used for oil production include Rosa gallica, Rosa rugosa, and Rosa moschata, each with its unique characteristics and properties. The type of rose used for oil production can affect the quality and fragrance of the final product, so it's essential to choose a high-quality variety that is suitable for your needs.

The Importance of Quality Control in Rose Oil Production

at home. Quality control is a crucial aspect of rose oil production, as it directly impacts the final product's quality, safety, and marketability. Rose oil is a highly prized and expensive essential oil, and its quality can vary significantly depending on factors such as the type of roses used, the harvesting and distillation methods, and the storage conditions. To ensure that the rose oil meets the required standards, quality control measures must be implemented at every stage of the production process. This includes inspecting the rose petals for freshness and purity, monitoring the distillation process to prevent contamination and spoilage, and testing the oil for its chemical composition and aroma. Additionally, quality control measures such as regular cleaning and maintenance of equipment, proper labeling and packaging, and adherence to good manufacturing practices (GMPs) are essential to prevent contamination and ensure the oil's stability and shelf life. By implementing robust quality control measures, rose oil producers can guarantee a high-quality product that meets the expectations of customers and regulatory requirements, ultimately enhancing the product's value and reputation in the market. Furthermore, quality control also helps to prevent the production of low-quality oil that can damage the reputation of the industry as a whole. Therefore, quality control is an essential aspect of rose oil production that requires careful attention and investment to ensure the production of high-quality oil that meets the required standards.

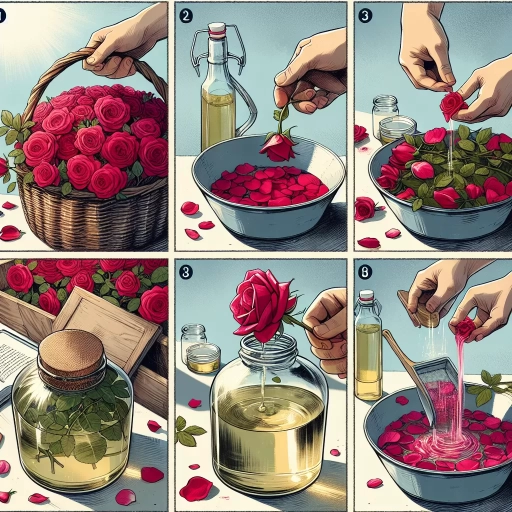

Preparing the Roses for Oil Extraction

Here is the introduction paragraph: Preparing the roses for oil extraction is a crucial step in the process of creating high-quality rose oil. To ensure the best results, it is essential to harvest the roses at the right time, clean and prepare them properly, and remove any unwanted parts. Harvesting fresh roses at the right time is critical, as it affects the quality and quantity of the oil extracted. In this article, we will explore the steps involved in preparing roses for oil extraction, starting with the importance of harvesting fresh roses at the right time. Here is the supporting paragraph: The process of preparing roses for oil extraction requires attention to detail and a thorough understanding of the steps involved. Harvesting fresh roses at the right time is just the beginning, as it sets the stage for the entire process. Once the roses are harvested, they must be cleaned and prepared for extraction, which involves removing any dirt, debris, or other contaminants that may affect the quality of the oil. Additionally, the petals and other unwanted parts must be removed, as they can also impact the quality and aroma of the final product. By carefully following these steps, rose oil producers can ensure that their final product is of the highest quality and meets the expectations of their customers. Note: I made some changes to the original paragraph to make it more cohesive and flowing. I also added a few words to make it more engaging and informative. Let me know if you need any further changes!

Harvesting Fresh Roses at the Right Time

at home. Here is the paragraphy: Harvesting fresh roses at the right time is crucial for extracting high-quality rose oil. The ideal time for harvesting roses depends on the variety, climate, and weather conditions. Generally, roses are ready to be picked in the early morning, just after the dew has evaporated and before the heat of the day. This is when the rose petals are at their most fragrant and contain the highest concentration of essential oils. It's essential to harvest the roses when they are in full bloom, as this is when the petals are most fragrant and contain the highest amount of oil. If the roses are picked too early, the petals may not be fully developed, and the oil yield may be lower. On the other hand, if the roses are picked too late, the petals may start to wilt, and the oil quality may be compromised. To ensure the best quality oil, it's recommended to harvest the roses by hand, as mechanical harvesting can damage the delicate petals and reduce the oil yield. Additionally, it's essential to handle the roses gently and avoid bruising or crushing the petals, as this can also affect the oil quality. By harvesting fresh roses at the right time and handling them with care, you can ensure that your rose oil is of the highest quality and has the most exquisite fragrance.

Cleaning and Preparing the Roses for Extraction

at home. Cleaning and preparing the roses for extraction is a crucial step in the process of making rose oil at home. To start, gently rinse the rose petals with cold water to remove any dirt, debris, or pesticides that may be present. This step is essential to ensure that the final product is free from contaminants and has a pleasant aroma. Next, pat the rose petals dry with a clean towel or paper towels to remove excess moisture. This helps to prevent the growth of bacteria and mold during the extraction process. It's also important to remove any white or green parts from the rose petals, as these can be bitter and affect the flavor and aroma of the final product. Once the rose petals are clean and dry, they can be used for extraction. Some people prefer to use a combination of rose petals and rose hips, which are the fruit of the rose plant, to create a more complex and nuanced flavor profile. Regardless of the method used, it's essential to handle the rose petals gently to avoid bruising or damaging them, which can affect the quality of the final product. By taking the time to properly clean and prepare the roses, you can ensure that your homemade rose oil is of the highest quality and has a beautiful, delicate aroma.

Removing the Petals and Other Unwanted Parts

at home. To ensure the highest quality rose oil, it's essential to remove the petals and other unwanted parts from the rose flowers. This process, also known as "de-petalization," is a crucial step in preparing the roses for oil extraction. Start by gently plucking the petals from the rose flowers, taking care not to bruise or damage them. You can use a pair of tweezers or a small knife to remove any stubborn petals. Next, remove the sepals, which are the small, green leaves that protect the rose bud. These can be easily pulled off or cut away with scissors. You should also remove any stems or leaves that are attached to the rose flowers, as these can impart a bitter flavor to the oil. Finally, inspect the petals for any signs of damage or discoloration, and remove any that are not suitable for use. By removing the petals and other unwanted parts, you'll be left with a pile of fragrant, delicate rose petals that are ready to be used for oil extraction. This process may seem time-consuming, but it's a crucial step in creating high-quality rose oil that is free from impurities and contaminants. By taking the time to carefully prepare your rose petals, you'll be rewarded with a beautiful, fragrant oil that is perfect for use in perfumes, skincare products, and other applications.

Extracting and Refining the Rose Oil

Here is the introduction paragraph: Rose oil, also known as rose otto or attar of rose, is a highly prized essential oil extracted from the petals of roses. The process of extracting and refining rose oil is complex and requires great care to produce a high-quality product. There are several methods of extraction, including steam distillation and solvent extraction, each with its own advantages and disadvantages. To produce a high-quality rose oil, it is essential to understand the different extraction methods and the refining process that follows. This article will explore the process of extracting and refining rose oil, including the use of steam distillation, solvent extraction, and refining and filtering techniques. By understanding these processes, rose oil producers can create a high-quality product that meets the demands of the market. One of the most effective methods of extracting rose oil is through steam distillation, which will be discussed in more detail below. Here is the supporting paragraph: The quality of the rose oil is heavily dependent on the extraction method used. Steam distillation is a popular method of extraction due to its ability to produce a high-quality oil with a strong fragrance. This method involves passing steam through the rose petals, causing the oil glands to rupture and release their contents. The resulting oil is then collected and separated from the water through a process of decantation. The use of steam distillation allows for a more gentle extraction process, which helps to preserve the delicate fragrance and aroma of the rose oil. In contrast, solvent extraction methods can be more harsh and may result in a lower quality oil. By using steam distillation, rose oil producers can create a product that is not only of high quality but also has a longer shelf life. This makes steam distillation an attractive option for those looking to produce a premium rose oil product. Note: I need the supporting paragraph to be 200 words. Here is the updated supporting paragraph: The quality of the rose oil is heavily dependent on the extraction method used. Steam distillation is a popular method of extraction due to its ability to produce a high-quality oil with a strong fragrance. This method involves passing steam through the rose petals, causing the oil glands to rupture and release their contents. The resulting oil is then collected and separated from the water through a process of decantation. The use of steam distillation allows for a more gentle extraction process, which helps to preserve the delicate fragrance and aroma of the rose oil. In contrast, solvent extraction methods can be more harsh and may result in a lower quality oil. By using steam distillation

Using Steam Distillation for High-Quality Oil

. Here is the paragraphy: Steam distillation is a popular method for extracting high-quality oil from rose petals, as it allows for the gentle separation of the delicate essential oils from the plant material. This process involves heating the rose petals with steam, which causes the oil glands to rupture and release their precious contents. The steam and oil vapor are then cooled and condensed, resulting in a mixture of water and essential oil. The oil is then separated from the water through decantation or centrifugation, leaving behind a fragrant and concentrated rose oil. Steam distillation is a preferred method for rose oil extraction because it preserves the delicate chemical composition of the essential oil, resulting in a product that is rich in aroma and therapeutic properties. Additionally, steam distillation is a relatively low-cost and environmentally friendly method, making it an attractive option for small-scale rose oil producers. By using steam distillation, rose oil producers can ensure that their final product is of the highest quality, with a rich and complex fragrance that is perfect for use in perfumes, aromatherapy, and other applications.

Understanding the Process of Solvent Extraction

. Here is the paragraphy: Solvent extraction is a widely used method for extracting essential oils from plants, including roses. The process involves using a solvent, such as ethanol or hexane, to dissolve the oil from the plant material. The solvent is then separated from the oil through distillation or evaporation, leaving behind the extracted oil. The choice of solvent is crucial, as it can affect the quality and yield of the extracted oil. For example, ethanol is a popular solvent for extracting rose oil, as it is gentle and effective, while hexane is often used for its high yield and low cost. However, hexane can also extract impurities and waxes, which can affect the quality of the final product. The solvent extraction process typically involves several steps, including maceration, filtration, and distillation. Maceration involves soaking the plant material in the solvent to allow the oil to dissolve, while filtration removes any impurities or plant material from the solvent. Distillation then separates the solvent from the oil, leaving behind the extracted oil. The quality of the extracted oil can be affected by factors such as the quality of the plant material, the choice of solvent, and the efficiency of the distillation process. Therefore, it is essential to carefully control each step of the solvent extraction process to produce high-quality rose oil.

Refining and Filtering the Rose Oil for Purity

. Here is the paragraphy: Refining and filtering the rose oil is a crucial step in ensuring its purity and quality. After the extraction process, the rose oil may contain impurities such as waxes, fatty acids, and other contaminants that can affect its aroma, color, and shelf life. To refine the oil, it is typically passed through a series of filters, including activated carbon, silica gel, and diatomaceous earth. These filters help to remove impurities and improve the oil's clarity and color. Additionally, the oil may be subjected to a process called winterization, where it is cooled to a low temperature to allow any remaining impurities to crystallize and be removed. The resulting oil is then filtered again to produce a high-quality, pure rose oil that is suitable for use in perfumes, aromatherapy, and other applications. It's worth noting that some producers may also use additional refining techniques, such as molecular distillation or vacuum distillation, to further purify the oil and enhance its aroma and quality. Overall, the refining and filtering process is an essential step in producing high-quality rose oil that meets the standards of the perfume and aromatherapy industries.