How To Make Maple Sugar

Here is the introduction paragraph: Making maple sugar is a traditional and rewarding process that requires patience, dedication, and a bit of know-how. For centuries, people have been tapping into the natural sweetness of maple trees to produce this delicious and versatile sweetener. But before you can start boiling down sap to create your own maple sugar, it's essential to understand the basics of maple sugar production, including the types of trees that can be tapped, the equipment needed, and the best practices for collecting sap. To get started, you'll also need to prepare your equipment and trees for the production process, which involves selecting the right trees, drilling and tapping, and collecting and storing sap. Once you have your sap, you can begin the process of transforming it into sugar, which involves boiling, filtering, and crystallizing. In this article, we'll take a closer look at the process of making maple sugar, starting with the basics of maple sugar production.

Understanding the Basics of Maple Sugar Production

Maple sugar production is a unique and fascinating process that has been a part of North American culture for centuries. To truly appreciate the art of maple sugar production, it's essential to understand its history, cultural significance, and the science behind it. From its rich history and cultural importance to the intricate process of sap collection and sugar production, there's more to maple sugar than meets the eye. In this article, we'll delve into the basics of maple sugar production, exploring its history and cultural significance, the science behind maple sap and sugar production, and what sets it apart from other types of sugar. By understanding these fundamental aspects, we can gain a deeper appreciation for the craftsmanship and tradition that goes into producing this beloved sweetener. So, let's start by examining what makes maple sugar so unique and how it differs from other types of sugar.

What is Maple Sugar and How is it Different from Other Types of Sugar

Maple sugar is a type of sugar made from the sap of maple trees, primarily the sugar maple (Acer saccharum) and black maple (Acer nigrum). It is different from other types of sugar in several ways. Firstly, maple sugar is made from a natural source, whereas many other types of sugar are derived from sugarcane or sugar beets. The sap of maple trees contains a unique combination of sucrose, glucose, and fructose, which gives maple sugar its distinct flavor and texture. Additionally, maple sugar is produced through a labor-intensive process that involves collecting the sap, boiling it down to concentrate the sugars, and then crystallizing it into a solid form. This process is often done on a small scale, which can result in a more nuanced and complex flavor profile compared to mass-produced sugars. Furthermore, maple sugar is often classified into different grades based on its color and flavor, with lighter grades having a more delicate taste and darker grades having a stronger, more robust flavor. Overall, the unique production process and natural source of maple sugar set it apart from other types of sugar.

The History and Cultural Significance of Maple Sugar Production

The history and cultural significance of maple sugar production dates back thousands of years to the indigenous peoples of North America, who first discovered the process of collecting sap from maple trees and boiling it down to create a sweet, syrupy liquid. The practice was later adopted by European colonizers, who brought their own techniques and technologies to the process, leading to the development of modern maple sugar production. Today, maple sugar production is an important part of the cultural heritage of many communities in North America, particularly in the northeastern United States and southeastern Canada, where the climate and geography are well-suited to maple tree growth. The production of maple sugar is not only a vital source of income for many families and communities, but also an important part of their cultural identity and tradition. Many maple sugar producers continue to use traditional methods and techniques that have been passed down through generations, while also incorporating modern technologies and innovations to improve efficiency and quality. The cultural significance of maple sugar production is also reflected in the many festivals and events that take place throughout the year, celebrating the harvest season and the rich history and heritage of this traditional industry. Overall, the history and cultural significance of maple sugar production is a rich and complex tapestry that reflects the ingenuity, resilience, and community spirit of the people who have been involved in this traditional industry for centuries.

The Science Behind Maple Sap and Sugar Production

The science behind maple sap and sugar production is a fascinating process that involves the unique biology of maple trees and the careful manipulation of temperature and chemistry. Maple trees, specifically sugar maples (Acer saccharum) and black maples (Acer nigrum), have a unique vascular system that allows them to transport water and nutrients from their roots to their leaves through a process called positive pressure. This positive pressure is created by the difference in water potential between the roots and the leaves, which drives the sap upwards through the tree's xylem tissue. In the late winter and early spring, when temperatures are below freezing at night and above freezing during the day, the positive pressure in the tree's xylem tissue increases, causing the sap to flow out of the tree through small incisions or taps. The sap is clear and has a slightly sweet taste, with a sugar content of around 2-3%. As the sap flows out of the tree, it is collected and boiled down to concentrate the sugars and other solids. The boiling process involves heating the sap to a temperature of around 212°F (100°C), which causes the water to evaporate and the sugars to concentrate. As the sap is boiled, the sugar content increases, and the sap becomes thicker and more syrupy. Eventually, the sap is boiled down to a consistency of around 66-67% sugar, at which point it is considered maple syrup. The syrup can then be filtered and bottled, or further boiled down to create maple sugar, which has a sugar content of around 90-95%. The entire process, from tapping the trees to boiling down the sap, is a delicate balance of temperature, chemistry, and timing, and requires careful attention to detail to produce high-quality maple sugar and syrup.

Preparing for Maple Sugar Production

Preparing for maple sugar production requires careful planning and attention to detail to ensure a successful harvest. To start, it's essential to choose the right maple tree species for sugar production, as some species produce more sap with a higher sugar content than others. Additionally, identifying the best time and conditions for tapping maple trees is crucial, as this will impact the quality and quantity of the sap collected. Furthermore, investing in the necessary equipment for maple sugar production is vital to ensure that the sap is collected, boiled, and processed efficiently. By considering these factors, maple syrup producers can set themselves up for success and enjoy a bountiful harvest. With the right tree species, timing, and equipment, producers can unlock the full potential of their maple trees and create high-quality maple syrup. To begin, let's take a closer look at choosing the right maple tree species for sugar production.

Choosing the Right Maple Tree Species for Sugar Production

When it comes to choosing the right maple tree species for sugar production, there are several factors to consider. The most common species used for maple syrup production are Sugar Maple (Acer saccharum), Black Maple (Acer nigrum), and Red Maple (Acer rubrum). Sugar Maple is the most popular choice due to its high sugar content, typically ranging from 2-3% sucrose, and its cold hardiness, making it well-suited for northern climates. Black Maple is similar to Sugar Maple but has a slightly lower sugar content, while Red Maple has a lower sugar content and is more commonly used for syrup production in warmer climates. Other species, such as Silver Maple (Acer saccharinum) and Bigleaf Maple (Acer macrophyllum), can also be used, but they tend to have lower sugar content and may not be as desirable for large-scale sugar production. When selecting a maple tree species, consider factors such as climate, soil type, and available space, as well as the desired level of sugar production. It's also important to note that maple trees typically take 40-50 years to mature, so it's essential to plan for the long-term when choosing a species for sugar production. By selecting the right maple tree species, you can ensure a successful and sustainable sugar production operation.

Identifying the Best Time and Conditions for Tapping Maple Trees

The best time for tapping maple trees is typically late winter to early spring, when temperatures are below freezing at night and above freezing during the day. This temperature fluctuation creates positive pressure inside the tree, causing the sap to flow out through the tap. The ideal temperature range for tapping is between 25°F and 40°F (-4°C and 4°C), with nighttime temperatures below 25°F (-4°C) and daytime temperatures above 40°F (4°C). It's essential to monitor weather forecasts and tap the trees when the temperature is expected to rise above freezing, as this will trigger the sap flow. Additionally, the trees should be at least 40 years old and in good health, with a diameter of at least 40 inches (100 cm). The tap should be placed about 3-4 feet (90-120 cm) off the ground, on the south or west side of the tree, and at a slight upward angle to allow the sap to flow freely. By tapping the trees at the right time and under the right conditions, you can ensure a successful maple sugar production season.

Investing in the Necessary Equipment for Maple Sugar Production

Investing in the necessary equipment is a crucial step in maple sugar production. To start, you'll need a few essential tools, including a drill bit, spiles or spouts, and a collection vessel. The drill bit is used to create a small hole in the maple tree, allowing the sap to flow out, while the spiles or spouts are inserted into the hole to direct the sap into the collection vessel. The collection vessel can be a bucket, bag, or tube, depending on your preference and the size of your operation. You'll also need a large, shallow pan or evaporator to boil the sap down to syrup, as well as a filter press or filter to remove any impurities from the syrup. Additionally, you may want to consider investing in a hydrometer to measure the sugar content of your sap, a thermometer to monitor the temperature of your syrup, and a bottling equipment to package your final product. It's also important to note that you'll need a heat source, such as a wood-fired arch or a propane burner, to power your evaporator. By investing in the right equipment, you'll be able to efficiently collect, boil, and filter your maple sap, resulting in high-quality maple sugar.

From Sap to Sugar: The Maple Sugar Production Process

The production of maple sugar is a multi-step process that requires careful attention to detail and a deep understanding of the natural world. From the initial collection of sap to the final product, maple sugar production involves a series of intricate steps that transform a clear, watery liquid into a rich, golden syrup or crystalline sugar. The journey from sap to sugar begins with the collection of sap from maple trees, which is then boiled to concentrate the sugars. This process is crucial in developing the flavor and texture of the final product. As the sap is boiled, it is filtered and clarified to improve its quality, removing any impurities or sediment that may affect the taste or appearance of the sugar. Finally, the concentrated sap is further processed to produce a range of maple sugar products, from syrup and sugar to cream and butter. In this article, we will delve into the specifics of each step, starting with the collection and boiling of maple sap to concentrate the sugars.

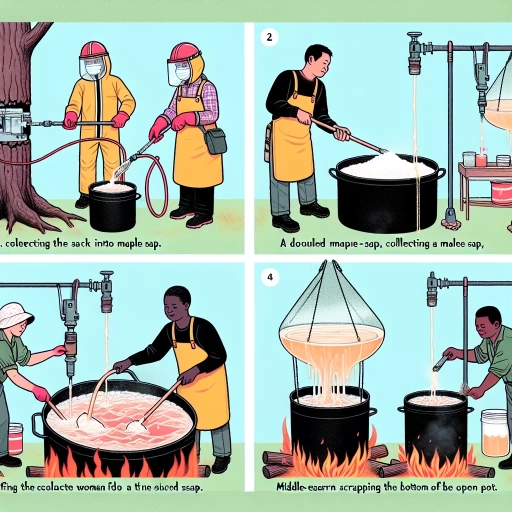

Collecting and Boiling Maple Sap to Concentrate the Sugars

Collecting and boiling maple sap is a labor-intensive process that requires careful attention to detail to concentrate the sugars and produce high-quality maple syrup. The process begins with collecting the sap from maple trees, typically sugar maples or black maples, through a network of tubes or by hanging buckets from the trees. The sap is clear and has a slightly sweet taste, with a sugar content of around 2-3%. To concentrate the sugars, the sap is boiled in a large, shallow pan called an evaporator, which is heated by a fire or a steam-powered machine. As the sap is boiled, the water content evaporates, and the sugar content increases, eventually reaching the desired consistency of 66-67% sugar. The boiling process can take several hours, during which time the sap is stirred and monitored to prevent scorching or the formation of unwanted compounds. The resulting syrup is filtered and bottled, ready for consumption. Throughout the process, careful attention is paid to temperature, humidity, and other environmental factors to ensure the production of high-quality maple syrup with a rich, complex flavor. By carefully controlling the boiling process, maple syrup producers can create a range of flavors and textures, from light and delicate to dark and robust. Whether you're a seasoned producer or a backyard enthusiast, collecting and boiling maple sap is a rewarding and delicious way to experience the magic of maple sugar production.

Filtering and Clarifying the Maple Sap to Improve Quality

The process of filtering and clarifying the maple sap is a crucial step in improving the quality of the final maple sugar product. After the sap is collected from the maple trees, it is filtered through a series of filters, including a coarse filter to remove any debris or sediment, and a finer filter to remove any remaining impurities. The filtered sap is then transferred to a large, shallow pan called an evaporator, where it is heated to concentrate the sugars and other solids. As the sap is heated, the water content evaporates, leaving behind a thicker, more concentrated liquid. This process is repeated several times, with the sap being filtered and reheated until it reaches the desired consistency. The resulting liquid is then filtered again, this time through a series of filters with increasingly smaller pores, to remove any remaining impurities and achieve a clear, transparent liquid. The final step in the filtering and clarifying process is to pass the liquid through a series of activated carbon filters, which remove any remaining impurities and improve the flavor and aroma of the maple sugar. The end result is a high-quality, pure maple sugar that is free from impurities and has a rich, complex flavor. By filtering and clarifying the maple sap, producers can ensure that their final product meets the highest standards of quality and purity, and is suitable for use in a variety of applications, from cooking and baking to making maple syrup and other maple products.

Concentrating the Sap to Produce Maple Sugar and Other Products

The process of concentrating the sap to produce maple sugar and other products is a crucial step in the maple sugar production process. After collecting the sap, it is transferred to a large, shallow pan called an evaporator, where it is heated to concentrate the sugars and other solids. The sap is boiled until the water content is reduced, and the sap reaches the desired consistency, which is typically around 66-67% sugar content. This process can take several hours, depending on the temperature, humidity, and sap flow. As the sap is boiled, the water content evaporates, and the sap becomes thicker and more concentrated. The concentrated sap is then filtered through a series of filters, including a coarse filter to remove any debris or sediment, and a finer filter to remove any remaining impurities. The filtered sap is then transferred to a smaller pan, where it is further concentrated to produce maple syrup, maple cream, or other maple products. The concentrated sap can also be crystallized to produce maple sugar, which is a popular natural sweetener. Throughout the concentrating process, the sap is carefully monitored to ensure that it reaches the desired consistency and quality, and to prevent any spoilage or contamination. By concentrating the sap, maple producers can create a range of delicious and versatile products that are rich in flavor and nutrients.