How To Make A Shaft

A shaft is a critical component in many mechanical systems, including engines, gearboxes, and pumps. It is a rotating or stationary rod that transmits power, motion, or torque from one part of a machine to another. Making a shaft requires careful planning, precision manufacturing, and rigorous testing to ensure it meets the required specifications and performs optimally. In this article, we will guide you through the process of making a shaft, from designing the shaft to manufacturing and testing it. We will start by discussing the design phase, where we will explore the key considerations and steps involved in designing a shaft that meets the required specifications. This will include selecting the right materials, determining the optimal dimensions and geometry, and considering factors such as stress, strain, and fatigue. By the end of this article, you will have a comprehensive understanding of how to make a shaft that is reliable, efficient, and effective. First, let's start with the design phase, where we will delve into the details of designing the shaft.

Designing the Shaft

Designing the shaft is a critical component of mechanical engineering, as it plays a vital role in the overall performance and efficiency of a machine or system. When designing a shaft, there are several key factors to consider in order to ensure optimal results. First, it is essential to define the shaft's purpose and function, as this will determine the type of loads it will be subjected to and the level of stress it will need to withstand. Additionally, selecting the appropriate materials and dimensions is crucial, as this will impact the shaft's strength, durability, and overall performance. Finally, creating a detailed blueprint or CAD design is necessary to ensure that the shaft is manufactured accurately and meets the required specifications. By carefully considering these factors, engineers can design a shaft that meets the needs of the machine or system, while also ensuring safety, efficiency, and reliability. By defining the shaft's purpose and function, engineers can begin to design a shaft that meets the specific needs of the application.

Defining the Shaft's Purpose and Function

A shaft is a critical component in various mechanical systems, and its purpose and function are multifaceted. The primary purpose of a shaft is to transmit power, motion, and torque from one part of a machine to another. It serves as a rotating or stationary axis that connects and supports various components, such as gears, pulleys, and bearings, allowing them to rotate or move in a specific manner. The shaft's function is to withstand the stresses and loads imposed by these components, ensuring smooth operation and efficient power transmission. In addition to transmitting power, a shaft can also provide support and stability to the surrounding components, helping to maintain their alignment and position. Furthermore, a shaft can be designed to absorb vibrations and shocks, reducing the risk of damage to the machine and its components. Overall, the shaft plays a vital role in the overall performance and reliability of a mechanical system, and its design and construction must be carefully considered to ensure optimal functionality.

Selecting the Appropriate Materials and Dimensions

When designing a shaft, selecting the appropriate materials and dimensions is crucial to ensure its performance, durability, and safety. The choice of material depends on the shaft's intended application, operating conditions, and required strength. Common materials used for shafts include steel, stainless steel, aluminum, and titanium, each with its unique properties and advantages. For example, steel is a popular choice for its high strength-to-weight ratio, corrosion resistance, and affordability, while stainless steel is ideal for applications where high corrosion resistance is required. Aluminum is often used for lightweight applications, and titanium is chosen for its high strength-to-weight ratio and corrosion resistance. In addition to material selection, determining the correct dimensions is also critical. The diameter, length, and wall thickness of the shaft must be carefully calculated to ensure it can withstand the expected loads and stresses. A shaft that is too small may fail under load, while one that is too large may be unnecessarily heavy and expensive. The American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO) provide guidelines and standards for shaft design, including material selection and dimensional tolerances. By following these guidelines and considering factors such as torque, bending, and axial loads, designers can select the appropriate materials and dimensions for their shaft, ensuring optimal performance and reliability.

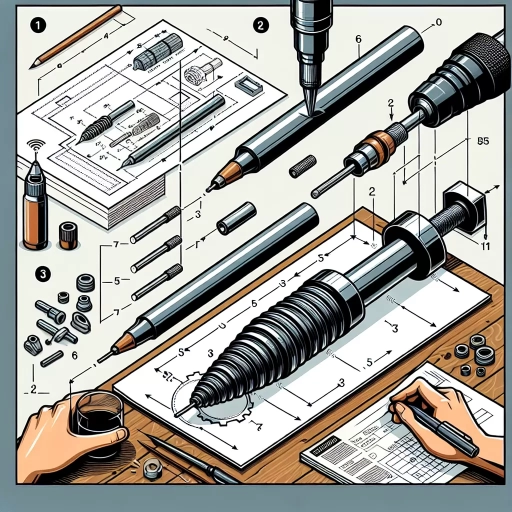

Creating a Detailed Blueprint or CAD Design

Creating a detailed blueprint or CAD design is a crucial step in the shaft manufacturing process. This stage involves translating the conceptual design into a precise and detailed technical drawing that outlines the shaft's dimensions, geometry, and material specifications. Using computer-aided design (CAD) software, engineers can create a 2D or 3D model of the shaft, taking into account factors such as the intended application, load capacity, and environmental conditions. The CAD design should include critical features such as the shaft's length, diameter, taper, and surface finish, as well as any necessary tolerances or clearances. Additionally, the design should specify the type of material to be used, including its composition, strength, and durability. By creating a detailed and accurate CAD design, manufacturers can ensure that the shaft meets the required specifications and performance standards, reducing the risk of errors or defects during production. Furthermore, a well-designed CAD model can be used to simulate the shaft's behavior under various loads and conditions, allowing engineers to optimize its design and performance before moving to the prototyping stage. Overall, a detailed blueprint or CAD design is essential for producing a high-quality shaft that meets the required specifications and performance standards.

Manufacturing the Shaft

Manufacturing a shaft is a complex process that requires precision and attention to detail. The process involves several stages, including cutting and machining the shaft to the desired length, turning and grinding the shaft to achieve the desired surface finish, and drilling and tapping holes for mounting and assembly. Each stage is crucial in producing a high-quality shaft that meets the required specifications. In this article, we will explore the manufacturing process of a shaft, highlighting the key stages involved. We will begin by examining the first stage, which is cutting and machining the shaft to the desired length. This stage is critical in ensuring that the shaft is the correct size and shape, and it sets the foundation for the subsequent stages. By understanding the manufacturing process of a shaft, manufacturers can produce high-quality products that meet the required standards. Let's start by looking at the first stage, cutting and machining the shaft to the desired length.

Cutting and Machining the Shaft to the Desired Length

Cutting and machining the shaft to the desired length is a critical step in the manufacturing process. This process involves using various cutting tools and techniques to achieve the precise length and surface finish required for the shaft. The first step is to measure the shaft accurately to determine the desired length, taking into account any tolerances or allowances for machining. Next, the shaft is secured in a lathe or machining center, and a cutting tool is selected based on the material and desired finish. The cutting tool is then used to cut the shaft to the desired length, using a combination of turning and facing operations. The turning operation involves rotating the shaft while the cutting tool moves along its length, removing material to achieve the desired diameter. The facing operation involves moving the cutting tool perpendicular to the shaft's axis, removing material to achieve a flat surface. Once the shaft has been cut to length, it is inspected for accuracy and surface finish, and any necessary additional machining operations are performed. The shaft is then deburred and cleaned to remove any sharp edges or debris, and it is ready for further processing or assembly. Throughout the cutting and machining process, it is essential to maintain tight tolerances and precise control over the cutting tools and machinery to ensure that the shaft meets the required specifications and performs optimally in its intended application.

Turning and Grinding the Shaft to Achieve the Desired Surface Finish

The turning and grinding processes are crucial steps in achieving the desired surface finish for a shaft. Turning involves rotating the shaft while a cutting tool removes material to create the desired shape and size. The cutting tool is typically a single-point tool, such as a lathe tool, which is designed to remove a small amount of material with each pass. The turning process can be used to create a variety of surface finishes, from rough to fine, depending on the tool used and the number of passes made. For example, a roughing tool can be used to quickly remove large amounts of material, while a finishing tool can be used to create a smooth, high-quality surface finish. Grinding, on the other hand, involves using an abrasive wheel to remove small amounts of material and create a high-quality surface finish. The grinding process is typically used to finish the surface of the shaft after turning, as it can create a very smooth and precise surface finish. The type of grinding wheel used will depend on the desired surface finish, with different wheels available for different finishes, such as rough, medium, and fine. By combining turning and grinding, manufacturers can achieve a high-quality surface finish that meets the required specifications for the shaft. For example, a shaft that requires a surface finish of 0.1 microns can be achieved by turning the shaft to a rough finish, followed by grinding to a fine finish. The turning and grinding processes can be performed using a variety of machines, including lathes, grinders, and CNC machines, which can be programmed to perform specific operations and achieve precise results. Overall, the turning and grinding processes are essential steps in achieving the desired surface finish for a shaft, and by combining these processes, manufacturers can produce high-quality shafts that meet the required specifications.

Drilling and Tapping Holes for Mounting and Assembly

Drilling and tapping holes for mounting and assembly is a crucial step in the shaft manufacturing process. This process involves creating precise holes in the shaft to accommodate various components such as bearings, gears, and other mechanical parts. To achieve accurate and efficient drilling and tapping, manufacturers employ specialized machinery and techniques. The first step is to select the appropriate drill bit and tap, taking into account the material properties of the shaft and the desired hole size and thread type. Next, the shaft is securely clamped in place to prevent movement during the drilling and tapping process. The drill bit is then carefully aligned with the desired hole location, and the drilling process begins. Once the hole is drilled, the tap is inserted, and the threading process commences. The tap is slowly rotated while applying gentle pressure, ensuring that the threads are cut evenly and accurately. To ensure the holes are precisely aligned and spaced, manufacturers often use CNC machines or other computer-controlled drilling and tapping equipment. These machines enable high-speed drilling and tapping with exceptional accuracy, reducing the risk of human error and increasing overall efficiency. Additionally, some manufacturers may use specialized drilling and tapping techniques, such as gun drilling or orbital drilling, to create complex hole geometries or to drill through hard or abrasive materials. By employing these advanced techniques and machinery, manufacturers can produce high-quality shafts with precise holes and threads, ensuring reliable performance and longevity in a wide range of applications.

Testing and Refining the Shaft

Testing and refining the shaft is a critical step in ensuring the overall performance and reliability of a machine or mechanical system. This process involves a series of meticulous steps to guarantee that the shaft meets the required specifications and standards. To achieve this, it is essential to inspect the shaft for defects and imperfections, conduct performance and load testing to ensure reliability, and refine the shaft's design and manufacturing process as needed. By doing so, manufacturers can identify and address any potential issues before they become major problems, ultimately leading to improved efficiency, reduced downtime, and increased productivity. In the first step of this process, inspecting the shaft for defects and imperfections is crucial in identifying any flaws that may affect its performance.

Inspecting the Shaft for Defects and Imperfections

Inspecting the shaft for defects and imperfections is a critical step in the manufacturing process. This step involves a thorough examination of the shaft to identify any flaws or irregularities that could affect its performance, safety, and overall quality. The inspection process typically begins with a visual examination, where the shaft is carefully checked for any visible signs of damage, such as cracks, dents, or scratches. The inspector will also check for any irregularities in the shaft's surface finish, such as rough spots or unevenness. In addition to visual inspection, the shaft may also undergo non-destructive testing (NDT) methods, such as ultrasonic testing or magnetic particle testing, to detect any internal defects or imperfections. These tests can help identify any flaws that may not be visible to the naked eye, such as cracks or porosity. The inspector will also check the shaft's dimensions and tolerances to ensure that they meet the required specifications. Any defects or imperfections found during the inspection process will be documented and addressed accordingly, which may involve reworking or replacing the shaft. The goal of the inspection process is to ensure that the shaft meets the required quality and safety standards, and that it will perform as intended in its intended application. By inspecting the shaft for defects and imperfections, manufacturers can help prevent costly repairs, reduce downtime, and improve overall product reliability.

Conducting Performance and Load Testing to Ensure Reliability

Conducting performance and load testing is a crucial step in ensuring the reliability of a shaft. This type of testing involves simulating real-world conditions to evaluate the shaft's ability to withstand various loads, stresses, and operating conditions. By conducting performance and load testing, manufacturers can identify potential weaknesses or defects in the shaft's design or materials, allowing for necessary modifications or improvements to be made before the shaft is put into service. This helps to prevent premature failure, reduce maintenance costs, and ensure the shaft operates safely and efficiently. Performance testing typically involves measuring the shaft's rotational speed, torque, and vibration levels, while load testing involves applying various loads to the shaft to evaluate its strength and durability. The results of these tests can be used to validate the shaft's design and materials, as well as to optimize its performance and extend its lifespan. By incorporating performance and load testing into the manufacturing process, manufacturers can ensure that their shafts meet the required specifications and performance standards, providing end-users with a reliable and high-quality product.

Refining the Shaft's Design and Manufacturing Process as Needed

The shaft's design and manufacturing process may need to be refined based on the results of the testing and analysis. This can involve making adjustments to the shaft's dimensions, material, or surface finish to improve its performance and durability. For example, if the testing reveals that the shaft is experiencing excessive vibration or deflection, the design may need to be modified to increase its stiffness or add additional support. Similarly, if the testing shows that the shaft is prone to wear or corrosion, the material or surface finish may need to be changed to improve its resistance to these factors. The manufacturing process may also need to be refined to ensure that the shaft is produced consistently and to the required quality standards. This can involve making adjustments to the machining or fabrication process, or implementing additional quality control measures to ensure that the shaft meets the required specifications. By refining the shaft's design and manufacturing process as needed, manufacturers can ensure that the shaft meets the required performance and durability standards, and that it is produced efficiently and cost-effectively.