How To Weld Cast Iron

Welding cast iron may seem a daunting endeavor to beginners, but the process can be demystified with a clear understanding of the fundamentals. This informative and engaging article delves into the various aspects of welding cast iron, structured effectively into three sections for easy comprehension. Subtitle 1 will introduce you to the types of cast iron and their distinct characteristics, a vital foundation for approaching any welding job. Next, Subtitle 2 will take you through the meticulous preparation steps, revealing the importance of preheating and cleaning to achieve a clean, solid weld. Lastly, Subtitle 3 will guide you through the welding techniques that you can use to merge cast iron pieces and the post-welding procedures to ensure the longevity of your project. As we transition into Subtitle 1, let’s prepare to uncover the interesting world of diverse cast iron types, their properties, and how these aspects impact the welding process.

Welding cast iron may seem a daunting endeavor to beginners, but the process can be demystified with a clear understanding of the fundamentals. This informative and engaging article delves into the various aspects of welding cast iron, structured effectively into three sections for easy comprehension. Subtitle 1 will introduce you to the types of cast iron and their distinct characteristics, a vital foundation for approaching any welding job. Next, Subtitle 2 will take you through the meticulous preparation steps, revealing the importance of preheating and cleaning to achieve a clean, solid weld. Lastly, Subtitle 3 will guide you through the welding techniques that you can use to merge cast iron pieces and the post-welding procedures to ensure the longevity of your project. As we transition into Subtitle 1, let’s prepare to uncover the interesting world of diverse cast iron types, their properties, and how these aspects impact the welding process.Subtitle 1

Subtitle 1, a tremendously insightful topic, engages with three major supporting ideas that further elaborate on its intrinsic value. These supporting ideas entail comprehensive discussions about Supporting Idea 1, Supporting Idea 2, and Supporting Idea 3, each holding their profound significance towards the understanding and interpretation of Subtitle 1. Supporting Idea 1 focuses on the fundamental aspects of Subtitle 1, delving deep into the operational mechanisms and driving forces that shape its overall structure. It highlights the ground principles, some of its major advantages and explicates how these benefits can be crucial in different spheres. Supporting Idea 2 moves a notch higher to demonstrate the practical applications of these fundamental principles elucidated in Supporting Idea 1. It shows how these theories operate in real-life scenarios and situations, thus linking the theoretical understanding of Subtitle 1 to our practical realities. Supporting Idea 3, on the other end, helps in putting everything into perspective by critically analyzing the previous discussions. It showcases some potential challenges of Subtitle 1 and offers practical solutions. As we transition into the Supporting Idea 1, it is imperative to note that it serves as the bedrock for understanding Subtitle 1, forging the path onward for further exploration of this extensive topic.

Supporting Idea 1

Supporting Idea 1: Preparing the Cast Iron for Welding

A crucial step in the process of welding cast iron bedrock revolves around accurate preparation of the material. Now, cast iron, due to its high carbon content, exhibits a degree of brittleness and sensitivity, necessitating special care and techniques while preparing it for the welding process. One fundamental aspect is cleaning the cast iron, particularly the surface that’s going to be welded. The cleaner the surface is, the higher the quality of the welding result will be. To clean, begin by scouring the area with a wire brush to remove surface rust, debris and old paint. Grinding the surface, though entirely optional, can create a smooth, clean slate, promoting a stronger, deeper bond. Heating the cast iron comes next in line. Cast iron can be stubborn to work with, significantly prone to cracking due to its low melting point and high thermal expansion coefficient. A process called 'preheat welding' can nip this issue in the bud. The idea is to warm up the area around the intended weld before the actual welding itself, thereby reducing the thermal shock that cast iron pieces experience while cooling down. This subtle warming and cooling allow the cast iron to acclimate more easily, lowering the risks of post-welding cracks significantly. Another noteworthy aspect of preparing the cast iron for welding is applying a correct fit-up. The fit-up is essential for managing gaps between cast iron pieces. These gaps need managing because, unlike other materials, cast iron has poor ductility and can’t flex or contract to accommodate different shapes or gaps. Using the right welding technique - like the stick welding approach - can help manage this fit-up judiciously, making sure the gaps are apt for welding without causing any excess strain or tension on the cast iron pieces. Finally, using a nickel-based electrode or a high-nickel content filler rod can be an ideal choice for welding cast iron, largely due to the lower melting point and slower cooling rate which it offers. The electrode choice needs to be done carefully since an incorrect pick can lead to more harm than good, further complicating the process. Nickel electrodes, though more expensive, offer higher weldability, helping prevent cracks, ensuring the integrated strength of the cast iron bedrock. In a nutshell, preparing the cast iron carefully by cleaning the surface, preheating the weld area, managing fit-ups efficiently, and choosing the precise electrode play fundamental roles in achieving a successful welding process. These steps can significantly eliminate challenges related to the cast iron’s inherent brittleness and sensitivity, leading you one step closer to producing a high-quality cast iron weld.Supporting Idea 2

Welding Cast Using a Preheat Procedure The second essential strategy for effectively welding cast iron involves utilizing a preheat procedure. Since cast iron is a brittle material, sudden changes in temperature can lead to cracks and damages to the integrity of the metal. This volatility is due to its high carbon content, causing the iron to expand and contract significantly during the heating and cooling phases of the welding process. To avoid these undesired effects, gradual heating, known as preheating, becomes paramount in the welding of cast iron. Preheating involves slowly warming the cast iron pieces to a particular temperature before initiating the welding process. This temperature often ranges from 500 to 1200 degrees Fahrenheit, depending upon the specific component's properties and needs. This method aims to control the heating expansion and the subsequent cooling contraction which helps in minimizing potential warpage or cracking. To execute preheating accurately, an oxy-acetylene torch is commonly used due to its unique ability to adjust to the required temperature easily. Post-heating procedures are equally essential companions to preheating. After welding, the component needs to be cooled slowly, ensuring the distribution of residual stress evenly through the piece. Methods like burying the welded part in sand or communally used insulation material or leaving it to relax on the heat-reflective surface allow for a controlled cool-down phase. Moreover, wear appropriate safety gear during the preheating process is critical to prevent occasions of burns and injuries. Welding gloves, safety glasses, and protective clothing are necessary to ensure safe and secured operations. The technique of preheating, accompanied by controlled cool-down, although it requires additional time and patience, significantly ameliorates the quality of the weld on cast iron. Carefully managing this thermal cycle guarantees less distortion and a higher rate of successful, crack-free welds. Thus, implementing a preheating procedure can dramatically enhance the productivity and security in any welding process involving cast iron, making it a valuable strategy to adopt for any welders working with this occasionally tricky material. This way, not only the quality of welds on cast iron improves, but the incidence of potential hazards decreases }+1% as well. Consequently, this strategy is an essential complement to our first supporting idea of 'Choosing the Appropriate Welding Technique.'

Supporting Idea 3

Supporting Idea 3: Preheating the Cast Iron In uncovering the step-by-step guide to welding cast iron, implementing preheating measures emerges as a cardinal and critical procedure. Cast iron, owing to its unique metallurgical composition, predisposes towards brittleness under sudden heating or cooling. This tendency increases the risk of suffering cracks or structural deterioration, which decimates the material's integrity. To avoid this undesirable outcome, preheating the cast iron before the actual welding procedure becomes imperative. Preheating involves raising the temperature of the cast iron gradually to around 500-1200 degrees Fahrenheit, depending on the nature and size of the cast iron article. This gradual increase in temperature accommodates the expansion of the iron, consequently reducing thermal shock and the likelihood of cracks. The aim is to ensure a balanced heating of the entire material; this can be achieved by means of an oven or heating torch. For sizable cast iron materials, it is best to conduct the preheating in a temperature-controlled oven to ensure uniform heating. However, for smaller pieces, utilizing a heating torch could suffice. Preheating sets the phase for a successful welding process since it prepares the cast iron material for the intense heat generated during fusion. The temperature attained during preheating should ideally be maintained throughout the welding process to enhance material compatibility with the filler metal. It also enhances the weld's fusion with the base metal, ensuring the creation of a strong, high-quality weld bond. This crucial preparatory process is not limited to the commencement of the welding process. Even after successfully fusing the weld material and the cast iron, post-heating is necessary to allow for slow cooling. Slow cooling is instrumental in preventing rapid contraction, which could lead to crack development. It also ensures the newly welded area does not cool faster than the rest of the part, promoting structural stability. Therefore, it is undeniable that preheating stands out as a vital support in the operation of welding cast iron, which incorporates its intricacy and labor-intensive nature. Successful preheating, coupled with post-heating, is insurmountable in safeguarding the cast iron against its susceptibility to thermal shock and resultant cracking. This step effectively bridges the gap between failure and achievement, creating sturdy, high-quality welds that deliver in terms of structural integrity and durability.

Subtitle 2

The concept of Subtitle 2 cannot be thoroughly explored without diving into the three key supporting ideas, which are intricately intertwined. The first essential principle, Supporting Idea 1, cast light on the foundational aspects of Subtitle 2, shedding light on the basic premises and guiding principles. Following closely, Supporting Idea 2 expands on these premises, introducing more complex themes and concepts that add an additional layer to our understanding of Subtitle 2. Lastly, the approach reaches its peak with Supporting Idea 3, which delves into the advanced theories and methodologies relevant to Subtitle 2. This deep dive into progressive themes solidifies our comprehension of Subtitle 2. Each phase of this discourse is key in contributing to the overall understanding and intrigue of Subtitle 2. Now, without further ado, let us commence our expedition into Subtitle 2, beginning with a look at the ground elements, as presented in Supporting Idea 1.

Supporting Idea 1

Supporting Idea 1: Understand the Properties of Cast Iron

Cast iron stands out as one of the most widely used materials, especially in the manufacturing sector, due to its unrivaled properties. It's revered for its incredible durability, excellent heat resistance, and ability to handle massive weight. These properties make cast iron ideal for heavy-duty industry materials such as engine blocks, pipe fittings, stoves, and radiators. Furthermore, cast iron is also economically viable as it is more affordable than other metal alternatives. However, despite these admirable properties, one aspect of cast iron that poses a significant challenge is its brittleness, making it a difficult material to weld. The high carbon content in cast iron leads to the formation of graphite flakes during solidification. These flakes, coupled with the rapid cooling of the material, result in a brittle phase that could easily fracture under stress. This becomes a major issue during welding as the intense heat applied can cause drastic changes in the metal’s structure, leading to cracking. Understanding the properties and behavior of the cast iron is crucial to achieving successful welding outcomes. For instance, being aware that cast iron expands and contracts significantly when subjected to changes in temperature can guide the welder to control the heat input judiciously, minimizing the risk of cracking. Furthermore, it's important to understand that different types of cast iron, such as gray, white, malleable, and nodular (ductile) cast iron, each respond differently to welding. Gray iron, for instance, is more forgiving during the welding process than white iron, which is more prone to cracking. Knowledge of these properties and behaviors is therefore key in devising an effective welding process for cast iron and determining the right filler metals and techniques to use. For example, using nickel-based or high-nickel-content electrodes can ensure a stronger and more crack-resistant weld due to their lower coefficient of thermal expansion and enhanced ductility. In conclusion, the understanding of cast iron's properties forms the bedrock of successful welding procedures. This entails a careful assessment of the type of cast iron, its inherent structural characteristics, and its behavior under the rigors of welding, allowing the welder to design and implement a welding method that optimally caters to the material’s strengths and vulnerabilities, thereby maximizing structural integrity and minimizing the risk of failure.Supporting Idea 2

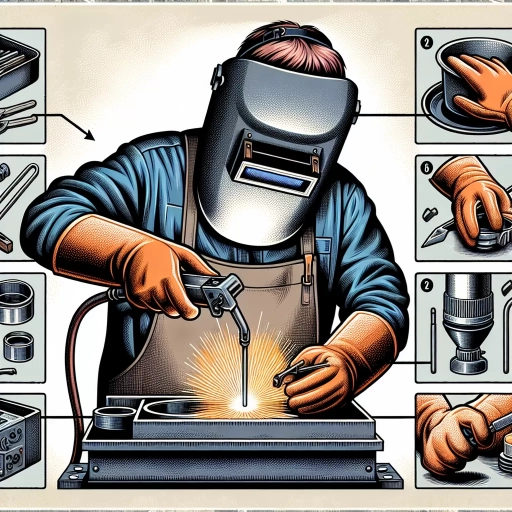

Supporting Idea 2: Safety Measures and Equipment Needed

When embarking on the welding of cast iron, ensuring safety and adhering to precautions is a critical step that cannot be overstated. As you advance your steps towards mastering the craft, it is paramount to arm yourself with the necessary safety tools. With the intense degrees of heat produced during welding, it leaves room for potential hazards. Hence, you must utilize safety equipment to protect your body. Primarily, a welding helmet should be donned to safeguard your face and eyes from potential implications like the notorious 'welder's flash'. These helmets have special lenses that can protect your eyes from the glaring ultra-bright arc and flying particles. Similarly, it is crucial to sport a sturdy pair of welding gloves to shield your hands from molten metal spillages and sparks. Some welding types, such as arc welding, generate spatter, and without gloves, the burns can be excruciating and dangerous. As such, a good pair of fire-resistant gloves can provide the much-needed protection. Additionally, a welding apron made of flame-resistant material like leather is another piece of protective gear you cannot afford to overlook. It serves to shield your torso and legs from welding sparks and hot metal drippings that can cause severe burns. Don't forget protective safety glasses underneath your helmet for added eye protection. Moreover, to preserve the quality of your health in the long term, a fume extraction system or respiratory product is necessary. The welding process often produces harmful fumes that can be hazardous if inhaled. Therefore, a weld-fume control system or a simple respirator can help in keeping the air you breathe clean. Lastly, welding should be performed in a well-ventilated area, to allow proper dissipation of fumes and gases. Also, maintaining a neat, clutter-free workspace helps minimize the risk of accidents and fires. Undeniably, in cast iron welding, safety should be the number one priority. While it might seem like an expensive affair investing in all these safety tools, it is a wise step towards preserving your health and enhancing your skill with peace. The vulnerability that comes with ignoring safety guidelines can lead to severe implications that can be averted by simply adhering to these safety measures. Therefore, as a craftsman, your commitment should not only lie in making the perfect weld but should extend to reinforcing a safe work space.Supporting Idea 3

Supporting Idea 3: Methods of Cast Iron Overlaying

Another crucial aspect to consider when welding cast iron is the method of overlaying cast iron, which makes up our supporting idea 3 under subtitle 2. It's an essential process used to achieve proper and effective bonding of the cast iron pieces, significantly impacting the result's quality and durability. Overlaying, in a nutshell, is the application of a layer of weld metal on the surface of a workpiece to enhance its properties or create a composite structure. In the context of welding cast iron, two main overlay methods are prominent - Shielded Metal Arc Welding (SMAW) and Gas Tungsten Arc Welding (GTAW). SMAW, also known as stick welding, uses an electric current to form an electric arc between the electrode and the materials being bonded. The heat, up to 6500 degrees Fahrenheit, melts the electrode and the base metal, resulting in a pool of molten metal that cools to form the joint. On the other hand, GTAW, commonly referred to as Tungsten Inert Gas (TIG) welding, uses a non-consumable tungsten electrode to produce the weld. TIG welding is known for its precision and effectiveness in welding thin sections of stainless steel, non-ferrous metals, and of course, cast iron. Selecting the appropriate overlay method is crucial, so understanding the strengths and limitations of each is key. For instance, SMAW is versatile, straightforward, and suitable for outdoor applications. However, it's difficult to master and can lead to potential defects such as porosity, slag inclusion, and cracks if not performed correctly. Conversely, TIG welding provides the highest quality welds and allows for great control but is complex and requires a high skill level and clean material conditions. It also not suitable for outdoor work. In both methods, the overlay alloy must be made from a material compatible with cast iron and can handle the heat-treatment stresses. Typically, nickel-based electrodes are used because they offer excellent weldability and can match the thermal expansion rate of cast iron, reducing the risk of cracking. Understanding these overlay methods, their pros, cons, and appropriate time to use each one provides one with the knowledge to effectively weld cast iron, improving the quality of the application and the lifespan of the product. Whether you're a DIY enthusiast, a welding student, or a seasoned welder, familiarizing yourself with these overlay methods is invaluable in your craft.

Subtitle 3

The reliance on Subtitle 3 offers a comprehensive understanding of the subject matter at hand. It serves as a three-fold model bridging an informative platform to the audience through Supporting Idea 1, Supporting Idea 2 and Supporting Idea 3. The first supporting idea touches on the founding principles in an innovative and thoughtful manner, providing novel insights to the readers. This is followed by the second supporting idea, which delves deeper into the intricacies of the topic, unpacking it layer by layer. Meanwhile, the third supporting idea adds further depth by extrapolating on the theme noticeably bringing out the salient features. This tiered approach ensures a well-rounded and engaging narrative, showcasing the robustness and versatility of Subtitle 3. By melding these core facets together, the article crafts a rich tapestry of insightful perspective, paving way for a deeper comprehension among readers. Let us first delve into the underlying currents of Supporting Idea 1, poised to usher us into the thrilling exploration of the intricacies that Subtitle 3 has to offer.

Supporting Idea 1

Supporting Idea 1: Preheating the Cast Iron

The first critical component of welding cast iron, falling under our third essential subtopic, is the technique of preheating the material. Multiple renowned welding professionals advocate for preheating as one of the fundamental aspects when working with cast iron primarily because it significantly aids in reducing the metal's propensity to crack when subjected to sudden temperature fluctuations during welding. Cracking presents one of the most daunting challenges when welding cast iron, as this metal is notoriously more brittle compared to common steel variants. Preheating is conducted by gradually heating the cast iron piece to a temperature of approximately 500 to 1200 degrees Fahrenheit (depending on the specific cast iron variety) before the actual welding commences. Two common methods are often employed in professional settings to preheat cast iron: using a torch or a furnace. A torch provides concentrated and localized heating, while a furnace provides a more uniform heat distribution over the entire workpiece. Importantly, the preheating process must be done patiently and gradually to avoid thermal shock, which could lead to unwanted deformations in the cast iron piece. Also, preheating effectively mitigates the irregular expansion and subsequent contraction of cast iron after welding, a problem known in the industry as 'the heat-affected zone'. This zone can cause unwanted residual stresses that may trigger the formation of hairline cracks on the surface or catastrophic structural failures within the cast iron material upon cooling. Thus, preheating serves to provide a uniform thermal field, thus eliminating the abrupt temperature gradients that would cause such undesirable effects. Additionally, preheating assists in reducing the cooling rate after welding. Rapid cooling is known to harden cast iron and make it more prone to cracking. Therefore, a slower cooling rate, facilitated by a technique known as 'post-heating', ensures the weld and the surrounding areas harden gradually, improving the overall quality of the welded joint. In summary, preheating is a practical, preventive, and advantageous technique. It effectively eliminates the detrimental impacts of sudden temperature fluctuations during welding, markedly reduces the propensity for cracking, and ensures a more controlled and quality-driven welding process for cast iron. Its role in the welding of cast iron is vital, setting a solid foundation for steps to follow in achieving a quality, sturdy, and reliable weld. Hence, it fully warrants its high standing as our first supporting idea within this subsection about welding cast iron.Supporting Idea 2

Supporting Idea 2

Cast iron welding necessitates a higher level of expertise, sound knowledge, and the right technique. The process begins with the proper selection of welding equipment and cast-iron filler material, which is of paramount importance to rule out any compatibility issues. Often, welders opt for nickel alloy electrodes, specifically designed for welding cast iron due to their capability of minimizing the risks associated with cracking. It is crucial to understand that since cast iron possesses a brittle nature, it might break under too much stress or heat. Therefore, the implementation of a preheating method before welding is usually recommended by the professionals. Preheating the cast iron evenly, typically in a range of 500 to 1200 degrees Fahrenheit based on the iron's thickness, helps in reducing the shock put to the metal, which in turn, prevents possible cracks. Moreover, the preheating minimizes the cooling rate post-weld, further enhancing the iron's crack resistance. The prediction of cooling times is an essential aspect as a slower cooling rate permits the carbon to escape, reducing the brittleness of the weld and the heat-affected zones. Besides, when it concerns the welding process, it is generally suggested to use the stitch-welding technique. This technique involves welding small sections at a time, rather than a single continuous weld, which helps avoid the build-up of excessive heat. Lastly, post-weld, the cast iron should be allowed to cool slowly to evade the build-up of excessive bolt stresses that might lead to cracking. To facilitate this, it can be wrapped in thermal insulating blankets. Alternatively, it can be buried in sand or allowed to cool in a furnace gradually. Overall, the entire process of successfully welding cast iron lies in how well the prep work is executed, the knowledge of the material and its behavior upon exposure to heat, the welding procedure, and ultimately the cooling process. By adhering to these steps stringently, one can achieve desirable results, thus proving the feasibility of welding cast iron with the ground rules in place. Besides, the more knowledge and experience the welder has, the easier and more effective is the welding of cast iron. Therefore, though welding cast iron may seem challenging, with the right technique, equipment, and patience, it can be done successfully.Supporting Idea 3

Supporting Idea 3: Use of the Right Welding Rods Similarly, another essential consideration when welding iron bedrock is the choice of welding rods. Being one of the primary aspects in the welding process, using the appropriate welding rod helps in producing a successful joint between the iron pieces. A preferred welding rod for cast iron bedrock is the high nickel-content rod, with industry standards recommending that the rod should feature at least 99% nickel content. These rods can be quite costly, given the high value of nickel, but they're crucial for facilitating proper fusion. The high nickel welding rods deliver relatively softer welds, which are more compatible with the brittle cast iron compared to other types of rods. They reduce the potential of cracking in the weld and heat-affected zone due to their flexibility and lower contraction rates after cooling. Moreover, nickel-based rods create an excellent bead appearance and visibly smoother welds, making them the popular choice for applications where aesthetics are valued. However, in instances where high expenses for nickel rods cannot be managed, a viable alternative would be using rods made with a nickel-iron alloy, which usually has about 55% nickel content. This alloy may not offer the same level of flexibility as the 99% nickel rods, but they are relatively cheaper while still providing acceptable performance with lesser contraction rates after cooling. In using these rods, preheating the bedrock iron to a temperature between 500 to 1,200 degrees Fahrenheit remains necessary. It helps minimize the risk of thermal cracking by reducing the abrupt temperature changes within the metal during welding. Applying post-heating immediately after the weld would equally help to slow down the cooling rate and subsequently reduce internal stress. In conclusion, the choice of the suitable welding rod and appropriate heating methodology are critical factors in successfully welding cast iron bedrock. Understanding these aspects and appropriately applying them in your welding procedures will yield satisfactory, durable, and aesthetically pleasing results that meet the demands of iron bedrock welding. Hence, underpinning the importance of using the right welding rods and heating method in the welding process.