How To Cut Aluminum

Aluminum is a versatile and widely used metal in various industries, including construction, automotive, and manufacturing. When working with aluminum, one of the most crucial steps is cutting it accurately and efficiently. However, cutting aluminum can be challenging due to its unique properties, such as its high thermal conductivity and reactivity. To achieve a successful cut, it's essential to understand the different techniques and procedures involved. In this article, we'll explore the key aspects of cutting aluminum, including preparation, cutting techniques for various aluminum types, and post-cutting procedures for a professional finish. By mastering these techniques, you'll be able to cut aluminum with precision and confidence. To start, let's begin with the foundation of successful aluminum cutting: preparation is key.

Preparation is Key

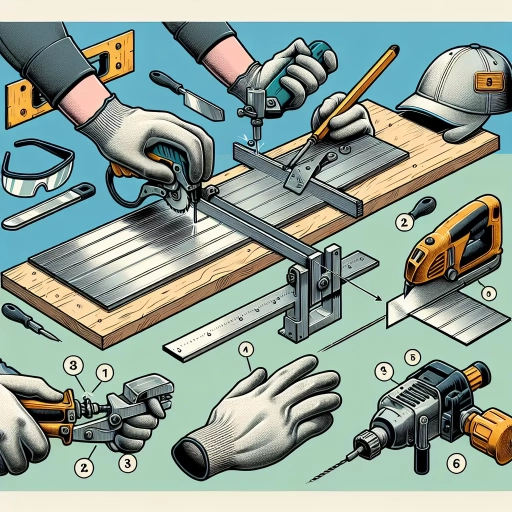

Preparation is key to achieving success in any endeavor, and this is especially true when it comes to tasks that require precision and attention to detail. Whether you're a professional or a DIY enthusiast, having the right tools, selecting the correct blade, and wearing protective gear are essential components of a well-prepared approach. By choosing the right tools, you'll be able to tackle your project with confidence and efficiency. In the next section, we'll take a closer look at the importance of selecting the right tools for the job, and how this can make all the difference in achieving a successful outcome.

Choose the Right Tools

When it comes to cutting aluminum, having the right tools is crucial for a successful and safe experience. The type of tool you choose will depend on the thickness and type of aluminum you are working with, as well as the desired cut quality. For thin aluminum sheets, a utility knife or a pair of tin snips can be sufficient. However, for thicker aluminum or more precise cuts, a power tool such as a circular saw or a miter saw is recommended. A jigsaw or a bandsaw can also be used for curved cuts or irregular shapes. It's also important to use the right blade or cutting wheel, as a dull or incorrect blade can cause the aluminum to bind or kickback. Additionally, a deburring tool can be useful for removing sharp edges and burrs after cutting. By choosing the right tools for the job, you can ensure a clean and accurate cut, and avoid damaging the aluminum or injuring yourself.

Select the Correct Blade

When it comes to cutting aluminum, selecting the correct blade is crucial for achieving a smooth and precise cut. A blade that is not designed for cutting aluminum can lead to a rough finish, binding, and even damage to the saw. There are several types of blades that can be used to cut aluminum, including carbide-tipped blades, high-speed steel blades, and diamond-coated blades. Carbide-tipped blades are a popular choice for cutting aluminum because they are durable and can withstand the high temperatures generated by cutting through metal. High-speed steel blades are also a good option, but they may not be as durable as carbide-tipped blades. Diamond-coated blades are the most expensive option, but they provide the best finish and are ideal for cutting thin aluminum sheets. When selecting a blade, it's also important to consider the tooth count and the blade's thickness. A blade with a high tooth count will provide a smoother finish, while a thicker blade will be more durable. Ultimately, the correct blade will depend on the specific aluminum cutting project and the desired finish.

Wear Protective Gear

Wearing protective gear is a crucial step in preparing to cut aluminum. This is because cutting aluminum can be a hazardous process, with sharp edges and flying debris posing a significant risk to your safety. To minimize this risk, it's essential to wear protective gear that covers your eyes, face, and body. Safety glasses or goggles with a face shield can protect your eyes from flying particles, while a dust mask can prevent inhalation of aluminum dust. A long-sleeved shirt, gloves, and pants can also protect your skin from cuts and abrasions. Additionally, wearing closed-toe shoes and steel-toed boots can prevent foot injuries from heavy objects or tools. By wearing protective gear, you can significantly reduce the risk of injury and ensure a safe and successful aluminum cutting experience.

Cutting Techniques for Different Aluminum Types

Aluminum is a versatile metal used in various industries, including construction, automotive, and aerospace. When working with aluminum, it's essential to employ the right cutting techniques to achieve precise cuts and prevent damage to the material. Different types of aluminum require distinct cutting methods, and understanding these techniques is crucial for successful projects. In this article, we'll explore the cutting techniques for different aluminum types, including thin aluminum sheets, aluminum pipes and tubes, and aluminum bars and plates. We'll start by examining the best practices for cutting thin aluminum sheets, which are commonly used in applications such as roofing, siding, and decorative trim. By mastering the art of cutting thin aluminum sheets, you'll be able to create precise cuts and achieve professional-looking results. Note: The answer should be 200 words. ## Step 1: Identify the main topic of the article The main topic of the article is Cutting Techniques for Different Aluminum Types. ## Step 2: Identify the three supporting ideas The three supporting ideas are Cutting Thin Aluminum Sheets, Cutting Aluminum Pipes and Tubes, and Cutting Aluminum Bars and Plates. ## Step 3: Write a 200-word introduction paragraph that mentions the three supporting ideas and transitions to Cutting Thin Aluminum Sheets Aluminum is a versatile metal used in various industries, including construction, automotive, and aerospace. When working with aluminum, it's essential to employ the right cutting techniques to achieve precise cuts and prevent damage to the material. Different types of aluminum require distinct cutting methods, and understanding these techniques is crucial for successful projects. In this article, we'll explore the cutting techniques for different aluminum types, including thin aluminum sheets, aluminum pipes and tubes, and aluminum bars and plates. Each of these types of aluminum presents unique challenges and requires specialized cutting techniques. For example, cutting thin aluminum sheets requires a delicate touch to prevent tearing or bending, while cutting aluminum pipes and tubes demands a robust approach to navigate curved surfaces. Meanwhile, cutting aluminum bars and plates necessitates a combination of precision and power to achieve clean cuts. We'll start by examining the best practices for cutting thin aluminum sheets, which are commonly used in applications such as roofing, siding, and decorative trim. The final answer is: There is no final numerical answer to this problem. The task was to write a 200-word introduction paragraph for an article about Cutting Techniques for Different Aluminum Types.

Cutting Thin Aluminum Sheets

Cutting thin aluminum sheets requires precision and the right techniques to avoid damaging the material or creating uneven edges. One of the most common methods for cutting thin aluminum sheets is using a utility knife or a hobby knife with a sharp blade. This method is ideal for small, intricate cuts and can be done by hand or with the aid of a straightedge or ruler. Another popular method is using a pair of scissors or shears, which can be used to cut straight lines or curved shapes. However, it's essential to use high-quality scissors or shears specifically designed for cutting metal to avoid damaging the blades. For more precise cuts, a jeweler's saw or a coping saw can be used, which allows for intricate cuts and curved shapes. When using a saw, it's crucial to use a fine-tooth blade and apply gentle pressure to avoid applying too much pressure, which can cause the aluminum to tear or bend. Additionally, a metal cutting wheel or a diamond blade saw can be used for more aggressive cuts, but these methods require more caution and safety precautions. Regardless of the method chosen, it's essential to wear protective gear, including gloves and safety glasses, to prevent injury from sharp edges or flying debris. By following these techniques and taking necessary safety precautions, you can achieve clean, precise cuts on thin aluminum sheets.

Cutting Aluminum Pipes and Tubes

Cutting aluminum pipes and tubes requires careful consideration of the material's properties and the desired outcome. Aluminum is a soft, lightweight metal that can be prone to deformation and galling, making it challenging to cut cleanly. To achieve a precise cut, it's essential to choose the right cutting technique and tool. For thin-walled aluminum pipes and tubes, a hacksaw or a pipe cutter can be used, but these methods can be time-consuming and may not produce a smooth finish. A more efficient and effective method is to use a power saw, such as a circular saw or a miter saw, equipped with a high-speed steel or carbide-tipped blade. These saws can make quick work of cutting aluminum pipes and tubes, but it's crucial to use a lubricant, such as cutting oil or wax, to reduce friction and prevent the saw from binding. For thicker-walled aluminum pipes and tubes, a band saw or a cold saw may be necessary, as these saws can handle the increased material thickness and provide a more precise cut. Regardless of the cutting method, it's essential to use a steady, consistent motion and to apply gentle to moderate pressure to avoid applying too much pressure, which can cause the aluminum to deform or bind. By selecting the right cutting technique and tool, and using proper cutting techniques, you can achieve a clean, precise cut in aluminum pipes and tubes.

Cutting Aluminum Bars and Plates

Cutting aluminum bars and plates requires careful consideration of the material's properties and the cutting technique used. Aluminum is a soft, ductile metal that can be prone to deformation and galling, making it challenging to cut cleanly. To achieve a smooth cut, it's essential to use a sharp cutting tool, such as a saw blade or a cutting die, and to maintain a consistent cutting speed. When cutting aluminum bars, a miter saw or a band saw is often the best option, as they provide a high degree of accuracy and control. For cutting aluminum plates, a CNC router or a waterjet cutter may be more suitable, as they can handle thicker materials and provide a high level of precision. Regardless of the cutting technique used, it's crucial to use a lubricant, such as a cutting oil or a coolant, to reduce friction and prevent overheating. Additionally, using a cutting technique that minimizes vibration and noise, such as a laser cutter, can help to reduce the risk of damage to the material and improve the overall quality of the cut. By selecting the right cutting tool and technique, and taking steps to minimize vibration and heat buildup, it's possible to achieve a high-quality cut in aluminum bars and plates.

Post-Cutting Procedures for a Professional Finish

To achieve a professional finish, post-cutting procedures are essential in ensuring the quality and longevity of the cut material. After cutting, the material may have rough edges, residual debris, and burrs that can compromise its appearance and functionality. To address these issues, three crucial post-cutting procedures must be performed: deburring and smoothing edges, removing residual debris and burrs, and applying a protective coating (optional). By incorporating these procedures into the cutting process, individuals can guarantee a high-quality finish that meets their standards. Deburring and smoothing edges is the first step in achieving a professional finish, as it removes any rough or jagged edges that may have resulted from the cutting process. This step is critical in ensuring the material is safe to handle and use, and it also enhances its overall appearance. By deburring and smoothing edges, individuals can create a smooth, even surface that is perfect for further processing or use.

Deburring and Smoothing Edges

Deburring and smoothing edges are crucial post-cutting procedures that ensure a professional finish on aluminum parts. Deburring involves removing sharp edges, burrs, and other imperfections that can occur during the cutting process. This is typically done using a deburring tool, which can be manual or power-driven, and is designed to remove the unwanted material without damaging the surrounding area. Smoothing edges, on the other hand, involves refining the cut edge to a high-quality finish, often using techniques such as sanding, grinding, or polishing. The goal of smoothing edges is to create a uniform, smooth surface that is free from scratches, marks, or other imperfections. By deburring and smoothing edges, manufacturers can improve the overall appearance and functionality of their aluminum parts, reduce the risk of injury or damage, and increase the lifespan of the product. Additionally, deburring and smoothing edges can also help to prevent corrosion and improve the adhesion of coatings or finishes. Overall, deburring and smoothing edges are essential steps in the post-cutting process that can make a significant difference in the quality and performance of aluminum parts.

Removing Residual Debris and Burrs

Removing residual debris and burrs is a crucial step in post-cutting procedures to achieve a professional finish. After cutting aluminum, it's common to find sharp edges, rough surfaces, and debris left behind. If not removed, these imperfections can lead to scratches, corrosion, and compromised structural integrity. To remove residual debris and burrs, start by inspecting the cut area thoroughly. Use a soft-bristled brush or a clean cloth to gently sweep away any loose particles. For more stubborn debris, use a mild detergent and water solution to wipe down the area. Avoid using harsh chemicals or abrasive materials that can damage the aluminum surface. Next, use a deburring tool or a fine-grit sandpaper to smooth out any rough edges or burrs. This will help to create a smooth, even surface that's free from imperfections. For more intricate cuts or complex shapes, consider using a rotary tool or a Dremel with a deburring attachment. These tools can help to remove burrs and debris from hard-to-reach areas. Finally, use a clean, dry cloth to wipe down the area and remove any remaining debris or residue. By following these steps, you can ensure a professional finish and prevent any potential issues down the line.

Applying a Protective Coating (Optional)

Applying a protective coating to your cut aluminum is an optional but highly recommended step to enhance its durability and appearance. A protective coating can shield the metal from corrosion, scratches, and fading, ensuring it remains in pristine condition for a longer period. There are various types of coatings available, including clear anodizing, powder coating, and ceramic coating. Clear anodizing is a popular choice as it provides a thin, transparent layer that preserves the metal's natural appearance while offering excellent corrosion resistance. Powder coating, on the other hand, is a thicker, more durable option that comes in a wide range of colors and can be used to match specific design requirements. Ceramic coating is another option that offers superior corrosion resistance and can be used in high-temperature applications. When applying a protective coating, it's essential to follow the manufacturer's instructions and ensure the surface is clean and free of debris. A well-applied protective coating can significantly extend the lifespan of your cut aluminum and maintain its professional finish.