How To Make Hooch

Here is the introduction paragraph: Making hooch, a type of homemade moonshine, can be a fun and rewarding experience for those who enjoy experimenting with spirits. However, it requires a good understanding of the basics, careful preparation of ingredients and equipment, and a patient approach to distillation and aging. In this article, we will guide you through the process of making hooch, starting with the fundamentals of what hooch is and how it's made. We will then move on to preparing the necessary ingredients and equipment, including the type of grains, yeast, and stills required. Finally, we will cover the distillation and aging process, including tips on how to achieve the perfect flavor and clarity. By the end of this article, you will have a comprehensive understanding of how to make hooch and be ready to start experimenting with your own recipes. So, let's begin by understanding the basics of hooch.

Understanding the Basics of Hooch

For those interested in exploring the world of homemade spirits, understanding the basics of hooch is essential. Hooch, a colloquial term for homemade liquor, has a rich history and a wide range of variations. To get started, it's crucial to define what hooch is and its origins, as well as explore the different types of hooch and their characteristics. Additionally, knowing the basic ingredients and equipment needed to produce hooch is vital for a successful brewing experience. In this article, we will delve into the world of hooch, starting with its definition and origins, to provide a comprehensive understanding of this popular homemade spirit. By understanding the basics of hooch, enthusiasts can create their own unique recipes and enjoy the fruits of their labor. So, let's begin by defining hooch and its origins.

Defining Hooch and Its Origins

Hooch, also known as prison wine, is a type of homemade alcoholic beverage that originated in the United States. The term "hooch" is believed to have come from the Hoochinoo tribe of Native Americans, who were known for their bootlegging activities during the Prohibition era. Hooch is typically made from a mixture of fermented fruit, sugar, and water, and is often brewed in secret, hence the association with prison culture. The drink gained popularity in the 1920s and 1930s, particularly among those who could not afford or access commercial liquor. Hooch was often made in hidden stills or makeshift breweries, and its production and consumption were frequently linked to organized crime. Despite its illicit origins, hooch has become a cultural phenomenon, with many enthusiasts experimenting with different recipes and ingredients to create unique flavors and strengths. Today, hooch is enjoyed by people from all walks of life, and its rich history and cultural significance continue to fascinate those interested in the world of homemade spirits.

Types of Hooch and Their Characteristics

Hooch, also known as moonshine or homemade whiskey, comes in various types, each with its unique characteristics. The most common types of hooch include corn whiskey, sugar shine, and fruit brandy. Corn whiskey is made from a mixture of corn, water, and yeast, and is known for its strong, rich flavor. Sugar shine, on the other hand, is made from a mixture of sugar, water, and yeast, and is often flavored with fruits or herbs. Fruit brandy is made from fermented fruit, such as apples or grapes, and is known for its sweet, fruity flavor. Other types of hooch include rum, made from sugarcane or molasses, and vodka, made from grains or potatoes. Each type of hooch has its own distinct flavor profile and production process, and can be enjoyed on its own or used as a base for cocktails.

Basic Ingredients and Equipment Needed

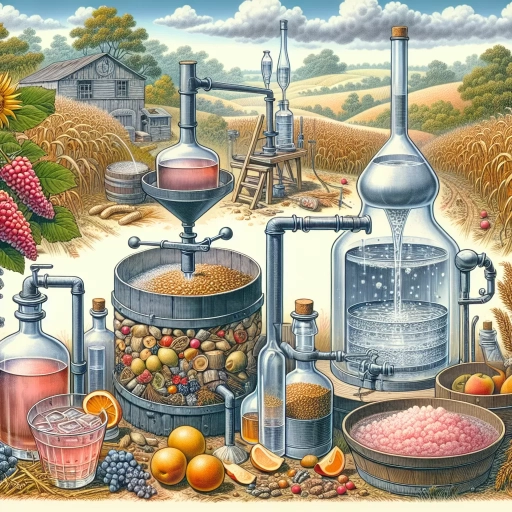

To make hooch, you'll need some basic ingredients and equipment. The ingredients include sugar, water, yeast, and a flavoring agent such as fruit or herbs. The type and amount of sugar used can vary depending on the desired strength and flavor of the hooch. Granulated sugar is a common choice, but other types of sugar like brown sugar or honey can also be used. Water is also a crucial ingredient, and it's recommended to use filtered or distilled water to prevent any impurities from affecting the fermentation process. Yeast is responsible for fermenting the sugars and producing the alcohol, and there are many types of yeast available, including baker's yeast, brewer's yeast, and distiller's yeast. Flavoring agents like fruit, herbs, or spices can be added to give the hooch a unique taste and aroma. In terms of equipment, you'll need a large pot or container to mix and heat the ingredients, a fermentation vessel to allow the mixture to ferment, and a distillation apparatus to separate the alcohol from the other ingredients. A hydrometer is also useful for measuring the specific gravity of the mixture and determining the alcohol content. Other equipment like a thermometer, siphon, and airlock can also be helpful in the process.

Preparing the Ingredients and Equipment

Preparing the ingredients and equipment is a crucial step in the brewing process. To ensure a successful brew, it's essential to have the right ingredients and equipment in place. This includes selecting the right yeast and fermentation vessel, preparing the mash and creating the wort, and sanitizing and sterilizing equipment for safe fermentation. By taking the time to properly prepare the ingredients and equipment, brewers can avoid common mistakes and ensure a high-quality brew. In this article, we'll explore the importance of selecting the right yeast and fermentation vessel, and how it sets the stage for a successful brew. With the right yeast and fermentation vessel, brewers can create a healthy fermentation environment that promotes the growth of desirable flavors and aromas. By choosing the right yeast and fermentation vessel, brewers can take the first step towards creating a delicious and unique beer. Note: The answer should be 200 words. Here is the answer: Preparing the ingredients and equipment is a crucial step in the brewing process. To ensure a successful brew, it's essential to have the right ingredients and equipment in place. This includes selecting the right yeast and fermentation vessel, preparing the mash and creating the wort, and sanitizing and sterilizing equipment for safe fermentation. By taking the time to properly prepare the ingredients and equipment, brewers can avoid common mistakes and ensure a high-quality brew. A well-prepared brew setup can make all the difference in the final product, and it all starts with the basics. Having the right ingredients and equipment can help brewers to achieve the desired flavor, aroma, and character in their beer. Furthermore, proper preparation can also help to prevent contamination and spoilage, which can ruin an entire batch of beer. In this article, we'll explore the importance of selecting the right yeast and fermentation vessel, and how it sets the stage for a successful brew. With the right yeast and fermentation vessel, brewers can create a healthy fermentation environment that promotes the growth of desirable flavors and aromas. By choosing the right yeast and fermentation vessel, brewers can take the first step towards creating a delicious and unique beer.

Selecting the Right Yeast and Fermentation Vessel

When it comes to selecting the right yeast and fermentation vessel for making hooch, there are several factors to consider. The type of yeast used can greatly impact the flavor and quality of the final product. There are two main types of yeast: ale yeast and champagne yeast. Ale yeast is best suited for fermenting at warmer temperatures and produces a fruitier, sweeter flavor, while champagne yeast is better suited for fermenting at cooler temperatures and produces a drier, crisper flavor. It's also important to choose a yeast that is specifically designed for the type of hooch being made, such as a yeast specifically designed for fermenting fruit or grains. In addition to selecting the right yeast, it's also important to choose a fermentation vessel that is suitable for the job. A food-grade plastic bucket or a glass carboy are good options, as they are easy to clean and sanitize. It's also important to ensure that the vessel is large enough to hold the entire batch of hooch, with enough headspace to allow for expansion during fermentation. A hydrometer is also a useful tool to have, as it allows you to measure the specific gravity of the hooch and track the progress of fermentation. By selecting the right yeast and fermentation vessel, you can ensure that your hooch turns out delicious and of high quality.

Preparing the Mash and Creating the Wort

Preparing the mash and creating the wort is a crucial step in the hooch-making process. To start, combine the milled grains and hot water in the mash tun, stirring gently to avoid compacting the grains. The ideal temperature for mashing is between 152°F and 158°F, which will help to extract the enzymes and sugars from the grains. Allow the mixture to sit for 60 minutes, or until the starches have been fully converted into fermentable sugars. Next, slowly drain the liquid from the mash tun into a large pot or kettle, being careful not to disturb the grain bed. This liquid is called the wort, and it will be the foundation of your hooch. To clarify the wort, you can add a small amount of hot water to the mash tun and stir gently, then drain the liquid again. This process is called sparging, and it will help to extract any remaining sugars from the grains. Once you have collected enough wort, bring it to a boil in the pot or kettle, then reduce the heat to a simmer and let it cook for 60-90 minutes. This will help to sterilize the wort and prepare it for fermentation. During this time, you can also add any additional ingredients, such as hops or flavorings, to the wort to give your hooch its unique character. By the end of this process, you should have a rich, flavorful wort that is ready to be fermented into delicious hooch.

Sanitizing and Sterilizing Equipment for Safe Fermentation

Sanitizing and sterilizing equipment is a crucial step in the fermentation process to ensure the production of safe and healthy hooch. Sanitizing involves reducing the number of microorganisms on the equipment to a safe level, while sterilizing involves eliminating all forms of microbial life. To sanitize equipment, a solution of water and sanitizer, such as bleach or Star San, is used to wipe down all surfaces that will come into contact with the ingredients. It's essential to follow the manufacturer's instructions for the recommended concentration and contact time to ensure effective sanitization. Sterilizing equipment, on the other hand, requires more extreme measures, such as autoclaving or using a UV sterilizer. Autoclaving involves subjecting the equipment to high temperatures and pressures to kill all microorganisms, while UV sterilizers use ultraviolet light to destroy microbial DNA. It's also important to sanitize and sterilize any ingredients that will be added to the fermentation vessel, such as yeast or flavorings, to prevent contamination. Regular sanitizing and sterilizing of equipment will help prevent the growth of unwanted microorganisms, such as bacteria and wild yeast, which can spoil the hooch and pose health risks to the consumer. By taking the time to properly sanitize and sterilize equipment, brewers can ensure a healthy and successful fermentation process, resulting in a delicious and safe final product.

Distilling and Aging the Hooch

Distilling and aging the hooch is an art that requires patience, skill, and attention to detail. To produce a high-quality spirit, one must carefully consider every step of the process, from setting up the distillation apparatus and process, to collecting and filtering the distillate, and finally, aging and blending the hooch for optimal flavor. Each of these steps plays a crucial role in determining the final product's character and quality. By understanding the intricacies of distillation and aging, one can unlock the secrets to creating a truly exceptional spirit. In this article, we will delve into the world of distilling and aging, starting with the foundation of the process: setting up the distillation apparatus and process.

Setting Up the Distillation Apparatus and Process

Setting up the distillation apparatus and process is a crucial step in making hooch. To begin, you'll need to assemble the distillation apparatus, which typically consists of a pot still, condenser, and collection vessel. The pot still is where the fermented mash is heated, causing the ethanol to vaporize and rise into the condenser. The condenser is a coiled tube that cools the vapor, causing it to condense back into a liquid. The collection vessel is where the distilled hooch is collected. Before starting the distillation process, make sure all connections are secure and the apparatus is properly vented to prevent pressure buildup. Next, heat the fermented mash in the pot still to a temperature of around 180°F to 190°F, which is the optimal range for ethanol vaporization. As the vapor rises into the condenser, it will start to condense and drip into the collection vessel. It's essential to monitor the temperature and adjust the heat as needed to maintain a consistent flow of vapor. The distillation process can take several hours, depending on the size of the batch and the efficiency of the apparatus. During this time, it's crucial to keep an eye on the temperature and the flow of vapor to ensure that the hooch is being distilled properly. By following these steps and paying close attention to the distillation process, you'll be able to produce a high-quality hooch that's ready for aging and enjoyment.

Collecting and Filtering the Distillate

Collecting and filtering the distillate is a crucial step in the hooch-making process. After the distillation process is complete, the distillate is collected in a separate container, usually a glass jar or a stainless steel container. It's essential to collect the distillate carefully to avoid contamination and ensure the quality of the final product. The distillate is typically cloudy and contains impurities, so it's necessary to filter it to remove any unwanted particles or sediment. There are several methods to filter the distillate, including using a coffee filter, a paper towel, or a cotton cloth. Some distillers also use activated carbon or charcoal to filter the distillate, which can help remove impurities and improve the flavor and aroma of the hooch. Once the distillate is filtered, it's ready to be aged, which is the next step in the hooch-making process. Aging the hooch allows the flavors to mature and blend together, resulting in a smoother and more refined final product. By collecting and filtering the distillate carefully, distillers can ensure that their hooch is of the highest quality and has a unique flavor and character.

Aging and Blending the Hooch for Optimal Flavor

Aging and blending the hooch is a crucial step in the distillation process, as it allows the flavors to mature and integrate, resulting in a smoother and more complex spirit. After distillation, the hooch is typically transferred to a secondary container, such as a glass carboy or oak barrel, where it is left to age for several months or even years. During this time, the hooch interacts with the container, absorbing flavors and aromas from the material, which can include vanilla, caramel, and oak notes. The aging process also allows the various compounds in the hooch to break down and recombine, resulting in a more balanced and refined flavor profile. Blending the hooch is also an important step, as it allows the distiller to combine different batches or styles of hooch to create a unique and consistent flavor profile. This can involve blending different ages, styles, or flavor profiles to create a complex and interesting spirit. For example, a distiller might blend a young, fruity hooch with an older, more mature hooch to create a balanced and refined spirit. Ultimately, the goal of aging and blending the hooch is to create a spirit that is smooth, complex, and full of character, with a flavor profile that is both unique and enjoyable.