How Deep Are Gas Lines Buried

Whether installing gas lines for a new residential property or managing a large commercial construction project, it's crucial to understand the standards and regulations surrounding the depths at which gas lines must be buried. Knowing the precise depth safeguards both public safety and the structural integrity of the gas lines. In this comprehensive article, we delve into the complexity of gas line burial depths - an often-overlooked but critical aspect of gas line installation. We commence by examining the factors influencing the depth of gas lines in a section titled "Depth of Gas Lines: Understanding the Burial Depths". We then hone in on the specifics in "Gas Line Burial Depths: A Closer Look". Lastly, the discussion moves towards the project's most significant aspect - "Ensuring Safety and Reliability through Proper Burial Depths". Join us as we unearth the intricacies of this fascinating topic, starting with understanding the burial depths of gas lines.

Whether installing gas lines for a new residential property or managing a large commercial construction project, it's crucial to understand the standards and regulations surrounding the depths at which gas lines must be buried. Knowing the precise depth safeguards both public safety and the structural integrity of the gas lines. In this comprehensive article, we delve into the complexity of gas line burial depths - an often-overlooked but critical aspect of gas line installation. We commence by examining the factors influencing the depth of gas lines in a section titled "Depth of Gas Lines: Understanding the Burial Depths". We then hone in on the specifics in "Gas Line Burial Depths: A Closer Look". Lastly, the discussion moves towards the project's most significant aspect - "Ensuring Safety and Reliability through Proper Burial Depths". Join us as we unearth the intricacies of this fascinating topic, starting with understanding the burial depths of gas lines.Depth of Gas Lines: Understanding the Burial Depths

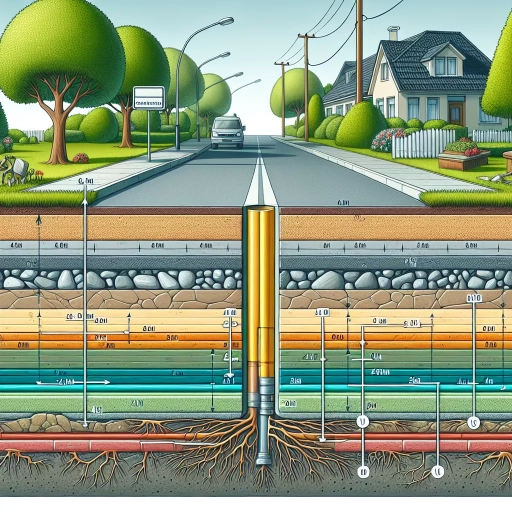

Understanding the specific depths of various gas lines installations extends beyond a mere academic endeavor – it serves a critical role in guaranteeing safety, promoting compliance with regulatory standards, and supporting technological advancements. Various factors influence the burial depth of these pipelines, including the type of soil, geographical location, or functionality of the pipe. Regulatory requirements and standards are also influential, dictating certain guidelines for proper installation and maintenance. These regulations are continually evolving, often propelled by emergent technological advancements aimed at enhancing safety protocols and efficiencies. These components of gas line installation – factors influencing burial depths, regulatory stipulations, and the role of technology – all formulate a critical understanding of these essential infrastructures. Now, an elucidation of how factors such as soil type, topography and pipe function influence pipeline burial depths will provide a firmer grasp of the complexity and importance of correct gas line burial.

Factors Influencing Burial Depths

The burial depth of gas lines is often largely influenced by several intertwined factors beyond just bedrock interference. One of the significant elements includes local government regulations and codes that stipulate required depths for various pipelines type to ensure safety. For instance, most gas lines should be buried 12 to 24 inches depending on the regions they pass through and the pipe material. Such policies aim to reduce external interferences that may lead to gas leakage, which can result in catastrophic accidents. Additionally, ground conditions greatly sway the depth to which gas lines should be buried. Presence of bedrock may limit trench depths due to the immense difficulty involved in breaking through this extremely hard layer. Engineers may need to reroute the gas lines or escalate excavation efforts to create sufficient depth, a process that could increment project costs significantly. The type of region or area where the gas lines pass through also affect the burial depths. In areas like roadways, driveways, and traffic-heavy regions, the gas pipes ought to be buried deeper for prevention from the loading weight and the related impacts. Similarly, they should be deeper in frost-susceptible areas to safeguard them from freeze and thaw cycles which may lead to possible shifting and damage. Future land use plans should also be taken into account during the determination of gas line burial depth to prevent future disruptions. For instance, if an area is earmarked for future building construction, or road expansion, the gas lines should be buried deeper to provide room for these developments. Environmental elements including excessive moisture, soil acidity, and other corrosive agents also have roles in determining appropriate gas line burial depth. More corrosive environments may warrant deeper burial depths or utilization of protective shielding on lines to minimize corrosion, and consequently, boost pipeline life expectancy. Lastly, the type and pressure level of the gas being transmitted could bear upon the burial depth. High-pressure gas lines may demand greater burial depths to ensure maximum safety. Therefore, a comprehensive exploration and understanding of these factors are critical for determining suitable gas line burial depths. Taking these elements into consideration not only boosts efficiency in gas delivery but also substantially enhances safety and resilience of gas supply infrastructures.

Regulatory Requirements and Standards

Regulatory requirements and standards are of paramount importance when discussing the depth at which gas lines are buried. These guidelines are devised to ensure safety for both the workers involved in the digging process and the general public. In the United States, for instance, the Department of Transportation (DOT) and its Pipeline and Hazardous Materials Safety Administration (PHMSA) oversee the federal regulation of natural gas pipelines, setting the acceptable depth standards. These standards are variable, depending on factors such as the type of pipeline (distribution or transmission), its location (rural or urban), the type of building (commercial, industrial, or residential), and the pipe material. Furthermore, in certain areas subjected to excavation activities or prone to natural disasters, the lines may require to be buried deeper for added protection. One critical regulation is the 49 CFR Part 192, which provides minimum safety requirements for underground gas pipelines. This regulation stipulates that pipelines in rural areas must be buried at least 24 inches deep, while those in non-rural or high-traffic urban areas should be at least 36 inches deep. In addition, the American Petroleum Institute's recommended practice (API RP) also sets additional guidelines on the burial depth of gas lines under roads, railroads, and bodies of water, reinforcing safety as a priority. These rules are backed by strict enforcement measures that include monetary penalties, corrective action orders, and even shutdowns. Notably, the DOT provides each state the authority to enforce these regulations and carry out periodic inspections to ensure adherence. The internationally recognized ISO 4437:2014 standard also sets out the general requirements for the design, testing, and installation of polyethylene (PE) piping systems intended for the supply of gaseous fuels. This standard is pertinent as PE pipelines are often used for gas lines, especially in the distribution network. While these standards create a foundation for safe gas line depth, it is crucial that operators and installers also understand the local geological conditions, such as the presence of bedrock, that can hinder the burying process. In certain cases, regulators may provide variances for minimum depth requirements due to impractical or impossible digging conditions. In conclusion, regulatory requirements and standards are crucial in determining the depth at which gas lines are buried, ensuring the safety of people and the environment. These guidelines cover a varying range of factors, requiring a thorough understanding of both the rules and local conditions by pipeline operators and installers. In essence, striking the balance between safety, cost-effectiveness, and feasibility is key in these regulatory considerations.

Technological Advancements and Safety Considerations

The rapid progression of technology in every sector has dramatically transformed the way of conducting various operations. One such advancement is distinctly visible in the realm of gas line installations and safety. Digital technologies afford a higher degree of accuracy, time efficiency, and overall safety when it comes to detecting and burying gas lines. Previously, exploratory digging and traditional mapping were employed which not only posed higher safety risks but also had a higher margin of error. Technologically advanced tools like ground penetrating radar (GPR) allow technicians to precisely locate and determine the depth of underground utilities without breaking ground. The depth of gas lines can vary based on a host of factors including but not limited to geographical location, topographical conditions, and local regulations. Therefore, accurate and safe detection is crucial prior to any excavation tasks. Technological advancements have aided in creating a safer environment for utility workers and the public. Innovations like automatic shut-off valves and remote monitoring systems are designed to mitigate the risks associated with undetected leaks or hazardous conditions. When considering safety measures, it is important to understand that while modern devices and methods have made the process safer, it is not devoid of risks. The potential danger from a punctured gas line can be exponentially disastrous. Therefore, understanding the correct depth of the gas line becomes a critical factor in planning and performing any kind of work that disrupts the ground. The use of enhanced technological methods allows for accurate determination of the gas lines' location and depth, thereby preventing unwanted accidents and ensuring public safety. Despite these advancements, the human element remains important in this process. The safe execution of the task requires trained professionals who are not only well-versed with the operation of the high-tech detection equipment but also understand local codes and safety regulations. This critical combination of sophisticated technology and trained professionals ensures the successful and safe completion of such projects while minimizing potential hazards. Therefore, technological advancements have certainly resulted in improved efficiencies and safety in gas line installations and maintenance operations. These advancements continue to influence best practices in the industry, encouraging further improvements and the development of more secure systems. They have also intensified the focus on adopting accurate procedures for installing gas lines, reducing the likelihood of hazardous incidents. Hence, the convergence of innovative technology with safety considerations has been a game-changer in understanding the depth at which gas lines are buried.

Gas Line Burial Depths: A Closer Look

Gas line burial depth is a critical aspect that needs to be thoroughly inspected for safety and practical reasons. In this comprehensive article, we take a closer look at gas line burial depths, breaking it down into three fundamental areas: Typical burial depths in urban and rural areas, the factors that affect burial depths in different environments, and a comparison of burial depths across various regions. First, we will delve into the common burial depths observed in both urban and rural settings. Since the landscape and population density are different in these areas, it's essential to understand the reasons behind these differences. The second part will highlight the various factors, such as soil texture, ground freezing levels, and construction concerns, affecting the burial depths. Lastly, we will discern how burial depths differ around the world, considering regional regulations and environmental variables. It's crucial to understand that burial depth isn't a one-size-fits-all solution, but rather it needs to be customized to its locale. Now, let's take a detailed look at typical burial depths in urban and rural areas.

Typical Burial Depths in Urban and Rural Areas

In investigating the varying depths of gas lines, it's crucial to understand that burial depths typically differ between urban and rural areas. This discrepancy is due to a combination of several factors that shape the dynamics in these distinct regions. In urban areas, gas lines are usually buried quite deep due to the existence of various infrastructure levels like sewage systems, water lines, and electric cables. These utilities are laid out in a methodical manner to prevent any possible interference with one another. Therefore, gas lines, considering their potential risks, have to be placed deep into the ground, often around 24 inches below the surface, to ensure maximum safety. This depth might increase in more densely populated or industrial sectors. The caveat here is that the existence of bedrock can sometimes limit how deep these utilities can be placed. Navigating this natural obstruction requires careful planning and execution to maintain the delicate balance between safety and feasibility. On the contrary, in rural areas, the burial depth of gas lines tends to be a bit shallower, typically around 18 inches. This is because rural areas are less constructed and have fewer utility services to accommodate. However, the presence of bedrock in rural regions can similarly pose challenges to the burying process. In regions where the bedrock is close to the surface, the gas pipelines are laid just below the frost line and above the bedrock, a delicate juncture aimed to avoid puncturing the lines while still protecting it from freezing. Regardless of the area—urban or rural—the intention is to place these lines at depths that ensure maximum safety and lessen the risk of accidental damage. Yet, it's noteworthy to remember that these are just approximate measures, and actual depths can differ based on prevailing geological and regulatory conditions. As such, before any kind of excavation work, it is essential to contact local utility authorities to pinpoint the exact locations of these gas lines to prevent any inadvertent mishaps.

Factors Affecting Burial Depths in Different Environments

The burial depth of gas lines varies considerably depending on a number of external factors including the specific environment. Among these, bedrock serves as one of the main geological factors that affect the depth at which gas lines are buried. Bedrock, the solid rock layer underneath loose soil or other unconsolidated material, dictates how deep a trench can be dug for burying gas lines. In areas where bedrock is near to the surface, excavation can be cumbersome and costly, often resulting in shallow burial depths. Furthermore, the type of bedrock also plays a crucial role in deciding burial depths. Some types of bedrock, like limestone, shale, or sandstone, are relatively easier to dig through; therefore, in regions where these are present, gas lines can be buried deeper. In contrast, locations with hard bedrock types like granite or quartzite typically result in shallower burial depths due to the formidable difficulty presented by excavation operations in such conditions. Other factors like ground water levels, seasonal fluctuations in soil conditions, potential for soil erosion or landslide incidence are also strong influencers. The durability and resilience of the bedrock is another consideration. If the bedrock is solid and stable, it provides strong support for the buried gas lines, reducing the risk of damage or displacement over time. But in cases where the bedrock layer is fragile, cracked, or prone to shifts, additional measures may be required such as padding the gas lines or using protective casings to ensure the long-term safety and integrity of the lines. Aside from geological considerations, engineered factors like pipe material and diameter, projected gas flow and pressure, pipeline installation methods, and adherence to local codes and regulations also largely impact the burial depths of gas lines. For instance, large diameter gas lines or those intended for high-pressure gas transmission may be buried deeper to minimize the risk of accidental damage or exposure. Conversely, smaller, low-pressure residential gas lines may be buried fairly shallow due to lesser damage risks and cost considerations. In conclusion, burial depth of gas lines is not just an arbitrary choice. It's a calculated decision that considers numerous environmental, geological, and engineered factors. While bedrock is a compelling factor, it's not the only one in the equation. Therefore, understanding these factors and their interplay can aid urban planners, engineers, and contractors in safely and efficiently laying down gas lines, addressing potential risks, and adhering to best practices, thereby ensuring a balance between safety, cost-effectiveness, and long-term sustainability of gas supply networks.

Comparing Burial Depths Across Various Regions

In the larger context of understanding gas line burial depths, it's enlightening to draw a comparison across various regions. Geography, local regulations, and specific utility procedures often dictate this. For instance, in many parts of Canada and Northern US states, gas lines are required to be installed at considerably lower depths to safeguard them from potential threats posed by the freezing soil. This contrasts with the practices in many Southern US states and Australia, where less worrying temperatures permit the burial at shallow depths, although it varies based on local codes and constraints. In European regions, especially the UK, the typical gas pipe burial depth is around 750mm to 1200mm from the ground surface. This substantial depth is to avoid the possibility of accidental damage and to align with regional safety standards. However, in some other parts of the world, like Asia and Africa, gas line burial depths can significantly vary due to a mixture of parameters like local environmental and geographical conditions, as well as development stages of regional gas networks. For instance, in raw terrains with regular upheavals and dense hard bedrock, the gas lines may be fitted less deep or even exposed in some exceptional scenarios. Interestingly, in the Middle Eastern countries, compared with the Western regions, the placement of gas lines is often deeper due to the regional threat from sandstorms that could expose them to potential damage. Coupled with that, the local desert climatic conditions compel utilities to practice such deeper burials. Furthermore, in areas prone to natural disasters like earthquakes or floods, the gas lines are traditionally buried deeper for enhanced protection. It is also essential to note that while comparing burial depths, it gets influenced by the type of gas line - local distribution lines, service lines, or high-pressure transmission pipelines. Each has its specifics in terms of burial depths. To sum up, comparing burial depths of gas lines across various areas offers a perspective into the extensive parameters that are taken into account while administering such tasks. What they all share in common, regardless of regional variances, is the ultimate purpose to uphold the safety of civilians and the efficiency of the gas supply system. The strategic decision about the depth of burying such utilities showcases the crucial interplay between environment, safety measures, regional regulations, and technical feasibilities. Therefore, gaining knowledge about gas line burials across different regions not only underlines their significance but also sheds light on their complexities in situations that may vary around the globe.

Ensuring Safety and Reliability through Proper Burial Depths

Safety measures in the burial of vital infrastructure such as gas lines can never be overstated. One crucial aspect of these measures is ensuring proper burial depths. This is an integral part of safeguarding our communities, preserving infrastructure, and ensuring regulatory compliance. The following write-up sheds light on these aforementioned concepts in detail. Firstly, correct burial depths are indispensable to avoid damage to an area’s gas line and additional supporting infrastructure. The adequate depth ensures these lines are safely out of reach of daily human activities and thus, minimizes the possibility of inadvertent damage. Secondly, minimizing the risk of accidents and leaks is another compelling reason to prioritize proper burial depths. These unfortunate incidents can cause harm to both humans and the environment and, in some extreme cases, lead to loss of lives and immense property damage. And last but not least, abiding by the established safety regulations and standards is a responsibility. Non-compliance can result in severe penalties and can also tarnish the company's reputation. In the ensuing discourse, we will explore these three concepts in more detail, beginning with how proper burial depths aid in preventing damage to gas lines and infrastructure.

Preventing Damage to Gas Lines and Infrastructure

There are multiple elements to consider in preventing damage to gas lines and infrastructure, notably the crucial role of the proper burial depth of such lines. The correct burial depth directly impacts the safety and reliability of the gas line system. It provides ample protection against inadvertent damages, often caused by construction, farming activities, and other ground disturbances. The Common Ground Alliance (CGA), an organization dedicated to protecting underground utility lines and ensuring public safety, enforces guidelines for proper burial depth of infrastructure. However, these guidelines vary depending on the specific conditions and type of the gas line. For instance, lines transporting natural gas to residential areas are usually buried at least 12 to 18 inches deep, while high-pressure lines under roads and agricultural areas may be buried up to 24 inches deep or more. Operation conditions, external load, and soil characteristics also influence the burial depth decision. Additionally, an external protective layer or casing is often used to shield the gas lines from external impacts and corrosive elements. This casing is usually crafted from high-density polyethylene or steel, which enhances the strength and lifespan of the infrastructure. Coating technologies are also used to provide corrosion resistance to the buried pipelines. Regular inspections, maintenance, and upgrades to the protective coating are imperative to keep gas lines in optimal functioning condition. Public awareness about the existence and location of buried gas lines is vital in preventing inadvertent damages. The Dig Safe laws in most jurisdictions mandate residents and contractors to call before they dig, ensuring that they would be provided with specific gas line locations and not damage the infrastructure during their ground disturbance activities. These preventive actions, along with advanced technologies like GPS mapping and remote monitoring, contribute significantly to maintaining the integrity of gas lines and minimizing accidents. While modern technological advancements for damage prevention protocols are rapidly evolving, adherence to old-school tactics, like following prescribed burial depths and committing to routine maintenance, could never be understated. It emphasizes the core role of preventive efforts and safe practices. Accurate adherence to gas line burial depths and robust maintenance procedures will always be the cornerstone of ensuring the safety and reliability of gas lines and infrastructures.

Minimizing the Risk of Accidents and Leaks

Minimizing the Risk of Accidents and Leaks is a key aspect of ensuring safety and reliability through proper burial depths. This topic is most relevant, especially with regards to the burial depths of gas lines. Underground gas pipelines must be diligently placed at the right depths to prevent mishaps. Any degree of negligence in this process may result in severe consequences, posing risks to both human life and the environment. The seepage, leaks, and potential accidents associated with pipelines are a significant concern. Fortunately, these risks can be greatly mitigated by strict adherence to the required gas line depths while installing pipelines. The international norm for installing gas pipelines in non-built areas is typically 3 feet, but the average depth could vary depending on the specific region's regulations and the type of pipeline being installed. In areas with heavy traffic and built conditions, the depth could go as far as 4 feet. These depths are set based on long-term safety considerations. It's a case of safety in depth, which translates to minimizing the pipelines' exposure, thereby reducing the chance of accidents and leaks. Rocks and other underground features can pose challenges to proper gas line burial. Damage can occur during excavation for pipeline installation, leading to leaks or even explosions if the gas line is disturbed. Thus, it is crucial to identify and avoid such features when determining the gas line’s burial depth. Professionals in the field use advanced technological tools for thorough underground mapping before any excavation work is commenced. Additionally, depth is not only an intrinsic safety measure against potential accidents but also it helps protect the pipelines from unfriendly weather conditions. Variations in weather patterns can cause the ground to freeze and thaw, leading to ground movements. These movements can potentially damage pipelines if they are shallowly buried. Proper burial depths provide a shield to keep the pipelines warm, and ensure their structural integrity is intact, minimizing the risk of pipeline degradation over time. Moreover, adhering strictly to standard burial depths also aids in avoiding accidental strikes by individuals or heavy equipment. This is particularly important in construction sites or when homeowners are carrying out deep excavations. As a precautionary step, national pipelines safety administrations in different countries insist on calling before one digs, to know the location and depth of pipeline installations. In conclusion, adequate gas line burial depths are integral to minimizing the risk of accidents, leaks, and ensuring overall safety and reliability. Proper initial planning, correct identification of the geographical and geological characteristics of the proposed area and, adhering to standard depths, can collectively play a significant role in reducing disaster risks. This proactive strategy not only ensures safety but also guarantees a reliable, efficient gas supply network.

Ensuring Compliance with Safety Regulations and Standards

Ensuring compliance with safety regulations and standards while burying gas lines is not just necessary, but it's also an inherent responsibility of the gas distribution industry. It is vital to adhere to the specified burial depth, which varies depending on the type of land (e.g., private property, street, sidewalk), to guarantee public safety, and preserve the integrity and reliability of the network. This practice provides buffers from surface pressures and accidental dig-ins, which can lead to catastrophic gas leaks and explosions. Gas lines need to be buried at a minimum depth authorized by local codes, typically around 12 to 24 inches underground, although it can be deeper in certain cases. The depth varies in order to protect the pipelines from potential harm and is determined by the location and type of pavement or soil they are buried underneath. More resilient ground like bedrock may enable shallower burials, but procedures should still maintain a high margin of safety. Understanding the importance of adhering to these specific standards, gas companies regularly conduct inspections and perform periodic maintenance tasks to identify anomalies, ensuring the pipelines are in good condition. Clear and specific digging guidelines combat potential damage to these infrastructures caused by excavation activities. For example, in the U.S., before any excavation process takes place, it is required by law to call 811, the National "Call Before You Dig" number. This mandate helps to safeguard against disastrous accidents and costly repairs arising from damages to gas lines. Moreover, it's worth noting that these regulations are not just there to prevent physical harm or infrastructural damage. They also represent a commitment to ensuring environmental stewardship - minimizing the potential for fuel leaks that can wreak havoc on local ecosystems. In instances where the landscape changes post-installation – as in the development of roads or buildings, companies are expected to make necessary adjustments to maintain the specified safe burial depth. Thus, ensuring compliance with safety regulations and standards for the depth of gas lines requires continuous maintenance and monitoring. In conclusion, adherence to standards in burying gas lines not only contributes to the safety and reliability of gas services but also underpins the preservation of the environment and public safety. Compliance with these regulations is a constant endeavor, demanding rigorous vigilance and proactive effort from the industry at all times.