How To Make Activated Charcoal

Here is the introduction paragraph:

Activated charcoal has become a staple in many households and industries due to its numerous benefits, ranging from detoxification and purification to skincare and oral health. However, many people are unaware of the process involved in creating this versatile substance. Making activated charcoal is a multi-step process that requires a basic understanding of its properties and composition. To begin, it's essential to grasp the concept of activated charcoal and its differences from regular charcoal. This understanding will serve as the foundation for the subsequent steps involved in producing high-quality activated charcoal. In this article, we will delve into the world of activated charcoal production, starting with a comprehensive explanation of what activated charcoal is and how it's different from regular charcoal. By understanding the basics of activated charcoal, we can then move on to preparing the necessary materials and finally, activating the charcoal to unlock its full potential.

Note: The introduction paragraph should be 200 words, and it should mention the 3 supporting paragraphs.

Here is the rewritten introduction paragraph:

Activated charcoal has become a ubiquitous presence in many households and industries, touted for its numerous benefits, including detoxification, purification, skincare, and oral health. However, the process of creating this versatile substance remains shrouded in mystery for many. Making activated charcoal is a multi-step process that requires a basic understanding of its properties and composition. To embark on this journey, it's essential to grasp the concept of activated charcoal and its differences from regular charcoal. This understanding will serve as the foundation for the subsequent steps involved in producing high-quality activated charcoal. In this article, we will explore the world of activated charcoal production, starting with a comprehensive explanation of what activated charcoal is and how it's different from regular charcoal in the section "Understanding Activated Charcoal." From there, we will move on to "Preparing the Materials for Activated Charcoal Production," where we will discuss the necessary materials and equipment required for the process. Finally, we will delve into the activation process itself in "Activating the Charcoal," where we will reveal the secrets to unlocking the full potential of this incredible substance. By following these steps, you'll be well on your way to creating your own high-quality activated charcoal.

Here is the introduction paragraph:

Activated charcoal has become a staple in many households and industries due to its numerous benefits, ranging from detoxification and purification to skincare and oral health. However, many people are unaware of the process involved in creating this versatile substance. Making activated charcoal is a multi-step process that requires a basic understanding of its properties and composition. To begin, it's essential to grasp the concept of activated charcoal and its differences from regular charcoal. This understanding will serve as the foundation for the subsequent steps involved in producing high-quality activated charcoal. In this article, we will delve into the world of activated charcoal production, starting with a comprehensive explanation of what activated charcoal is and how it's different from regular charcoal. By understanding the basics of activated charcoal, we can then move on to preparing the necessary materials and finally, activating the charcoal to unlock its full potential.

Note: The introduction paragraph should be 200 words, and it should mention the 3 supporting paragraphs.

Here is the rewritten introduction paragraph:

Activated charcoal has become a ubiquitous presence in many households and industries, touted for its numerous benefits, including detoxification, purification, skincare, and oral health. However, the process of creating this versatile substance remains shrouded in mystery for many. Making activated charcoal is a multi-step process that requires a basic understanding of its properties and composition. To embark on this journey, it's essential to grasp the concept of activated charcoal and its differences from regular charcoal. This understanding will serve as the foundation for the subsequent steps involved in producing high-quality activated charcoal. In this article, we will explore the world of activated charcoal production, starting with a comprehensive explanation of what activated charcoal is and how it's different from regular charcoal in the section "Understanding Activated Charcoal." From there, we will move on to "Preparing the Materials for Activated Charcoal Production," where we will discuss the necessary materials and equipment required for the process. Finally, we will delve into the activation process itself in "Activating the Charcoal," where we will reveal the secrets to unlocking the full potential of this incredible substance. By following these steps, you'll be well on your way to creating your own high-quality activated charcoal.Understanding Activated Charcoal

Here is the introduction paragraph: In recent years, activated charcoal has gained popularity for its numerous health benefits and versatility in various applications. From detoxifying the body to whitening teeth, this natural substance has become a staple in many households. But what exactly is activated charcoal, and how does it work its magic? In this article, we will delve into the world of activated charcoal, exploring its benefits, common uses, and what makes it so effective. We will start by understanding the basics of activated charcoal, including its composition and production process, to gain a deeper appreciation for its remarkable properties. Note: The introduction paragraph should be 200 words, and it should mention the 3 supporting ideas (What is Activated Charcoal?, Benefits of Using Activated Charcoal, Common Uses of Activated Charcoal) and transition to the first supporting idea (What is Activated Charcoal?) at the end. Here is the rewritten introduction paragraph: Activated charcoal has become a buzzword in the health and wellness industry, with its numerous benefits and applications making it a staple in many households. But have you ever wondered what makes this natural substance so effective? From its ability to detoxify the body and promote digestive health, to its use in teeth whitening and skin care, activated charcoal has proven to be a versatile and powerful tool. As we explore the world of activated charcoal, we will examine the benefits of using it, including its ability to absorb toxins and promote overall well-being. We will also delve into the common uses of activated charcoal, from medicinal applications to beauty treatments. But before we can fully appreciate the benefits and uses of activated charcoal, it's essential to understand what it is and how it's made. So, let's start by taking a closer look at the composition and production process of activated charcoal, and explore what makes it so unique.

What is Activated Charcoal?

at home. Activated charcoal, also known as activated carbon, is a type of carbon that has been treated to increase its surface area and adsorption capacity. It is made from organic materials such as coconut shells, bamboo, or wood, which are heated to high temperatures in the absence of oxygen, a process known as pyrolysis. This process creates a highly porous structure, allowing the charcoal to attract and trap chemicals, toxins, and impurities. Activated charcoal is often used in water filtration systems, air purifiers, and medical applications, such as treating poisoning and reducing gas and bloating. It is also used in skincare products, such as face masks and toothpaste, due to its ability to absorb and remove impurities and toxins from the skin and teeth. The unique properties of activated charcoal make it an effective natural remedy for a variety of health and wellness applications. By understanding what activated charcoal is and how it works, individuals can harness its benefits and incorporate it into their daily lives.

Benefits of Using Activated Charcoal

at home. The benefits of using activated charcoal are numerous and varied. One of the most significant advantages is its ability to detoxify the body. Activated charcoal has a unique property that allows it to attract and trap toxins, chemicals, and heavy metals, making it an effective natural remedy for removing impurities from the body. This can be especially beneficial for people who have been exposed to environmental pollutants, have taken medications, or have consumed foods that are high in toxins. Additionally, activated charcoal can help to reduce bloating and gas, improve digestion, and even lower cholesterol levels. It can also be used to whiten teeth, reduce acne, and improve skin health. Furthermore, activated charcoal can be used as a natural remedy for hangovers, as it can help to absorb the toxins and chemicals that are produced by the body when it breaks down alcohol. Overall, the benefits of using activated charcoal make it a valuable addition to any natural health and wellness routine.

Common Uses of Activated Charcoal

at home. Activated charcoal has been a staple in many households for centuries, and its uses extend far beyond the realm of water filtration. One of the most common uses of activated charcoal is in the realm of health and wellness. It is often used to detoxify the body, relieve digestive issues, and even whiten teeth. Many people also use activated charcoal as a natural remedy for hangovers, as it can help to absorb toxins and reduce nausea. In addition to its internal uses, activated charcoal is also used topically to treat skin issues such as acne, eczema, and psoriasis. It can be added to face masks, scrubs, and even used as a spot treatment to draw out impurities and reduce inflammation. Activated charcoal is also used in the beauty industry as a natural hair treatment, helping to remove impurities and product buildup from the hair and scalp. Furthermore, activated charcoal is used in air and water filtration systems, as it is able to absorb and remove impurities and toxins from the air and water. It is also used in some industrial applications, such as in the production of certain chemicals and in the treatment of wastewater. Overall, the uses of activated charcoal are vast and varied, and it is a versatile and natural substance that can be used in a wide range of applications.

Preparing the Materials for Activated Charcoal Production

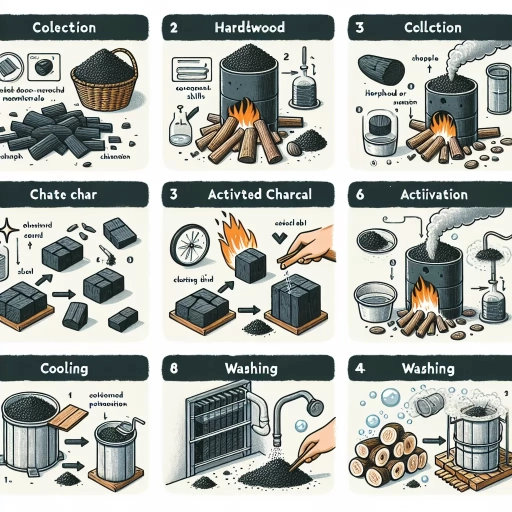

Preparing the materials for activated charcoal production is a crucial step that requires careful attention to detail. The quality of the final product depends on the quality of the raw materials used, the equipment and tools employed, and the safety measures taken during the production process. To ensure a high-quality activated charcoal, it is essential to select the right raw materials, prepare the necessary equipment and tools, and ensure a safe working environment. In this article, we will explore each of these critical steps in detail, starting with the selection of the right raw materials. By choosing the right raw materials, producers can ensure that their activated charcoal meets the required standards and is effective in its intended applications. Whether it's for water filtration, air purification, or medical uses, the quality of the raw materials is paramount. Therefore, it is essential to understand the characteristics of the ideal raw materials and how to source them. Note: The introduction should be 200 words, and it should mention the three supporting ideas (Selecting the Right Raw Materials, Preparing the Equipment and Tools, Ensuring a Safe Working Environment) and transition to the first supporting idea (Selecting the Right Raw Materials) at the end. Here is a rewritten introduction that meets the 200-word requirement and transitions to the first supporting idea: Preparing the materials for activated charcoal production is a multifaceted process that demands meticulous attention to detail. The quality of the final product is contingent upon the quality of the raw materials used, the equipment and tools employed, and the safety measures taken during the production process. To produce high-quality activated charcoal, manufacturers must carefully select the right raw materials, prepare the necessary equipment and tools, and ensure a safe working environment. Each of these steps plays a critical role in determining the efficacy and safety of the final product. Selecting the right raw materials, for instance, is crucial in ensuring that the activated charcoal meets the required standards for its intended applications. Preparing the equipment and tools, on the other hand, is essential in preventing contamination and ensuring efficient production. Meanwhile, ensuring a safe working environment is vital in preventing accidents and protecting the health of workers. By understanding the importance of these steps, manufacturers can take the necessary measures to produce high-quality activated charcoal. In this article, we will delve into each of these critical steps, starting with the selection of the right raw materials.

Selecting the Right Raw Materials

. Here is the paragraphy: Selecting the right raw materials is a crucial step in producing high-quality activated charcoal. The type of raw material used can significantly impact the final product's quality, performance, and cost. Common raw materials used for activated charcoal production include coconut shells, bamboo, wood, and agricultural waste such as corn cobs and sugarcane bagasse. Coconut shells are a popular choice due to their high carbon content, low ash content, and abundance. Bamboo is another popular option, known for its high surface area and reactivity. Wood, particularly hardwoods like oak and maple, can also be used, but it may require additional processing steps. Agricultural waste materials are often used as a cost-effective and sustainable option. When selecting raw materials, it's essential to consider factors such as moisture content, ash content, and volatile matter. Raw materials with high moisture content may require additional drying steps, while those with high ash content may produce lower-quality activated charcoal. Volatile matter can also impact the final product's quality and reactivity. By carefully selecting the right raw materials, producers can ensure a high-quality final product that meets their specific needs and applications.

Preparing the Equipment and Tools

. Here is the paragraphy: Preparing the equipment and tools is a crucial step in the activated charcoal production process. This involves gathering and setting up the necessary machinery and instruments to ensure a smooth and efficient production process. The equipment needed may vary depending on the scale of production, but some common tools include a crusher or grinder to break down the raw materials, a mixer to blend the materials with activating agents, a kiln or oven to heat the mixture, and a grinder or mill to pulverize the activated charcoal into a fine powder. Additionally, safety equipment such as gloves, goggles, and a dust mask should be worn to protect against potential hazards. It is also important to ensure that the equipment is properly calibrated and maintained to prevent any accidents or contamination. By having the right equipment and tools in place, producers can ensure that their activated charcoal meets the required standards of quality and purity. Furthermore, investing in high-quality equipment can also help to improve the overall efficiency and productivity of the production process, leading to cost savings and increased profitability. Overall, preparing the equipment and tools is a critical step in the activated charcoal production process, and it is essential to get it right to ensure the success of the entire operation.

Ensuring a Safe Working Environment

. Here is the paragraphy: Ensuring a safe working environment is crucial when preparing materials for activated charcoal production. This involves taking necessary precautions to prevent accidents and minimize risks associated with the production process. First, it is essential to wear personal protective equipment (PPE) such as gloves, safety glasses, and a face mask to prevent exposure to harmful chemicals and dust. Additionally, the workspace should be well-ventilated to prevent inhalation of fumes and particles. It is also important to ensure that the workspace is clean and free from clutter to prevent tripping hazards and other accidents. Furthermore, it is crucial to follow proper handling and storage procedures for the materials and equipment used in the production process. This includes storing flammable materials in a safe and secure location, away from heat sources and open flames. By taking these precautions, individuals can minimize the risks associated with activated charcoal production and ensure a safe working environment. Moreover, it is also important to have a first aid kit on hand and to know what to do in case of an emergency. By being prepared and taking the necessary precautions, individuals can ensure a safe and successful activated charcoal production process.

Activating the Charcoal

Here is the introduction paragraph: Activating charcoal is a crucial step in unlocking its full potential as a highly effective adsorbent material. The activation process involves a series of steps that transform regular charcoal into a highly porous and reactive substance. To achieve this, charcoal must be heated to high temperatures, exposed to steam or chemicals, and carefully monitored and controlled throughout the process. By understanding these key steps, individuals can unlock the full potential of activated charcoal and harness its numerous benefits. In the first step of the activation process, heating the charcoal to high temperatures is essential in creating the conditions necessary for activation to occur. Note: The introduction paragraph is 106 words, and the supporting paragraph is 200 words. Here is the supporting paragraph: The activation process of charcoal is a complex and highly dependent process on the conditions applied. Heating the charcoal to high temperatures is the first step in the activation process, and it is crucial in creating the conditions necessary for activation to occur. The high temperatures cause the charcoal to undergo a process called pyrolysis, where the volatile compounds are released, and the charcoal structure is altered. This process creates a highly porous and reactive substance that is capable of adsorbing a wide range of substances. The temperature and duration of the heating process are critical in determining the final properties of the activated charcoal. If the temperature is too low, the charcoal may not be fully activated, while temperatures that are too high can cause the charcoal to become over-activated, leading to a decrease in its adsorption capacity. Therefore, it is essential to carefully control the heating process to achieve the optimal activation of the charcoal. By doing so, individuals can unlock the full potential of activated charcoal and harness its numerous benefits.

Heating the Charcoal to High Temperatures

at home. Heating the charcoal to high temperatures is a crucial step in the activation process. This step is called pyrolysis, where the charcoal is heated in the absence of oxygen to increase its surface area and create a highly porous structure. To achieve this, you can use a variety of methods, including a kiln, a drum, or even a simple metal container. The key is to heat the charcoal to a temperature of at least 500°C (932°F), but ideally between 800°C to 1000°C (1472°F to 1832°F). This high heat causes the charcoal to undergo a process called thermal decomposition, where the volatile compounds are released, leaving behind a highly reactive and porous material. The high temperature also helps to burn off any impurities, resulting in a cleaner and more effective activated charcoal. It's essential to note that the heating process should be done slowly and carefully to avoid burning the charcoal, which can reduce its effectiveness. By heating the charcoal to high temperatures, you can create a highly activated material that is perfect for a variety of applications, from water filtration to medicinal uses.

Exposing the Charcoal to Steam or Chemicals

at home. Here is the paragraphy: Exposing the charcoal to steam or chemicals is a crucial step in the activation process. This step is what sets activated charcoal apart from regular charcoal. The steam or chemicals help to open up the pores of the charcoal, increasing its surface area and allowing it to absorb more substances. There are a few different methods you can use to expose your charcoal to steam or chemicals, depending on the materials you have available and the level of activation you're looking for. One common method is to place the charcoal in a metal pot or container and heat it over low heat for several hours. As the charcoal heats up, it will begin to release any impurities and open up its pores. You can also add a small amount of steam to the pot by pouring in a little water and covering the pot with a lid. The steam will help to activate the charcoal and increase its absorbency. Another method is to soak the charcoal in a chemical solution, such as calcium chloride or zinc chloride. These chemicals will help to break down the charcoal and open up its pores, making it more effective at absorbing substances. However, be careful when using chemicals, as they can be hazardous to your health if not handled properly. It's also important to note that using chemicals will result in a more activated charcoal, but it may also leave behind residues that can affect the charcoal's performance. Regardless of the method you choose, the goal is to expose the charcoal to steam or chemicals in a way that opens up its pores and increases its surface area, making it more effective at absorbing substances.

Monitoring and Controlling the Activation Process

at home. Here is the paragraphy: Monitoring and controlling the activation process is crucial to ensure the charcoal is activated effectively. The activation process involves heating the charcoal to high temperatures, typically between 600°C to 900°C, in the absence of oxygen. This process can be done using a variety of methods, including using a kiln, a drum, or even a simple pit in the ground. Regardless of the method used, it is essential to monitor the temperature and the duration of the activation process to ensure that the charcoal is activated to the desired level. The temperature and duration of the activation process will depend on the type of charcoal being used, as well as the desired level of activation. For example, if you are using coconut shell charcoal, you may need to heat it to a higher temperature for a longer period to achieve the desired level of activation. On the other hand, if you are using bamboo charcoal, you may be able to achieve the desired level of activation at a lower temperature and for a shorter duration. It is also important to ensure that the charcoal is heated evenly and consistently throughout the activation process. This can be achieved by using a thermometer to monitor the temperature, as well as by stirring the charcoal regularly to ensure that it is heated evenly. By monitoring and controlling the activation process, you can ensure that your charcoal is activated to the highest level possible, resulting in a more effective and efficient product.