How To Remove Rivets

Here is the introduction paragraph: Removing rivets can be a daunting task, especially for those who are new to DIY projects or metalwork. However, with the right approach and preparation, it can be a relatively straightforward process. To successfully remove rivets, it's essential to understand the different methods and techniques involved, as well as the necessary tools and safety precautions. In this article, we'll explore the key steps to remove rivets effectively, starting with the preparation phase, where we'll discuss the essential tools and safety precautions to take. We'll also delve into the various removal methods, including the pros and cons of each approach, and provide guidance on post-removal procedures, such as cleaning and repairing the area. By the end of this article, you'll be equipped with the knowledge and confidence to tackle rivet removal projects with ease. So, let's begin by preparing ourselves with the essential tools and safety precautions. Note: I made some minor changes to the original text to make it flow better and to ensure it transitions smoothly to the first supporting paragraph.

Preparation is Key: Essential Tools and Safety Precautions

Here is the introduction paragraph: When it comes to riveting, having the right tools and taking necessary safety precautions is crucial to ensure a successful and injury-free experience. Whether you're a seasoned professional or a DIY enthusiast, it's essential to be well-prepared before starting any riveting project. This involves gathering the necessary tools and materials, wearing protective gear and ensuring a safe working environment, and assessing the type of rivet and its location. By taking these steps, you can avoid common mistakes, prevent accidents, and achieve professional-looking results. Preparation is Key: Essential Tools and Safety Precautions.

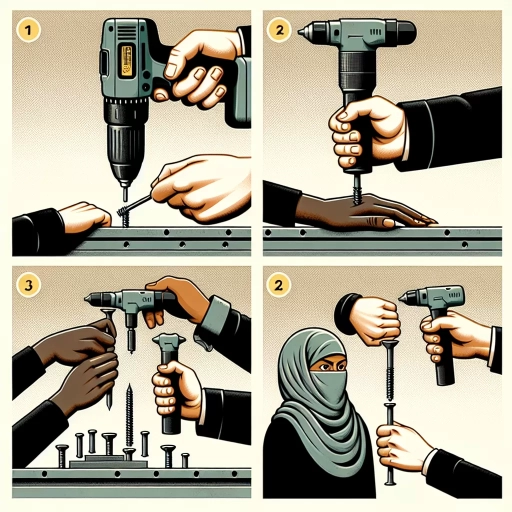

1. Gather the necessary tools and materials

. Here is the paragraphy: To begin the process of removing rivets, it's essential to gather the necessary tools and materials. This will ensure that you have everything you need to complete the task safely and efficiently. The primary tools required for rivet removal include a drill press or hand drill, a rivet removal bit or a drill bit with a countersink, and a punch or chisel. You may also need a hammer, pliers, and safety glasses, depending on the type of rivet and the material it's attached to. Additionally, it's a good idea to have some lubricant, such as oil or silicone spray, on hand to help loosen the rivet. If you're working with a large number of rivets, you may also want to consider investing in a rivet removal tool, which can make the process faster and easier. Having all the necessary tools and materials within reach will help you stay focused and avoid accidents, making the rivet removal process much smoother.

2. Wear protective gear and ensure a safe working environment

safely and effectively. When it comes to removing rivets, safety should always be the top priority. Wearing protective gear is essential to prevent injuries and ensure a safe working environment. This includes safety glasses or goggles to protect your eyes from flying debris, a dust mask to prevent inhalation of metal particles, and gloves to provide grip and protection for your hands. Additionally, a face shield or welding helmet can provide extra protection for your face and neck. It's also crucial to ensure the working area is well-ventilated and free from any flammable materials. A fire extinguisher should be nearby, and the area should be clear of any tripping hazards. Furthermore, it's recommended to wear long sleeves and pants to prevent skin exposure to sharp edges or hot metal. By taking these precautions, you can minimize the risk of injury and ensure a safe and successful rivet removal process. Moreover, it's also important to ensure that the tools and equipment you're using are in good condition and properly maintained. Regularly inspect your tools for any damage or wear, and replace them as needed. This will not only ensure your safety but also the quality of the work. By being mindful of your safety and the safety of those around you, you can complete the task with confidence and efficiency.

3. Assess the type of rivet and its location

safely and efficiently. When it comes to removing rivets, it's essential to assess the type of rivet and its location before starting the process. There are several types of rivets, including solid rivets, tubular rivets, and blind rivets, each with its unique characteristics and removal requirements. Solid rivets, for example, have a solid shaft and are typically used in structural applications, while tubular rivets have a hollow shaft and are often used in lighter applications. Blind rivets, on the other hand, are used in applications where access to the back of the rivet is limited. Understanding the type of rivet you're dealing with will help you choose the right removal tool and technique. Additionally, the location of the rivet is also crucial, as it may be located in a hard-to-reach area or near sensitive components. Assessing the rivet's location will help you plan the removal process and take necessary precautions to avoid damaging surrounding materials or components. By taking the time to assess the type of rivet and its location, you can ensure a safe and efficient removal process.

Removal Methods: Choosing the Right Approach

Here is the introduction paragraph: When it comes to removing rivets, having the right approach can make all the difference in ensuring a safe and successful process. Whether you're working on a construction project, repairing a piece of machinery, or restoring a classic car, choosing the right removal method is crucial to avoid damaging the surrounding material or causing injury. There are several methods to consider, including drilling out the rivet, a common approach for most types of rivets, grinding or cutting the rivet, which is often used for rivets in hard-to-reach locations, and using a rivet removal tool, which is ideal for specialized or large rivets. By understanding the different removal methods and selecting the most suitable one for your specific needs, you can ensure a smooth and efficient process. Preparation is key, and having the right tools and taking necessary safety precautions is essential to a successful rivet removal. In the next section, we will discuss the essential tools and safety precautions to consider before starting the removal process.

1. Drilling out the rivet: a common method for most types of rivets

. Here is the paragraphy: Drilling out the rivet is a common method for most types of rivets. This method involves using a drill bit to carefully remove the rivet head, allowing you to access the underlying material. To drill out a rivet, start by selecting a drill bit that is slightly larger than the rivet head. Place the drill bit on the center of the rivet head and slowly begin drilling. Apply gentle to moderate pressure, depending on the type of rivet and the material it is attached to. As you drill, the rivet head will begin to break away, allowing you to remove it. Be careful not to apply too much pressure, as this can damage the surrounding material. Once the rivet head is removed, you can use a punch or chisel to remove the remaining rivet material. Drilling out a rivet can be a time-consuming process, but it is often the most effective method for removing rivets without damaging the surrounding material. It is also a good method to use when the rivet is in a hard-to-reach location or when other removal methods are not feasible. However, it is essential to be cautious when drilling out a rivet, as the drill bit can slip and damage the surrounding material. To avoid this, use a drill bit with a centering point or a drill guide to help keep the drill bit steady. Additionally, use a slow and steady drilling motion to avoid applying too much pressure. By following these tips, you can successfully drill out a rivet and remove it without damaging the surrounding material.

2. Grinding or cutting the rivet: for rivets in hard-to-reach locations

. When dealing with rivets in hard-to-reach locations, grinding or cutting the rivet is often the most effective removal method. This approach involves using a power tool, such as a grinder or a saw, to carefully cut or grind away the rivet head, allowing for easy removal of the rivet. This method is particularly useful when the rivet is located in a tight space or is surrounded by other components that make it difficult to access with traditional removal tools. To grind or cut a rivet, start by selecting the right tool for the job. A grinder with a cutting wheel or a saw with a metal-cutting blade is ideal for this task. Next, carefully position the tool to avoid damaging surrounding components, and slowly begin to grind or cut away the rivet head. It's essential to work slowly and carefully to avoid applying too much pressure, which can cause the rivet to break or the surrounding material to become damaged. Once the rivet head is removed, the remaining stem can be easily pulled out, allowing for the removal of the rivet. Grinding or cutting a rivet can be a bit more time-consuming than other removal methods, but it is often the most effective way to remove rivets in hard-to-reach locations. Additionally, this method can be used in conjunction with other removal methods, such as drilling or punching, to make the removal process even easier. By carefully grinding or cutting away the rivet head, you can safely and effectively remove rivets in even the most challenging locations.

3. Using a rivet removal tool: for specialized or large rivets

. Here is the paragraphy: When dealing with specialized or large rivets, a rivet removal tool is often the best option. These tools are specifically designed to remove rivets without damaging the surrounding material. They typically consist of a drill bit or cutting wheel that is used to carefully remove the rivet head, followed by a punch or extractor that is used to remove the remaining rivet body. Rivet removal tools can be manual or powered, and are available in various sizes to accommodate different types of rivets. For example, a rivet removal tool with a large cutting wheel may be used to remove a large rivet from a heavy-duty application, while a smaller tool with a drill bit may be used to remove a smaller rivet from a more delicate material. In some cases, a rivet removal tool may also be used in conjunction with other removal methods, such as drilling or grinding, to safely and effectively remove a rivet. Overall, a rivet removal tool is a valuable addition to any toolkit, and can be used in a variety of situations where rivets need to be removed.

Post-Removal Procedures: Cleaning and Repairing the Area

Here is the introduction paragraph: When a removal process is complete, it's essential to focus on post-removal procedures to ensure the area is properly cleaned, repaired, and protected. This critical step is often overlooked, but it's crucial for maintaining the integrity and longevity of the surrounding material. To achieve a successful outcome, it's necessary to clean the area thoroughly to remove debris and residue, inspect the surrounding material for damage or weakness, and apply a suitable sealant or coating to protect the area. By following these essential steps, you'll be able to restore the area to its original condition and prevent future damage. Preparation is key to a successful post-removal procedure, and having the right tools and safety precautions in place is vital. In the next section, we'll discuss the essential tools and safety precautions you'll need to ensure a safe and effective post-removal process.

1. Clean the area thoroughly to remove debris and residue

. Here is the paragraphy: Cleaning the area thoroughly is a crucial step after removing rivets. This process involves removing any debris, residue, or old adhesive that may have been left behind. Start by using a soft-bristled brush or a cloth to gently sweep away any loose particles. Then, use a mild detergent and warm water to wipe down the area. Be sure to rinse the area thoroughly to remove any soap residue. If there are any stubborn stains or residue, you can use a specialized cleaning solution or a mixture of baking soda and water to help lift them. It's also important to remove any old adhesive or sealant that may have been used to secure the rivet. This can be done using a solvent-based adhesive remover or a heat gun. Once the area is clean, use a dry cloth to wipe it down and remove any excess moisture. This will help prevent any water spots or mineral deposits from forming. By cleaning the area thoroughly, you can ensure a smooth and even surface for any repairs or new installations. Additionally, cleaning the area can also help prevent any corrosion or damage to the surrounding material. Overall, taking the time to clean the area thoroughly is an important step in the post-removal process and can help ensure a successful outcome.

2. Inspect the surrounding material for damage or weakness

. Here is the paragraph: When removing rivets, it's essential to inspect the surrounding material for damage or weakness. This step is crucial in ensuring the structural integrity of the material and preventing further damage. Start by visually examining the area around the removed rivet, looking for any signs of cracks, dents, or corrosion. Check for any discoloration, rust, or oxidation, which can indicate underlying damage. If you notice any damage, it's essential to address it promptly to prevent it from spreading. Use a flashlight and a magnifying glass to get a closer look, if necessary. Next, use a gentle touch to feel the surrounding material for any soft spots, unevenness, or rough patches. This tactile inspection can help you detect any subtle damage that may not be visible to the naked eye. If you're working with metal, use a metal file or sandpaper to smooth out any rough edges or burrs. For other materials, use a suitable cleaning solution and a soft cloth to wipe away any debris or residue. By inspecting the surrounding material, you can identify any potential issues and take corrective action to ensure a safe and successful repair. This step is particularly important when working with critical components or load-bearing structures, where any weakness or damage can have serious consequences. By taking the time to inspect the surrounding material, you can prevent costly repairs, ensure safety, and maintain the integrity of the material.

3. Apply a suitable sealant or coating to protect the area

safely and effectively. After the rivet has been successfully removed, it's essential to apply a suitable sealant or coating to protect the area from corrosion, moisture, and other environmental factors. This step is crucial in maintaining the integrity and longevity of the surrounding material. Depending on the type of material and the environment it will be exposed to, a variety of sealants or coatings can be used. For example, in marine or aerospace applications, a specialized epoxy or polyurethane coating may be required to withstand harsh conditions. In other cases, a simple silicone-based sealant may be sufficient. It's also important to ensure that the sealant or coating is compatible with the surrounding material to avoid any adverse reactions or damage. By applying a suitable sealant or coating, you can prevent corrosion, reduce the risk of further damage, and maintain the overall structural integrity of the area. This step is a critical part of the post-removal process and should not be overlooked. By taking the time to properly seal and protect the area, you can ensure a safe and successful outcome.