How Much Cream To Make A Pound Of Butter

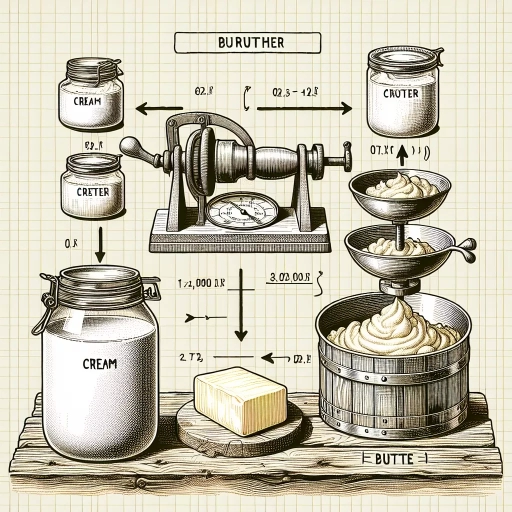

The process of making butter from cream is a delicate one, requiring a deep understanding of the various factors that influence the final product. One of the most crucial considerations is the amount of cream needed to produce a pound of butter. While it may seem like a straightforward question, the answer is not as simple as it appears. The quality of the cream, the churning process, and the underlying science of butter production all play significant roles in determining the amount of cream required. For instance, the fat content and type of cream used can greatly impact the yield of butter. Similarly, the churning process, whether done by hand or machine, can affect the efficiency of butter production. Furthermore, understanding the science behind butter production, including the separation of butterfat from buttermilk, is essential in determining the optimal amount of cream needed. The Cream Quality Affects the Amount Needed, let's dive deeper into this critical factor and explore how it influences the amount of cream required to make a pound of butter.

The Cream Quality Affects the Amount Needed

When it comes to cooking and baking, the quality of the cream used can significantly impact the final product. The amount of cream needed can vary greatly depending on several factors, including the fat content of the cream, the type of cream used, and the freshness and handling of the cream. Understanding these factors is crucial to achieving the desired consistency, texture, and flavor in your dishes. For instance, using a high-fat cream can result in a richer and more luxurious texture, but it may also require less cream overall. On the other hand, using a low-fat cream may require more cream to achieve the same consistency. The type of cream used, such as heavy cream, whipping cream, or sour cream, can also affect the amount needed. Furthermore, the freshness and handling of the cream can impact its performance in recipes. In this article, we will delve into the specifics of how the quality of cream affects the amount needed, starting with the impact of fat content on the yield.

The Fat Content of the Cream Impacts the Yield

The fat content of the cream directly influences the yield of butter produced. Heavy cream, which typically contains 36-40% fat, is ideal for churning butter because of its high fat content. This high percentage of fat means that more butterfat is available to be separated from the buttermilk during the churning process, resulting in a higher yield of butter. On the other hand, lighter creams with lower fat content, such as whipping cream or half-and-half, will produce less butter due to the lower amount of butterfat present. Additionally, the fat content of the cream can also affect the quality and texture of the butter produced. Higher-fat creams tend to produce a richer, more flavorful butter, while lower-fat creams may result in a lighter, more crumbly butter. Therefore, the type of cream used and its fat content play a crucial role in determining the yield and quality of the butter produced.

The Type of Cream Used Can Influence the Amount Required

The type of cream used can significantly influence the amount required to make a pound of butter. Heavy cream, which has a high fat content of around 36-40%, is the most commonly used type of cream for butter-making. This is because it yields a higher percentage of butterfat, resulting in a richer and more flavorful butter. However, this also means that less cream is required to produce the same amount of butter compared to lighter creams. For example, it may take around 1.5-2 quarts of heavy cream to produce a pound of butter. On the other hand, lighter creams such as half-and-half or whipping cream, which have a lower fat content of around 10-30%, require more volume to produce the same amount of butter. This is because they have a lower butterfat content, resulting in a lower yield of butter. As a result, it may take around 2.5-3.5 quarts of lighter cream to produce a pound of butter. Ultimately, the type of cream used will impact the amount required, and it's essential to consider this when planning to make butter.

Freshness and Handling of the Cream Affects the Outcome

Freshness and handling of the cream can significantly impact the outcome of making butter. Fresh cream is essential for producing high-quality butter, as it contains a higher percentage of fat and a lower percentage of water. If the cream is old or has been handled improperly, it may contain off-flavors, bacteria, or other contaminants that can affect the taste, texture, and overall quality of the butter. Additionally, the way the cream is handled during the churning process can also impact the outcome. Over-churning or under-churning can result in butter that is too grainy or too soft, respectively. Furthermore, the temperature of the cream can also play a crucial role in the churning process. If the cream is too warm, the butter may not form properly, while cream that is too cold may not churn efficiently. Therefore, it is essential to use fresh, high-quality cream and handle it properly during the churning process to produce the best possible butter.

The Churning Process Plays a Significant Role

The churning process is a critical step in butter production, and its significance cannot be overstated. The method of churning, the temperature of the cream, and the speed and duration of churning all play a crucial role in determining the efficiency and yield of butter production. The method of churning, in particular, has a significant impact on the efficiency of butter production, as it affects the separation of butterfat from other components of the cream. In this article, we will explore the importance of the churning process in butter production, starting with the method of churning and its effects on efficiency. We will also examine the impact of temperature and speed on the churning process, and how these factors can be optimized to improve the yield and quality of butter. By understanding the churning process and its various components, dairy farmers and manufacturers can improve the efficiency and profitability of their operations. The Method of Churning Affects the Efficiency of Butter Production.

The Method of Churning Affects the Efficiency of Butter Production

The method of churning affects the efficiency of butter production in several ways. The traditional method of churning cream using a wooden churn or a hand-cranked churn is a time-consuming process that requires a lot of physical effort. This method can be inefficient as it relies on manual labor, which can lead to fatigue and inconsistent results. In contrast, modern electric churns and food processors can churn cream much faster and with less effort, resulting in higher efficiency and better quality butter. Additionally, the temperature and consistency of the cream can also impact the churning process. Cold cream is easier to churn and produces better results, while warm cream can be more difficult to work with and may result in lower quality butter. Furthermore, the type of cream used can also affect the efficiency of butter production. Heavy cream with a high fat content is ideal for churning, while lighter creams may not produce as much butter. Overall, the method of churning, temperature, consistency, and type of cream all play a significant role in determining the efficiency of butter production.

The Temperature of the Cream During Churning is Crucial

Here is the paragraphy: The temperature of the cream during churning is crucial in determining the quality and yield of the butter. If the cream is too cold, the churning process will be slow and laborious, resulting in a lower yield of butter. On the other hand, if the cream is too warm, the butter will be soft and may not hold its shape well. The ideal temperature for churning cream is between 50°F and 60°F (10°C and 15°C). At this temperature range, the cream will churn quickly and efficiently, resulting in a high-quality butter with a smooth and creamy texture. Additionally, the temperature of the cream can also affect the flavor of the butter. If the cream is too warm, it may develop off-flavors or become rancid, while cold cream will result in a sweeter and more delicate flavor. Therefore, it is essential to monitor the temperature of the cream during churning to ensure that it falls within the optimal range.

The Speed and Duration of Churning Impact the Yield

Here is the paragraphy: The speed and duration of churning significantly impact the yield of butter. Faster churning speeds and longer churning times can lead to a higher yield of butter, but they can also result in a lower quality product. When cream is churned too quickly or for too long, the butterfat globules can become damaged, leading to a grainy or separated texture. On the other hand, slower churning speeds and shorter churning times can result in a lower yield of butter, but the product is often of higher quality and has a more desirable texture. The ideal churning speed and time will depend on the type of cream being used, as well as the desired texture and quality of the final product. In general, it is recommended to churn cream at a moderate speed for a shorter period of time to achieve the best balance between yield and quality.

Understanding the Science Behind Butter Production

The process of creating butter is a complex one that involves a deep understanding of the science behind it. To produce high-quality butter, it is essential to comprehend the intricacies of cream composition, the role of cultures and additives, and the significance of pH levels in the churning process. The chemical composition of cream and butter, for instance, plays a crucial role in determining the final product's taste, texture, and shelf life. Cultures and additives, on the other hand, can enhance the flavor and aroma of butter, while also extending its shelf life. Furthermore, maintaining optimal pH levels during the churning process is vital to ensure the production of butter with the desired characteristics. By understanding these key factors, butter manufacturers can produce high-quality butter that meets the demands of consumers. Let's start by examining the chemical composition of cream and butter, which serves as the foundation for the entire butter production process.

The Chemical Composition of Cream and Butter

The chemical composition of cream and butter is a complex mixture of various compounds that contribute to their unique properties and characteristics. Cream, the raw material used to produce butter, is primarily composed of water, carbohydrates, proteins, and lipids. The lipid fraction, which accounts for approximately 35-40% of cream's total composition, is the most critical component in butter production. This lipid fraction is comprised of triglycerides, which are molecules consisting of glycerol and three fatty acid chains. The fatty acid chains can vary in length and saturation, influencing the melting point, texture, and flavor of the resulting butter. Additionally, cream contains small amounts of other compounds, such as phospholipids, sterols, and vitamins, which also impact the final product's quality and characteristics. During the churning process, the triglycerides in cream are broken down into butterfat and buttermilk, resulting in a semi-solid mass of butter that is approximately 80% fat. The remaining 20% consists of water, milk proteins, and other minor components. The chemical composition of butter can vary depending on factors such as the type of cream used, the churning process, and the addition of any ingredients or preservatives. Understanding the chemical composition of cream and butter is essential for optimizing butter production, ensuring consistent quality, and developing new products with unique characteristics.

The Role of Cultures and Additives in Butter Production

The role of cultures and additives in butter production is multifaceted and plays a significant part in shaping the final product's flavor, texture, and overall quality. Cultures, which are essentially microorganisms such as bacteria or yeast, are added to the cream before churning to ferment the lactose, producing lactic acid and contributing to the development of the butter's flavor and aroma. This process, known as culturing, can take anywhere from a few hours to several days, depending on the type of culture used and the desired outcome. Additives, on the other hand, are substances added to the butter after churning to enhance its appearance, texture, or shelf life. Common additives include salt, which not only adds flavor but also acts as a preservative, and annatto, a natural coloring agent that gives butter its characteristic yellow hue. Other additives, such as potassium sorbate or natamycin, may be used to inhibit the growth of mold and yeast, extending the butter's shelf life. The use of cultures and additives can vary greatly depending on the type of butter being produced, with some artisanal producers opting for minimal or no additives to preserve the natural flavor and texture of the cream, while larger commercial operations may rely more heavily on additives to achieve consistency and extend shelf life. Ultimately, the judicious use of cultures and additives can elevate the quality and character of butter, making it a truly exceptional product.

The Importance of pH Levels in the Churning Process

The churning process of butter production is significantly impacted by the pH levels of the cream. pH levels, or the measure of acidity and alkalinity, play a crucial role in determining the quality and yield of butter. When the pH level of the cream is too high or too low, it can affect the separation of butterfat from other components, leading to reduced butter production or lower-quality butter. Ideally, the pH level of the cream should be between 6.5 and 6.8, allowing for optimal churning and separation of butterfat. If the pH level is too low, the cream may not churn properly, resulting in a lower yield of butter. Conversely, if the pH level is too high, the butter may become too soft or develop off-flavors. Maintaining the optimal pH range ensures that the churning process occurs efficiently, resulting in high-quality butter with the desired taste, texture, and consistency. Therefore, monitoring and controlling pH levels is essential in the churning process to produce premium-quality butter.