How To Make Sake

Sake, Japan's national beverage, has been a staple in the country's culture for centuries. With its rich history and unique brewing process, sake has become a popular drink worldwide. However, many people are unaware of the intricacies involved in making this traditional Japanese drink. To brew sake, one must first understand the basics of sake production, including the types of sake, the role of yeast and koji, and the importance of water quality. Once the basics are grasped, the next step is to prepare the necessary ingredients and equipment, such as rice, water, and fermentation tanks. Finally, the sake brewing process can begin, involving multiple steps including steaming, fermentation, and filtration. In this article, we will delve into the world of sake production, starting with the fundamentals. Understanding the basics of sake production is crucial to creating a high-quality brew, and it is the first step in our journey to making sake.

Understanding the Basics of Sake Production

Sake, a traditional Japanese beverage, has been enjoyed for centuries, with its rich history and production process captivating the interest of many. To truly appreciate this unique drink, it's essential to understand the basics of sake production. This involves delving into the history and origins of sake, exploring the ingredients and equipment required for its production, and examining the crucial role of yeast and fermentation in the brewing process. By grasping these fundamental aspects, one can gain a deeper appreciation for the craftsmanship and dedication that goes into creating this iconic beverage. Let's begin by exploring the fascinating history of sake, which dates back to ancient Japan, and uncover the secrets behind its enduring popularity. What is Sake and Its History?

What is Sake and Its History

Sake is a traditional Japanese beverage made from fermented rice, water, and koji (a type of fungus). With a history dating back over 2,000 years, sake has evolved from a simple, rustic drink to a sophisticated and nuanced liquor. The earliest recorded sake production was in the 3rd century AD, during the Yayoi period, where it was brewed for ceremonial and medicinal purposes. Over time, sake production spread throughout Japan, with different regions developing their unique brewing techniques and styles. The Edo period (1603-1867) saw the rise of sake as a popular drink among the general population, with the establishment of sake breweries and the development of new brewing methods. Today, sake is enjoyed not only in Japan but also around the world, with many breweries experimenting with innovative techniques and ingredients to create a wide range of sake styles. From the delicate and floral daiginjo to the rich and full-bodied junmai, sake offers a diverse and complex world of flavors and aromas, making it a fascinating and rewarding drink to explore.

The Ingredients and Equipment Needed

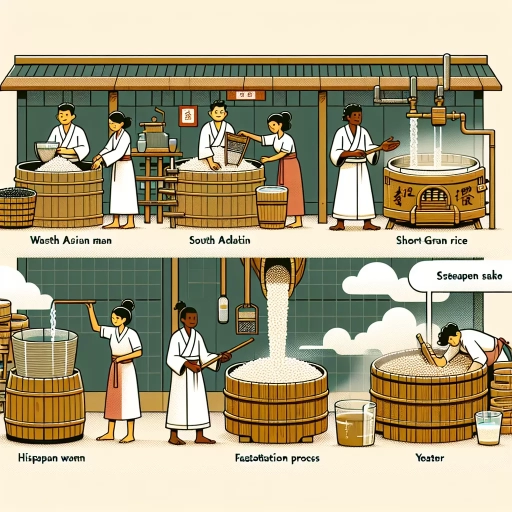

The ingredients and equipment needed to make sake are crucial components in the brewing process. The main ingredients required are Japanese rice, water, and koji (Aspergillus oryzae), a type of fungus that helps to break down the starches in the rice into fermentable sugars. The quality of the rice is particularly important, with sake breweries typically using short-grain rice varieties that are high in starch and low in protein. The water used should be soft and free of impurities, with a low iron content to prevent off-flavors. In addition to these ingredients, sake breweries also use yeast, typically a type of sake yeast that is specifically designed for sake production. The equipment needed to make sake includes large fermentation tanks, called kioke, which are typically made of cedar or stainless steel. The kioke are used to ferment the sake mash, which is a mixture of rice, water, and koji. Other equipment needed includes rice mills, which are used to polish the rice to the correct level of fineness, and sake presses, which are used to separate the liquid sake from the solids. A sake brewery will also need a series of filters, including a rough filter to remove large particles and a fine filter to remove smaller particles and impurities. Finally, a sake brewery will need a bottling and packaging system to fill and seal the sake bottles.

The Role of Yeast and Fermentation in Sake Production

Yeast and fermentation play a crucial role in sake production, as they are responsible for converting the starches in the rice into fermentable sugars and ultimately producing the alcohol and flavor compounds that characterize sake. The type of yeast used can significantly impact the final product, with different strains producing varying levels of esters, aldehydes, and other compounds that contribute to the sake's aroma and flavor. In sake production, a combination of koji and sake yeast is used, with the koji breaking down the rice's starches into fermentable sugars and the sake yeast fermenting those sugars into alcohol. The fermentation process typically takes place over a period of several days, during which time the mixture is stirred and monitored to ensure optimal conditions for yeast growth and fermentation. The temperature, pH, and other environmental factors are carefully controlled to promote the desired type of fermentation and to prevent the growth of unwanted microorganisms. The resulting sake is then filtered, pasteurized, and bottled, ready for consumption. Throughout the fermentation process, the brewer must carefully monitor the progress of the fermentation, making adjustments as necessary to ensure that the final product meets the desired standards of quality and flavor. By carefully controlling the yeast and fermentation process, sake brewers can produce a wide range of sake styles, from light and delicate to rich and full-bodied, each with its own unique characteristics and flavor profile.

Preparing the Ingredients and Equipment

Preparing the ingredients and equipment is a crucial step in sake production. To produce high-quality sake, brewers must carefully select and prepare the right type of rice, prepare the rice for fermentation, and sanitize and prepare the equipment for use. Selecting the right type of rice is essential, as it affects the flavor, aroma, and overall quality of the sake. Preparing the rice for fermentation involves rinsing, soaking, and steaming the rice to create the perfect environment for the fermentation process. Sanitizing and preparing the equipment for use is also vital, as it prevents contamination and ensures a clean and healthy fermentation process. By carefully preparing the ingredients and equipment, brewers can set the stage for a successful sake production. In this article, we will explore the importance of selecting the right type of rice for sake production.

Selecting the Right Type of Rice for Sake Production

Selecting the right type of rice is a crucial step in sake production, as it directly affects the flavor, aroma, and overall quality of the final product. There are several types of rice suitable for sake production, each with its unique characteristics and requirements. Japanese sake breweries typically use short-grain rice varieties, such as Yamada Nishiki, Gohyakumangoku, and Akita Sake Komachi, which are specifically cultivated for their high starch content and ability to absorb water. These varieties are preferred for their delicate flavor and aroma, as well as their ability to produce a smooth, creamy texture. When selecting rice for sake production, brewers consider factors such as the rice's protein content, moisture level, and grain size, as these can impact the fermentation process and final product. For example, rice with high protein content can result in a sake with a richer, more full-bodied flavor, while rice with low protein content may produce a lighter, more delicate sake. Ultimately, the type of rice used will depend on the desired flavor profile and style of sake being produced. By carefully selecting the right type of rice, brewers can create a high-quality sake that showcases the unique characteristics of the rice and the craftsmanship of the brewer.

Preparing the Rice for Fermentation

Preparing the rice for fermentation is a crucial step in the sake-making process. To start, the rice is first rinsed and soaked in water to remove any impurities and excess starch. The rice is then steamed to break down the starches and make them more accessible to the enzymes that will convert them into fermentable sugars. The steaming process also helps to kill off any bacteria or wild yeast that may be present on the rice, which could potentially contaminate the sake. After steaming, the rice is cooled to a temperature that is suitable for the addition of koji, a type of fungus that is used to break down the starches into fermentable sugars. The koji is sprinkled evenly over the cooled rice, and the mixture is then left to sit for a period of time to allow the enzymes to take effect. This process is called "saccharification," and it is a critical step in the sake-making process. The resulting mixture of rice and koji is then ready to be added to the fermentation tank, where it will be combined with water and yeast to begin the fermentation process. Throughout the preparation process, it is essential to maintain a clean and sanitized environment to prevent contamination and ensure the quality of the final product. By carefully preparing the rice for fermentation, brewers can set the stage for a successful sake-making process and create a high-quality, delicious sake.

Sanitizing and Preparing the Equipment for Use

Sanitizing and preparing the equipment for use is a crucial step in the sake brewing process. Before starting, it's essential to ensure that all equipment is clean and sanitized to prevent contamination and spoilage. Begin by washing all equipment, including the brew pot, fermentation vessel, and utensils, with hot water and a mild detergent. Rinse thoroughly to remove any soap residue. Next, sanitize the equipment using a sanitizer specifically designed for brewing, such as bleach or Star San. Follow the manufacturer's instructions for the recommended concentration and contact time. Allow the equipment to air dry, as any residual moisture can create an environment conducive to bacterial growth. Once the equipment is dry, it's ready for use. It's also important to sanitize any ingredients, such as rice and koji, before use. This can be done by rinsing them with hot water and then soaking them in a sanitizer solution. By taking the time to properly sanitize and prepare the equipment, brewers can ensure a healthy fermentation and a high-quality final product. Additionally, it's a good idea to sanitize the workspace and any surrounding areas to prevent cross-contamination. This includes wiping down surfaces with a sanitizer and ensuring that any equipment or ingredients are stored in a clean and dry environment. By following these steps, brewers can create a clean and sanitized environment that is ideal for brewing sake.

The Sake Brewing Process

The sake brewing process is a complex and nuanced art that requires great skill and attention to detail. From the initial preparation of the sake mash to the final bottling of the product, every step is crucial in creating a high-quality sake. In this article, we will delve into the intricacies of the sake brewing process, exploring the key stages that transform simple ingredients into a sophisticated and refined beverage. We will examine the process of creating the sake mash and adding yeast, which sets the stage for fermentation. We will also discuss the importance of monitoring and controlling the fermentation process, as well as the final steps of filtering and bottling the final product. By understanding these critical stages, sake enthusiasts and brewers alike can gain a deeper appreciation for the craftsmanship and dedication that goes into creating this beloved Japanese drink. To begin, let's take a closer look at the first stage of the sake brewing process: creating the sake mash and adding yeast.

Creating the Sake Mash and Adding Yeast

The sake mash, also known as the moromi, is a critical component of the sake brewing process. To create the mash, a combination of steamed rice, water, and koji is mixed together in a large tank. The steamed rice is typically prepared by soaking it in water, then steaming it to break down the starches and make them more accessible to the koji. The koji, a type of fungus that converts starches into fermentable sugars, is added to the steamed rice and water mixture, and the combination is left to sit for a period of time, allowing the koji to break down the starches and create a sugary liquid. Once the mash has reached the desired consistency and sugar content, yeast is added to the mixture to begin the fermentation process. The yeast, typically a type of sake yeast, feeds on the sugars in the mash and produces ethanol and carbon dioxide as byproducts. The fermentation process typically takes several days to a week, during which time the mash is stirred and monitored regularly to ensure that the fermentation is progressing smoothly. As the fermentation process comes to an end, the mash is pressed to separate the liquid from the solids, and the resulting liquid is transferred to a new tank for further fermentation and aging. The entire process, from creating the mash to adding yeast, requires great care and attention to detail, as the quality of the final product is heavily dependent on the quality of the mash and the fermentation process.

Monitoring and Controlling the Fermentation Process

The fermentation process in sake brewing is a critical phase that requires careful monitoring and control to ensure the production of high-quality sake. During this stage, the yeast converts the sugars present in the moromi into alcohol and carbon dioxide, producing a mixture of compounds that contribute to the flavor, aroma, and overall character of the sake. To monitor the fermentation process, brewers typically track the specific gravity of the moromi, which decreases as the yeast consumes the sugars and produces alcohol. They also monitor the temperature, pH, and yeast activity to ensure that the fermentation is proceeding at the optimal rate. In addition, brewers may use techniques such as tasting and smelling the moromi to assess its flavor and aroma development. By controlling factors such as temperature, yeast strain, and nutrient levels, brewers can influence the fermentation process and produce a sake that meets their desired specifications. For example, a slower fermentation at a lower temperature can result in a sake with a more delicate flavor and aroma, while a faster fermentation at a higher temperature can produce a sake with a bolder character. Overall, careful monitoring and control of the fermentation process are essential for producing high-quality sake that meets the brewer's standards.

Filtering and Bottling the Final Product

The final step in the sake brewing process is filtering and bottling the final product. After the sake has been pressed and separated from the lees, it is filtered to remove any remaining impurities and sediment. This is typically done using a combination of coarse and fine filters, such as activated carbon and membrane filters, to ensure that the sake is crystal clear and free of any off-flavors or aromas. Once the sake has been filtered, it is bottled and prepared for distribution. Some breweries may choose to add a small amount of distilled water to the sake to adjust the flavor and alcohol content, while others may choose to leave it unadulterated. The bottles are then sealed and labeled, and the sake is ready to be enjoyed. Some breweries may also choose to age their sake for a period of time to allow the flavors to mature and develop, while others may release it immediately. Regardless of the approach, the end result is a delicious and refreshing beverage that is perfect for sipping on its own or pairing with a variety of Japanese dishes.