How To Measure Chainsaw Bar

Measuring a chainsaw bar is a crucial step in ensuring the optimal performance and longevity of your chainsaw. A well-measured bar can improve cutting efficiency, reduce wear and tear, and even enhance safety. However, many chainsaw users overlook this critical step, often leading to subpar performance and premature wear. In this article, we will delve into the world of chainsaw bar measurement, exploring the importance of getting it right, the tools and techniques required, and a step-by-step guide to help you measure your chainsaw bar with confidence. By understanding the significance of measuring your chainsaw bar, you'll be able to appreciate the value of accurate measurement and take the first step towards optimizing your chainsaw's performance. So, let's start by understanding the importance of measuring chainsaw bar.

Understanding the Importance of Measuring Chainsaw Bar

Measuring a chainsaw bar is a crucial step in ensuring the optimal performance and safety of the saw. A chainsaw bar that is not properly measured can lead to a range of problems, from decreased efficiency to serious accidents. In this article, we will explore the importance of measuring a chainsaw bar, including why it is crucial for safety, how it affects performance, and the consequences of not measuring it. By understanding the significance of measuring a chainsaw bar, users can take the necessary steps to ensure their saw is running at its best and minimize the risk of accidents. One of the most critical reasons for measuring a chainsaw bar is to ensure safety, and we will explore this topic in more detail next.

Why Measuring Chainsaw Bar is Crucial for Safety

Measuring a chainsaw bar is crucial for safety because it directly affects the performance and control of the chainsaw. A bar that is too long or too short can lead to kickback, which is a sudden and violent reaction that can cause serious injury or even death. Kickback occurs when the chain gets pinched or binds, causing the saw to jerk back towards the operator. By measuring the bar accurately, you can ensure that it is the correct length for your saw and the type of cutting you will be doing, reducing the risk of kickback and maintaining control over the saw. Additionally, a properly measured bar will also help to prevent the chain from getting stuck or binding, which can cause the saw to stall or even break. This not only ensures the safety of the operator but also prolongs the life of the saw and reduces maintenance costs. Furthermore, measuring the bar also helps to ensure that the chain is properly tensioned, which is essential for safe and efficient cutting. A chain that is too loose can cause the saw to vibrate excessively, leading to loss of control, while a chain that is too tight can cause the saw to bind and kickback. By measuring the bar and ensuring proper chain tension, you can ensure a safe and efficient cutting experience. Overall, measuring a chainsaw bar is a critical step in ensuring safe and effective operation, and it is essential to take the time to do it accurately.

How Measuring Chainsaw Bar Affects Performance

Measuring a chainsaw bar is crucial for optimal performance, as it directly affects the saw's cutting efficiency, safety, and overall durability. A bar that is too long or too short can lead to reduced cutting power, increased vibration, and premature wear on the saw's components. When a bar is too long, it can cause the saw to bind or kickback, resulting in loss of control and potential injury. Conversely, a bar that is too short can lead to reduced cutting capacity and increased strain on the saw's engine. By measuring the bar accurately, users can ensure that their saw is properly matched to the task at hand, whether it's felling large trees or making precise cuts in tight spaces. Furthermore, measuring the bar allows users to identify any wear or damage that may be affecting performance, enabling them to take corrective action and maintain their saw in optimal condition. Overall, measuring a chainsaw bar is a simple yet critical step in ensuring safe, efficient, and effective cutting performance.

The Consequences of Not Measuring Chainsaw Bar

The consequences of not measuring a chainsaw bar can be severe and far-reaching, impacting both the user and the saw itself. One of the most significant risks is reduced cutting efficiency, as a bar that is too long or too short for the saw can lead to decreased performance and increased fatigue. This can result in longer cutting times, increased fuel consumption, and a higher risk of accidents. Furthermore, a poorly fitted bar can cause the saw to vibrate excessively, leading to premature wear on the engine, bearings, and other components. This can ultimately result in costly repairs or even render the saw unusable. Additionally, a bar that is not properly measured can also lead to kickback, a phenomenon where the saw kicks back towards the user, potentially causing serious injury. In extreme cases, not measuring a chainsaw bar can even lead to catastrophic failures, such as the bar breaking or the saw exploding, resulting in severe injury or even death. Therefore, it is essential to accurately measure a chainsaw bar to ensure safe and efficient operation.

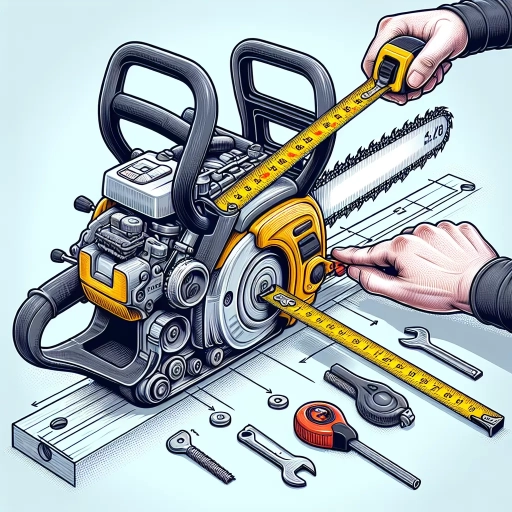

Tools and Techniques for Measuring Chainsaw Bar

Measuring the length of a chainsaw bar is a crucial step in ensuring the correct fit and optimal performance of the saw. There are several tools and techniques that can be employed to accurately measure a chainsaw bar, each with its own advantages and limitations. Three common methods include using a caliper for precise measurements, measuring with a ruler or tape measure for a more straightforward approach, and utilizing a specialized chainsaw bar measuring tool for added convenience. By understanding the strengths and weaknesses of each method, users can choose the best approach for their specific needs. For those seeking the highest level of accuracy, using a caliper is often the preferred choice, as it provides precise measurements down to a fraction of an inch.

Using a Caliper for Accurate Measurements

Using a caliper for accurate measurements is a crucial step in determining the correct size of a chainsaw bar. A caliper is a precision measuring instrument that can provide accurate readings to within 0.01 inches. To use a caliper, start by placing the jaws of the caliper on either side of the bar, making sure they are parallel to each other and perpendicular to the bar. Then, slowly close the jaws until they make contact with the bar, taking care not to apply too much pressure, which can cause the caliper to slip or the bar to become damaged. Once the jaws are in place, take a reading from the caliper's display, which will show the exact measurement of the bar's width or diameter. It's essential to take multiple measurements at different points along the bar to ensure accuracy, as the bar's dimensions can vary slightly along its length. Additionally, it's recommended to use a digital caliper, as they are more accurate and easier to read than analog calipers. By using a caliper to take precise measurements, you can ensure that you purchase a chainsaw bar that fits your saw perfectly, which is essential for optimal performance and safety.

Measuring Chainsaw Bar with a Ruler or Tape Measure

Measuring a chainsaw bar with a ruler or tape measure is a straightforward process that requires attention to detail. To start, locate the mounting point of the bar on the chainsaw, which is usually marked by a small notch or a raised edge. This point serves as the reference for measuring the bar's length. Next, place the ruler or tape measure along the center of the bar, ensuring it is aligned with the mounting point. Take note of the measurement at the tip of the bar, which is usually marked by a small notch or a rounded edge. Record this measurement in inches or centimeters, depending on your preference. It's essential to measure the bar from the mounting point to the tip, as this will give you the overall length of the bar. Additionally, you may also want to measure the bar's width, which is usually measured at the widest point, typically near the mounting point. By taking these measurements, you'll be able to determine the correct replacement bar or ensure that your existing bar is the correct size for your chainsaw.

Utilizing a Chainsaw Bar Measuring Tool

When it comes to measuring a chainsaw bar, accuracy is crucial to ensure optimal performance and safety. A chainsaw bar measuring tool is a specialized device designed to provide precise measurements of the bar's length, width, and other critical dimensions. Utilizing a chainsaw bar measuring tool is a straightforward process that requires minimal technical expertise. First, ensure the tool is calibrated and set to the correct unit of measurement. Next, place the tool on the bar, aligning it with the bar's centerline. Take note of the measurements displayed on the tool, which typically include the bar's length, width, and pitch. Record these measurements for future reference, as they will be essential for ordering replacement bars or making adjustments to the saw. By using a chainsaw bar measuring tool, users can ensure accurate measurements, reduce the risk of errors, and optimize their chainsaw's performance. Regular use of the tool can also help extend the life of the bar and prevent premature wear. Overall, a chainsaw bar measuring tool is an essential accessory for any chainsaw owner, providing a quick and easy way to obtain accurate measurements and maintain their saw's optimal performance.

Step-by-Step Guide to Measuring Chainsaw Bar

Measuring a chainsaw bar is a crucial step in ensuring the optimal performance and longevity of your chainsaw. To do this accurately, it's essential to follow a step-by-step guide that covers the entire process. This guide will walk you through the process of measuring a chainsaw bar, starting with locating the measurement points on the chainsaw bar, which is the first and most critical step. By understanding where to take your measurements, you'll be able to gather accurate data, which is then used to record and interpret the measurement results. This information will help you determine the correct replacement bar or chain, ensuring your chainsaw runs smoothly and efficiently. With this guide, you'll be able to take accurate measurements of the chainsaw bar, and by the end of it, you'll have a clear understanding of how to record and interpret the measurement results. So, let's get started by locating the measurement points on the chainsaw bar.

Locating the Measurement Points on the Chainsaw Bar

When measuring a chainsaw bar, it's essential to locate the measurement points accurately to ensure precise calculations. The measurement points on a chainsaw bar are typically located at the center of the bar, where the chain sprocket is attached, and at the tip of the bar. To locate the center point, look for the chain sprocket or the bar's mounting hole, which is usually marked with a small notch or a line. This point is crucial, as it serves as the reference point for measuring the bar's length. The tip of the bar is the other measurement point, and it's usually marked with a small notch or a line as well. Make sure to take note of any wear or damage on the bar, as this can affect the accuracy of your measurements. Additionally, if your chainsaw bar has a nose sprocket or a replaceable sprocket nose, you'll need to measure from the center of the bar to the tip of the nose sprocket. By accurately locating these measurement points, you'll be able to take precise measurements and ensure a proper fit for your chainsaw chain.

Taking Accurate Measurements of the Chainsaw Bar

When taking accurate measurements of the chainsaw bar, it's essential to consider a few key factors to ensure you get the right size for your needs. First, identify the type of measurement you need, whether it's the overall length, cutting length, or pitch. The overall length is the total length of the bar, including the mounting hardware, while the cutting length is the actual length of the bar that comes into contact with the wood. The pitch, on the other hand, refers to the distance between the teeth on the chain. To take accurate measurements, use a ruler or caliper to measure the bar from the mounting point to the tip, taking note of any obstructions or irregularities. It's also crucial to consider the bar's nose sprocket, which can affect the overall length. Additionally, if you're replacing a worn-out bar, take note of the wear pattern to determine the correct size and type of bar you need. By carefully considering these factors and taking precise measurements, you can ensure you get the right chainsaw bar for your specific needs, whether you're a professional logger or a DIY enthusiast.

Recording and Interpreting the Measurement Results

When recording and interpreting the measurement results, it's essential to be meticulous and accurate. Start by writing down the measurements in a clear and organized manner, using a table or chart to help visualize the data. Record the length of the chainsaw bar, the pitch, and the gauge, as well as any other relevant measurements, such as the kerf width or the number of drive links. Be sure to note the unit of measurement used, such as inches or millimeters, to avoid confusion. When interpreting the results, consider the specifications of the chainsaw and the intended use of the bar. For example, if the bar is intended for heavy-duty cutting, a longer length and a wider kerf may be necessary. On the other hand, if the bar is intended for precision cutting, a shorter length and a narrower kerf may be more suitable. Additionally, consider the type of material being cut, as different materials may require different bar specifications. By carefully recording and interpreting the measurement results, you can ensure that your chainsaw bar is properly sized and configured for optimal performance.