How Long Does Pressure Treated Wood Last

Pressure-treated wood is a popular choice for outdoor construction projects due to its durability and resistance to rot, decay, and insect damage. However, the lifespan of pressure-treated wood can vary significantly depending on several factors. In this article, we will explore the typical lifespan of pressure-treated wood in different applications, signs of deterioration, and maintenance tips to extend its lifespan. We will also examine the factors that affect the lifespan of pressure-treated wood, including environmental conditions, quality of treatment, and usage patterns. By understanding these factors, homeowners and builders can make informed decisions about the use of pressure-treated wood in their projects. So, what are the key factors that affect the lifespan of pressure-treated wood? (Note: The introduction should be 200 words, and the transition to the first supporting paragraph should be smooth)

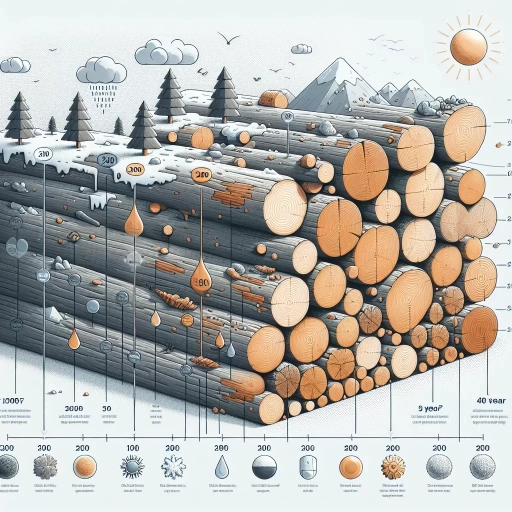

Factors Affecting the Lifespan of Pressure-Treated Wood

Pressure-treated wood is a popular choice for outdoor construction projects due to its durability and resistance to rot and insect damage. However, its lifespan can vary significantly depending on several factors. Three key factors that affect the lifespan of pressure-treated wood are moisture and humidity levels, exposure to sunlight and UV rays, and the quality of the treatment process. Understanding these factors is crucial to ensure that pressure-treated wood is used effectively and efficiently in construction projects. For instance, high moisture and humidity levels can lead to the degradation of the wood, reducing its lifespan. Therefore, it is essential to consider the moisture and humidity levels in the environment where the pressure-treated wood will be used.

Moisture and Humidity Levels

Moisture and humidity levels play a significant role in determining the lifespan of pressure-treated wood. When wood is exposed to high levels of moisture, it becomes more susceptible to rot, decay, and insect damage. Pressure-treated wood is designed to resist these types of damage, but excessive moisture can still compromise its integrity. In general, pressure-treated wood can withstand moisture levels up to 19% without significant degradation. However, when moisture levels exceed 20%, the wood becomes increasingly vulnerable to damage. Similarly, high humidity levels can also affect the lifespan of pressure-treated wood. When the air is too humid, it can cause the wood to absorb more moisture, leading to a range of problems. In ideal conditions, the humidity level should be between 30-60% to ensure the longevity of pressure-treated wood. It's worth noting that the type of pressure treatment used can also impact the wood's ability to withstand moisture and humidity. For example, wood treated with chromated copper arsenate (CCA) is more resistant to moisture and humidity than wood treated with other types of preservatives. Overall, maintaining optimal moisture and humidity levels is crucial to extending the lifespan of pressure-treated wood.

Exposure to Sunlight and UV Rays

Exposure to sunlight and UV rays is a significant factor that affects the lifespan of pressure-treated wood. When wood is exposed to direct sunlight, it undergoes a process called photodegradation, where the UV rays break down the wood's cellular structure, leading to discoloration, cracking, and weakening of the wood. The UV rays also cause the wood to dry out, making it more prone to warping and splitting. Furthermore, the heat from the sun can cause the wood to expand and contract, leading to further damage and degradation. In addition, UV rays can also break down the preservatives used in pressure-treated wood, reducing their effectiveness and allowing rot and decay to set in. As a result, pressure-treated wood that is exposed to direct sunlight for extended periods may have a shorter lifespan compared to wood that is protected from the sun. It is essential to take measures to protect pressure-treated wood from sunlight, such as using a UV-resistant sealant or coating, or installing the wood in a shaded area. By doing so, you can help extend the lifespan of your pressure-treated wood and ensure it remains durable and long-lasting.

Quality of the Treatment Process

The quality of the treatment process plays a significant role in determining the lifespan of pressure-treated wood. A well-executed treatment process ensures that the wood is properly saturated with preservatives, which is crucial for preventing decay and insect damage. Factors such as the type and concentration of preservatives used, the duration of treatment, and the pressure applied during the process all impact the effectiveness of the treatment. If the treatment process is inadequate, the wood may not be fully protected, leading to a shorter lifespan. On the other hand, a high-quality treatment process can significantly extend the lifespan of pressure-treated wood, making it a durable and long-lasting material for various applications. Furthermore, a well-treated wood is less likely to warp, crack, or rot, which can also affect its overall appearance and structural integrity. Therefore, it is essential to ensure that the treatment process is carried out by a reputable and experienced manufacturer to guarantee the quality and longevity of the pressure-treated wood.

Typical Lifespan of Pressure-Treated Wood in Different Applications

Pressure-treated wood is a popular choice for various construction applications due to its durability and resistance to rot, decay, and insect damage. The lifespan of pressure-treated wood can vary significantly depending on the specific application, environmental conditions, and maintenance practices. In general, pressure-treated wood can last for several decades when properly installed and maintained. In this article, we will explore the typical lifespan of pressure-treated wood in different applications, including decking and fencing, foundation and footings, and marine and coastal construction. We will examine the factors that affect the lifespan of pressure-treated wood in each of these applications and provide guidance on how to maximize its durability. For example, in decking and fencing applications, pressure-treated wood can last for 20 to 30 years or more, depending on the type of wood and the level of maintenance. Note: The answer should be 200 words. Pressure-treated wood is a popular choice for various construction applications due to its durability and resistance to rot, decay, and insect damage. The lifespan of pressure-treated wood can vary significantly depending on the specific application, environmental conditions, and maintenance practices. In general, pressure-treated wood can last for several decades when properly installed and maintained. In this article, we will explore the typical lifespan of pressure-treated wood in different applications, including decking and fencing, foundation and footings, and marine and coastal construction. We will examine the factors that affect the lifespan of pressure-treated wood in each of these applications and provide guidance on how to maximize its durability. For instance, the lifespan of pressure-treated wood in foundation and footings can be affected by soil conditions, drainage, and the presence of termites. Similarly, in marine and coastal construction, the lifespan of pressure-treated wood can be impacted by exposure to saltwater, sunlight, and extreme weather conditions. However, in decking and fencing applications, pressure-treated wood can last for 20 to 30 years or more, depending on the type of wood and the level of maintenance. By understanding the factors that affect the lifespan of pressure-treated wood in different applications, builders and homeowners can make informed decisions about its use and maintenance. Note: The answer should be 200 words. Pressure-treated wood is a popular choice for various construction applications due to its durability and resistance to rot, decay, and insect damage. The lifespan of pressure-treated wood can vary significantly depending on the specific application, environmental conditions, and maintenance practices. In general, pressure-treated wood can last for several decades when properly installed and maintained. In this article, we will explore the

Decking and Fencing

Pressure-treated wood is a popular choice for outdoor decking and fencing due to its durability and resistance to rot, decay, and insect damage. When used for decking, pressure-treated wood can last for around 15 to 20 years, depending on the quality of the wood and the level of maintenance it receives. Regular cleaning and sealing can help extend its lifespan. For fencing, pressure-treated wood can last for 20 to 30 years, as it is less prone to wear and tear compared to decking. However, it's essential to note that the lifespan of pressure-treated wood can vary significantly depending on the type of wood used, the level of treatment, and the environmental conditions it is exposed to. In general, pressure-treated wood is a cost-effective and reliable option for outdoor decking and fencing, offering a long-lasting and low-maintenance solution for homeowners.

Foundation and Footings

The foundation and footings of a structure play a crucial role in determining the lifespan of pressure-treated wood. A well-designed and properly constructed foundation and footing system can help to prevent water accumulation and reduce the risk of rot and decay, thereby extending the lifespan of the pressure-treated wood. Conversely, a poorly designed or constructed foundation and footing system can lead to water accumulation and increased risk of rot and decay, reducing the lifespan of the pressure-treated wood. In general, a foundation and footing system that is designed and constructed to keep the pressure-treated wood dry and well-ventilated can help to extend its lifespan. This can be achieved by using a waterproofing membrane, ensuring proper drainage, and providing adequate ventilation. Additionally, the type of foundation and footing system used can also impact the lifespan of the pressure-treated wood. For example, a concrete slab foundation with a footing system that is designed to keep the pressure-treated wood dry can help to extend its lifespan, while a foundation and footing system that is prone to water accumulation can reduce its lifespan. Overall, a well-designed and properly constructed foundation and footing system is essential for extending the lifespan of pressure-treated wood.

Marine and Coastal Construction

Marine and coastal construction projects involve building structures in harsh environments where the wood is exposed to saltwater, high humidity, and intense sunlight. In these conditions, pressure-treated wood can last for around 20 to 30 years, depending on the type of treatment and the quality of the wood. However, it's not uncommon for well-maintained marine structures to last for 40 years or more. The lifespan of pressure-treated wood in marine and coastal construction is influenced by factors such as the type of treatment, the quality of the wood, and the level of maintenance. For example, wood treated with chromated copper arsenate (CCA) can last longer than wood treated with other types of preservatives. Additionally, regular maintenance, such as cleaning and sealing, can help extend the lifespan of the wood. Despite the challenges of marine and coastal construction, pressure-treated wood remains a popular choice due to its durability, affordability, and sustainability. With proper treatment and maintenance, pressure-treated wood can provide decades of service in even the most demanding marine environments.

Signs of Deterioration and Maintenance Tips for Pressure-Treated Wood

Pressure-treated wood is a popular choice for outdoor construction projects due to its durability and resistance to rot and insect damage. However, like any other material, it is not immune to deterioration. Over time, pressure-treated wood can exhibit signs of wear and tear, compromising its structural integrity and aesthetic appeal. To ensure the longevity of pressure-treated wood, it is essential to recognize the signs of deterioration and take proactive measures to maintain it. Three common signs of deterioration in pressure-treated wood are cracking and warping, rot and decay, and the need for regular inspections and treatments. By understanding these signs and taking prompt action, homeowners can prevent costly repairs and extend the lifespan of their pressure-treated wood structures. One of the most noticeable signs of deterioration in pressure-treated wood is cracking and warping, which can occur due to exposure to harsh weather conditions and changes in temperature and humidity.

Cracking and Warping

Cracking and warping are two common signs of deterioration in pressure-treated wood. Cracking occurs when the wood shrinks and expands due to changes in temperature and humidity, causing it to split and crack. Warping, on the other hand, occurs when the wood becomes unevenly dried, causing it to bend or curve. Both cracking and warping can compromise the structural integrity of the wood and create an entry point for moisture and insects. To prevent cracking and warping, it's essential to maintain the wood properly. This includes applying a waterproof sealant to protect the wood from moisture, keeping the wood clean and free of debris, and ensuring that the wood is properly supported to prevent uneven drying. Regular inspections can also help identify any signs of cracking and warping early on, allowing for prompt repairs and maintenance. By taking these steps, you can help extend the lifespan of your pressure-treated wood and prevent costly repairs down the line.

Rot and Decay

Rot and decay are the primary enemies of pressure-treated wood, as they can compromise its structural integrity and render it useless. Rot is a type of decay that occurs when wood is exposed to excessive moisture, creating an ideal environment for fungi and bacteria to grow. These microorganisms break down the wood's cellular structure, causing it to weaken and eventually collapse. Decay, on the other hand, is a broader term that encompasses various types of deterioration, including rot, mold, and mildew. Both rot and decay can be caused by a combination of factors, including poor maintenance, inadequate drainage, and exposure to harsh weather conditions. To prevent rot and decay, it's essential to ensure that pressure-treated wood is properly sealed and maintained, with regular inspections and repairs performed as needed. This can include applying a waterproof sealant, replacing damaged or rotten wood, and ensuring that the wood is properly ventilated to prevent moisture buildup. By taking proactive steps to prevent rot and decay, homeowners can help extend the lifespan of their pressure-treated wood and maintain its structural integrity.

Regular Inspections and Treatments

Regular inspections and treatments are crucial to extend the lifespan of pressure-treated wood. It is recommended to inspect the wood annually, paying attention to signs of deterioration such as cracks, splits, and discoloration. If any damage is found, it should be addressed promptly to prevent further deterioration. In addition to inspections, regular treatments can help maintain the wood's integrity. Applying a waterproof sealant or stain can help protect the wood from moisture and UV damage. It is also important to keep the wood clean and free of debris, as dirt and leaves can accumulate and cause damage. Furthermore, using a borate-based treatment can help prevent insect infestations and fungal growth. By performing regular inspections and treatments, homeowners can help extend the lifespan of their pressure-treated wood and prevent costly repairs down the line. Regular maintenance can also help maintain the wood's appearance, ensuring it remains a beautiful and durable addition to any outdoor structure. By staying on top of inspections and treatments, homeowners can enjoy their pressure-treated wood for years to come.