How To Make Flour

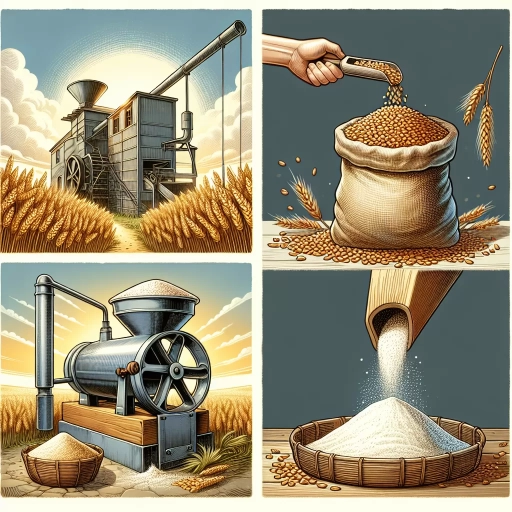

Making flour from scratch can be a rewarding and delicious experience, especially for those who value freshness and quality. With the right tools and techniques, anyone can create their own flour at home. The process involves several key steps, including choosing the right grain, preparing the grain for milling, and milling and sifting the flour. By selecting the perfect grain, you can ensure that your flour has the desired flavor, texture, and nutritional profile. In this article, we will explore the ins and outs of making flour from scratch, starting with the crucial first step: choosing the right grain.

Choosing the Right Grain

Choosing the right grain is a crucial decision for bakers, chefs, and food enthusiasts alike. With the numerous types of grains available, selecting the perfect one can be overwhelming. However, by understanding the different types of wheat, exploring alternative grains for flour production, and considering the protein content of the grain, individuals can make an informed decision that suits their needs. For instance, wheat is a popular choice, but it comes in various forms, including hard red, soft red, and hard white. Each type of wheat has its unique characteristics, uses, and nutritional profiles. To begin with, let's delve into the world of wheat and explore the different types available, which will help us better understand their applications and benefits. By doing so, we can make a more informed decision when it comes to choosing the right grain for our baking and cooking needs. Understanding the different types of wheat is the first step in this journey, and it is essential to grasp the nuances of each type to make the most of their potential.

Understanding the Different Types of Wheat

There are several types of wheat, each with its own unique characteristics, uses, and nutritional profiles. The main types of wheat are hard red winter wheat, hard red spring wheat, soft red winter wheat, soft white wheat, and durum wheat. Hard red winter wheat is high in protein and gluten, making it ideal for bread making, while hard red spring wheat is also high in protein but has a slightly sweeter flavor. Soft red winter wheat is lower in protein and gluten, making it better suited for baked goods, such as cakes and pastries. Soft white wheat is low in protein and gluten, making it ideal for Asian-style baked goods, such as noodles and dumplings. Durum wheat is high in protein and gluten, making it ideal for pasta and semolina production. Understanding the different types of wheat is essential for choosing the right grain for your specific needs, whether you're a baker, pasta maker, or simply looking to incorporate more whole grains into your diet. By selecting the right type of wheat, you can ensure that your final product has the desired texture, flavor, and nutritional profile.

Exploring Alternative Grains for Flour Production

Exploring alternative grains for flour production can be a fascinating and rewarding experience, offering a world of flavors, textures, and nutritional benefits beyond traditional wheat flour. For those looking to diversify their baking repertoire or cater to specific dietary needs, alternative grains provide a rich source of inspiration. Ancient grains like Kamut, Spelt, and Einkorn, for instance, boast higher protein content and a nuttier flavor profile compared to modern wheat varieties. Other options, such as Buckwheat, Quinoa, and Amaranth, are gluten-free and packed with minerals, making them ideal for those with gluten intolerance or sensitivity. Additionally, grains like Oats, Barley, and Rye offer distinct flavor profiles and textures, perfect for crafting artisanal breads, pastries, and other baked goods. When exploring alternative grains, it's essential to consider factors like flavor profile, nutritional content, and gluten content to ensure the best results in your baking endeavors. By experimenting with different grains and blends, you can unlock a world of new flavors and textures, elevating your baking to the next level. Whether you're a seasoned baker or just starting out, exploring alternative grains can be a fun and rewarding journey, allowing you to create unique and delicious baked goods that cater to a wide range of tastes and dietary needs.

Considering the Protein Content of the Grain

When it comes to choosing the right grain for flour production, one crucial factor to consider is the protein content. The protein content of a grain can significantly impact the final product's texture, structure, and overall quality. Grains with high protein content, such as wheat, barley, and rye, tend to produce stronger, more elastic dough, making them ideal for bread-making and other yeast-based products. On the other hand, grains with lower protein content, like oats, rice, and corn, yield softer, more delicate flours, better suited for baked goods, such as cakes, cookies, and pastries. Understanding the protein content of the grain is essential to determine the best use for the flour and to achieve the desired outcome in the final product. For instance, if you're looking to produce a high-quality bread flour, you'll want to choose a grain with a high protein content, typically above 12%. Conversely, if you're aiming to create a delicate pastry flour, a grain with a lower protein content, around 8-10%, would be more suitable. By considering the protein content of the grain, you can make informed decisions about the type of flour to produce and ensure that your final product meets your expectations.

Preparing the Grain for Milling

Preparing the grain for milling is a crucial step in the production of high-quality flour. To ensure that the final product meets the desired standards, it is essential to follow a series of steps that prepare the grain for the milling process. This involves cleaning the grain to remove impurities, drying the grain to optimal moisture levels, and tempering the grain for easier milling. By following these steps, millers can ensure that their grain is properly prepared for the milling process, resulting in a higher-quality final product. In this article, we will explore each of these steps in more detail, starting with the importance of cleaning the grain to remove impurities.

Cleaning the Grain to Remove Impurities

Cleaning the grain to remove impurities is a crucial step in the flour-making process. This step involves removing any debris, dirt, or unwanted particles from the grain to ensure that the final product is of high quality. The cleaning process typically begins with a series of sieves or air jets that separate the grain from any large debris or impurities. The grain is then passed through a series of smaller sieves or screens to remove any smaller particles or dust. In some cases, the grain may also be washed or rinsed with water to remove any remaining impurities. The cleaned grain is then dried to remove any excess moisture, which helps to prevent spoilage and ensure that the grain is in optimal condition for milling. The cleaning process is an essential step in producing high-quality flour, as it helps to remove any impurities that could affect the flavor, texture, or nutritional content of the final product. By removing impurities, the cleaning process also helps to reduce the risk of contamination and ensures that the flour is safe for consumption. Overall, cleaning the grain to remove impurities is a critical step in the flour-making process that requires careful attention to detail and a commitment to producing high-quality products.

Drying the Grain to Optimal Moisture Levels

Drying the grain to optimal moisture levels is a crucial step in preparing it for milling. The ideal moisture content for milling varies depending on the type of grain, but generally falls between 12% and 15%. If the grain is too moist, it can be prone to mold and spoilage, while grain that is too dry can be brittle and prone to breakage. To achieve the optimal moisture level, grain can be dried using a variety of methods, including air drying, sun drying, or machine drying. Air drying involves spreading the grain out in a well-ventilated area, allowing it to dry slowly over time. Sun drying involves spreading the grain out in the sun, either on a concrete pad or on a series of racks. Machine drying uses a combination of heat and air flow to dry the grain quickly and efficiently. Regardless of the method used, it's essential to monitor the grain's moisture level regularly to ensure it reaches the optimal range. This can be done using a moisture meter, which provides a quick and accurate reading of the grain's moisture content. By drying the grain to the optimal moisture level, millers can ensure that their flour is of the highest quality and has the best possible texture and flavor.

Tempering the Grain for Easier Milling

Tempering the grain is a crucial step in preparing it for milling, as it helps to make the grain easier to grind and produces a higher-quality flour. Tempering involves adding a small amount of moisture to the grain, typically in the form of water or steam, to increase its moisture content. This process helps to relax the grain's natural moisture barrier, making it more receptive to grinding. The ideal moisture level for tempering varies depending on the type of grain, but generally falls between 14% and 16%. When the grain is tempered correctly, it becomes softer and more pliable, allowing the millstones to grind it more efficiently and producing a finer, more consistent flour. Additionally, tempering helps to reduce the amount of heat generated during the milling process, which can damage the grain and affect the quality of the flour. By tempering the grain, millers can produce a higher-quality flour with better texture and flavor, making it ideal for baking and other culinary applications.

Milling and Sifting the Flour

Milling and sifting the flour is a crucial step in the baking process that can significantly impact the final product's quality and texture. To produce high-quality flour, it is essential to use the right equipment and techniques. One of the most critical steps in milling and sifting the flour is using a grain mill or food processor to break down the grains into a fine powder. Additionally, sifting the flour to remove large particles is also vital to ensure that the flour is smooth and even. Finally, storing the flour properly to maintain its freshness is also crucial to prevent spoilage and contamination. By following these steps, bakers can produce high-quality flour that will result in delicious and consistent baked goods. To start the process, it is essential to begin with the right equipment, and that is where using a grain mill or food processor for milling comes in.

Using a Grain Mill or Food Processor for Milling

Using a Grain Mill or Food Processor for Milling Milling your grains is a crucial step in making flour, and there are several options to choose from, including grain mills and food processors. A grain mill is a specialized appliance designed specifically for grinding grains into flour, and it's the best option if you plan on milling large quantities or want a high degree of control over the grinding process. Grain mills come in different types, including stone, steel, and burr mills, each with its own unique characteristics and advantages. Stone mills, for example, produce a more traditional, stone-ground flour, while steel mills are faster and more efficient. Burr mills, on the other hand, offer a high degree of control over the grind size and are ideal for milling small batches. If you don't have a grain mill, a food processor can also be used to mill grains, although it may not produce the same level of quality as a dedicated grain mill. When using a food processor, it's essential to use the correct blade and to process the grains in small batches to avoid overloading the machine. Additionally, food processors can generate heat, which can damage the grains and affect the flavor of the flour. To minimize this risk, it's recommended to process the grains in short bursts, allowing the machine to cool down between batches. Overall, whether you choose to use a grain mill or a food processor, the key to producing high-quality flour is to mill the grains slowly and carefully, taking care to avoid generating excessive heat or over-processing the grains.

Sifting the Flour to Remove Large Particles

Sifting the flour is a crucial step in the flour-making process that involves removing large particles and aerating the flour to achieve a smooth and even texture. This process is typically done after milling the grains into a coarse flour, and it serves several purposes. Firstly, sifting helps to remove any large particles or bran that may have been left behind during the milling process, which can affect the texture and consistency of the final product. By removing these particles, sifting ensures that the flour is uniform and free from any lumps or imperfections. Secondly, sifting helps to aerate the flour, which is essential for incorporating air and improving the flour's ability to absorb liquid ingredients. This is particularly important when making baked goods, as it allows the dough to rise evenly and gives the final product a light and fluffy texture. Finally, sifting also helps to remove any dust or debris that may have accumulated during the milling process, which can affect the flavor and quality of the final product. Overall, sifting is an essential step in the flour-making process that helps to produce high-quality flour that is perfect for baking and cooking.

Storing the Flour Properly to Maintain Freshness

Storing flour properly is crucial to maintaining its freshness and quality. Flour can absorb moisture and odors from the air, which can cause it to become stale, rancid, or even develop off-flavors. To prevent this, it's essential to store flour in a cool, dry place, away from direct sunlight and heat sources. Airtight containers, such as glass jars or plastic bins with tight-fitting lids, are ideal for storing flour. These containers should be kept in a pantry or cupboard with a consistent temperature between 50°F and 70°F (10°C and 21°C). It's also important to keep flour away from strong-smelling foods, as it can absorb odors easily. Additionally, it's recommended to store flour in smaller quantities, such as 2-5 pounds (1-2.5 kg), to ensure that it is used within a reasonable timeframe and to prevent staleness. By following these storage tips, you can help maintain the freshness and quality of your flour, ensuring that it remains suitable for baking and cooking.