How To Make A Saddle

Here is the introduction paragraph: Making a saddle is a complex and intricate process that requires a deep understanding of the craft, attention to detail, and a passion for creating something truly unique. Whether you're a seasoned craftsman or a beginner looking to try your hand at saddle making, the process can be broken down into three key stages: understanding the basics of saddle making, designing and building the saddle, and finishing and customizing the saddle. To get started, it's essential to lay a solid foundation by understanding the fundamentals of saddle making, including the different types of saddles, the materials used, and the tools required. By grasping these basics, you'll be able to move forward with confidence and create a saddle that is both functional and beautiful. In this article, we'll delve into the world of saddle making, starting with the basics, and explore the key elements that will help you create a high-quality saddle. Understanding the basics of saddle making is the first step in this journey, and it's where we'll begin.

Understanding the Basics of Saddle Making

Saddle making is a traditional craft that requires a deep understanding of various aspects, including the purpose and type of saddle, materials and tools, and the saddle tree. To create a high-quality saddle, one must first define the purpose and type of saddle they intend to make, as this will determine the design, materials, and construction methods used. This involves considering factors such as the intended use of the saddle, the type of horse it will be used on, and the level of comfort and support required. Additionally, choosing the right materials and tools is crucial, as this will affect the durability, comfort, and overall quality of the saddle. The saddle tree, which is the internal framework of the saddle, also plays a critical role in determining the fit and comfort of the saddle. By understanding these fundamental aspects of saddle making, craftsmen can create saddles that are both functional and comfortable for horses and riders. In this article, we will delve into the basics of saddle making, starting with defining the purpose and type of saddle.

Defining the Purpose and Type of Saddle

The purpose and type of saddle are crucial factors to consider when creating a saddle, as they determine the saddle's design, functionality, and overall performance. The primary purpose of a saddle is to provide a comfortable and secure seat for the rider, while also allowing for effective communication and control of the horse. There are several types of saddles, each designed for specific disciplines, riding styles, and horse breeds. For example, Western saddles are designed for trail riding, reining, and working cattle, while English saddles are suited for dressage, show jumping, and other English disciplines. Endurance saddles are designed for long-distance riding, while Australian saddles are ideal for rugged terrain and stock work. The type of saddle also influences the tree style, seat size, and skirt design, which must be carefully considered to ensure a proper fit for both the horse and rider. Additionally, the saddle's purpose and type will also dictate the materials and craftsmanship used in its construction, such as the type of leather, padding, and hardware. By defining the purpose and type of saddle, saddle makers can create a high-quality, functional, and comfortable saddle that meets the specific needs of the rider and horse.

Choosing the Right Materials and Tools

Choosing the right materials and tools is crucial in saddle making, as it can significantly impact the quality and durability of the final product. The type of leather used, for example, can affect the saddle's comfort, flexibility, and resistance to wear and tear. Top-grain leather, which is strong and durable, is often preferred for saddles, while full-grain leather offers excellent flexibility and suppleness. Other materials, such as synthetic leather, nylon, or canvas, may also be used for specific parts of the saddle, such as the skirt or rigging. In addition to leather, other essential materials include threads, yarns, and dyes, which must be carefully selected to ensure a strong and long-lasting stitch. The right tools, including leather cutters, edge bevelers, and stitching awls, are also vital for precise cutting, shaping, and stitching. A well-stocked toolbox should also include a variety of hand tools, such as hammers, mallets, and shaping irons, to help shape and form the leather into the desired shape. Furthermore, a good saddle maker should also have a reliable source of hardware, such as buckles, conchos, and rivets, to ensure a secure and durable attachment of the saddle's various components. By carefully selecting the right materials and tools, a saddle maker can ensure a high-quality finish and a long-lasting saddle that will provide years of comfortable and reliable service.

Understanding Saddle Tree and Its Importance

The saddle tree is the foundation of a saddle, providing the structural integrity and shape that allows a rider to sit comfortably and securely. It is typically made from a rigid material such as wood, fiberglass, or plastic, and is designed to distribute the weight of the rider evenly across the horse's back. The saddle tree is usually composed of several key components, including the pommel, cantle, and skirts, which work together to provide support and stability. A well-made saddle tree is essential for a comfortable and safe ride, as it helps to prevent pressure points and discomfort for both the horse and rider. In addition, a good saddle tree can help to improve the horse's posture and movement, by providing a stable and balanced platform for the rider. Understanding the saddle tree and its importance is crucial for anyone looking to make a saddle, as it requires careful consideration of the horse's anatomy and the rider's needs. By selecting the right materials and designing the saddle tree with care, saddle makers can create a high-quality saddle that provides years of comfortable and safe riding.

Designing and Building the Saddle

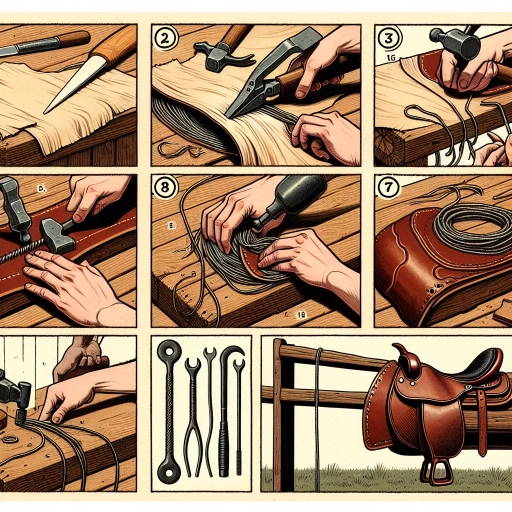

Designing and building a saddle is a meticulous process that requires attention to detail, precision, and a deep understanding of the rider's needs and the horse's anatomy. A well-crafted saddle can make all the difference in the comfort and performance of both the rider and the horse. To create a high-quality saddle, one must first create a pattern and template that takes into account the rider's measurements, the horse's breed and size, and the intended use of the saddle. This involves careful consideration of the saddle's shape, size, and features, such as the seat, skirt, and cantle. Once the pattern and template are created, the next step is to cut and shape the leather and other materials, such as wood or synthetic materials, to precise specifications. Finally, the saddle components must be assembled and hardware attached, requiring a high degree of skill and craftsmanship. By following these steps, a saddle maker can create a truly exceptional saddle that meets the needs of both the rider and the horse. Creating a pattern and template for the saddle is the first and most critical step in this process.

Creating a Pattern and Template for the Saddle

Creating a pattern and template for the saddle is a crucial step in the saddle-making process. This involves creating a detailed outline of the saddle's shape, size, and features, which will serve as a guide for cutting and shaping the leather and other materials. To create a pattern, saddle makers typically use a combination of measurements, sketches, and cardboard or paper templates. The pattern should include the saddle's overall shape, including the seat, skirts, and flaps, as well as the location of any hardware, such as buckles and rivets. The template should also take into account the type of horse and rider the saddle is intended for, as well as any specific design or stylistic elements. Once the pattern is complete, it can be used to cut out the leather and other materials, ensuring a precise and accurate fit. A well-made pattern and template are essential for creating a high-quality saddle that is both functional and aesthetically pleasing.

Cutting and Shaping the Leather and Other Materials

Cutting and shaping the leather and other materials is a crucial step in the saddle-making process. To begin, the saddle maker carefully selects and cuts out the leather pieces, using a combination of hand tools and machinery to achieve precise cuts. The leather is typically cut into various components, including the skirts, jockeys, and seat, each requiring specific dimensions and shapes. The saddle maker must also cut out additional materials, such as foam, felt, or synthetic materials, to create the saddle's internal components, like the tree points and panels. Next, the leather pieces are carefully shaped and molded to fit the saddle tree, using a combination of hand tools, such as edge bevelers and mallets, and specialized machinery, like leather shapers and stretchers. The saddle maker must also shape and form the internal components, ensuring a precise fit and smooth, even surface. Throughout the cutting and shaping process, the saddle maker must maintain attention to detail, ensuring that each piece is accurately cut and shaped to fit together seamlessly, ultimately resulting in a well-crafted and functional saddle.

Assembling the Saddle Components and Attaching Hardware

Assembling the saddle components and attaching hardware is a critical step in the saddle-making process. This stage requires precision, patience, and attention to detail to ensure a sturdy and functional saddle. Begin by gathering all the necessary components, including the tree, skirts, seat, and hardware such as conchos, screws, and rivets. Next, carefully attach the skirts to the tree using a strong adhesive and reinforcing stitches, making sure to align them properly to prevent any wrinkles or creases. The seat is then attached to the tree, ensuring a snug and even fit, and the hardware is installed according to the design specifications. Conchos are typically attached to the skirts, while screws and rivets are used to secure the hardware in place. It is essential to double-check the alignment and tension of all components to guarantee a comfortable and balanced ride. Additionally, applying a finish, such as leather conditioner or wax, to the assembled saddle components will enhance their appearance and durability. By meticulously assembling the saddle components and attaching hardware, you will create a sturdy and functional saddle that will provide years of reliable service.

Finishing and Customizing the Saddle

Finishing and customizing a saddle is a crucial step in creating a high-quality, functional, and visually appealing piece of equestrian equipment. A well-finished saddle not only enhances the rider's experience but also reflects the craftsmanship and attention to detail of the saddle maker. To achieve a superior finish, saddle makers employ various techniques, including adding decorative elements and tooling, applying finishing treatments and conditioners, and testing and adjusting the saddle for fit and comfort. These processes not only enhance the saddle's aesthetic appeal but also ensure its durability and performance. By incorporating these finishing touches, saddle makers can create a truly unique and exceptional saddle that meets the specific needs and preferences of the rider. One of the most creative and visually striking aspects of saddle customization is the addition of decorative elements and tooling, which can elevate the saddle's design and make it a true work of art.

Adding Decorative Elements and Tooling

Here is the paragraphy: Adding decorative elements and tooling to a saddle can elevate its aesthetic appeal and make it truly unique. Decorative elements such as intricate stitching, carved designs, and ornate hardware can add a touch of elegance and sophistication to the saddle. Tooling, on the other hand, involves using specialized tools to create intricate designs and patterns on the leather. This can include techniques such as stamping, carving, and molding. By incorporating decorative elements and tooling, saddle makers can create a one-of-a-kind piece that reflects the rider's personality and style. Additionally, decorative elements and tooling can also serve a functional purpose, such as providing additional grip or support for the rider. For example, decorative stitching can be used to reinforce the saddle's seams, while carved designs can be used to create a more comfortable seat. Overall, adding decorative elements and tooling to a saddle is a great way to add visual interest and create a truly custom piece.

Applying Finishing Treatments and Conditioners

Applying finishing treatments and conditioners is a crucial step in the saddle-making process, as it enhances the appearance, durability, and functionality of the saddle. Finishing treatments, such as waxes, oils, and varnishes, protect the leather from drying out, cracking, and fading, while also providing a rich, luxurious finish. Conditioners, on the other hand, moisturize and nourish the leather, keeping it supple and flexible. When applying finishing treatments and conditioners, it's essential to follow a specific sequence to achieve the desired results. First, the saddle should be thoroughly cleaned and prepared to ensure a smooth, even finish. Next, a conditioner should be applied to the leather, allowing it to penetrate and moisturize the material. Once the conditioner has been fully absorbed, a finishing treatment can be applied, such as a wax or oil, to provide a protective barrier and enhance the appearance of the leather. It's also important to note that different types of leather may require specific finishing treatments and conditioners, so it's crucial to choose the right products for the job. For example, aniline leathers may require a gentle, non-greasy conditioner, while pigmented leathers may benefit from a more robust, protective finish. By applying the right finishing treatments and conditioners, saddle makers can create a beautiful, long-lasting saddle that not only looks great but also provides a comfortable and secure ride for the horse and rider. Additionally, regular maintenance and conditioning can help extend the life of the saddle, ensuring it remains in excellent condition for years to come. Overall, applying finishing treatments and conditioners is a critical step in the saddle-making process, requiring attention to detail, patience, and a deep understanding of the materials and techniques involved. By following the right sequence and using the right products, saddle makers can create a truly exceptional saddle that meets the highest standards of quality and craftsmanship.

Testing and Adjusting the Saddle for Fit and Comfort

The saddle is now ready to be tested and adjusted for fit and comfort. To do this, place the saddle on the horse's back, ensuring it is centered and even. Check the clearance between the saddle and the horse's withers, making sure there is enough space to accommodate the horse's movement. The saddle should sit comfortably on the horse's back, with the skirts not pinching or rubbing against the horse's sides. Next, check the gullet plate, ensuring it is the correct width and not putting pressure on the horse's spine. The rider should then sit in the saddle, checking for comfort and balance. The saddle should feel secure and stable, with the rider able to sit comfortably in the seat. If necessary, make adjustments to the tree points, skirts, or gullet plate to achieve the perfect fit. Additionally, consider adding padding or shims to the saddle to provide extra comfort and support for the horse and rider. By carefully testing and adjusting the saddle, you can ensure a comfortable and secure ride for both the horse and rider.