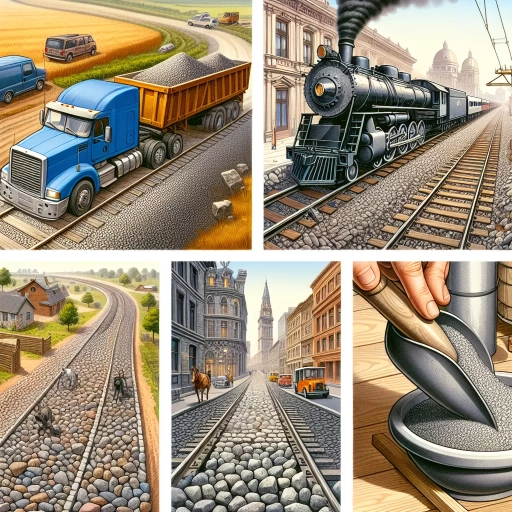

How Are Rocks Used In Transportation

Rocks play a vital role in the transportation sector, serving as a fundamental component in the construction of various infrastructure projects. From the foundation to the surface, rocks are used in different forms and applications to ensure the stability, durability, and safety of transportation systems. In this article, we will explore the various ways rocks are utilized in transportation, including the construction of roads and highways, railway infrastructure, and waterway and port development. We will examine how rocks are used to build strong foundations, provide drainage, and create stable surfaces for vehicles to travel on. By understanding the importance of rocks in transportation, we can appreciate the critical role they play in connecting communities and facilitating the movement of goods and people. Let's start by looking at how rocks are used in the construction of roads and highways.

Construction of Roads and Highways

The construction of roads and highways is a complex process that requires careful planning, precise execution, and the use of high-quality materials. A well-constructed road or highway is essential for ensuring the safety of drivers and passengers, as well as facilitating the efficient transportation of goods and services. In this article, we will explore the key components of road construction, including the base course material, drainage and erosion control, and surface layer material. These elements work together to provide a strong and durable foundation for the road, prevent water damage and erosion, and create a smooth and safe driving surface. By understanding the importance of each of these components, we can appreciate the complexity and expertise involved in building modern roads and highways. Let's start by examining the base course material, which provides the foundation for the entire road structure.

Base Course Material

The base course material is a crucial component in the construction of roads and highways, serving as the foundation upon which the entire pavement structure is built. Typically consisting of a layer of compacted aggregate material, such as crushed stone, gravel, or sand, the base course provides a stable and durable base for the pavement. Its primary function is to distribute the weight of traffic evenly, preventing settlement and deformation of the pavement, and to provide drainage and prevent water from accumulating in the pavement structure. The base course material is usually 2-4 inches thick and is placed on top of the subgrade, which is the natural soil or rock surface. The material is then compacted using heavy machinery, such as rollers or plate compactors, to achieve the desired density and stability. The base course material plays a critical role in the overall performance and longevity of the pavement, and its selection and installation are carefully considered to ensure that it meets the required specifications and standards. By providing a solid foundation for the pavement, the base course material helps to prevent premature wear and tear, reduces the risk of potholes and other defects, and ensures a smooth and safe ride for vehicles.

Drainage and Erosion Control

Drainage and erosion control are crucial components in the construction of roads and highways, as they play a significant role in ensuring the longevity and safety of the infrastructure. Effective drainage systems help to prevent water accumulation on the road surface, reducing the risk of hydroplaning, flooding, and damage to the pavement. This is achieved through the installation of drainage features such as culverts, catch basins, and storm drains, which collect and redirect water away from the road. Additionally, erosion control measures, such as riprap, geotextiles, and retaining walls, are used to prevent soil erosion and stabilize slopes, thereby maintaining the road's structural integrity. By implementing these measures, road builders can minimize the risk of accidents, reduce maintenance costs, and ensure a smooth and safe driving experience for users. Furthermore, proper drainage and erosion control can also help to prevent environmental damage, such as sedimentation and pollution, by reducing the amount of sediment and pollutants that enter nearby waterways. Overall, the incorporation of effective drainage and erosion control systems is essential for building durable, sustainable, and environmentally friendly roads and highways.

Surface Layer Material

The surface layer material, also known as the wearing course, is the topmost layer of a road or highway that comes into direct contact with traffic. It is designed to provide a smooth, durable, and skid-resistant surface for vehicles to travel on. The surface layer material is typically made from a combination of aggregate materials, such as crushed stone, gravel, or sand, bound together with a binding agent like asphalt or concrete. The choice of surface layer material depends on various factors, including the volume of traffic, climate, and geographical location. For high-traffic roads, a more durable and resistant material like asphalt or concrete is often used, while for low-traffic roads, a less expensive material like gravel or chip seal may be sufficient. The surface layer material plays a critical role in ensuring the safety and comfort of road users, as it provides traction, reduces noise levels, and helps to prevent accidents. Regular maintenance of the surface layer material is essential to extend its lifespan and prevent damage from wear and tear.

Railway Infrastructure

The development of a reliable and efficient railway infrastructure is crucial for the growth of a country's economy. A well-planned railway system enables the transportation of goods and people over long distances, connecting cities, towns, and industries. To ensure the stability and longevity of railway tracks, it is essential to focus on three critical aspects: the quality of ballast material, the stabilization of the track bed, and the construction of tunnels and bridges. The selection of suitable ballast material is vital, as it provides drainage, prevents track settlement, and reduces the risk of derailments. In this article, we will delve into the importance of these three components, starting with the significance of ballast material in railway infrastructure.

Ballast Material

Ballast material is a crucial component of railway infrastructure, playing a vital role in the stability and safety of rail tracks. The primary function of ballast is to provide a stable and level base for the rail tracks, allowing trains to run smoothly and efficiently. Ballast material is typically made from crushed stone, such as granite, basalt, or limestone, which is carefully selected and processed to meet specific requirements. The ballast is laid beneath the rail tracks, usually in a layer of around 200-300 mm, and is designed to distribute the weight of the trains evenly, preventing the tracks from shifting or becoming uneven. The ballast also helps to drain water away from the tracks, reducing the risk of erosion and damage. In addition, ballast material can help to reduce noise pollution by absorbing sound waves, making it an essential component of modern railway infrastructure. Overall, the use of high-quality ballast material is essential for ensuring the safe and efficient operation of rail networks, and its importance cannot be overstated.

Track Bed Stabilization

Track bed stabilization is a crucial aspect of railway infrastructure, ensuring the stability and safety of rail tracks. The track bed, also known as the subgrade, is the layer of material beneath the rail tracks that provides a solid foundation for the rails. Over time, the track bed can become unstable due to various factors such as settlement, erosion, and weathering, which can lead to track geometry issues and even derailments. To prevent this, track bed stabilization techniques are employed to improve the stability and load-bearing capacity of the track bed. One common method is the use of geosynthetic materials, such as geogrids and geotextiles, which are placed beneath the track bed to provide additional support and stability. Another technique is the use of ballast stabilization, where the ballast material is treated with chemicals or other additives to improve its stability and resistance to settlement. Additionally, track bed stabilization can also be achieved through the use of underlayment materials, such as asphalt or concrete, which provide a solid and stable base for the track bed. By stabilizing the track bed, railway operators can ensure a smoother and safer ride for passengers and freight, while also reducing maintenance costs and extending the lifespan of the rail tracks. Overall, track bed stabilization is a critical component of railway infrastructure, and its importance cannot be overstated.

Tunnel and Bridge Construction

Tunnel and bridge construction are critical components of railway infrastructure, enabling trains to traverse challenging terrain and connect distant regions. Tunnels are built to pass through mountains, hills, and other obstacles, while bridges are constructed to span rivers, valleys, and other waterways. The construction of tunnels and bridges requires careful planning, precise engineering, and specialized equipment. Geologists play a crucial role in tunnel construction, as they assess the geological conditions of the terrain and identify potential hazards such as rockfalls, landslides, and groundwater infiltration. The type of rock encountered during tunnel construction also determines the choice of excavation method, with hard rocks requiring drilling and blasting, and soft rocks allowing for mechanical excavation. Bridge construction, on the other hand, involves the use of various materials such as steel, concrete, and composite materials, with the choice of material depending on factors such as span length, load capacity, and environmental conditions. The construction of tunnels and bridges not only facilitates the transportation of people and goods but also has a significant impact on the environment and local communities. As such, railway infrastructure projects must be carefully planned and executed to minimize environmental disruption and ensure the safety of both passengers and workers.

Waterway and Port Development

Effective waterway and port development is crucial for facilitating global trade, economic growth, and environmental sustainability. A well-planned and executed waterway and port development project can significantly enhance the efficiency and capacity of maritime transportation, while also minimizing its environmental impact. To achieve this, three key components must be carefully considered: Breakwater and Seawall Construction, Channel Dredging and Excavation, and Marine Terminal and Dock Construction. By incorporating these elements, waterway and port development projects can ensure safe and efficient navigation, accommodate increasing vessel sizes, and support the growth of international trade. One of the most critical components of waterway and port development is the construction of breakwaters and seawalls, which provide essential protection against harsh weather conditions and erosion, thereby safeguarding the integrity of the port infrastructure.

Breakwater and Seawall Construction

Breakwater and seawall construction are crucial components of waterway and port development, serving as protective barriers against the harsh marine environment. A breakwater is a structure built offshore to absorb the energy of incoming waves, thereby reducing the impact of wave action on the shoreline. It is typically constructed using large rocks, concrete blocks, or a combination of both, and is designed to withstand the forces of waves, tides, and currents. On the other hand, a seawall is a structure built along the shoreline to prevent erosion and protect the land from the sea. It is often constructed using rocks, concrete, or a combination of both, and is designed to withstand the forces of waves, tides, and storms. The construction of breakwaters and seawalls requires careful planning and design, taking into account factors such as wave patterns, tidal ranges, and soil conditions. The use of rocks in breakwater and seawall construction provides a durable and long-lasting solution, as rocks can withstand the harsh marine environment and require minimal maintenance. Additionally, rocks can be used to create a natural-looking shoreline, blending in with the surrounding environment. Overall, breakwater and seawall construction play a vital role in protecting coastal infrastructure and ensuring the safe and efficient operation of ports and waterways.

Channel Dredging and Excavation

Channel dredging and excavation are crucial components of waterway and port development, enabling the safe and efficient passage of vessels through waterways and harbors. Dredging involves the removal of sediment, soil, and rocks from the bottom of a waterway or harbor, while excavation refers to the removal of material from the sides or banks of a waterway. These processes are essential for maintaining navigable channels, ensuring the stability of waterway structures, and facilitating the transportation of goods and people. Channel dredging and excavation also play a critical role in preventing erosion, reducing the risk of flooding, and promoting environmental sustainability. By removing sediment and debris, dredging and excavation help to maintain the natural flow of water, prevent the accumulation of pollutants, and protect aquatic habitats. Furthermore, these processes enable the construction of new waterway infrastructure, such as canals, locks, and dams, which are vital for supporting economic growth, trade, and commerce. In addition, channel dredging and excavation are used to create and maintain recreational waterways, such as marinas, boat launches, and fishing areas, which provide opportunities for leisure activities and tourism. Overall, channel dredging and excavation are essential for the development and maintenance of waterways and ports, supporting a wide range of economic, environmental, and social benefits.

Marine Terminal and Dock Construction

Marine terminal and dock construction play a crucial role in the development of waterways and ports, enabling the efficient loading and unloading of cargo and passengers. The construction of marine terminals and docks involves the use of various types of rocks and materials, including granite, basalt, and limestone, which provide the necessary strength and durability to withstand the harsh marine environment. The process of constructing a marine terminal or dock typically begins with site preparation, which includes the removal of existing soil and rock to create a stable foundation. This is followed by the installation of a foundation system, such as a pile foundation or a caisson foundation, which provides the necessary support for the terminal or dock structure. The foundation system is then topped with a layer of rock or concrete, which serves as the base for the terminal or dock. The terminal or dock structure is then built on top of the base, using a combination of steel, concrete, and rock to create a strong and durable structure. The use of rocks in marine terminal and dock construction provides several benefits, including improved stability, increased durability, and enhanced safety. Additionally, the use of rocks can also help to reduce the environmental impact of the construction process, as they can be sourced locally and require minimal processing. Overall, the construction of marine terminals and docks is a complex process that requires careful planning and execution, but the use of rocks can help to ensure that the resulting structure is strong, durable, and safe.