How Long Does Caulking Take To Dry

Understanding the Drying Process of Caulk

The Importance of Proper Drying

To fully appreciate the extent of time it takes for caulking to dry, one must first understand the importance of the drying process. Caulk works to seal gaps in various structures, providing insulation, preventing water leaks, and even improving structural stability. The drying (or curing) process allows the caulk to harden and firmly adhere to the surfaces, achieving its purpose. Rushing this process can lead to subpar results, such as caulk that does not adhere properly, leaving room for the penetration of water, thus defeating its main purpose.

Variables in The Drying Rate of Caulk

Various factors contribute to the rate at which caulk dries. These factors include the kind of caulk used, the width of the gap being filled, and the environmental conditions around the area. For example, silicone caulk dries faster than acrylic caulk under similar conditions. Additionally, a wider gap will require more time to dry than a thinner one. Environmental conditions such as temperature and humidity can also influence the drying process. In warmer and less humid conditions, caulk tends to dry faster.

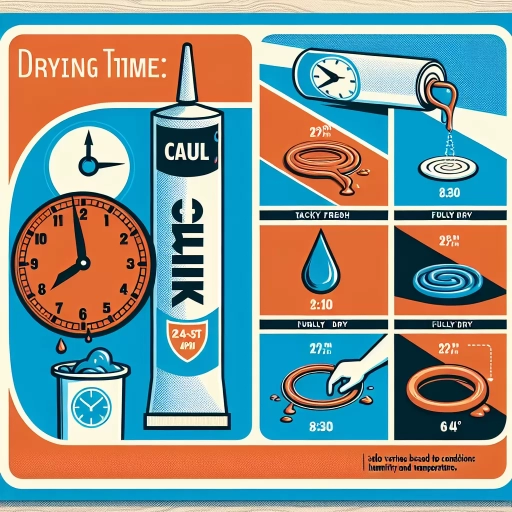

Average Drying Times for Different Types of Caulk

Different types of caulk exist and they all come with specific drying and curing times. Acrylic caulk, also known as latex caulk, commonly used for its flexibility and paintability, takes an average of 48 hours to cure completely. Silicone caulk, preferred for its water resistance and durability, usually cures within 24 hours. The fast-drying or quick-set caulk variant is designed to curb the waiting time, usually drying within a few hours. However, it's worth remembering that these are average times under ideal conditions; variations could occur based on the variables previously discussed.

Practical Tips for Faster Caulk Drying

Ensuring Proper Application

To minimize drying time, applying caulk properly is crucial. It involves cleaning and preparing the surfaces to be caulked, ensuring there's no dust or debris that could potentially hinder proper adhesion. Applying the caulk evenly with the right tools, such as a caulk gun, helps ensure an even layer that will dry consistently across the gap. Attention should be given to creating the right bead size, as a bigger bead means more depth and thickness, which corresponds with longer drying times.

Environmental Control

Controlling environmental factors allows for faster drying times. Ideal conditions for caulk to dry are warm weather and low humidity. Maintaining a room temperature of around 70 degrees Fahrenheit (21 degrees Celsius) and a humidity level between 40% to 50% is advised. Dehumidifiers and heaters can be used to control these conditions, particularly in areas with naturally high humidity or low temperatures.

Using Quick-Drying Caulk

If time is a major concern, opting for quick-drying caulk variants might be the best option. These products are designed to dry and cure at an accelerated rate, with some types advertised to be ready for use or exposure to water within an hour or less. Despite their certification, it's always good practice to allow for a little extra drying time where possible to ensure optimal results.

What Happens If Caulk Doesn’t Dry Properly?

Weak Adhesion and Poor Sealing

When caulk doesn’t dry properly, it cannot achieve strong adhesion to the substrates, thus weakening the sealing quality. This can lead to several consequences, including air leaks which could affect energy efficiency, and water leaks which may lead to structural damages like mold growth and rotting of materials. Without proper drying, the caulk could also easily peel off or crack, necessitating repeated applications.

Compromised Aesthetic Appeal

Caulk contributes to the final aesthetic appearance of a structure. Improperly dried caulk could result in a messy finish that reduces the overall aesthetic appeal of the area. Additionally, if the caulk fails to dry thoroughly before painting over, it may lead to uneven paint thickness, causing discoloration or bubbles on the painted surface.

Potential Chemical Hazards

Most caulks release chemicals during the drying process such as volatile organic compounds (VOCs). Until the caulk completely cures, these chemicals can linger and pose potential health risks, especially in poorly ventilated areas. Proper drying and curing of caulk are, therefore, essential not just for structural integrity but also for health safety.