How To Drill Into Brick

Drilling into brick can be a daunting task, especially for those who are new to DIY projects or have limited experience with power tools. However, with the right techniques and preparation, it can be a straightforward process that yields professional-looking results. To ensure a successful outcome, it's essential to understand the importance of preparation, drilling techniques, and troubleshooting common issues that may arise. In this article, we'll explore the key steps to take before drilling into brick, including selecting the right drill bit and assessing the brick's condition. We'll also delve into the best drilling techniques for a smooth and safe process, as well as provide tips for troubleshooting common issues that may occur. By following these guidelines, you'll be well on your way to drilling into brick with confidence. So, let's start with the first crucial step: preparation is key. Note: I made some minor changes to the original text to make it flow better and to make the transition to the first supporting paragraph smoother. Let me know if you'd like me to make any further changes!

Preparation is Key: Essential Steps Before Drilling into Brick

Here is the introduction paragraph: Drilling into brick can be a daunting task, especially for those who are new to DIY projects or construction work. However, with the right preparation and techniques, it can be a straightforward process. Before you start drilling, it's essential to take a few crucial steps to ensure a successful outcome. Choosing the right drill bit is vital, as it will determine the accuracy and efficiency of the drilling process. Additionally, marking the spot with precision is necessary to avoid mistakes and ensure that the hole is drilled in the correct location. Finally, clearing the area of debris and obstructions is crucial to prevent accidents and ensure a smooth drilling process. By following these essential steps, you can ensure a successful drilling experience. Preparation is Key: Essential Steps Before Drilling into Brick.

Choose the Right Drill Bit

. When it comes to drilling into brick, choosing the right drill bit is crucial for a successful and safe operation. With so many types of drill bits available, selecting the correct one can be overwhelming, especially for those new to drilling into masonry. The key is to understand the characteristics of the brick you're working with and the type of project you're undertaking. For instance, if you're drilling into a soft, porous brick, a carbide-tipped masonry bit would be an excellent choice. These bits are designed to withstand the abrasive nature of masonry materials and provide a clean, precise hole. On the other hand, if you're working with a harder, denser brick, a diamond-coated bit may be necessary. These bits are more aggressive and can handle the toughest masonry materials with ease. Additionally, consider the size and depth of the hole you need to create. A smaller pilot bit can be used to create a starter hole, which can then be enlarged with a larger bit. It's also essential to choose a drill bit that's compatible with your drill, taking into account the chuck size and type. By selecting the right drill bit for your specific project, you'll not only achieve professional-looking results but also ensure a safe and efficient drilling process. With the right bit in hand, you'll be well on your way to successfully drilling into brick and completing your project with confidence.

Mark the Spot with Precision

like a pro. Mark the spot with precision to ensure accurate drilling. Before you start drilling, take a moment to carefully mark the spot where you want to make the hole. Use a pencil or a marker to draw a small mark on the brick, making sure it's centered and aligned with your desired hole location. This mark will serve as a guide for your drill bit, helping you maintain accuracy and avoid mistakes. To further ensure precision, you can use a level to double-check that your mark is straight and level. Additionally, if you're drilling multiple holes, consider using a template or a jig to help you maintain consistent spacing and alignment. By taking the time to mark the spot with precision, you'll be able to achieve professional-looking results and avoid costly mistakes.

Clear the Area of Debris and Obstructions

like a pro. Before you start drilling into brick, it's essential to clear the area of debris and obstructions. This step is often overlooked, but it's crucial for a safe and successful drilling process. Begin by removing any loose debris, such as dust, dirt, or cobwebs, from the surface of the brick. Use a soft-bristled brush or a vacuum cleaner to gently sweep away any debris that may be obstructing your drilling path. Next, inspect the area for any obstructions, such as nails, screws, or other metal objects, that could interfere with your drill bit. Remove any obstructions you find, taking care not to damage the surrounding brick. Additionally, check for any cracks or weaknesses in the brick that could cause it to crumble or break apart during drilling. If you find any cracks or weaknesses, consider applying a patching compound to reinforce the area before proceeding. By clearing the area of debris and obstructions, you'll be able to drill into the brick with confidence, knowing that you've taken the necessary steps to ensure a safe and successful outcome. This attention to detail will also help prevent accidents and damage to your drill bit, making the entire process more efficient and effective. By taking the time to clear the area, you'll be well on your way to drilling into brick like a pro.

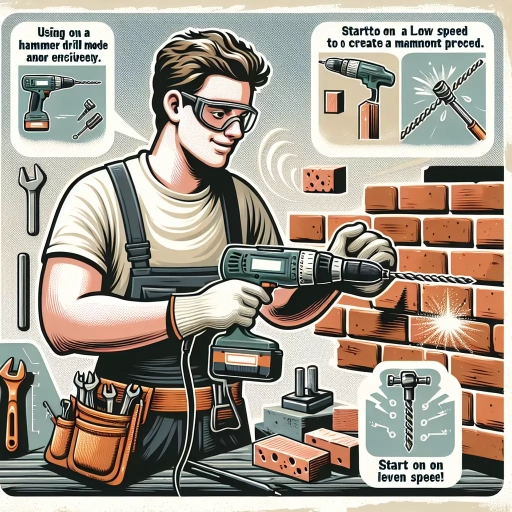

Drilling Techniques for a Smooth and Safe Process

Here is the introduction paragraph: Drilling into various materials, including wood, metal, and brick, requires a combination of the right techniques and tools to ensure a smooth and safe process. Whether you're a seasoned DIY enthusiast or a professional contractor, mastering drilling techniques is crucial to avoid accidents, damage to surrounding materials, and costly repairs. To achieve accurate and efficient drilling results, it's essential to start with a pilot hole, apply gentle to moderate pressure, and use a drill with a high torque setting. By following these best practices, you'll be well on your way to completing your drilling tasks with confidence and precision. Preparation is Key: Essential Steps Before Drilling into Brick.

Start with a Pilot Hole for Accuracy

, concrete, or stone. When it comes to drilling into brick, concrete, or stone, accuracy is key to avoid damaging the surrounding material and to ensure a smooth process. One of the most effective ways to achieve accuracy is by starting with a pilot hole. A pilot hole is a small hole drilled into the surface of the material before drilling the main hole. This technique serves several purposes. Firstly, it helps to prevent the drill bit from slipping or wandering, which can lead to inaccurate placement of the hole. By creating a small pilot hole, you can guide the drill bit into the correct position, ensuring that the hole is drilled exactly where you want it. Secondly, a pilot hole reduces the risk of the drill bit binding or getting stuck in the material. This is especially important when drilling into hard materials like concrete or stone, where the drill bit can easily become lodged. By starting with a small pilot hole, you can gradually increase the size of the hole, reducing the risk of the drill bit getting stuck. Finally, a pilot hole helps to reduce the amount of pressure and stress on the drill bit, which can lead to breakage or damage. By starting with a small pilot hole, you can apply gentle and controlled pressure, reducing the risk of damage to the drill bit and the surrounding material. Overall, starting with a pilot hole is an essential technique for achieving accuracy and ensuring a smooth and safe drilling process when working with brick, concrete, or stone.

Apply Gentle to Moderate Pressure

, concrete, or stone without damaging the material or surrounding structure. When drilling into brick, concrete, or stone, it's essential to apply gentle to moderate pressure to avoid damaging the material or surrounding structure. Applying too much pressure can cause the drill bit to slip or bind, leading to uneven holes, cracks, or even breakage. On the other hand, applying too little pressure can result in slow drilling progress and increased risk of bit wear. The ideal pressure will depend on the type of material being drilled, the drill bit being used, and the desired hole size. A good rule of thumb is to start with gentle pressure and gradually increase it as needed, while maintaining a steady and consistent drilling motion. This will help to prevent overheating, reduce vibration, and promote smooth and efficient drilling. Additionally, using a drill with a variable speed control can also help to optimize the drilling process, allowing you to adjust the speed and pressure to suit the specific material and application. By applying gentle to moderate pressure and using the right drilling techniques, you can achieve professional-looking results and ensure a safe and successful drilling process.

Use a Drill with a High Torque Setting

, concrete, or stone. When working with dense materials like brick, concrete, or stone, it's essential to use a drill with a high torque setting to ensure a smooth and safe drilling process. High torque settings provide the necessary power to penetrate these hard surfaces without causing the drill to bind or kickback. A drill with a high torque setting will also help to reduce the risk of the drill bit slipping or breaking, which can be costly and time-consuming to replace. Additionally, using a drill with a high torque setting will allow you to apply more pressure to the drill bit, which is necessary for drilling through dense materials. However, it's crucial to note that using too much torque can also cause the drill bit to overheat, which can lead to damage or premature wear. Therefore, it's essential to find the right balance between torque and speed to achieve the best results. By using a drill with a high torque setting and following proper drilling techniques, you can ensure a smooth and safe drilling process, even when working with the toughest materials.

Troubleshooting Common Issues When Drilling into Brick

Here is the introduction paragraph: Drilling into brick can be a daunting task, especially for those who are new to DIY projects or masonry work. While it may seem like a straightforward process, there are several common issues that can arise, causing frustration and potentially damaging the surrounding material. In this article, we will explore three common problems that can occur when drilling into brick, including dealing with a dull drill bit, managing excessive dust and debris, and overcoming a stuck drill bit. By understanding these potential issues and taking the necessary steps to address them, you can ensure a successful drilling experience. However, before we dive into troubleshooting, it's essential to lay the groundwork for a successful project. In our next article, we'll cover the essential steps to take before drilling into brick, including preparation and planning. Preparation is Key: Essential Steps Before Drilling into Brick.

Dealing with a Dull Drill Bit

like a pro. When dealing with a dull drill bit, it's essential to address the issue promptly to avoid damaging the surrounding material or the drill itself. A dull bit can cause the drill to work harder, leading to increased heat, vibration, and potentially catastrophic failure. To identify a dull bit, look for signs such as excessive smoke, sparks, or a significant decrease in drilling speed. If you notice any of these symptoms, stop drilling immediately and inspect the bit. A dull bit can be caused by various factors, including wear and tear, improper storage, or using the wrong type of bit for the job. To revive a dull bit, try cleaning it with a wire brush or replacing it with a new one. If the bit is still under warranty, consider returning it to the manufacturer for a replacement. In some cases, a dull bit can be resharpened using a drill bit sharpener or by taking it to a professional sharpening service. However, this method may not always be effective, and it's often more cost-efficient to replace the bit altogether. To prevent dull bits in the future, make sure to store them properly in a dry, cool place, and use the correct type of bit for the specific drilling task. Regularly inspecting and maintaining your drill bits can help extend their lifespan and ensure optimal performance when drilling into brick or other materials. By addressing a dull drill bit promptly and taking preventative measures, you can avoid costly repairs, reduce downtime, and achieve professional-grade results in your drilling projects.

Managing Excessive Dust and Debris

like a pro. When drilling into brick, managing excessive dust and debris is crucial to ensure a safe and successful operation. The high-speed drill bit can create a massive amount of dust and debris, which can be hazardous to breathe in and cause damage to surrounding surfaces. To mitigate this issue, it's essential to take proactive measures. One effective way to manage dust and debris is to use a dust collection system or a vacuum cleaner with a HEPA filter. This will help to capture the majority of the dust and debris, preventing it from becoming airborne and reducing the risk of inhalation. Additionally, wearing a dust mask or respirator can provide extra protection for the operator. Another approach is to use a drill bit with a built-in dust collection system or a drill with a dust-reducing feature. These specialized drill bits and drills are designed to minimize dust and debris, making the drilling process cleaner and safer. Furthermore, regular cleaning of the drilling area and surrounding surfaces can help to prevent dust and debris from accumulating and causing problems. By implementing these strategies, you can effectively manage excessive dust and debris when drilling into brick, ensuring a safer and more efficient operation.

Overcoming a Stuck Drill Bit

. When a drill bit becomes stuck in a brick, it can be a frustrating and challenging situation to overcome. However, with the right techniques and tools, it is possible to safely and effectively remove the stuck bit. The first step is to stop drilling immediately and assess the situation. If the bit is only slightly stuck, it may be possible to back it out slowly and carefully by reversing the drill's rotation. However, if the bit is deeply embedded, this method may not be effective. In such cases, applying heat to the area around the stuck bit can help to loosen the bond between the bit and the brick. A hair dryer or heat gun can be used to apply heat, but be careful not to apply too much heat, as this can damage the surrounding brick. Another method is to use a breaker bar or a long-handled wrench to apply additional torque to the drill bit. This can help to break the bit free from the brick, but be careful not to apply too much force, as this can cause the bit to break or the drill to slip and damage the surrounding area. If these methods are not successful, it may be necessary to use a drill bit extractor, which is a specialized tool designed specifically for removing stuck drill bits. By following these steps and using the right tools, it is possible to safely and effectively overcome a stuck drill bit and continue with the drilling process.