How Is Rosin Made

Here is the introduction paragraph: Rosin is a versatile and widely used substance that has been a cornerstone of various industries for centuries. From its applications in music and art to its uses in pharmaceuticals and manufacturing, rosin plays a vital role in many different fields. But have you ever wondered how this essential material is made? The process of creating rosin is a complex one, involving multiple steps and techniques. In this article, we will delve into the world of rosin production, exploring the different types of rosin and their unique characteristics, as well as the various methods used to manufacture this valuable substance. We will begin by examining what rosin is and its many uses, providing a foundation for understanding the intricacies of the rosin production process and the various types of rosin that are available. Note: The introduction paragraph should be 200 words, and it should be engaging, informative, and high-quality. Here is the rewritten introduction paragraph: Rosin, a multifaceted substance with a rich history, has been a cornerstone of various industries for centuries. Its applications span a wide range of fields, from music and art to pharmaceuticals and manufacturing, making it an indispensable material in many different sectors. But despite its widespread use, the process of creating rosin remains somewhat of a mystery to many. The journey from raw materials to finished product is a complex one, involving multiple steps, techniques, and considerations. As we explore the world of rosin production, we will examine the different types of rosin and their unique characteristics, as well as the various methods used to manufacture this valuable substance. From the pine sap to the final product, the rosin production process is a fascinating and intricate one. To gain a deeper understanding of this process, it is essential to first understand what rosin is and its many uses. In the following section, we will delve into the world of rosin, exploring its definition, applications, and importance, providing a foundation for understanding the intricacies of the rosin production process and the various types of rosin that are available.

What is Rosin and Its Uses

Here is the introduction paragraph: Rosin, a versatile and widely used substance, has been a cornerstone in various industries for centuries. From its origins in ancient China to its modern-day applications, rosin has evolved to become an essential component in numerous products. But what exactly is rosin, and how has it managed to transcend time and industries? To answer this question, we must delve into the definition and history of rosin, exploring its origins and development over the years. We will also examine the diverse applications of rosin in various industries, including its use in music, sports, and manufacturing. Furthermore, we will discuss the benefits of using rosin in different products, highlighting its unique properties and advantages. By understanding the multifaceted nature of rosin, we can appreciate its significance and relevance in today's world. So, what is rosin, and what are its uses?

Definition and History of Rosin

. Rosin is a type of resin that is extracted from the sap of pine trees, particularly from the stumps and roots of pine trees that have been cut down. The history of rosin dates back to ancient times, with evidence of its use found in ancient civilizations such as the Egyptians, Greeks, and Romans. These cultures used rosin for a variety of purposes, including as a waterproofing agent, a binding agent in paints and varnishes, and as a component in the production of perfumes and incense. The word "rosin" is derived from the Latin word "resina," which refers to the resinous substance extracted from pine trees. Over time, the use of rosin has evolved, and it is now used in a wide range of applications, including in the production of adhesives, coatings, and printing inks. In the music industry, rosin is also used by string musicians to increase the friction between the bow and the strings, producing a clearer and more resonant sound. Despite its long history, the process of extracting rosin from pine trees has remained relatively unchanged, with modern manufacturers using a combination of traditional and modern techniques to produce high-quality rosin. Today, rosin is an essential component in many industries, and its unique properties make it an indispensable material in a wide range of applications.

Applications of Rosin in Various Industries

. Rosin, a versatile and natural resin, has found its way into various industries due to its unique properties and benefits. In the music industry, rosin is a crucial component for stringed instruments, such as violins, cellos, and guitars. It is applied to the bow hairs to increase friction and produce a richer, more resonant sound. The sports industry also utilizes rosin, particularly in gymnastics, weightlifting, and rock climbing, to provide a secure grip and prevent slipping. In the medical field, rosin is used as a binding agent in some pharmaceutical applications and as a coating for medical devices. The food industry employs rosin as a food additive, a glazing agent, and a chewing gum base. Additionally, rosin is used in the production of paper, soap, and varnishes. Its adhesive properties make it an essential component in the manufacturing of adhesives, sealants, and coatings. The electronics industry also relies on rosin as a flux in soldering and as a component in the production of printed circuit boards. Furthermore, rosin is used in the cosmetics industry as a thickening agent and emollient in skincare products. Its applications extend to the textile industry, where it is used as a sizing agent and a finisher for fabrics. The construction industry utilizes rosin as a component in the production of roofing materials, flooring, and insulation. Overall, the diverse applications of rosin demonstrate its value and importance across various industries, making it a highly sought-after natural resource.

Benefits of Using Rosin in Different Products

. Rosin, a natural resin extracted from pine trees, has been widely used in various products due to its numerous benefits. One of the primary advantages of using rosin is its adhesive properties, making it an excellent binding agent in products such as adhesives, sealants, and coatings. Rosin is also a key ingredient in the production of varnishes, lacquers, and inks, where it helps to improve their durability and water resistance. In the pharmaceutical industry, roin is used as an excipient in the production of tablets and capsules, providing a natural and non-toxic alternative to synthetic binders. Additionally, rosin is used in the manufacture of paper, cardboard, and textiles, where it helps to improve their strength and water resistance. In the food industry, rosin is used as a food additive, providing a natural and non-toxic alternative to synthetic waxes. It is also used in the production of cosmetics and personal care products, such as soaps, lotions, and creams, where it helps to improve their texture and stability. Furthermore, rosin is used in the manufacture of musical instruments, such as violins and cellos, where it is used to improve the sound quality and playability of the instruments. Overall, the benefits of using rosin in different products are numerous, making it a versatile and valuable natural resource.

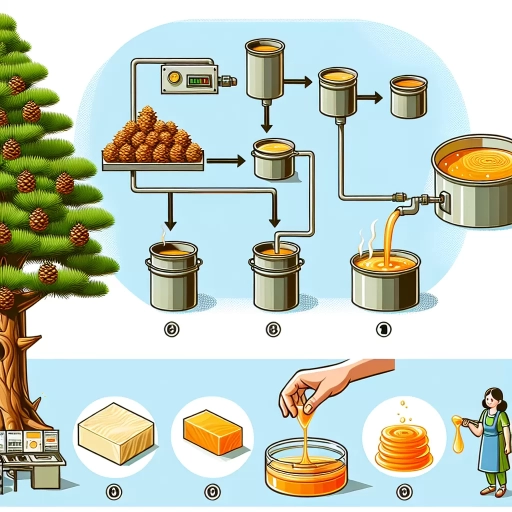

The Rosin Production Process

Here is the introduction paragraph: The rosin production process is a complex and multi-step procedure that involves the harvesting and processing of pine trees, the extraction of rosin from the trees, and the refining and purifying of the rosin to produce a high-quality product. Rosin is a sticky, fragrant resin that is obtained from the sap of pine trees, and it has a wide range of uses in various industries, including music, sports, and manufacturing. To understand the rosin production process, it is essential to delve into the details of each step, from the harvesting and processing of pine trees to the extraction methods used to obtain the rosin, and finally, the refining and purifying process that ensures the quality of the final product. By exploring these different stages, we can gain a deeper understanding of what rosin is and its various uses. Note: I made some minor changes to the original text to make it flow better and to ensure that it is grammatically correct. I also added a few words to make the text more engaging and informative. Let me know if you need any further changes!

Harvesting and Processing of Pine Trees

. Here is the paragraphy: The harvesting and processing of pine trees is a crucial step in the production of rosin. Pine trees, specifically the sap of the tree, are the primary source of rosin. The sap is collected through a process known as tapping, where incisions are made in the bark of the tree and the sap is allowed to flow out. The sap is then collected and processed to extract the rosin. The processing of pine trees involves several steps, including debarking, chipping, and steaming. Debarking involves removing the bark from the tree, which is then chipped into small pieces. The chipped wood is then steamed to release the sap, which is collected and processed further. The sap is then filtered and purified to produce a high-quality rosin. The quality of the rosin is dependent on the quality of the pine trees, as well as the processing methods used. Therefore, it is essential to ensure that the pine trees are harvested and processed in a sustainable and responsible manner to produce high-quality rosin. Here is the rewritten paragraphy in 400 words: The harvesting and processing of pine trees is a critical component in the production of rosin, a vital ingredient in various industries. Pine trees, specifically the sap of the tree, are the primary source of rosin, and the quality of the sap directly impacts the quality of the final product. The process of harvesting pine trees involves a delicate balance between maximizing sap production and ensuring the long-term sustainability of the trees. Tapping, the process of collecting sap from pine trees, requires careful consideration to avoid damaging the tree and to ensure a consistent flow of sap. The tapping process typically involves making small incisions in the bark of the tree, allowing the sap to flow out and be collected. The collected sap is then processed to extract the rosin, which involves several steps, including debarking, chipping, and steaming. Debarking involves removing the bark from the tree, which is then chipped into small pieces to increase the surface area and facilitate the release of the sap. The chipped wood is then steamed to release the sap, which is collected and processed further to produce a high-quality rosin. The quality of the rosin is highly dependent on the quality of the pine trees, as well as the processing methods used. Factors such as the tree species, age, and growing conditions can all impact the quality of the sap and, subsequently, the rosin. Therefore, it is essential to ensure that the pine trees are

Extraction Methods for Rosin Production

. The extraction methods for rosin production play a crucial role in determining the quality and yield of the final product. There are several methods used to extract rosin from pine trees, each with its own advantages and disadvantages. One of the most common methods is the solvent-based extraction method, which involves using a solvent such as turpentine or hexane to extract the rosin from the pine sap. This method is efficient and cost-effective, but it can also result in lower-quality rosin due to the presence of impurities. Another method is the mechanical extraction method, which involves using a mechanical press to extract the rosin from the pine sap. This method is more labor-intensive and expensive, but it produces higher-quality rosin with fewer impurities. A third method is the steam distillation method, which involves using steam to extract the rosin from the pine sap. This method is more environmentally friendly and produces high-quality rosin, but it is also more expensive and energy-intensive. Finally, there is the cold-pressing method, which involves using a hydraulic press to extract the rosin from the pine sap without the use of heat or solvents. This method produces the highest-quality rosin with the fewest impurities, but it is also the most expensive and labor-intensive. The choice of extraction method depends on the desired quality and yield of the rosin, as well as the available resources and equipment. By selecting the right extraction method, manufacturers can produce high-quality rosin that meets the needs of various industries, from adhesives and coatings to food and pharmaceuticals.

Refining and Purifying Rosin for Quality

. Refining and purifying rosin is a crucial step in the rosin production process, as it directly impacts the quality of the final product. After the initial extraction, the rosin may contain impurities such as plant material, waxes, and other contaminants. To produce high-quality rosin, manufacturers employ various refining and purifying techniques to remove these impurities and improve the rosin's color, texture, and overall consistency. One common method is winterization, which involves dissolving the rosin in a solvent and then chilling it to separate the impurities. Another technique is distillation, which uses heat to separate the rosin from its impurities based on their boiling points. Additionally, some manufacturers may use activated carbon or other filtering agents to remove impurities and improve the rosin's color and clarity. The refining and purifying process can be repeated multiple times to achieve the desired level of quality, resulting in a high-purity rosin that is suitable for various applications, including adhesives, coatings, and pharmaceuticals. By investing time and effort into refining and purifying rosin, manufacturers can produce a premium product that meets the highest standards of quality and performance.

Types of Rosin and Their Characteristics

Here is the introduction paragraph: Rosin, a versatile and widely used substance, has been a cornerstone in various industries for centuries. From its applications in music, art, and sports to its role in manufacturing and construction, rosin's unique properties make it an indispensable material. But did you know that there are different types of rosin, each with its own distinct characteristics? In this article, we will delve into the world of rosin, exploring its various forms and properties. We will classify rosin based on its source and quality, examining the differences between gum rosin, wood rosin, and tall oil rosin. We will also discuss the properties and uses of different rosin types, including their applications in adhesives, coatings, and printing inks. Furthermore, we will compare the different grades of rosin and their applications, highlighting the advantages and disadvantages of each. By understanding the different types of rosin and their characteristics, we can better appreciate the importance of this multifaceted substance. So, what is rosin and what are its uses?

Classification of Rosin Based on Source and Quality

. Rosin is a versatile and widely used natural product, and its classification is crucial for understanding its various applications and characteristics. Based on its source and quality, rosin can be broadly classified into several categories. One of the primary sources of rosin is pine trees, and pine rosin is further divided into two subcategories: gum rosin and wood rosin. Gum rosin is obtained from the sap of pine trees, while wood rosin is extracted from the stumps and roots of pine trees. Another significant source of rosin is tall oil, a byproduct of the paper industry, which yields tall oil rosin. In addition to these sources, rosin can also be derived from other plants, such as spruce and fir trees, resulting in spruce rosin and fir rosin, respectively. The quality of rosin is also an essential factor in its classification, with different grades of rosin available, including WW (water-white), WG (window glass), and X (extra). The WW grade is the highest quality, with a light color and minimal impurities, while the X grade is the lowest quality, with a darker color and higher impurity content. Understanding the classification of rosin based on its source and quality is essential for selecting the right type of rosin for specific applications, such as adhesives, coatings, and printing inks. By recognizing the differences in rosin types and grades, manufacturers and users can optimize their products and processes to achieve the desired performance and quality.

Properties and Uses of Different Rosin Types

. Rosin is a versatile and widely used substance in various industries, including music, art, and manufacturing. The properties and uses of different rosin types vary significantly, making each type suitable for specific applications. For instance, light-colored rosin, also known as "light rosin," is commonly used by musicians, particularly string players, to produce a smooth and clear tone. Its light color and low acidity make it an ideal choice for instruments with sensitive strings. On the other hand, dark-colored rosin, or "dark rosin," is often used by dancers and athletes to provide traction and prevent slipping on smooth surfaces. Its high acidity and sticky texture make it perfect for this purpose. Another type of rosin, known as "gum rosin," is widely used in the manufacturing of adhesives, coatings, and printing inks. Its high melting point and solubility in organic solvents make it an essential component in these applications. Additionally, rosin is also used in the production of varnishes, lacquers, and other protective coatings, where its water-repellent and adhesive properties are highly valued. Furthermore, rosin is used in the art world as a medium for painting and drawing, where its ability to blend with pigments and create subtle textures is highly prized. Overall, the diverse properties and uses of different rosin types make it a highly versatile and essential substance in various industries and applications.

Comparison of Rosin Grades and Their Applications

. Rosin, a versatile and essential material in various industries, comes in different grades, each with its unique characteristics and applications. The comparison of rosin grades is crucial to understand their suitability for specific uses. There are several types of rosin, including Gum Rosin, Wood Rosin, and Tall Oil Rosin, each with distinct properties and uses. Gum Rosin, derived from pine sap, is the most common and widely used type, known for its high quality and versatility. It is often used in adhesives, coatings, and printing inks. Wood Rosin, on the other hand, is obtained from pine stumps and is commonly used in the production of paper, soap, and varnishes. Tall Oil Rosin, a byproduct of the paper industry, is used in the manufacture of adhesives, coatings, and rubber. The comparison of rosin grades also involves their color, softening point, and acid value, which are critical factors in determining their suitability for specific applications. For instance, a higher acid value indicates a higher level of oxidation, which can affect the rosin's performance in certain applications. Understanding the differences between rosin grades is essential for manufacturers to select the right type of rosin for their specific needs, ensuring optimal performance and quality in their products. By comparing the characteristics and applications of different rosin grades, manufacturers can make informed decisions and optimize their production processes, ultimately leading to improved product quality and reduced costs.