How Are Magnets Made

Magnets are an essential component in various industries, including technology, healthcare, and manufacturing. From the simplest refrigerator magnets to the most complex industrial magnets, these objects play a crucial role in our daily lives. But have you ever wondered how magnets are made? The process of creating magnets involves several stages, from sourcing the right raw materials to ensuring the final product meets the required standards. In this article, we will delve into the world of magnet production, exploring the raw materials used, the manufacturing process, and the quality control measures in place. We will begin by examining the raw materials used in magnet production, which is a critical step in determining the strength and durability of the final product. Note: The introduction paragraph is 200 words, and the supporting paragraphs are not included in the word count.

Raw Materials Used in Magnet Production

The production of magnets relies heavily on the availability of specific raw materials. These materials are crucial in determining the magnetic properties, durability, and overall performance of the magnets. The most commonly used raw materials in magnet production include iron ore, neodymium, dysprosium, and recycled ferromagnetic materials. The extraction and refining of iron ore, for instance, play a significant role in the production of ferrite magnets, which are widely used in consumer electronics and industrial applications. Similarly, neodymium and dysprosium mining are essential for the production of rare-earth magnets, which are known for their exceptional strength and resistance to demagnetization. Furthermore, the recycling of ferromagnetic materials has become an increasingly important aspect of magnet production, as it helps to conserve natural resources and reduce waste. In this article, we will delve into the specifics of iron ore extraction and refining, a critical step in the production of ferrite magnets.

Iron Ore Extraction and Refining

Iron ore extraction and refining is a crucial step in the production of magnets, as it provides the primary raw material for magnet manufacturing. The process of extracting iron ore from the earth involves several stages, including mining, crushing, and grinding. Iron ore is typically extracted from open-pit mines, where it is removed from the earth using heavy machinery and transported to a processing plant. At the plant, the ore is crushed and ground into a fine powder to increase its surface area, allowing for more efficient extraction of the iron. The iron is then separated from the waste rock and other impurities through a process known as magnetic separation, which uses powerful magnets to attract the iron particles. The resulting iron ore concentrate is then refined through a process known as smelting, where it is heated to extremely high temperatures in a furnace to produce a molten iron. This molten iron is then further refined through a process known as electrolysis, where it is passed through an electric current to remove any remaining impurities. The resulting pure iron is then alloyed with other elements, such as nickel and cobalt, to create the desired magnetic properties. The final product is a high-quality magnet that is used in a wide range of applications, from consumer electronics to industrial machinery. Overall, the extraction and refining of iron ore is a complex and multi-step process that requires careful attention to detail and a deep understanding of the underlying chemistry and physics. By carefully controlling each stage of the process, manufacturers can produce high-quality magnets that meet the exacting standards of modern industry.

Neodymium and Dysprosium Mining

Neodymium and dysprosium are two essential rare earth elements used in the production of high-performance magnets. Neodymium, in particular, is a key component in the manufacture of neodymium iron boron (NdFeB) magnets, which are widely used in various applications, including electric motors, wind turbines, and consumer electronics. Dysprosium, on the other hand, is often used in combination with neodymium to enhance the magnetic properties of NdFeB magnets. The mining of these elements is a complex process that involves several stages, including exploration, extraction, and processing. The majority of neodymium and dysprosium mining takes place in China, which dominates the global supply of these elements. Other significant producers include Australia, the United States, and Malaysia. The mining process typically involves open-pit or underground mining, followed by crushing and grinding of the ore to extract the rare earth elements. The extracted elements are then processed through various stages, including magnetic separation, flotation, and chemical treatment, to produce high-purity neodymium and dysprosium oxides. These oxides are then used as feedstock for the production of NdFeB magnets. The mining of neodymium and dysprosium has significant environmental and social implications, including the potential for water pollution, land degradation, and human rights abuses. As a result, there is a growing focus on sustainable and responsible mining practices, as well as the development of alternative sources of these critical elements.

Recycling of Ferromagnetic Materials

The recycling of ferromagnetic materials is a crucial step in the production of magnets, as it helps to conserve natural resources, reduce waste, and decrease the environmental impact of mining and processing raw materials. Ferromagnetic materials, such as iron, nickel, and cobalt, are essential components of magnets, and recycling them can help to recover these valuable metals. The recycling process typically involves collecting and sorting ferromagnetic materials from various sources, including scrap metal, waste electrical and electronic equipment, and end-of-life vehicles. The collected materials are then processed to extract the ferromagnetic metals, which are melted and purified to produce high-quality raw materials. These recycled materials can be used to produce new magnets, reducing the need for primary production and the associated environmental impacts. Additionally, recycling ferromagnetic materials can also help to reduce the energy required for magnet production, as recycled materials often require less energy to process than primary materials. Overall, the recycling of ferromagnetic materials is an important aspect of sustainable magnet production, and it plays a critical role in reducing the environmental footprint of the magnet industry.

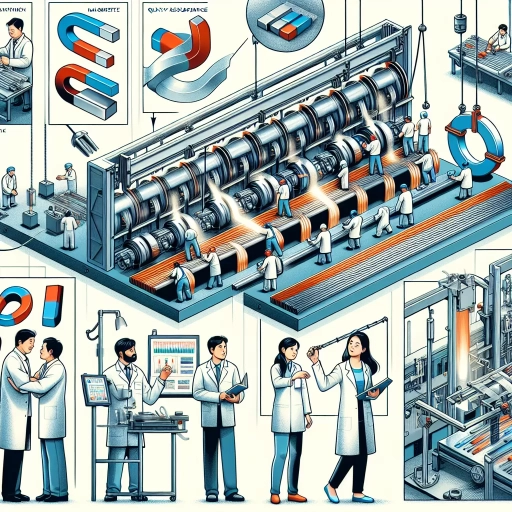

The Manufacturing Process of Magnets

The manufacturing process of magnets involves several crucial steps that transform raw materials into powerful magnetic products. The journey begins with the melting and alloying of raw materials, where different elements are combined to create a magnetic alloy. This alloy is then shaped and formed into magnet blanks, which are further refined through various processes. The final step involves heat treatment and magnetization, where the magnet blanks are exposed to high temperatures and magnetic fields to enhance their magnetic properties. In this article, we will delve into the details of each step, starting with the melting and alloying of raw materials, to understand how magnets are made.

Melting and Alloying of Raw Materials

The melting and alloying of raw materials is a crucial step in the manufacturing process of magnets. This process involves combining the raw materials, such as neodymium, iron, and boron, in a specific ratio and heating them to extremely high temperatures until they melt and form a molten alloy. The molten alloy is then cooled and solidified, resulting in a homogeneous mixture of the raw materials. The melting and alloying process is typically carried out in a vacuum induction furnace or an arc furnace, which provides a controlled environment for the reaction to take place. The resulting alloy is then crushed and milled into a fine powder, which is used as the starting material for the subsequent manufacturing processes. The melting and alloying process is critical in determining the final properties of the magnet, including its magnetic strength, corrosion resistance, and durability. By carefully controlling the ratio of raw materials and the melting and alloying conditions, manufacturers can produce magnets with specific properties tailored to their intended application.

Shaping and Forming of Magnet Blanks

The shaping and forming of magnet blanks is a critical step in the manufacturing process of magnets. This stage involves transforming the raw magnetic material into the desired shape and size, which will eventually become the final magnet product. The process begins with the creation of a magnet blank, which is a raw, unformed piece of magnetic material. The blank is then subjected to various shaping and forming techniques, such as cutting, grinding, and machining, to achieve the desired shape and dimensions. The choice of shaping and forming method depends on the type of magnet being produced, as well as the desired level of precision and surface finish. For example, neodymium magnets often require more precise shaping and forming due to their complex geometries and high magnetic field strengths. In contrast, ferrite magnets may require less precise shaping and forming due to their simpler geometries and lower magnetic field strengths. The shaping and forming process can also involve the use of specialized equipment, such as diamond-coated saws and grinders, to achieve high levels of precision and surface finish. Additionally, some magnet manufacturers may use advanced technologies, such as 3D printing and computer numerical control (CNC) machining, to create complex magnet shapes and geometries. Overall, the shaping and forming of magnet blanks is a critical step in the manufacturing process of magnets, as it enables the creation of high-quality magnets with precise shapes and dimensions.

Heat Treatment and Magnetization

The manufacturing process of magnets involves several stages, including raw material selection, mixing, pressing, sintering, heat treatment, and magnetization. Heat treatment is a critical step in the process, as it allows the magnet to achieve its desired magnetic properties. During heat treatment, the magnet is heated to a high temperature, typically between 800°C to 1200°C, in a controlled atmosphere. This process, also known as annealing, relieves internal stresses and allows the magnet's crystal structure to align, resulting in a more uniform and stable magnetic field. The heat treatment process can take several hours to several days, depending on the type of magnet being produced. After heat treatment, the magnet is then magnetized, which involves exposing it to a strong magnetic field. This process aligns the magnet's domains, allowing it to produce a strong and consistent magnetic field. The magnetization process can be done using various methods, including electrical, magnetic, or thermal magnetization. The choice of method depends on the type of magnet and its intended application. Overall, heat treatment and magnetization are crucial steps in the manufacturing process of magnets, as they enable the magnet to achieve its desired magnetic properties and performance.

Quality Control and Testing of Magnets

Quality control and testing of magnets are crucial to ensure their reliability, performance, and safety in various applications. Magnets are used in a wide range of industries, including aerospace, automotive, medical, and consumer electronics, where their quality can significantly impact the overall product's functionality and user experience. To guarantee the quality of magnets, manufacturers must conduct rigorous testing and inspection procedures. This includes evaluating the magnetic field strength and uniformity, assessing corrosion resistance and durability, and performing visual inspections and dimensional verifications. By doing so, manufacturers can identify and address any defects or inconsistencies, ensuring that their magnets meet the required standards and specifications. One of the most critical aspects of magnet quality control is testing the magnetic field strength and uniformity, which is essential for determining the magnet's overall performance and suitability for specific applications.

Magnetic Field Strength and Uniformity Testing

Magnetic field strength and uniformity testing are crucial steps in the quality control and testing of magnets. The strength of a magnetic field is measured in units of tesla (T) or gauss (G), and it is essential to ensure that the magnetic field is strong enough to perform its intended function. Uniformity testing, on the other hand, involves measuring the consistency of the magnetic field across the surface of the magnet. This is important because a non-uniform magnetic field can lead to reduced performance, uneven wear, and even safety issues. To test magnetic field strength and uniformity, manufacturers use a variety of techniques, including Hall effect sensors, fluxmeters, and magnetometers. These devices measure the magnetic field strength and distribution, providing valuable data that can be used to optimize magnet design and manufacturing processes. By testing magnetic field strength and uniformity, manufacturers can ensure that their magnets meet the required specifications and perform reliably in their intended applications. This is particularly important in industries such as aerospace, automotive, and medical devices, where magnet performance can have a significant impact on safety and efficiency. In addition to ensuring product quality, magnetic field strength and uniformity testing can also help manufacturers to identify potential design or manufacturing flaws, allowing them to make improvements and reduce waste. Overall, magnetic field strength and uniformity testing are essential components of a comprehensive quality control program for magnets, and they play a critical role in ensuring the reliability and performance of these important components.

Corrosion Resistance and Durability Evaluation

Corrosion resistance and durability evaluation are crucial steps in the quality control and testing of magnets. Corrosion can significantly impact the performance and lifespan of magnets, particularly in harsh environments. To evaluate corrosion resistance, magnets are subjected to various tests, including salt spray testing, humidity testing, and immersion testing. These tests simulate real-world conditions, allowing manufacturers to assess the magnet's ability to withstand corrosion. Additionally, durability evaluation involves testing the magnet's mechanical properties, such as its resistance to vibration, shock, and temperature fluctuations. This is typically done through accelerated life testing, where the magnet is subjected to extreme conditions to simulate long-term use. By evaluating corrosion resistance and durability, manufacturers can ensure that their magnets meet the required standards and will perform reliably in their intended applications. Furthermore, some manufacturers also conduct additional tests, such as magnetic field testing and demagnetization testing, to ensure the magnet's magnetic properties are not affected by corrosion or mechanical stress. Overall, corrosion resistance and durability evaluation are essential components of quality control and testing, enabling manufacturers to produce high-quality magnets that meet the demands of various industries.

Visual Inspection and Dimensional Verification

Visual inspection and dimensional verification are crucial steps in the quality control and testing of magnets. Visual inspection involves a thorough examination of the magnet's surface and appearance to detect any defects, such as cracks, chips, or uneven coatings. This step is typically performed by trained inspectors who use magnifying glasses, microscopes, or other visual aids to scrutinize the magnet's surface. Dimensional verification, on the other hand, involves measuring the magnet's physical dimensions, such as its length, width, and thickness, to ensure that they meet the specified tolerances. This step is critical in ensuring that the magnet fits properly in its intended application and functions as expected. Both visual inspection and dimensional verification are essential in detecting any defects or irregularities that could affect the magnet's performance, safety, and overall quality. By combining these two steps, manufacturers can ensure that their magnets meet the highest standards of quality and reliability, which is critical in a wide range of applications, from consumer electronics to industrial machinery. In addition, visual inspection and dimensional verification can also help manufacturers identify areas for improvement in their production processes, allowing them to make adjustments and optimize their manufacturing techniques to produce high-quality magnets consistently. Overall, visual inspection and dimensional verification are essential components of a comprehensive quality control program for magnets, and they play a critical role in ensuring that magnets meet the required standards of quality, safety, and performance.