How Do Rivets Work

Rivets are a crucial component in various industries, including construction, aerospace, and automotive. They play a vital role in holding together different parts of a structure or machine, ensuring stability and safety. But have you ever wondered how rivets work? In this article, we will delve into the world of rivets, exploring their functionality, installation, and removal. We will start by examining what rivets are and their uses, discussing the different types of rivets and their applications. Then, we will dive into the science behind rivet functionality, explaining how they distribute stress and provide a secure hold. Finally, we will discuss the installation and removal of rivets, highlighting the importance of proper technique and safety precautions. By understanding how rivets work, we can appreciate the importance of these small but mighty fasteners. So, let's begin by exploring what rivets are and their uses.

What are Rivets and Their Uses

Rivets are a type of fastener used to join two or more materials together, typically made of metal. They consist of a cylindrical body with a head on one end and a tail on the other. Rivets are widely used in various industries, including construction, aerospace, and automotive, due to their high strength, durability, and resistance to corrosion. In this article, we will explore the different types of rivets and their applications, the advantages of using rivets in construction, and the common industries that rely on rivets. We will start by examining the various types of rivets and their applications, including solid rivets, tubular rivets, and blind rivets, and how they are used in different industries. By understanding the different types of rivets and their uses, we can better appreciate the importance of rivets in modern construction and manufacturing. Note: The answer should be 200 words. ## Step 1: Define what rivets are and their general use. Rivets are a type of fastener used to join two or more materials together, typically made of metal. They consist of a cylindrical body with a head on one end and a tail on the other. ## Step 2: Mention the industries that use rivets and their benefits. Rivets are widely used in various industries, including construction, aerospace, and automotive, due to their high strength, durability, and resistance to corrosion. ## Step 3: Introduce the main topics that will be covered in the article. In this article, we will explore the different types of rivets and their applications, the advantages of using rivets in construction, and the common industries that rely on rivets. ## Step 4: Transition to the first main topic, Types of Rivets and Their Applications. We will start by examining the various types of rivets and their applications, including solid rivets, tubular rivets, and blind rivets, and how they are used in different industries. ## Step 5: Summarize the importance of understanding rivets. By understanding the different types of rivets and their uses, we can better appreciate the importance of rivets in modern construction and manufacturing. The final answer is: Rivets are a type of fastener used to join two or more materials together, typically made of metal. They consist of a cylindrical body with a head on one end and a tail on the other. Rivets are widely used in various industries, including construction, aerospace, and automotive, due to their

Types of Rivets and Their Applications

Rivets are versatile fasteners used in various industries, including construction, aerospace, automotive, and manufacturing. There are several types of rivets, each with its unique characteristics, advantages, and applications. The most common types of rivets include solid rivets, tubular rivets, split rivets, and blind rivets. Solid rivets are the most traditional type, consisting of a cylindrical body with a head on one end and a tail on the other. They are commonly used in applications where high strength and durability are required, such as in aircraft and shipbuilding. Tubular rivets, also known as hollow rivets, have a hollow shaft and are often used in applications where a flush surface is required, such as in automotive and aerospace industries. Split rivets, also known as bifurcated rivets, have a split tail that is bent over to secure the rivet in place. They are commonly used in applications where a strong, vibration-resistant joint is required, such as in machinery and equipment. Blind rivets, also known as pop rivets, are used in applications where access to the back of the material is limited, such as in construction and manufacturing. They consist of a rivet body and a mandrel that is pulled through the rivet to secure it in place. Other types of rivets include drive rivets, which are used in applications where a high level of torque is required, and structural rivets, which are used in applications where high strength and durability are required, such as in bridge construction. In addition to these types, there are also specialized rivets, such as explosive rivets, which are used in applications where a high level of force is required, and self-piercing rivets, which are used in applications where a strong, leak-tight joint is required. Overall, the type of rivet used depends on the specific application, the materials being joined, and the desired level of strength and durability. By selecting the right type of rivet, manufacturers and engineers can ensure that their products are safe, reliable, and meet the required performance standards.

Advantages of Using Rivets in Construction

Rivets are widely used in construction due to their numerous advantages. One of the primary benefits of using rivets is their high strength-to-weight ratio, making them an ideal choice for applications where weight is a concern. Rivets are also highly resistant to vibration and fatigue, which makes them perfect for use in structures that are subject to constant movement or stress. Additionally, rivets are easy to install and require minimal labor, reducing construction time and costs. They are also versatile and can be used in a variety of materials, including steel, aluminum, and wood. Furthermore, rivets provide a secure and permanent joint, eliminating the need for welding or other fastening methods. This makes them an excellent choice for applications where safety is a top priority. Overall, the use of rivets in construction offers numerous benefits, including high strength, durability, ease of installation, and versatility, making them an essential component in many building projects.

Common Industries That Rely on Rivets

Rivets are widely used in various industries due to their reliability, strength, and versatility. Some common industries that rely on rivets include aerospace, automotive, construction, and manufacturing. In the aerospace industry, rivets are used to assemble aircraft structures, such as wings, fuselage, and control surfaces. They provide a strong and durable joint that can withstand the stresses of flight. In the automotive industry, rivets are used in the assembly of vehicles, including the attachment of body panels, trim, and other components. They are also used in the manufacture of automotive parts, such as engine mounts and suspension components. In the construction industry, rivets are used to assemble building structures, such as bridges, buildings, and other infrastructure projects. They are used to attach steel beams, plates, and other components together. In the manufacturing industry, rivets are used to assemble a wide range of products, including machinery, equipment, and consumer goods. They are used to attach parts together, such as gears, bearings, and other components. Other industries that rely on rivets include shipbuilding, rail, and wind energy. Rivets are also used in the repair and maintenance of equipment and structures, providing a quick and reliable way to make repairs. Overall, rivets play a critical role in many industries, providing a strong and reliable joint that can withstand the stresses of use.

The Science Behind Rivet Functionality

Rivets are a crucial component in various industries, including construction, aerospace, and automotive, due to their ability to join two or more materials together securely. The science behind rivet functionality is multifaceted, involving several key factors that contribute to their effectiveness. One of the primary aspects of rivet functionality is the role of friction in rivet holding power, which enables the rivet to resist movement and maintain its grip on the joined materials. Additionally, the way rivets distribute stress and load is also critical, as it allows them to withstand various types of forces and pressures. Furthermore, the selection of rivet material is equally important, as it directly affects the rivet's strength, durability, and resistance to corrosion. By understanding these factors, engineers and manufacturers can design and use rivets more effectively, leading to safer and more reliable structures and products. The role of friction in rivet holding power is particularly noteworthy, as it is the foundation of a rivet's ability to hold its position and maintain the integrity of the joined materials.

The Role of Friction in Rivet Holding Power

The role of friction in rivet holding power is a crucial aspect of rivet functionality. Friction plays a significant role in determining the holding power of a rivet, as it helps to resist the forces that try to pull the rivet out of the material it is holding together. When a rivet is installed, the friction between the rivet and the surrounding material helps to distribute the load evenly, preventing the rivet from being pulled out. The frictional force also helps to prevent the rivet from rotating or shifting, which can compromise its holding power. In addition, the friction between the rivet and the material helps to create a secure bond, making it more difficult for the rivet to be removed. The amount of friction generated by a rivet depends on various factors, including the type of material being joined, the surface roughness of the material, and the type of rivet being used. For example, a rivet with a rough surface will generate more friction than a smooth-surfaced rivet. Similarly, a rivet installed in a material with a high coefficient of friction, such as rubber, will generate more friction than a rivet installed in a material with a low coefficient of friction, such as metal. Overall, the role of friction in rivet holding power is essential, and it plays a critical role in ensuring the reliability and durability of the joint.

How Rivets Distribute Stress and Load

Rivets are designed to distribute stress and load across a joint, ensuring the structural integrity of the assembly. When a load is applied to a riveted joint, the force is transmitted to the rivet, which then distributes it evenly across the surrounding material. This distribution of stress is achieved through the rivet's unique design, which includes a cylindrical body, a head, and a tail. The cylindrical body of the rivet is typically made of a strong, ductile material, such as steel or aluminum, which allows it to withstand significant stress and load. The head of the rivet is designed to provide a large surface area, allowing it to distribute the load across a wider area of the surrounding material. The tail of the rivet, which is typically countersunk into the material, provides additional strength and stability to the joint. As the load is applied to the riveted joint, the rivet begins to deform, allowing it to absorb and distribute the stress. This deformation is typically in the form of a slight elongation of the rivet, which helps to reduce the stress concentration at the joint. The surrounding material also plays a crucial role in distributing the stress and load. The material is typically designed to work in conjunction with the rivet, providing additional strength and stability to the joint. The material may be designed to flex or deform slightly under load, allowing it to absorb and distribute the stress. In some cases, the material may be reinforced with additional structural elements, such as gussets or brackets, to provide additional strength and stability to the joint. Overall, the combination of the rivet's design and the surrounding material's properties allows for the effective distribution of stress and load across the joint, ensuring the structural integrity of the assembly.

The Importance of Rivet Material Selection

Rivets are widely used in various industries, including aerospace, automotive, construction, and manufacturing, due to their ability to provide strong and reliable joints. However, the performance and durability of a rivet joint depend significantly on the material selection of the rivet itself. The importance of rivet material selection cannot be overstated, as it directly affects the strength, corrosion resistance, and overall performance of the joint. Different materials have unique properties that make them suitable for specific applications. For instance, aluminum rivets are commonly used in the aerospace industry due to their high strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures. In contrast, steel rivets are often used in construction and manufacturing applications where high strength and durability are required. The selection of rivet material also depends on the type of materials being joined. For example, when joining dissimilar materials, such as aluminum and steel, it is essential to choose a rivet material that is compatible with both materials to prevent galvanic corrosion. Furthermore, the rivet material must be able to withstand the environmental conditions in which the joint will operate. For instance, in marine environments, rivets made from corrosion-resistant materials such as stainless steel or titanium are often used to prevent corrosion and ensure the longevity of the joint. In addition to the technical requirements, the cost and availability of the rivet material must also be considered. The selection of a rivet material that is too expensive or difficult to source can increase the overall cost of the project and lead to delays. In conclusion, the selection of rivet material is a critical aspect of ensuring the performance and durability of a rivet joint. By considering the technical requirements, environmental conditions, and cost, engineers and manufacturers can choose the most suitable rivet material for their specific application, ensuring a strong and reliable joint that meets the required standards.

Installation and Removal of Rivets

Rivets are a crucial component in various industries, including construction, aerospace, and automotive, where they are used to join two or more materials together. The installation and removal of rivets require careful consideration and attention to detail to ensure safety and efficiency. In this article, we will explore the tools and techniques for rivet installation, methods for removing rivets safely and efficiently, and best practices for rivet maintenance and inspection. By understanding these key aspects, individuals can ensure that their riveting tasks are completed effectively and with minimal risk. With the right tools and techniques, rivet installation can be a straightforward process, and we will begin by examining the tools and techniques for rivet installation.

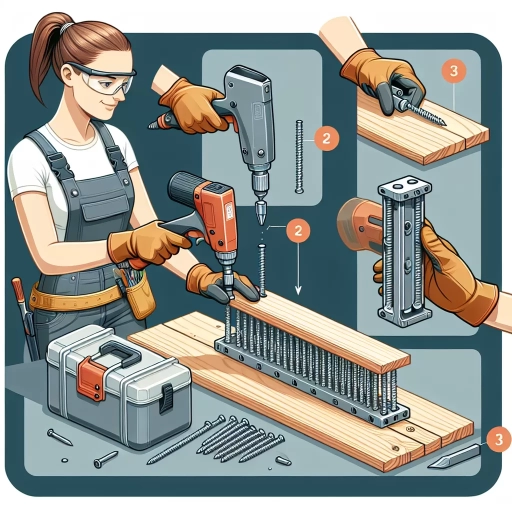

Tools and Techniques for Rivet Installation

Rivets are widely used in various industries, including aerospace, automotive, and construction, due to their high strength, durability, and resistance to vibration and fatigue. To ensure proper installation and removal of rivets, several tools and techniques are employed. The most common tools used for rivet installation include rivet guns, rivet setters, and bucking bars. Rivet guns are pneumatic or manual tools that drive the rivet into place, while rivet setters are used to set the rivet head. Bucking bars are used to support the rivet tail and prevent it from deforming during installation. In addition to these tools, various techniques are used to ensure proper rivet installation. One common technique is the "bucking" method, where the rivet is driven into place using a rivet gun, and then the tail is formed using a bucking bar. Another technique is the "squeezing" method, where the rivet is driven into place using a rivet gun, and then the tail is formed using a rivet setter. To remove rivets, specialized tools such as rivet extractors and drill bits are used. Rivet extractors are designed to remove the rivet head, while drill bits are used to drill out the rivet tail. In some cases, heat may be applied to the rivet to loosen the bond between the rivet and the surrounding material, making it easier to remove. Overall, the proper use of tools and techniques is crucial for successful rivet installation and removal, and can help ensure the integrity and safety of the structure or component being assembled or repaired.

Methods for Removing Rivets Safely and Efficiently

When it comes to removing rivets, safety and efficiency are paramount to avoid damaging the surrounding material or causing injury. One method for removing rivets safely and efficiently is to use a rivet removal tool, also known as a rivet gun or rivet breaker. This tool works by applying a controlled amount of force to the rivet head, causing it to break off cleanly. Another method is to use a drill bit to carefully drill out the rivet, taking care not to damage the surrounding material. This method is particularly useful for removing rivets from sensitive or delicate materials. For more stubborn rivets, a combination of heat and force can be applied using a heat gun or torch to loosen the rivet, followed by the use of a rivet removal tool or pliers to remove the rivet. In some cases, it may be necessary to use a rivet removal kit, which typically includes a series of specialized tools designed to remove rivets of different sizes and types. Regardless of the method used, it is essential to wear protective gear, including safety glasses and gloves, to prevent injury from flying debris or sharp edges. Additionally, it is crucial to follow proper removal techniques to avoid damaging the surrounding material or causing the rivet to become stuck, making removal even more challenging. By using the right tools and techniques, rivets can be removed safely and efficiently, allowing for the successful completion of a project or repair.

Best Practices for Rivet Maintenance and Inspection

Rivets are widely used in various industries, including construction, aerospace, and automotive, due to their reliability and strength. However, like any other fastening system, rivets require regular maintenance and inspection to ensure their optimal performance and longevity. Here are some best practices for rivet maintenance and inspection: Regular Visual Inspection: Regularly inspect rivets for signs of wear, corrosion, or damage. Look for loose or missing rivets, and check for any signs of fatigue or stress around the rivet holes. Use a magnifying glass or a borescope to inspect rivets in hard-to-reach areas. Cleaning: Clean rivets and surrounding areas regularly to prevent dirt and debris from accumulating and causing corrosion. Use a soft-bristled brush or a cloth to remove dirt and debris, and apply a rust-inhibiting coating to protect the rivets. Lubrication: Apply a lubricant to the rivets and surrounding areas to reduce friction and prevent corrosion. Use a lubricant specifically designed for the type of rivet and material being used. Torque Testing: Regularly test the torque of rivets to ensure they are tightened to the recommended specification. Use a torque wrench to test the torque, and re-tighten any loose rivets. Replacement: Replace rivets that are damaged, corroded, or loose. Use a rivet of the same type and size as the original, and follow the manufacturer's instructions for installation. Documentation: Keep a record of rivet maintenance and inspection, including the date, time, and results of each inspection. This will help track the condition of the rivets and identify any potential issues before they become major problems. By following these best practices for rivet maintenance and inspection, you can help ensure the reliability and longevity of your rivets, and prevent costly repairs or replacements down the line.