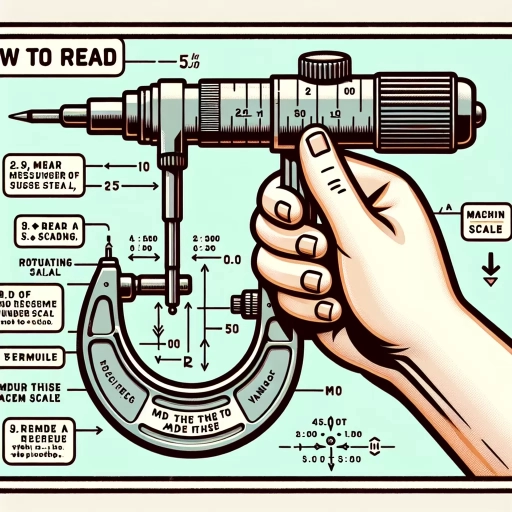

How To Read Micrometer

A micrometer is a precision measuring instrument used to measure small distances, thicknesses, and diameters with high accuracy. To read a micrometer, one must first understand its components, including the anvil, spindle, and barrel. Once familiar with these parts, the next step is to set up and calibrate the micrometer to ensure accurate measurements. With the micrometer properly calibrated, one can then take precise measurements by carefully rotating the barrel and reading the resulting measurement. In this article, we will delve into the world of micrometers, starting with the fundamental understanding of its components, followed by a step-by-step guide on setting up and calibrating the instrument, and finally, providing tips on how to take accurate measurements. By the end of this article, readers will be equipped with the knowledge and skills necessary to confidently read a micrometer and take precise measurements. Let's begin by understanding the micrometer's components.

Understanding the Micrometer's Components

A micrometer is a precision measuring instrument used to measure small distances or thicknesses with high accuracy. To use a micrometer effectively, it is essential to understand its components and their functions. The micrometer consists of several key parts, including the frame, anvil, and spindle, which work together to provide precise measurements. Additionally, the sleeve, lock nut, and ratchet play crucial roles in ensuring accurate readings. Furthermore, the thimble, barrel, and gradations are vital components that enable users to take precise measurements. By understanding the functions of these components, users can ensure accurate and reliable measurements. In this article, we will explore the components of a micrometer in detail, starting with the identification of the frame, anvil, and spindle.

Identifying the Frame, Anvil, and Spindle

The frame, anvil, and spindle are three crucial components of a micrometer that work together to provide precise measurements. The frame is the outer casing of the micrometer, which houses the other components and provides a stable base for the instrument. It is typically made of a durable material, such as metal or plastic, and is designed to withstand regular use. The anvil is a flat, stationary surface that is attached to the frame and serves as a reference point for the spindle. It is usually made of a hard, wear-resistant material, such as steel or carbide, to ensure accurate measurements. The spindle is a rotating shaft that moves in and out of the frame, with one end attached to the anvil and the other end attached to the thimble. As the thimble is turned, the spindle moves, allowing the user to take precise measurements. The spindle is typically made of a high-strength material, such as steel or titanium, to ensure smooth and accurate movement. By understanding the function and relationship of the frame, anvil, and spindle, users can better appreciate the precision and accuracy of the micrometer and take more accurate measurements.

Recognizing the Sleeve, Lock Nut, and Ratchet

The sleeve, lock nut, and ratchet are three essential components of a micrometer that work together to provide precise measurements. The sleeve is the stationary part of the micrometer that houses the anvil and the spindle, and it is typically marked with a scale that indicates the measurement range of the micrometer. The lock nut is a rotating ring that is used to secure the spindle in place once the desired measurement has been obtained, ensuring that the measurement is not accidentally altered. The ratchet is a mechanism that provides a tactile feedback when the spindle is turned, allowing the user to feel when the measurement is being taken. It is typically located at the end of the thimble and is designed to provide a smooth and consistent feel when the spindle is being turned. By understanding the function of these components, users can ensure accurate and reliable measurements with their micrometer.

Locating the Thimble, Barrel, and Gradations

The micrometer's thimble, barrel, and gradations are crucial components that work together to provide precise measurements. To locate these parts, start by identifying the thimble, which is the rotating ring at the end of the micrometer. The thimble is typically marked with a series of lines or numbers that indicate the measurement being taken. Next, look for the barrel, which is the stationary part of the micrometer that the thimble rotates around. The barrel is usually marked with a series of lines or numbers that correspond to the thimble's markings. Finally, examine the gradations, which are the lines or markings on the barrel that indicate the measurement being taken. The gradations are usually divided into units of measurement, such as millimeters or inches, and may include additional markings for finer measurements. By understanding the relationship between the thimble, barrel, and gradations, you can accurately read the micrometer and take precise measurements.

Setting Up and Calibrating the Micrometer

Setting up and calibrating a micrometer is a crucial step in ensuring accurate measurements in various fields, including engineering, manufacturing, and quality control. A micrometer is a precision measuring instrument that requires careful setup and calibration to provide reliable results. To achieve this, it is essential to follow a series of steps, including zeroing the micrometer and ensuring accuracy, calibrating the micrometer with a calibration standard, and adjusting the micrometer's tension and alignment. By following these steps, users can ensure that their micrometer is functioning correctly and providing accurate measurements. In this article, we will explore each of these steps in detail, starting with the importance of zeroing the micrometer and ensuring accuracy.

Zeroing the Micrometer and Ensuring Accuracy

When zeroing the micrometer, it is crucial to ensure accuracy to obtain reliable measurements. To do this, start by closing the micrometer until the spindle touches the anvil, then rotate the thimble clockwise until it stops. This sets the micrometer to its zero position. Next, check the micrometer's zero error by reading the thimble and sleeve scales. If the thimble scale reads zero and the sleeve scale reads a non-zero value, the micrometer has a zero error. To correct this, rotate the thimble counterclockwise until the sleeve scale reads zero. Now, the micrometer is zeroed and ready for use. To ensure accuracy, it is essential to handle the micrometer with care, avoiding any shocks or vibrations that could affect its calibration. Additionally, regular calibration checks should be performed to ensure the micrometer remains accurate over time. By following these steps, you can ensure that your micrometer is accurately zeroed and ready to provide precise measurements.

Calibrating the Micrometer with a Calibration Standard

Calibrating the micrometer with a calibration standard is a crucial step in ensuring the accuracy of measurements. A calibration standard is a precision-made object with known dimensions, used to verify the micrometer's accuracy. To calibrate the micrometer, start by selecting a calibration standard that matches the micrometer's range and resolution. Next, carefully clean the micrometer and the calibration standard to prevent any debris or contamination from affecting the measurement. Then, place the calibration standard between the micrometer's anvil and spindle, ensuring it is securely seated and aligned. Take multiple readings of the calibration standard using the micrometer, rotating the standard 90 degrees between each reading to account for any potential errors. Record the average reading and compare it to the known dimension of the calibration standard. If the readings are within the acceptable tolerance, the micrometer is calibrated and ready for use. However, if the readings are outside the tolerance, adjustments may be necessary to the micrometer's zero point or scale. Regular calibration with a calibration standard ensures the micrometer remains accurate and reliable, providing precise measurements for a variety of applications.

Adjusting the Micrometer's Tension and Alignment

Adjusting the micrometer's tension and alignment is a crucial step in ensuring accurate measurements. To begin, hold the micrometer in your dominant hand, with your thumb and index finger supporting the frame and your middle finger on the thimble. Gently rotate the thimble clockwise to increase the tension, and counterclockwise to decrease it. The ideal tension is when the thimble rotates smoothly and freely, without any binding or play. Next, check the alignment of the micrometer by placing it on a flat surface and ensuring that the anvil and spindle are parallel to each other. If necessary, adjust the micrometer's alignment by gently twisting the frame while holding the thimble stationary. It's essential to note that over-tightening or over-loosening the micrometer can lead to inaccurate readings, so it's crucial to find the optimal tension and alignment. Additionally, regular cleaning and maintenance of the micrometer can help prevent wear and tear, ensuring that it remains accurate and reliable over time. By following these steps, you can ensure that your micrometer is properly adjusted and aligned, providing you with precise measurements and confidence in your work.

Measuring with the Micrometer

Measuring with a micrometer requires attention to detail and a thorough understanding of the instrument's components and functionality. To accurately measure an object's dimensions, it is essential to take initial and final readings with the micrometer, using the graduations on the barrel and thimble to determine precise measurements. Additionally, understanding how to record and interpret measurement results is crucial for ensuring the accuracy and reliability of the data. By mastering these skills, individuals can confidently use a micrometer to obtain precise measurements, which is critical in various fields such as engineering, manufacturing, and quality control. To begin, it is essential to learn how to take initial and final readings with the micrometer, which involves setting the instrument to zero and carefully rotating the thimble to make contact with the object being measured.

Taking Initial and Final Readings with the Micrometer

When taking initial and final readings with the micrometer, it is essential to follow a systematic approach to ensure accuracy and reliability. To begin, ensure the micrometer is properly calibrated and the anvil and spindle are clean and free from debris. Next, place the object being measured between the anvil and spindle, making sure it is centered and secure. Take the initial reading by rotating the thimble clockwise until the spindle makes contact with the object. Record the reading on the sleeve, barrel, and thimble, taking note of the direction of the measurement. To take the final reading, rotate the thimble counterclockwise until the spindle is released from the object. Again, record the reading on the sleeve, barrel, and thimble, ensuring to note the direction of the measurement. It is crucial to take multiple readings to account for any human error or variations in the measurement. By following this systematic approach, you can ensure accurate and reliable measurements with the micrometer.

Using the Micrometer's Gradations to Determine Measurements

When using a micrometer to take precise measurements, it's essential to understand how to read the graduations on the device. The micrometer's barrel is typically divided into four main parts: the frame, the anvil, the spindle, and the sleeve. The sleeve is the part that rotates, and it's marked with graduations that indicate the measurement. The graduations on the sleeve are usually divided into four lines: the main scale, the vernier scale, the pitch line, and the zero line. The main scale is the largest scale and is usually marked with numbers that represent the measurement in millimeters or inches. The vernier scale is a smaller scale that's used to take more precise measurements. It's usually marked with numbers that represent the measurement in smaller units, such as 0.01 mm or 0.001 inches. The pitch line is a line that indicates the direction of the measurement, and the zero line is the line that indicates the starting point of the measurement. To take a measurement, the user must align the zero line on the sleeve with the zero line on the anvil, and then rotate the sleeve until the spindle is in contact with the object being measured. The measurement is then read by looking at the graduations on the sleeve and adding the values together. For example, if the main scale reads 10 mm and the vernier scale reads 0.05 mm, the total measurement would be 10.05 mm. By understanding how to read the graduations on the micrometer, users can take precise measurements with confidence.

Recording and Interpreting Measurement Results

When recording and interpreting measurement results, it is essential to follow a systematic approach to ensure accuracy and reliability. First, the measurement should be taken carefully using a calibrated micrometer, and the result should be recorded in a clear and concise manner. The measurement should be expressed in the correct unit of measurement, such as millimeters or inches, and should include the appropriate number of decimal places. For example, if the measurement is 10.25 mm, it should be recorded as such, rather than rounding it to 10 mm. Additionally, the measurement should be recorded in a way that indicates the level of precision, such as ±0.01 mm, to provide context for the result. When interpreting the measurement result, it is crucial to consider the context in which the measurement was taken, including the object being measured, the environmental conditions, and the calibration of the micrometer. The measurement result should be compared to the expected value or tolerance to determine if it is within the acceptable range. If the measurement result is outside of the expected range, it may indicate an error in the measurement process or a problem with the object being measured. By following a systematic approach to recording and interpreting measurement results, individuals can ensure that their measurements are accurate, reliable, and meaningful.