How To Make Olive Oil

Olive oil is a staple in many cuisines around the world, and its rich flavor and numerous health benefits have made it a popular choice for cooking and dressing salads. But have you ever wondered how this liquid gold is made? From the harvesting of olives to the bottling of the final product, the process of making olive oil is a complex and nuanced one. To understand the art of olive oil production, it's essential to start with the basics. In this article, we'll delve into the world of olive oil production, exploring the process of extracting the oil from the olives, refining it to perfection, and bottling the final product. We'll begin by understanding the basics of olive oil production, including the different types of olives used, the importance of timing, and the role of climate and soil in shaping the flavor and quality of the oil.

Understanding the Basics of Olive Oil Production

Olive oil production is a complex process that requires careful attention to detail, from the initial stages of cultivation to the final stages of bottling. To produce high-quality olive oil, it is essential to understand the basics of the process. This includes choosing the right olive variety, harvesting olives at the right time, and preparing the olives for production. By selecting the right variety, producers can ensure that their olives have the desired flavor and aroma profiles. Harvesting at the right time is also crucial, as it can affect the quality and quantity of the oil. Finally, proper preparation of the olives is necessary to extract the oil efficiently and effectively. In this article, we will explore these key aspects of olive oil production, starting with the importance of choosing the right olive variety.

Choosing the Right Olive Variety

When it comes to choosing the right olive variety for olive oil production, there are several factors to consider. With over 200 varieties of olives worldwide, each with its unique characteristics, flavor profile, and oil yield, selecting the right one can be overwhelming. However, by understanding the key characteristics of different olive varieties, producers can make informed decisions that suit their specific needs and climate. For example, popular varieties like Frantoio, Koroneiki, and Arbequina are known for their high oil yield and are often used in commercial production. On the other hand, varieties like Kalamata and Gaeta are prized for their distinct flavor profiles and are often used in specialty or artisanal production. Climate and region also play a significant role in determining the best olive variety, as some varieties are more resistant to heat, cold, or disease than others. For instance, varieties like Picual and Cornicabra are well-suited for hot and dry climates, while varieties like Leccino and Pendolino thrive in cooler and more humid environments. Ultimately, the right olive variety will depend on the specific goals and conditions of the producer, and careful consideration of these factors is essential for producing high-quality olive oil.

Harvesting Olives at the Right Time

Harvesting olives at the right time is crucial for producing high-quality olive oil. The ideal time for harvesting olives depends on the variety, climate, and region. Generally, olives are ready to be harvested between October and December, when they are ripe and have reached their optimal flavor and aroma. Harvesting too early can result in unripe olives, which can produce a bitter taste, while harvesting too late can lead to overripe olives, which can become too soft and lose their flavor. To determine the optimal harvest time, farmers typically check the color, texture, and taste of the olives. They look for olives that are a deep purple or black color, have a slightly soft texture, and a fruity, slightly bitter taste. Some farmers also use a refractometer to measure the sugar content of the olives, which can indicate the optimal harvest time. Once the olives are harvested, they are typically sorted and cleaned to remove any leaves, twigs, or damaged olives, before being transported to the mill for processing. The timing of the harvest can also impact the yield and quality of the olive oil, with some varieties producing more oil when harvested at a specific time. For example, some varieties may produce more oil when harvested in the morning, when the olives are cooler and more turgid, while others may produce more oil when harvested in the afternoon, when the olives are warmer and more ripe. Overall, harvesting olives at the right time is a critical step in producing high-quality olive oil, and requires careful attention to the variety, climate, and region.

Preparing the Olives for Production

Preparing the olives for production is a crucial step in the olive oil production process. After harvesting, the olives are sorted and cleaned to remove any leaves, twigs, or damaged fruit. This is typically done by hand or using a mechanical sorter, which helps to ensure that only high-quality olives are used for production. The olives are then washed to remove any dirt, bacteria, or other contaminants that may affect the flavor and quality of the oil. Some producers may also use a process called "crushing" or "milling" to break down the olives and release their oil, while others may use a more traditional method called "stone milling" which uses a large stone wheel to crush the olives. The goal of this step is to release the oil from the olives and prepare it for extraction. The type of preparation method used can affect the flavor and quality of the final product, so it's essential to choose a method that suits the specific variety of olives being used. By carefully preparing the olives, producers can ensure that their olive oil is of the highest quality and meets the desired standards.

The Process of Extracting Olive Oil

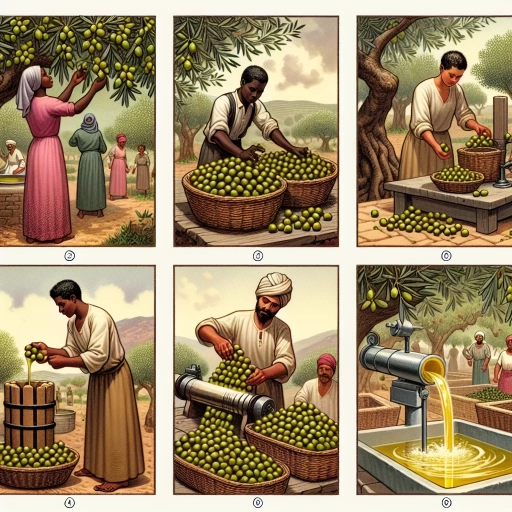

The process of extracting olive oil is a multi-step procedure that requires great care and attention to detail. The journey from olive tree to bottle involves several crucial stages, each playing a vital role in producing high-quality olive oil. First, the olives must be crushed to release their oil, a process that requires precision to avoid damaging the delicate fruit. Following crushing, the mixture undergoes malaxation, a period of rest that allows the oil to separate from the solids. Finally, the oil is separated from the solids through a process of centrifugation or pressing. In this article, we will delve into each of these stages, starting with the initial step of crushing the olives to release the oil.

Crushing the Olives to Release the Oil

The process of crushing the olives to release the oil is a crucial step in extracting olive oil. This process, also known as malaxation, involves breaking down the olives' cellular structure to release the oil from the vacuoles, where it is stored. The crushing process can be done using a traditional stone mill or a modern steel crusher. The stone mill, which is still used in many traditional olive oil-producing countries, uses a large stone wheel to crush the olives, while the steel crusher uses a series of rollers to break down the olives. The goal of the crushing process is to release the oil from the olives without damaging the pit or the skin, as this can impart bitter flavors to the oil. The crushing process typically takes place within 24 hours of harvesting the olives, as this helps to preserve the oil's flavor and aroma. After crushing, the olives are left to sit for a period of time, allowing the oil to seep out of the vacuoles and mix with the natural juices of the olive. This process can take anywhere from a few hours to a few days, depending on the type of olives and the desired flavor profile of the oil. The resulting mixture is then transferred to a centrifuge or press, where the oil is separated from the solids and liquids. The quality of the crushing process can greatly impact the final flavor and aroma of the olive oil, making it a critical step in the extraction process.

Malaxation: Allowing the Oil to Separate

Malaxation is a critical step in the process of extracting olive oil, allowing the oil to separate from the solids and water. After crushing, the olive paste is left to sit for a period of time, which can range from a few hours to a few days, depending on the desired flavor and quality of the oil. During this time, the natural enzymes in the olives break down the cellular structure, releasing the oil from the solids and allowing it to coalesce and separate. The longer the malaxation time, the more complex and full-bodied the flavor of the oil will be. However, if the malaxation time is too long, the oil can become bitter and of poor quality. The ideal malaxation time will depend on factors such as the variety of olive, the ripeness of the fruit, and the desired style of oil. In general, a malaxation time of 24-48 hours is considered optimal for producing high-quality extra virgin olive oil. After malaxation, the oil is extracted from the solids using a centrifuge or press, resulting in a high-quality oil that is rich in flavor and aroma.

Separating the Oil from the Solids

The process of separating the oil from the solids is a crucial step in extracting high-quality olive oil. This process is typically done using a centrifuge or a press, which helps to separate the oil from the solids and liquids. The centrifuge uses a spinning motion to separate the different components, while the press uses a mechanical force to extract the oil. The resulting liquid is a mixture of oil and water, which is then separated using a decanter or a centrifuge. The oil is then transferred to a storage tank, where it is left to settle and separate from any remaining impurities. This process is repeated several times to ensure that the oil is of the highest quality and has the desired flavor and aroma. The solids, on the other hand, are often used as animal feed or compost, while the water is either discarded or used for irrigation purposes. Overall, the process of separating the oil from the solids is a critical step in producing high-quality olive oil that is rich in flavor and nutrients.

Refining and Bottling the Final Product

Refining and bottling the final product is a crucial step in the production of high-quality oil. This process involves several key steps that ensure the oil meets the desired standards of clarity, flavor, and consistency. First, the oil must be filtered to remove any impurities and achieve the desired level of clarity. This is followed by blending the oil to ensure a consistent flavor profile. Finally, the oil is bottled and labeled, ready for distribution and consumption. In this article, we will explore each of these steps in more detail, starting with the importance of filtering the oil for clarity and quality.

Filtering the Oil for Clarity and Quality

The process of filtering the oil for clarity and quality is a crucial step in the production of high-quality olive oil. After the oil has been extracted from the olives, it may still contain impurities and sediment that can affect its flavor, aroma, and overall quality. Filtering the oil helps to remove these impurities and improve its clarity, resulting in a more refined and polished product. There are several methods of filtering olive oil, including paper filtration, plate filtration, and centrifugal filtration. Paper filtration involves passing the oil through a paper filter, which traps impurities and sediment, while plate filtration uses a series of plates with small holes to filter the oil. Centrifugal filtration, on the other hand, uses a centrifuge to separate the impurities from the oil. Regardless of the method used, the goal of filtering the oil is to produce a clear and high-quality product that meets the desired standards. By filtering the oil, producers can ensure that their olive oil is free from impurities and has a smooth, consistent flavor and aroma. This is especially important for high-end olive oils, where clarity and quality are paramount. In addition to improving the quality of the oil, filtering also helps to extend its shelf life by removing impurities that can cause the oil to become rancid over time. Overall, filtering the oil for clarity and quality is an essential step in the production of high-quality olive oil, and is a key factor in determining the final product's flavor, aroma, and overall quality.

Blending the Oil for Consistent Flavor

The art of blending oil for consistent flavor is a crucial step in the olive oil production process. It requires a deep understanding of the different flavor profiles of various olive varieties and the ability to balance them to create a harmonious and consistent taste. The goal of blending is to achieve a flavor that is greater than the sum of its parts, where each component enhances the others to create a unique and delicious oil. To achieve this, producers must carefully select and combine oils from different olive varieties, taking into account factors such as the region, climate, and ripeness of the olives. The blending process typically involves tasting and evaluating different combinations of oils, making adjustments as needed to achieve the desired flavor profile. This process can be time-consuming and requires a great deal of expertise, but the end result is well worth the effort. A well-blended oil can elevate the flavor of any dish, from salads and sauces to roasted vegetables and grilled meats. By mastering the art of blending, producers can create a consistent and high-quality oil that showcases the best of what their olives have to offer.

Bottling and Labeling the Final Product

The final step in the olive oil production process is bottling and labeling the final product. This stage is crucial in preserving the quality and flavor of the olive oil. The bottling process typically involves filling glass bottles with the refined olive oil, leaving a small amount of headspace to prevent oxidation. The bottles are then sealed with a tight-fitting cap or cork to prevent air from entering and spoiling the oil. Some producers may also use nitrogen or argon gas to flush out any oxygen in the bottle, further protecting the oil from oxidation. Once the bottles are filled and sealed, they are labeled with the producer's information, the type of olive oil, and any relevant certifications or awards. The labels may also include information about the oil's acidity level, polyphenol content, and production date. Finally, the bottles are packaged and prepared for distribution to retailers and consumers. It's worth noting that some producers may choose to bottle their olive oil in larger containers, such as tins or drums, for commercial or industrial use. In these cases, the bottling and labeling process may be slightly different, but the goal of preserving the quality and flavor of the oil remains the same.