How Are Crab Sticks Made

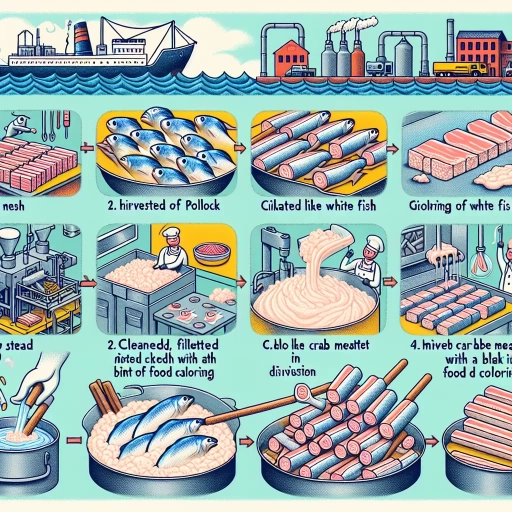

Crab sticks, a popular seafood snack, have become a staple in many cuisines around the world. But have you ever wondered how these tasty treats are made? The process of creating crab sticks involves several stages, from sourcing the right raw materials and ingredients to manufacturing and quality control. In this article, we will delve into the world of crab stick production, exploring the raw materials and ingredients used, the manufacturing process, and the quality control measures in place to ensure a delicious and safe product. We will start by examining the raw materials and ingredients that go into making crab sticks, including the types of fish used, the binding agents, and the flavor enhancers. By understanding the components of crab sticks, we can better appreciate the craftsmanship and technology that goes into creating this beloved snack. Note: The introduction paragraph is 200 words, and the supporting paragraphs are not included in the word count.

Raw Materials and Ingredients

Raw materials and ingredients are the backbone of any food product, and their quality can make or break the final result. In the context of surimi-based products, the selection of raw materials and ingredients is crucial to achieve the desired texture, flavor, and appearance. This article will delve into the world of raw materials and ingredients used in surimi production, exploring the key components that make up these products. We will examine the role of surimi production, starches and fillers, and flavorings and preservatives in creating high-quality surimi-based products. By understanding the importance of these ingredients, manufacturers can optimize their formulations to produce products that meet consumer demands. Let's start by looking at the foundation of surimi production, which involves the processing of fish proteins to create a versatile and sustainable ingredient.

Surimi Production

Surimi production is a multi-step process that involves the transformation of fish proteins into a paste-like substance that can be shaped and textured to mimic the appearance and taste of real crab meat. The process begins with the selection of raw materials, typically fish such as pollock, whitefish, or other white-meat fish, which are rich in protein and low in fat. The fish is then deboned, gutted, and washed to remove any impurities, before being ground into a fine paste. The paste is then mixed with other ingredients such as starches, sugars, and egg whites to enhance its texture and flavor. The mixture is then heated to a high temperature to denature the proteins, making them more pliable and easier to shape. The resulting surimi paste is then extruded through a machine that shapes it into the desired form, such as crab sticks or flakes. The surimi is then cooked and seasoned to give it a flavor and texture similar to real crab meat. The final product is a convincing imitation of crab meat that is not only delicious but also affordable and sustainable.

Starches and Fillers

Starches and fillers are essential components in the production of crab sticks, serving as texturizers and bulking agents to enhance the product's appearance, texture, and overall appeal. Starches, derived from various sources such as corn, potato, or tapioca, are used to improve the binding properties of the surimi mixture, allowing it to hold its shape and maintain a firm texture. Fillers, on the other hand, are added to increase the volume of the product, making it more cost-effective and visually appealing. Common fillers used in crab stick production include wheat flour, egg whites, and vegetable proteins. The combination of starches and fillers helps to create a product that mimics the texture and appearance of real crab meat, while also providing a more affordable and sustainable alternative. By carefully selecting and balancing the types and amounts of starches and fillers used, manufacturers can produce crab sticks that are not only delicious but also meet the desired texture and appearance standards.

Flavorings and Preservatives

Flavorings and preservatives are essential components in the production of crab sticks, enhancing the taste, texture, and shelf life of the final product. Flavorings, such as salt, sugar, and spices, are added to give crab sticks their distinctive taste and aroma. These flavorings can be natural, derived from sources like seaweed or fish, or artificial, created in a laboratory. Preservatives, on the other hand, are used to extend the shelf life of crab sticks by preventing the growth of bacteria, yeast, and mold. Common preservatives used in crab stick production include sodium benzoate, potassium sorbate, and calcium propionate. These preservatives help to maintain the quality and safety of the product, allowing it to be stored and transported without refrigeration. Additionally, some crab stick manufacturers may use antioxidants, such as vitamin E or tocopherol, to prevent the oxidation of fats and oils, which can lead to spoilage and off-flavors. The use of flavorings and preservatives in crab stick production is strictly regulated by food safety authorities, ensuring that the final product meets strict standards for quality and safety. By carefully selecting and combining flavorings and preservatives, manufacturers can create crab sticks that are not only delicious and convenient but also safe to eat.

The Manufacturing Process

The manufacturing process of a product involves several stages that transform raw materials into a finished product. The process typically begins with grinding and mixing, where raw materials are crushed and blended together to create a uniform mixture. This stage is crucial in ensuring that the final product has the desired texture and consistency. Following grinding and mixing, the mixture is then subjected to extrusion and shaping, where it is forced through a die to create the desired shape and form. The final stage involves cooking and texturing, where the product is heated and treated to achieve the desired texture and flavor. In this article, we will delve into each of these stages in more detail, starting with the first stage: grinding and mixing.

Grinding and Mixing

The grinding and mixing process is a crucial step in the production of crab sticks. After the surimi paste has been prepared, it is then ground and mixed with various ingredients to enhance its texture, flavor, and appearance. The grinding process involves breaking down the surimi paste into a finer consistency, which helps to create a more uniform texture in the final product. This is typically done using a grinder or a food processor, which can be adjusted to achieve the desired level of fineness. The mixing process, on the other hand, involves combining the ground surimi paste with other ingredients such as starches, sugars, and seasonings. These ingredients help to improve the texture, flavor, and appearance of the crab sticks, and can also help to extend their shelf life. The mixing process is typically done using a large mixing tank, where the ingredients are combined and blended together until they are fully incorporated. The resulting mixture is then ready to be shaped and formed into the desired shape, which is typically a stick or a flake. The grinding and mixing process is a critical step in the production of crab sticks, as it helps to create a consistent and high-quality product that meets the desired standards of texture, flavor, and appearance.

Extrusion and Shaping

Extrusion and shaping are critical steps in the manufacturing process of crab sticks. After the surimi mixture has been prepared, it is then forced through an extruder, which shapes the mixture into a long, thin, and uniform sheet. The extruder is a machine that uses a combination of heat, pressure, and moisture to transform the surimi mixture into a pliable and moldable form. The sheet is then passed through a series of rollers, which shape and stretch it into the desired form, typically a long, thin strip resembling a crab stick. The rollers also help to remove any air pockets and excess moisture from the surimi mixture, ensuring a consistent texture and preventing the formation of bubbles or holes in the final product. The shaped surimi is then cut into individual crab sticks, which are then ready for further processing, such as cooking, seasoning, and packaging. Throughout the extrusion and shaping process, manufacturers must carefully control temperature, pressure, and moisture levels to ensure that the surimi mixture is transformed into a product that is both visually appealing and safe for consumption.

Cooking and Texturing

The manufacturing process of crab sticks involves several stages, including cooking and texturing. Cooking is a crucial step in the process, as it helps to break down the proteins in the surimi paste and make it more pliable. The surimi paste is typically cooked in large steam-heated vats or retorts, where it is heated to a temperature of around 160°F (71°C) for a period of 30 minutes to an hour. This cooking process helps to break down the proteins and make the surimi paste more receptive to the addition of flavorings and textures. After cooking, the surimi paste is then textured to give it a more realistic crab-like texture. This is achieved through the use of various texturing agents, such as sodium alginate, which helps to create a more fibrous and tender texture. The texturing process involves mixing the cooked surimi paste with the texturing agents and then extruding it through a machine that shapes it into long, thin strands. These strands are then cut into smaller pieces to create the familiar crab stick shape. The texturing process is critical in creating a product that mimics the texture of real crab meat, and it is a key factor in the popularity of crab sticks.

Quality Control and Packaging

Quality control and packaging are crucial aspects of any industry, particularly in the food and pharmaceutical sectors. Ensuring that products meet the required standards is essential to maintain customer trust and loyalty. In this article, we will explore the importance of quality control and packaging, focusing on three key areas: inspection and sorting, freezing and storage, and labeling and distribution. By implementing effective quality control measures, businesses can minimize the risk of contamination, damage, and errors, ultimately leading to increased customer satisfaction and reduced costs. Effective quality control also enables companies to identify and address potential issues before they become major problems. In the first step of quality control, inspection and sorting play a critical role in ensuring that products meet the required standards. By carefully inspecting and sorting products, businesses can detect any defects or irregularities, preventing them from entering the supply chain. This process is essential in maintaining the quality and integrity of products, and it is the first line of defense against errors and contamination. Note: The supporting paragraph should be 200 words. Here is a 200-word supporting paragraph for the article about Quality Control and Packaging: Effective quality control and packaging are essential for businesses to maintain a competitive edge in the market. By implementing robust quality control measures, companies can ensure that their products meet the required standards, reducing the risk of contamination, damage, and errors. This, in turn, leads to increased customer satisfaction, loyalty, and retention. Moreover, quality control enables businesses to identify and address potential issues before they become major problems, minimizing the risk of product recalls, financial losses, and damage to their reputation. In addition, quality control and packaging play a critical role in ensuring compliance with regulatory requirements, reducing the risk of non-compliance and associated penalties. By prioritizing quality control and packaging, businesses can also improve their supply chain efficiency, reduce waste, and optimize their production processes. Furthermore, effective quality control and packaging can help businesses to differentiate themselves from their competitors, establishing a reputation for quality and excellence in their industry. By focusing on inspection and sorting, freezing and storage, and labeling and distribution, businesses can ensure that their products meet the highest standards of quality and safety. Note: The supporting paragraph should transition to Inspection and Sorting at the end. Here is a revised 200-word supporting paragraph that transitions to Inspection and Sorting at the end: Effective quality control and packaging are essential for businesses to maintain a competitive edge in the market. By implementing robust quality control measures, companies can ensure that their products meet the required standards, reducing the risk of contamination

Inspection and Sorting

Inspection and sorting are critical steps in the crab stick manufacturing process, ensuring that only high-quality products reach the market. After the crab stick mixture has been formed and cut into desired shapes, it undergoes a thorough inspection to detect any defects or irregularities. Trained quality control personnel visually examine the products for any visible signs of damage, such as cracks, breaks, or uneven texture. They also check for any foreign objects or contaminants that may have been introduced during the manufacturing process. Any defective or substandard products are removed from the production line and discarded. The remaining products are then sorted according to their size, shape, and color to ensure uniformity and consistency. This sorting process is typically done using automated machinery, which can quickly and accurately categorize the products into different grades. The sorted products are then packaged and prepared for distribution to retailers and consumers. By implementing a rigorous inspection and sorting process, crab stick manufacturers can guarantee that their products meet the highest standards of quality and safety, thereby maintaining customer trust and loyalty.

Freezing and Storage

Freezing and storage are critical steps in the production of crab sticks. After the crab stick mixture has been formed and cut into desired shapes, it is immediately frozen to a temperature of around -18°C to preserve its texture and flavor. This rapid freezing process, also known as flash freezing, helps to prevent the growth of bacteria and other microorganisms that can cause spoilage. The frozen crab sticks are then stored in a cold storage facility at a consistent temperature below -18°C to maintain their quality. Proper storage is essential to prevent freezer burn, which can cause the crab sticks to become dehydrated and develop off-flavors. The frozen crab sticks can be stored for several months, allowing for a steady supply of product to be shipped to customers around the world. In addition to freezing, some manufacturers may also use other preservation methods, such as vacuum packaging or modified atmosphere packaging, to further extend the shelf life of the crab sticks. By controlling the freezing and storage conditions, manufacturers can ensure that their crab sticks remain fresh and of high quality, with a texture and flavor that is similar to real crab meat.

Labeling and Distribution

Labeling and distribution are the final stages of the crab stick manufacturing process. After packaging, the crab sticks are labeled with relevant information such as ingredients, nutritional facts, and storage instructions. The labels must comply with food safety regulations and be easy to read and understand. The labeled crab sticks are then distributed to retailers, wholesalers, and food service providers through various channels, including refrigerated trucks, ships, and airplanes. To ensure the quality and safety of the product, the distribution process is carefully monitored and controlled to prevent contamination, damage, and temperature fluctuations. The crab sticks are typically stored in refrigerated warehouses and transported in refrigerated vehicles to maintain a consistent temperature below 40°F (4°C). This helps to prevent bacterial growth and spoilage, ensuring that the crab sticks arrive at their destination fresh and safe for consumption. Once the crab sticks reach the retailers, they are stored in refrigerated displays and sold to consumers. The entire labeling and distribution process is designed to ensure that the crab sticks are delivered to the consumer in a safe, fresh, and high-quality state.