How To Use A Stud Finder

Navigating the world of home improvement can seem daunting, particularly when handling unfamiliar tools such as a stud finder. For the uninitiated, a stud finder isn't just a technical marvel—understanding this tool is imperative for precise drilling and perfect walls. To provide you with a comprehensive guideline, this article will outline how to effectively use your stud finder. Read on as we demystify the basics of this peculiar device, shed light on the best practices for its efficient utilization, and provide insights into maintaining it for optimal functioning. Get ready to journey across the fundamental mechanisms of a stud finder—your first step into becoming home improvement savvy. This deep understanding is our springboard, setting us up perfectly to delve into the effective use of a stud finder in the forthcoming section.

Navigating the world of home improvement can seem daunting, particularly when handling unfamiliar tools such as a stud finder. For the uninitiated, a stud finder isn't just a technical marvel—understanding this tool is imperative for precise drilling and perfect walls. To provide you with a comprehensive guideline, this article will outline how to effectively use your stud finder. Read on as we demystify the basics of this peculiar device, shed light on the best practices for its efficient utilization, and provide insights into maintaining it for optimal functioning. Get ready to journey across the fundamental mechanisms of a stud finder—your first step into becoming home improvement savvy. This deep understanding is our springboard, setting us up perfectly to delve into the effective use of a stud finder in the forthcoming section.Understanding the Basic Mechanisms of a Stud Finder

Understanding the basic mechanisms of a stud finder can go a long way in ensuring a successful DIY home project. These tools, while compact, play an invaluable role in establishing the structural integrity of your walls, thus preventing any unexpected surprises during home improvements. This article will take you on a deep-dive to comprehend the intricacies of this tool by exploring three critical aspects - an introduction to the stud finder, its essential components and parts, and the different varieties of stud finders each with their unique features. Our first topic, the introduction, will paint a broader picture of what a stud finder is and its significance. We'll then deconstruct the device, taking a closer look at its combined parts in the second section. Lastly, we’ll delve into the various models available in the market today and highlight their distinguishing attributes. By the end of this read, not only will you acquire a fundamental understanding of a stud finder, but you'll also be equipped to make an informed choice tailored to suit your specific needs. So, let's begin with understanding what exactly a stud finder is and what it does.

1. Introduction to the Stud Finder

A stud finder is an indispensable tool with a simple yet significant function. A device used by both DIY enthusiasts and construction professionals alike, a stud finder essentially allows for the identification of underlying structural supports in walls known as "studs". The advantage? It accurately pinpoints where you can safely drill or hammer nails without causing damage to your walls. 'to use a stud finder to its full potential, though, one must first understand its basic mechanisms. A general stud finder operates via one of two technologies – magnetic or electronic. Magnetic stud finders, as the name suggests, utilise the power of magnetism to locate either metal fasteners or the metal nails which bind the studs to the wall. Ideal for basic tasks and the occasional handyman, they are small, reliable, and notably more affordable. 'On the other hand, electronic stud finders are a more sophisticated option; they detect changes in the wall's dielectric constant that occur due to an obstruction such as a stud. These detectors are more accurate and feature-rich than their magnetic counterparts, often incorporating additional functions like detection of live wires, pipes, and other essential building components. They are particularly useful for tasks requiring greater precision or when working on walls made of less standard materials. 'Thus, understanding these mechanisms is crucial for making the most of your stud finder. After all, a successful project, whether it involves mounting a flat-screen TV or hanging a heavy picture, starts with a secure anchor on a sturdy stud.

2. Components and Parts of a Stud Finder

Understanding the Basic Mechanisms of a Stud Finder: Components and Parts Delving into the inner workings of a stud finder, it becomes clear how this humble device proves invaluable to both professional contractors and DIY enthusiasts alike. At its heart, a stud finder is made up of a few key components. Firstly, it's essential to understand that the stud finder's primary role is to detect the density changes within wall structures. This process is powered by a phenomenon known as capacitance, which is the ability of a system to store an electric charge. Therein lies the primary component of a stud finder – the capacitor plates. These plates produce an electric field capable of penetrating the wall surface. Essentially, when these plates pass over a stud, the density change is detected, triggering a response in the stud finder. Another critical component found in some advanced stud finders is the inclusion of a magnetic detection element. This mechanism can identify metal nails or screws located within the stud, offering an extra layer of detection precision. In essence, it works by detecting minute shifts in the Earth's magnetic field caused by the embedded metal. A further aspect to consider is the user interface. Depending on the model, a stud finder might display visual signals, auditory signals, or both when it detects a stud. For instance, some models light up, some beep, and some do both, providing user-friendly signals to identify and locate the studs efficiently. Additionally, most stud finders are battery-operated, requiring a power source to create the necessary electric field. This battery is typically housed within the body of the stud finder, contributing to its handheld, portable nature. In conclusion, a stud finder, though simple in appearance, is a complex piece of technology. From capacitors and magnetic detectors to user interfaces and power sources, understanding these integral components and parts can greatly enhance one's overall proficiency in using this handy tool. They each contribute to the stud finder's core function, facilitating the efficient and accurate identification of studs located within walls. This comprehension of basic mechanisms forms the foundation of mastering how to effectively use a stud finder—everything from securing art on walls to carrying out large-scale renovation projects.

3. Different Varieties of Stud Finders and Their Unique Features

When delving into the world of stud finders, it is essential to understand that there are actually three main varieties, each with its unique features. First, there are electronic stud finders. These are the most common and utilize sensors to detect changes in the wall density, thus locating the stud. They usually come with indicators such as LED lights or beeping sounds as soon as a stud's edge is detected. However, these might vary in accuracy depending on the brand and model. Second, we have magnetic stud finders, which are considered the pioneers in the tool industry. These devices rely on the natural principle of magnetism, providing the user with a reliable tool to locate metal nails or screws embedded in the studs. What sets them apart is their lack of need for batteries and, in turn, a long-life span. Due to their simplistic design revolving around magnetism, they're often very compact, extremely user-friendly, durable, and pocket-friendly. Lastly, we also have the emerging trend of radar scanners. This variety is seen in advanced stud finders. Equipped with radar technology, these highly innovative devices can scan through different materials and provide more comprehensive information on what lies behind the wall. Unlike their counterparts, they can not only locate the stud but also detect potentially obstructing elements such as pipes, wires or other metallic objects. This advanced feature makes them a favorite for professionals, particularly for complex projects which require thorough scanning and tracking. Each variety caters to differing project requirements and user preferences, ensuring there's a stud finder out there for every need. Selecting the right stud finder will greatly enhance your understanding of its basic mechanisms and improve your proficiency in using this indispensable tool. By choosing the right one, your task of locating studs becomes not just more manageable and efficient, but also more accurate and safe.

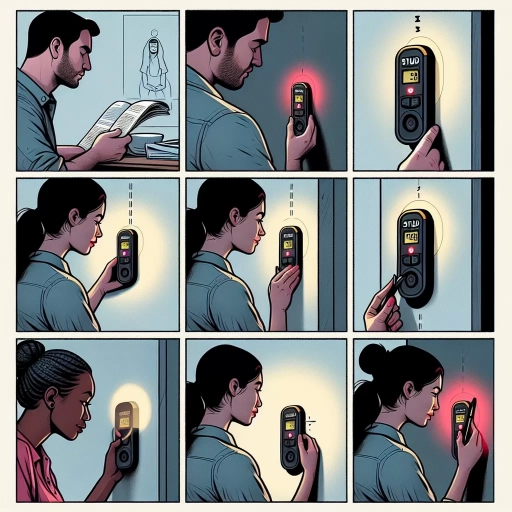

Guidelines for Effective Use of a Stud Finder

To successfully locate studs beneath your wall surface, a stud finder is a tool of necessity, not luxury. Yet, using this tool effectively requires far more than just sliding it along the wall. It demands a comprehensive understanding of not only its functionality, but also how to aptly maneuver it and how to properly interpreting the readings. This article seeks to demystify the key guidelines for efficient use of the stud finder by providing a three-pronged approach to help you become a pro at this. We'll delve into the importance of proper calibration of a stud finder to ensure optimum functionality. Additionally, we'll explore some effective techniques for scanning your wall proficiently, leaving no room for guesswork. Furthermore, we'll equip you with tips on identifying false positives to ensure precise detection of studs. Understanding these three aspects will arm you with the knowledge you need to effectively locate studs. As we begin, let's shed more light on the first crucial step: proper calibration of a stud finder.

1. Proper Calibration of a Stud Finder

Proper calibration of a stud finder is an essential step that shouldn't be neglected. When you use a stud finder, you're not just scanning your walls for the sake of it, you’re embarking on a mission to locate the most secure areas of your walls that will hold up your decor or other wall-mounted items perfectly. Where so much hangs in the balance, improper calibration could not only provide inaccurate results, but it can also lead to damage or instability in your projects. To ensure your stud finder works correctly, you need to start in an area of the wall you believe is free of studs, electrical wiring, or piping. Turning on the stud finder away from the wall and then placing it on the surface might lead to inaccurate calibrations. Hence, initiating the calibration on the wall is crucial. Remember, different wall materials like drywall, plaster, and wood will necessitate different calibration levels. Therefore, refer to your stud finder's manual to determine the right method for your specific wall. Once you place your finder against the wall, press and hold the power button until the calibration process is completed. It typically takes a few seconds, signified by a beep or display on the digital screen. Keeping the device stead during this process is paramount since it allows the device to read 'emptiness.' That will be its baseline reading against which it will compare other readings. If your device shows a stud reading immediately after calibration, that typically signifies an error. You might need to reposition it or wait for it to adjust. An aspect to remember, however, is that high-quality stud finders have a self-calibrating feature. They frequently update their calibrations as you move them over the wall, increasing the accuracy of finding studs. If you correctly calibrate your stud finder, it can be the difference between a successful decor installation and an unfortunate disaster with a hole-ridden wall. The importance of this crucial step cannot be overlooked, and understanding it is an integral part of the guidelines for the effective use of a stud finder.

2. Techniques for Scanning the Wall Efficiently

Techniques for Scanning the Wall Efficiently When it comes to discovering the hidden structure of your walls using a stud finder, an essential part of the process is understanding how to scan the wall efficiently. The first step is having a clear idea of where you want to hang an object or run a wire to prevent unnecessary holes and damage to structural supports. Then, learning the correct scanning technique contributes to the accuracy of the results. One primary method is the left-to-right technique. Starting from the left side of the wall, move your stud finder smoothly across the surface. Ensure the device maintains constant contact with the wall, not tilting or lifting it during the scan. The steady, unbroken contact improves the stud finder’s accuracy and effectiveness in detecting studs behind the drywall. Another method is the grid scanning approach, especially useful for larger wall spaces. In this, you start from a corner and move the stud finder in a horizontal line across the wall. Once done, you drop down a few inches and scan back in the opposite direction. This process repeats until the entire wall is covered, forming a grid pattern. This technique maximizes your chances of finding all the studs in one go. Remember, patience is a vital aspect of efficient wall scanning. Rushing the process leads to mistakes and missed studs. Therefore, slow and steady is the recommended rhythm for the scanning process—the stud finder needs ample time to sense changes in the wall’s density and accurately pinpoint a stud's location. Importantly, check the wall condition before you start scanning. A wall with a thick layer of paint, uneven texture, or wallpaper might interfere with the workings of the stud finder. In such cases, minor adjustments to scanning methods or using advanced stud finders with deep scanning capabilities can be beneficial. Notably, you should always double-check or validate the results by using the "two-pass" testing. This means scanning the same area twice, once from the left and then from the right, ensuring consistency in the results. This eliminates false positives and guarantees that you've truly found a stud. In summary, mastering the technique of efficient wall scanning with a stud finder involves understanding the various scanning procedures, being patient and thorough, and making necessary adjustments based on the wall’s condition. Adopting these strategies increases the chances of a successful DIY project while minimizing potential wall damage. A stud finder is indeed a handy tool, but its effectiveness largely depends on the user’s proficiency in handling and interpreting the device.

3. Tips for Identifying False Positives

Identifying false positives when using a stud finder can be tricky for uninitiated users, but there are some essential tips that can guide you through the process. Remember, stud finders are essentially predicting what's behind the wall, which can vary from the intended metal studs to hidden pipes or wires. As such, false positives are common and can lead to unexpected surprises during your drilling process. Firstly, multiple scans are your friend. Often, a false positive occurs when the stud finder detects an object only once or twice in multiple pass-overs. It's critical to repeat the scanning process in the same area to ensure consistency. Look for positive identifications that persist over several scans, which will likely indicate a true stud. Secondly, understanding the type of walls you have is crucial. For instance, metallic lath or foil-insulated walls can confuse your stud finder, resulting in false positives. Knowing your wall type can help you interpret the stud finder's readings more accurately. Furthermore, high-end stud finders with a feature that allows for calibration based on wall density can eliminate these false identifications. Lastly, the use of a deep-scanning mode can help eliminate shallow positives. Some objects just behind your wall's surface can trigger a positive reading but may not be the stud you are looking for. Hence, setting your device in a deep-scanning mode can look past these superficial elements, reducing the chance of false positives. Remember, no single technique can wholly eliminate the possibility of false positives when using a stud finder. However, employing these three tips; multiple scans, understanding your wall type, and the usage of deep-scanning mode, can dramatically enhance the accuracy of your stud finder, reducing the potential for false positives and ensuring a smoother, safer drilling process. A better understanding of your tool and the circumstances in which you use it will ultimately result in more accurate readings. And isn't that what we're all looking for when venturing into a DIY project?

Maintaining Your Stud Finder for Optimum Functioning

High-quality construction tools such as a stud finder are essential components of any handyman's toolbox. However, to ensure their optimum functionality, these tools need regular maintenance and care. This article will guide you on how to maintain your stud finder for its optimum functioning. Our focus will be on three crucial maintenance aspects: routine care and cleaning of your stud finder, troubleshooting common problems, and understanding the importance of regular battery check-ups and replacements. Firstly, we will emphasize the routine care and cleaning. A clean stud finder not only increases its efficiency but also extends its lifespan. By following easy cleaning procedures, you can keep your device at its prime and avoid unnecessary problems down the line. Transitioning from standard care, we will journey into the realm of troubleshooting, where understanding common stud finder problems can save you time, frustration, and money. Lastly, never underestimate the power of a fully charged battery. Regular check-ups and replacements of your device's batteries are key to its functionality. The following sections will delve deeper into these aspects, starting with routine care and cleaning.

1. Routine Care and cleaning

Proper routine care and cleaning of your stud finder is essential in maintaining its efficiency and reliability. Since this device is a crucial tool for identifying precise stud locations behind the surfaces of walls, floors, and ceilings, it's vital to keep it in perfect working condition to avoid incorrect readings that might lead to unsuccessful home improvement tasks. Firstly, before initiating the cleaning process, make sure to switch off your stud finder to prevent potential electrical concerns. Use a dry, soft cloth for cleaning the exterior of this device. Avoid abrasive cleaners as these may scratch or damage the stud finder’s surface. Dust and dirt may accumulate over time and interfere with the stud finder's electrical conductivity, so regular wiping of the device can prevent this buildup. For more rigorous cleaning, use a can of compressed air. Direct a gentle stream of air into the crevices and corners of the device to dislodge any hidden dust particles. This method is particularly efficient for stud finders with moving parts since it gets to areas a cloth can't reach. However, care should be taken not to use excessive air force which could potentially damage internal components. In addition to routine cleaning, proper storage of your stud finder also contributes to its longevity. Store your tool in a cool, dry place and away from direct sunlight and extreme temperatures - these factors may deteriorate the device's plastic housing and its internal electronic components. Protect your stud finder from accidental drops or unintentional pressures by keeping it inside a protective case or tool box when not in use. Also, remember to remove the batteries if you don't plan to use the stud finder for an extended period of time as batteries might leak and corrode the tool's inner circuits. Regularly check your stud finder for any battery leakage or rust and handle them immediately to keep your device in optimum working agility. Adhering to these routine care and cleaning practices will ensure your stud finder remains reliable and accurate for years to come, supporting all your DIY or professional construction projects with precision and efficiency. Proper maintenance cultivates your tools' performance and extends their life, thus safeguarding your investment.

2. Troubleshooting Common Stud Finder Problems

Stud finders are undoubtedly essential tools for every DIYer, yet sometimes they can pose certain common issues that might leave you frustrated. However, understanding how to troubleshoot these problems can greatly aid in the maintenance of your stud finder for optimum functioning. One of the prevalent problems is the inaccurate detection of studs. This problem often arises if the batteries of the tool are weak or dead; It is imperative to always use an efficient power source. Another potential cause can be attributed to moving the device too quickly across the wall, hence patience and slow movement are essential for precise results. Other times, the walls may be too thick or consist of multiple layers, causing the sensor in your stud finder to become confused. For cases like these, getting a stud finder that works with thicker walls or has a deep scanning option will prove beneficial. Yet another frustrating issue could be false positives - the stud finder indicating studs where there are none. This typically happens when the device picks up conduits, pipes, or wires that are often located behind the walls. To address this, a careful sweep with the stud finder is recommended, to differentiate between the high spots of pipes and wires and the consistent high reading of studs. Sometimes, stud finders may not work as effectively on textured walls; their efficiency might differ when working with drywall versus lath and plaster walls. In this case, acquiring a stud finder based on your specific wall type will help enhance accuracy. Calibrating your stud finder regularly is something that shouldn't be overlooked too. Finally, always remember, troubleshooting isn't just about adjustments to the device. The user needs to understand the basics of house framing and realize that studs will typically be 16 inches to 24 inches apart. Computing this with the results provided by a well-maintained and properly calibrated tool will ensure high-quality results. Troubleshooting common stud finder problems is vital towards maintaining your tool for optimum functioning. Just as the key to SEO content creation lies in understanding and working around algorithms, the secret to leveraging the utility of a stud finder depends on being acquainted with its problems and how to troubleshoot them. Hence, get acquainted with these solutions and enjoy hassle-free usage of your stud finder.