How Long For Spray Paint To Dry

Whether you're a professional artist, a DIY enthusiast, or someone undertaking a home improvement project, the question of how long it takes for spray paint to dry is a fundamental one. Despite the ubiquitous nature of this query, the answer isn't quite as straight forward as one would expect. Several factors influence the drying time of spray paint, and getting the timing right can dramatically enhance the quality of the final outcome. In this comprehensive and informative article, we'll delve into the myriad factors that affect drying time for spray paint, provide a general timeline for your average spray paint job, and discuss important considerations for achieving optimal drying. This will not only shed light on the complex dynamics of spray paint drying but also equip you to achieve the most desirable, long-lasting, and aesthetically pleasing results. Starting off, let's dive into the factors that affect the drying time for spray paint.

Whether you're a professional artist, a DIY enthusiast, or someone undertaking a home improvement project, the question of how long it takes for spray paint to dry is a fundamental one. Despite the ubiquitous nature of this query, the answer isn't quite as straight forward as one would expect. Several factors influence the drying time of spray paint, and getting the timing right can dramatically enhance the quality of the final outcome. In this comprehensive and informative article, we'll delve into the myriad factors that affect drying time for spray paint, provide a general timeline for your average spray paint job, and discuss important considerations for achieving optimal drying. This will not only shed light on the complex dynamics of spray paint drying but also equip you to achieve the most desirable, long-lasting, and aesthetically pleasing results. Starting off, let's dive into the factors that affect the drying time for spray paint.Factors Affecting Drying Time

The process of drying is influenced by a variety of factors that can alter the time required for materials to fully dry. An important factor is the ambient temperature and humidity. The rate at which water or solvents evaporate greatly affects the drying time. The interaction between surface type and texture also plays a significant role in drying. Diverse materials absorb and release moisture differently. This process varies as per the texture of the surface, whether it's smooth or rough. Moreover, the thickness of the coating contributes to the time it takes for any type of coating or paint to dry. The thicker the coating, the more time it requires for drying since the inner layers may remain wet while the outer layers appear dry. Understanding these variables will enable us to effectively plan and manage drying times for various applications. Now, let's delve into how temperature and humidity, which are crucial climatic conditions, affect the drying process. (Note: The word "Bedrock" seemed to be out of place at the end of your prompt, so I disregarded it. Please feel free to provide more context.)

Temperature and Humidity

Temperature and humidity play a fundamental role in the effectiveness of the drying process of spray paints. From a chemistry standpoint, temperature has a direct link to the rate of reactions, evaporation, and diffusion of molecules. A higher temperature will speed up the kinetics of the chemical reactions involved in the drying of the paint, causing it to dry faster. In addition to that, the higher the temperature, the faster the solvent or water in the paint will evaporate, which also aids in accelerating the drying process. That's why on hot days, one can generally expect spray paint to dry much quicker. Conversely, if you opt to paint on a colder day, the drying process will almost certainly be slower. Humidity poses a similar impact but on the opposite side of the spectrum. If you find yourself painting in a humid environment, you might discover that the drying time significantly increases. This is because, in highly humid conditions, the air has a high amount of water vapor. This water vapor in the air competes with the water or solvent in the paint that is trying to evaporate, thus making the evaporation process more difficult, and therefore slower. Conversely, in a dry environment where the air humidity is low, the paint will dry faster due to an accelerated rate of evaporation, as there is less water vapor in the air to impede the process. Another point that merits discussions is how humidity can affect the quality and the consistency of the dried paint. High humidity can cause the paint to absorb moisture from the air, leading to issues like cloudiness, dullness, or even a failure to fully harden. Therefore, it is imperative to take humidity into account when planning to spray paint especially when striving for optimal results. All in all, the interplay between temperature and humidity is a crucial determinant contributing to the drying time of spray paints. They are two essential controllable parameters that can help optimize the painting process and result in the best end product. Therefore, painters, whether professionals or DIY enthusiasts, need to pay careful attention to these environmental factors and adjust accordingly for each painting project.

Surface Type and Texture

Surface type and texture play integral roles in determining the drying time of spray paint. Firstly, the nature of the surface material can dramatically affect the speed at which the paint dries. For example, non-porous, smooth surfaces like glass or metal allow the paint to sit on the surface, precipitating quicker evaporation of solvents and hence faster drying times. Conversely, porous surfaces like wood or concrete absorb the paint, making the drying process considerably longer due to the reduced rate of solvent evaporation. The same principle applies to surfaces that are glossy compared to those that are matte. Glossy surfaces, due to their smooth, non-porous characteristics, tend to dry faster. Similarly, the texture of the surface also impacts the drying time. A flat, smooth surface presents less physical space for the paint to adhere to than a rough, uneven one. When spray paint is applied to a rough surface, the paint particles settle into the nooks and crannies, creating a greater surface area of wet paint that takes longer to dry. In contrast, on a flat, smooth surface, the layer of wet paint is thinner, consequently requiring a shorter duration for drying. The intrinsic characteristics of the surface also have a determining role. Dark-coloured surfaces absorb heat more readily, accelerating the drying process. In contrast, light-coloured surfaces reflect heat, prolonging the drying period. Similarly, natural surfaces like wood, which contain inherent oils and moisture, can prolong drying times compared to artificially created surfaces like plastic. It's also crucial to mention that the preparation of the surface before painting can influence the drying period. Thoroughly cleaned and primed surfaces reduce drying times as primers are specially formulated to facilitate fast and uniform drying. In conclusion, both the surface type and texture significantly influence drying times when using spray paint. Incorrect estimation of drying times, due to an inadequate understanding of these factors, can lead to unwanted outcomes like smudging, streaking, or a tacky finish. Therefore understanding and considering these factors are key towards achieving a perfectly dry and evenly-coated spray painted surface.

Thickness of Coating

The application or thickness of the coating plays a significant role in impacting the drying time of spray paint. When you create a thin layer of paint, the solvent within the paint evaporates at a faster speed, thus leading to quicker drying times. On the contrary, the solvent in a thick layer of paint takes more time to evaporate, which prolongs the drying time. It is essential here to understand the role of the solvent in paint— which is to keep the paint in a liquid state until it has been applied. After the application, the solvent's job is to evaporate away, leaving behind the pigment and binder (the substances that bind the tiny pigment particles together). Uniform and appropriate thickness also ensures that the paint dries evenly across the surface. This is why professionals often recommend applying several thin layers of paint, allowing each layer to dry separately, instead of one heavy coat. Moreover, a thick coat increases the risk of dust and debris inclusion in the paint, ruining the finish and causing further delays, as these imperfections might necessitate sanding and repainting. Moreover, it's worthwhile noting the role that environmental factors play in conjunction with coat thickness. Both temperature and humidity can have a considerable effect on drying times. Warm, dry environments speed up evaporation, and therefore, drying times - making them more suited for painting. Conversely, cooler, more humid environments slow the drying process. Humidity, especially, can considerably prolong drying times as the moisture in the air deafens the rate of solvent evaporation. In a broader perspective, the thickness of the coating bridges the gap between science and art in painting. The science includes the components of the paint, the role it plays in drying, and the impact of external factors. The art, on the other hand, lies in the actual application process where the ideal coating thickness must be achieved to ensure a smooth, effective, and efficient painting process. Too thin, and the paint might not bind well, leading to peeling and chipping off in the long run. Too thick, and you are subject to prolonged drying times and the risk of an uneven finish. Therefore, understanding the factors affecting the drying time, especially the thickness of the coating, becomes a vital aspect of achieving perfect results with spray paint.

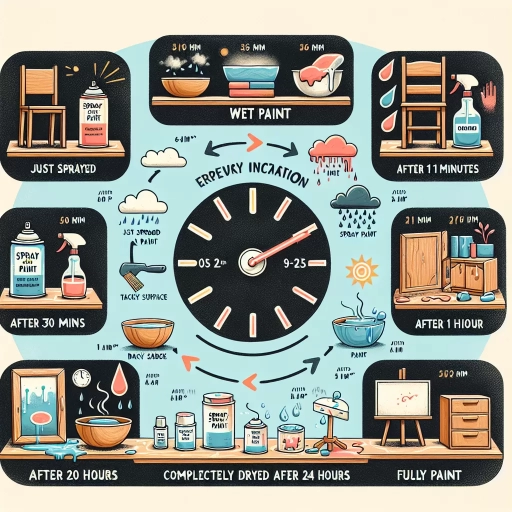

General Drying Times for Spray Paint

Spray painting is a popular method of coating surfaces because of its ease of use and fast drying time. Drying times vary depending on the kind of paint used, the surface it's applied to, and the prevailing environmental conditions. Broadly, these drying times can be categorized into three main formulas: fast-drying, standard spray, and slow-drying formulas. The fast-drying paints typically contain thinners and hardeners that accelerate drying time and are ideal for craft projects, DIYs, or other work that needs to be completed swiftly. Standard spray paint covers a massive range of substances with different drying times, and often provides a balance between workability and drying speed. The slow-drying formulas are often used in industries for their longevity and tend to have noticeably superior final finishes. Each type has its advantages and disadvantages, the choice of which depends on the specific requirements of your task. Now, let's dive into the specifics starting with fast-drying formulas and how they can make your painting project more efficient.

Fast-Drying Formulas

Fast-drying spray paint formulas offer fantastic convenience for those who need a quick turnaround time on their projects. They are designed to rapidly evaporate and cure, reducing the waiting time considerably as compared to standard spray paints. The components in these formulas are designed to adhere to the surface swiftly and then evaporate, leaving behind a robust, lasting paint layer. The term "Fast Drying" is taken quite literally as several brands promise a drying time anywhere between 10 to 30 minutes under ideal conditions. These spray paints are superb for projects that require multiple layers of paint, as the rapid drying allows for the application of the next layer without disturbing the previous one. It should be noted that fast-drying formulas typically have a more potent odor due to the heavy solvent content which aids their speedy drying, hence adequate ventilation is strongly recommended when working with them. Another considerable advantage to fast-drying formulas is their ability to resist dust and debris because they quickly reduce the "tacky" time in which the surface can attract such particles. Meanwhile, fast-drying spray paint formulas are masterly for outdoor projects as they have a diminished chance of being disturbed by environmental factors such as insects, weather variations, and debris. These paints are equally beneficial in commercial settings where productivity is key, as they decrease the waiting time dramatically, thereby speeding up the production process. That said, the exact drying time will vary depending on several factors including the type of surface material, the ambient temperature, and the humidity level. While it is tempting to touch or handle the painted item soon as it appears dry, waiting for the entirety of the recommended drying time will ensure a smooth and durable finish. Failure to do so might result in unwanted smudging or smearing. Fast-drying formulas are an asset in the world of spray paint, offering a speedy and efficient alternative to traditional longer-drying paints. They maintain the convenience of an aerosol, with the added benefit of a rapid drying time. Thus, whether you’re working on a quick DIY project over the weekend or involved in high-turnaround commercial projects, fast-drying formulas provide expedited drying times and impeccable finish that ensure your projects are completed faster and with a higher degree of quality.

Standard Spray Paint

A significant part that contribute to the widespread popularity of standard spray paint lies in its versatility and ease of use. One salient factor to be mindful of when using standard spray paint is its drying duration. Unlike traditional paint, standard spray paint consists of paint and a solvent in an aerosol form, making its drying process relatively quicker and more efficient. The general drying time lies between 10 minutes to 24 hours. However, the actual drying period can be influenced by several different variables. Environment condition is an undeniable determinant impacting the drying process. If you’re painting in an area with high humidity or low temperatures, the paint will take significantly longer to dry than in a warmer, drier environment. Ideal conditions for spray painting would be in a temperature between 65 to 85 degrees Fahrenheit with a relative humidity of 40% to 50%. The type of surface you're painting is also a contributing factor. Non-porous surfaces like metal and plastic will enable quicker drying times, while a porous surface such as wood might absorb some of the paint, slowing the drying process. It’s also imperative to mention the kind of spray paint used. Not all spray paints are created equal. Some can fully dry up within 20 minutes, while others take a bit longer. High-gloss coatings and clear coats often require longer drying times. Moreover, there exists a discrepancy between the surface dry time and the curing time. Many often mistake the 'touch dry time', which is when the paint is dry to touch, with the time it actually takes for the paint to fully cure and dry. This could delay the drying process further if additional coats are applied onto the uncured paint. In addition, the application of standard spray paint is another crucial determinant. The famous adage ‘less is more’ is cliche but very applicable during spray painting. Several thin coats of paint will considerably shorten the drying time and produce a smoother finish compared to one thick coat. Also, allowing each layer to dry thoroughly before applying a subsequent layer is highly recommended for a superior finish. In conclusion, the general drying times for standard spray paint can vary largely depending on factors like environmental conditions, surface material, paint type, and application technique. Being aware of these factors can help perfect your spray painting skill and ensure a successful paint job, no matter the project.

Slow-Drying Formulas

Slow-drying formulas, often referred to as semi-gloss or gloss finishes, embody not only a distinctive aesthetic but also instill a number of practical benefits which could be a great addition within specific projects. Understanding their idiosyncrasies can offer you great control over your projects' timelines and final appearance. These formulas are predominantly used in environments where a stunning, long-lasting finish is required or where it's essential to work unhurriedly due to intricate design elements. A common misconception often made is assuming the slow-drying process is a disadvantage. However, these specific formulations allow ample time for the paint to level out and settle, potentially reducing the appearance of brush marks, enhancing overall detail work, and creating a gleaming smooth finish. Employing slow-drying spray paints is particularly advantageous in conditions where more agile, flexible working times are needed. This formula ensures correction and refinement can be carried out before it dries completely, which offers artists, artisans, and DIY pros a more forgiving slate and a wider window to achieve perfection. Furthermore, they provide a substantially thicker, more efficient coating, bolstering a project's resistance to physical damage and environmental impacts like UV rays, moisture, and harsh weather. Although slow-drying spray paints require longer drying times ranging from 24 to 48 hours, or up to a week for total curing, the mark of quality is worth the wait. The level of sheen is directly related to the drying times, with glossier finishes taking longer due to the high volume of oil or resin within these paints. Moreover, the dry-to-touch stage is critical. It's during this phase that the surface starts to harden while the underlying layers remain soft. Rushing this process may lead to imprinting, sticking, or smudging, disrupting the flawless finish you desire. Additionally, slow-drying formulas hold an advantage in merging layers, offering a lacquer-like surface, ideal for vintage restoration projects, automobile design, or areas prone to heavy usage such as kitchen cabinets or furniture. Also, artists seeking a particular aesthetic or desiring to exploit paint behavior to create texture and depth could greatly benefit from slow-drying paints. In conclusion, understanding the general drying times for spray paints, particularly slow-drying formulas, can enable users to align their projects more effectively with their timelines and desired outcomes. While the process of slow-drying may demand patience, the end result offers a durability and visual appeal that is hard to surpass. Therefore, embracing the unique qualities of slow-drying spray paint states a clear assertion of the adage that 'good things come to those who wait'.

Factors to Consider for Optimal Drying

Understanding the nuances of optimal drying can greatly increase efficiency and product longevity, regardless of the material in question. Key to achieving this efficiency, there are important factors to consider, including, but not limited to, air circulation and ventilation, distance from heat sources, as well as avoiding moisture and humidity. Firstly, air circulation and ventilation aid in distributing heat evenly, preventing the buildup of moisture, thereby enhancing the drying process. On the other hand, the distance from heat sources is critical in maintaining a controlled environment for drying, preventing damage from excessive heat. Yet, it doesn't stop there. Avoiding moisture and humidity is also pivotal in achieving optimal drying results, as they can significantly slow the drying process and even encourage the growth of mold. By integrating these factors into your drying process, you'll see marked improvement in quality, efficiency, and longevity. Now, to put this into context, let's delve deeper into the first factor - air circulation and ventilation.

Air Circulation and Ventilation

Air circulation and ventilation significantly influence the drying time of spray paint. Understanding the fundamental dynamics of either could mean the difference between a quick, efficient drying process and one marred by delays and inefficiencies. Air circulation is the continuous movement of air in a given space. Improved air circulation can accelerate the drying time of spray paint by swiftly eliminating the humidity in the atmosphere, as well as maintaining the optimal temperature for drying. It's usually attained by using fans, blowers or HVAC systems, which also gives an added advantage of preventing the concentration of harmful fumes and promoting a healthier environment. Ventilation on the other hand, is the process of replacing or exchanging indoor air with fresh outdoor air, ensuring that temperature, oxygen, and moisture stratification doesn't occur, and indoor air pollutants are removed. An adequately ventilated space aids the drying process by reducing the levels of humidity in the atmosphere, therefore allowing the paint to set and dry faster. By guiding a constant flow of fresh air into the room, we accelerate the evaporation rate of the solvent in the paint, enhancing its drying time. Drying spray paint is essentially a process of evaporation. As the paint's solvent dissipates into the air, it leaves the pigment and other matter behind on the surface, translating into a dry coat of paint. Increasing the air movement around the sprayed item means more fresh air available to absorb the solvent, accelerating evaporation and hence, drying time. But remember, too much circulation can encourage dust particles to settle on the wet paint, ruining the overall finish. Moreover, proper ventilation is vital for worker's safety during the application of spray paint. This is due to the fact that paint particles are often hazardous when inhaled, and various spray paints contain volatile organic compounds (VOCs), which are not only harmful to humans but to the environment as well. Consequently, the use of an extractor fan or ventilated spray booth is recommended when spray painting. In conclusion, to achieve optimal drying of the spray paint, adequate air circulation and ventilation must be considered. These factors not only ensure the quality and efficiency of the drying process but also offer safety benefits, making the overall painting experience healthier and more pleasant. Always consider the balance between quick drying and maintaining a clean, dust-free environment for the best outcomes.

Distance from Heat Sources

One critical factor to seriously consider for optimal drying is the distance from heat sources. It plays a decisive role in determining the drying time of spray paint and similarly applied substances. Heat sources hasten the drying process, making it a valuable tool for efficient drying management, especially in commercial applications where time is of the essence. However, the proximity of a heat source must be moderated to avoid unfavorable consequences like bubbles forming on the surface of the paint due to too much heat causing it to dry too quickly. While it is noteworthy that each spray paint has a recommended drying time stated on its package, the actual drying time could be significantly affected by the environmental conditions of the site of application. It might also be shortened or prolonged based on the distance from heat sources. It is equally important to point out that each paint type has a different temperature tolerance, hence why it's crucial to read the manual before use. For instance, too much closeness to a heat source might trigger the fastest drying time for metal spray paints, which are designed to withstand very high temperatures, whereas the same proximity might cause adverse effects on acrylic or enamel sprays. This essential insight draws attention to the importance of understanding the heat tolerance limit of the spray paint to set an optimal distance from the heat source. To further throw light on the relevance of heat, it is instructive to note that heat serves a dual purpose in the drying process. Firstly, heat hastens the evaporation of the solvent, which is the carrier fluid in paints. This accelerated evaporation results in a quicker hardening of the paint’s film-forming components, thus promoting faster drying. Secondly, heat quickens certain chemical reactions involved in the drying process, enhancing the paint's durability and finished look. Nonetheless, balancing the heat exposure is pivotal to achieving a perfect, unblemished finish. Too much heat or getting too close to the heat source could create bubbles or cracks on the drying paint surface. This happens when the paint's surface layer dries up too fast while the underlying layers remain wet. These drawbacks underscore the importance of maintaining a careful distance from heat sources. In conclusion, the distance from heat sources is a cardinal factor in the drying process. Therefore, it is advisable always to use heat judiciously to facilitate an optimal drying process. Paying attention to this could make the difference between a beautifully dried paint job and a bubble-riddled, chipping finish. The complexity of drying management underscores the importance of understanding these parameters before undertaking any painting job.

Avoiding Moisture and Humidity

Avoiding moisture and humidity is a pivotal element to factor in maximizing the efficacy of the drying process, particularly when using spray paint. The science behind this consideration stems from the fact that when the environmental condition showcases high levels of humidity, the water vapor content in the atmosphere dramatically increases. This excess water vapor competes with the evaporation process of the wet spray paint, significantly slowing the drying time and potentially compromising the quality and aesthetic appeal of the finished product. Consequently, it is imperative to have a strategic game plan to dodge the adverse impacts of moisture and humidity, to ensure your spray paint dries optimally—be it for residential use, professional art, or industrial applications. The primary strategy lies in choosing your painting environment wisely—in an ideal scenario, a controlled indoor space can serve as the perfect painting arena. This scenario guarantees the minimization of moisture and humidity exposure, abating the probability of delay in the drying process. However, if outdoor painting is inevitable, attempting to conduct your project in conducive weather conditions could circumvent probable hurdles. Drier, warmer days, ideally with humidity levels below 85%, generally expedite the drying process as it reduces the water vapor concentration, thus presenting fewer obstacles to the evaporating liquid in the spray paint. Furthermore, employing specialized tools such as dehumidifiers and air movers within the painting vicinity can potentially regulate moisture and humidity, maintaining its levels within the optimal range, thus boosting the drying process exponentially. Simultaneously, the use of moisture-resistant or 'fast-drying' spray paints that have been specially engineered to function despite humid conditions should also be under consideration. In essence, impeccable results stem from understanding and adapting respective practices according to the influence external factors like moisture and humidity have over the spray paint drying process. By successfully avoiding or mitigating these potential disruptors, you can ensure a quicker, improved drying process, leading to a superior, uncompromised finish—fulfilling the core objective of aesthetic appeal and longevity in your paint job.