How To Measure A Bolt

Accurately measuring a bolt is a crucial step in various industries, including construction, automotive, and manufacturing. A small mistake in measurement can lead to costly errors, safety hazards, and equipment damage. To ensure precision and accuracy, it's essential to understand the different aspects of bolt measurement. In this article, we'll delve into the world of bolt measurement, exploring the key concepts and techniques to help you get it right. We'll start by understanding bolt measurements, including the various types of measurements and how they're used. Then, we'll dive into the practical aspects of measuring bolt length and diameter, providing you with step-by-step instructions and expert tips. Finally, we'll discuss special considerations for bolt measurement, including how to handle unusual bolt shapes and sizes. By the end of this article, you'll be equipped with the knowledge and skills to measure bolts with confidence. So, let's begin by understanding bolt measurements.

Understanding Bolt Measurements

Understanding bolt measurements is crucial for any project that involves working with bolts and fasteners. When it comes to selecting the right bolt for the job, there are several key factors to consider, including thread count and pitch, bolt head types and sizes, and shank and body lengths. Each of these factors plays a critical role in ensuring that the bolt is properly secured and functions as intended. Thread count and pitch, for example, determine the bolt's grip and holding power, while bolt head types and sizes affect the tool required for tightening and the overall appearance of the finished product. Shank and body lengths, on the other hand, impact the bolt's overall length and its ability to accommodate various materials and applications. By understanding these different measurement factors, individuals can make informed decisions when selecting bolts for their projects. In this article, we will delve into the specifics of thread count and pitch, exploring how these measurements impact the performance and functionality of bolts.

Thread Count and Pitch

Thread count and pitch are two critical components of bolt measurements that are often misunderstood or overlooked. Thread count refers to the number of threads per inch (TPI) or the number of threads per millimeter (TPM) on a bolt. It is a measure of how fine or coarse the threads are. A higher thread count indicates finer threads, while a lower thread count indicates coarser threads. For example, a bolt with a thread count of 20 TPI has 20 threads per inch, while a bolt with a thread count of 10 TPI has 10 threads per inch. Thread count is usually measured using a thread gauge or a caliper. Pitch, on the other hand, refers to the distance between two adjacent threads. It is measured in inches or millimeters and is usually denoted by the letter "p". For example, a bolt with a pitch of 1.5 mm has a distance of 1.5 mm between two adjacent threads. Pitch is an important factor in determining the strength and durability of a bolt. A bolt with a finer pitch (i.e., a smaller distance between threads) is generally stronger and more durable than a bolt with a coarser pitch. In summary, thread count and pitch are two essential parameters that need to be considered when measuring a bolt. Understanding these parameters is crucial in selecting the right bolt for a specific application and ensuring the safety and reliability of the assembly.

Bolt Head Types and Sizes

Bolts come in a variety of head types and sizes, each designed for specific applications and uses. The most common head types include hex, square, and round, with hex being the most widely used. Hex head bolts have a six-sided head and are often used in construction, automotive, and industrial applications. Square head bolts have a four-sided head and are commonly used in furniture and cabinetry. Round head bolts have a circular head and are often used in applications where a flush surface is required. In addition to these common head types, there are also specialized head types such as socket head, Torx, and security head bolts. Socket head bolts have a recessed area in the head that allows for the use of a socket wrench, while Torx head bolts have a star-shaped head that requires a Torx driver. Security head bolts have a unique head design that makes them difficult to remove without a specialized tool. When it comes to sizes, bolts can range from small, such as #6 or #8, to large, such as 1/2" or 3/4". The size of the bolt is typically measured in terms of its diameter, with the diameter being the distance across the widest part of the bolt head. It's also important to consider the length of the bolt, which can vary from a few inches to several feet. Understanding the different head types and sizes of bolts is crucial for selecting the right bolt for a particular application and ensuring a secure and reliable connection.

Shank and Body Lengths

Shank and body lengths are critical components of a bolt's overall length. The shank is the smooth, unthreaded portion of the bolt, while the body is the threaded portion. When measuring a bolt, it's essential to understand the difference between these two lengths to ensure accurate measurements. The shank length is typically measured from the underside of the bolt head to the point where the threads begin. This length can vary depending on the type of bolt and its intended application. For example, a bolt with a long shank may be used in a situation where the bolt needs to pass through a thick material or a spacer, while a bolt with a short shank may be used in a situation where the bolt needs to be countersunk into a material. The body length, on the other hand, is measured from the point where the threads begin to the end of the bolt. This length is critical in determining the overall length of the bolt and ensuring that it is long enough to engage with the nut or other threaded component. When measuring the body length, it's essential to consider the thread pitch and the number of threads per inch. A bolt with a coarse thread pitch will have a longer body length than a bolt with a fine thread pitch, even if the overall length of the bolt is the same. In summary, understanding the difference between shank and body lengths is crucial when measuring a bolt. By accurately measuring these lengths, you can ensure that your bolt is the correct size and will function properly in its intended application.

Measuring Bolt Length and Diameter

Measuring bolt length and diameter is a crucial step in various industries, including construction, automotive, and manufacturing. To ensure accuracy and precision, it is essential to use the right tools and techniques. In this article, we will discuss the importance of measuring bolt length and diameter, and provide a step-by-step guide on how to do it accurately. We will explore the use of calipers for accurate measurements, discuss how to measure the bolt head and shank, and provide a method for calculating the thread length. By the end of this article, you will have a comprehensive understanding of how to measure bolt length and diameter with precision. To start, let's take a closer look at the first step in the process: using calipers for accurate measurements.

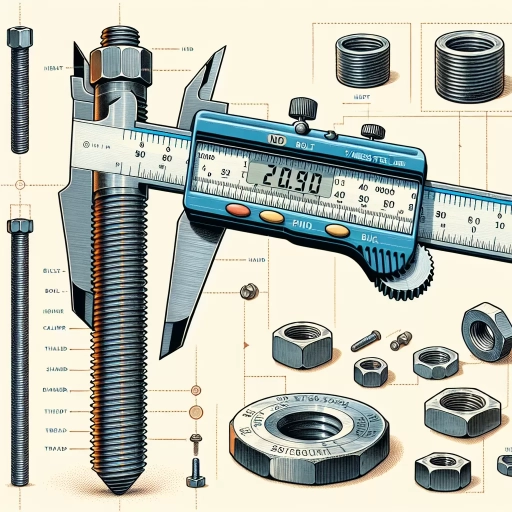

Using Calipers for Accurate Measurements

Using calipers for accurate measurements is a crucial step in determining the length and diameter of a bolt. Calipers are precision instruments that provide precise measurements, allowing you to accurately assess the dimensions of a bolt. To use calipers, start by placing the bolt between the caliper's jaws, ensuring that the bolt is centered and the jaws are parallel to each other. Next, close the jaws until they make contact with the bolt, taking care not to apply too much pressure, which can damage the calipers or the bolt. Once the jaws are in place, read the measurement on the caliper's display or dial. For digital calipers, the measurement will be displayed on the screen, while for dial calipers, the measurement will be indicated by the position of the dial. When measuring the length of a bolt, use the caliper's depth measurement function to measure from the underside of the head to the tip of the bolt. For measuring the diameter, use the caliper's outside measurement function to measure across the widest part of the bolt. By using calipers, you can ensure accurate measurements, which is essential for selecting the correct bolt for your application.

Measuring the Bolt Head and Shank

When measuring the bolt head and shank, it's essential to consider the type of bolt you're working with, as different types have distinct characteristics. The bolt head is the part that you'll be turning with a wrench or socket, and its size is crucial for ensuring a proper fit. To measure the bolt head, start by determining its shape, which can be hexagonal, square, or round. For hexagonal heads, measure the distance across the flats, which is the distance between two opposite sides of the hexagon. For square heads, measure the distance between two opposite sides of the square. For round heads, measure the diameter of the head. The shank, on the other hand, is the long, cylindrical part of the bolt that passes through the material being fastened. To measure the shank, simply measure its diameter using a caliper or micrometer. It's also important to note the thread type and pitch, as this will affect the overall length of the bolt. By accurately measuring the bolt head and shank, you can ensure that you're using the correct bolt for your project and avoid any potential issues with fit or function.

Calculating the Thread Length

When calculating the thread length of a bolt, it's essential to consider the type of bolt and its intended application. The thread length is the distance from the point where the threads start to the point where they end. For bolts with a shoulder or a head, the thread length is typically measured from the base of the head or shoulder to the end of the threads. For bolts without a shoulder or head, the thread length is measured from the point where the threads start to the end of the threads. To calculate the thread length, you can use the following formula: Thread Length = Overall Length - Head Height - Shank Length. The overall length is the total length of the bolt, the head height is the height of the head or shoulder, and the shank length is the length of the unthreaded portion of the bolt. By subtracting the head height and shank length from the overall length, you can determine the thread length. It's crucial to accurately measure these dimensions to ensure the correct thread length, as this can affect the bolt's performance and safety. Additionally, it's recommended to consult the manufacturer's specifications or industry standards for specific guidelines on calculating thread length for different types of bolts.

Special Considerations for Bolt Measurement

When it comes to bolt measurement, there are several special considerations that must be taken into account to ensure accurate and reliable results. One of the key factors to consider is the type of thread on the bolt, as coarse and fine threads require different measurement approaches. Additionally, the style and shape of the bolt head can also impact measurement, and must be accounted for to avoid errors. Furthermore, bolts that have been exposed to rust, corrosion, or damage may require special handling to ensure accurate measurement. By understanding these special considerations, engineers and technicians can ensure that their bolt measurements are accurate and reliable, and that their projects are completed successfully. In this article, we will explore these special considerations in more detail, starting with the importance of measuring coarse and fine threads accurately.

Measuring Coarse and Fine Threads

Measuring coarse and fine threads requires attention to detail and the right tools. Coarse threads have a larger pitch, or distance between threads, and are typically used for applications where high strength and durability are required. Fine threads, on the other hand, have a smaller pitch and are often used for applications where precision and low torque are necessary. To measure coarse and fine threads, you'll need a thread gauge or a caliper with a thread measuring attachment. Start by identifying the thread type and pitch, then use the gauge or caliper to measure the thread's major diameter, pitch diameter, and minor diameter. For coarse threads, you may also need to measure the thread's root radius and crest radius. When measuring fine threads, be careful not to damage the threads with the measuring tool. It's also important to note that fine threads can be more prone to stripping, so be gentle when handling them. By accurately measuring coarse and fine threads, you can ensure that your bolts are properly sized and will function as intended in your application.

Accounting for Bolt Head Styles and Shapes

When measuring bolts, it's essential to consider the head style and shape, as this can affect the overall length and functionality of the bolt. There are several common bolt head styles, including hex, square, and round, each with its unique characteristics. Hex head bolts, for example, have a six-sided head that provides a secure grip for wrenches and sockets, making them ideal for applications where high torque is required. Square head bolts, on the other hand, have a four-sided head that provides a flat surface for wrenches and sockets, making them suitable for applications where a low profile is necessary. Round head bolts, also known as carriage bolts, have a rounded head that provides a smooth surface for applications where a flush finish is required. In addition to head style, bolt shape is also an important consideration. Bolts can be either straight or tapered, with tapered bolts having a conical shape that allows them to be countersunk into a hole. When measuring bolts, it's crucial to take into account the head style and shape, as well as the length and diameter, to ensure accurate and reliable measurements. By considering these factors, individuals can ensure that their bolts are properly sized and installed, which is critical for maintaining the integrity and safety of the surrounding structure or equipment.

Dealing with Rust, Corrosion, or Damage

When dealing with rust, corrosion, or damage on a bolt, it's essential to take extra precautions to ensure accurate measurements. Rust and corrosion can weaken the bolt's structure, making it prone to breakage, while damage can alter its dimensions. To measure a bolt with rust, corrosion, or damage, start by cleaning the affected area gently with a soft brush or cloth to remove any loose debris. Avoid using harsh chemicals or abrasive materials that can further damage the bolt. Next, inspect the bolt for any visible signs of damage, such as cracks, dents, or worn-out threads. If the damage is severe, it's best to replace the bolt altogether. If the damage is minor, you can proceed with measuring the bolt, taking note of any areas that may have been affected. When measuring, use a caliper or micrometer that can accommodate the bolt's irregularities, and take multiple measurements to ensure accuracy. It's also crucial to consider the bolt's material and its potential impact on the measurement. For instance, some materials may be more prone to corrosion or damage than others, which can affect the measurement. By taking these precautions, you can obtain accurate measurements of a bolt with rust, corrosion, or damage, ensuring that any repairs or replacements are done correctly.