How To Get Spray Foam Off Skin

Spray foam, commonly used in a variety of household applications and construction projects, is beloved for its insulating properties and easy application. However, its convenience and effectiveness come with a unique challenge—getting it off skin. Many users often find themselves in a sticky situation, literally, when spray foam adheres to their skin. Getting it off can require more than just soap and water, raising questions about safe and effective removal options. This informative and engaging article will demystify the complex world of spray foam, exploring its composition and how it works. We will delve into the correct and safe usage of spray foam, highlighting vital safety precautions users must bear in mind. Lastly, we will share effective techniques on how you can get spray foam off your skin without resorting to harmful or abrasive methods. Our journey starts with understanding the beast in its den - the spray foam; a closer look at what it is and how it works is the first step in defeating the sticky enemy.

Spray foam, commonly used in a variety of household applications and construction projects, is beloved for its insulating properties and easy application. However, its convenience and effectiveness come with a unique challenge—getting it off skin. Many users often find themselves in a sticky situation, literally, when spray foam adheres to their skin. Getting it off can require more than just soap and water, raising questions about safe and effective removal options. This informative and engaging article will demystify the complex world of spray foam, exploring its composition and how it works. We will delve into the correct and safe usage of spray foam, highlighting vital safety precautions users must bear in mind. Lastly, we will share effective techniques on how you can get spray foam off your skin without resorting to harmful or abrasive methods. Our journey starts with understanding the beast in its den - the spray foam; a closer look at what it is and how it works is the first step in defeating the sticky enemy.Understanding Spray Foam: What is it and How it Works

Spray foam insulation, a widely used building material, puzzles a casual observer, but comprehending its make-up, characteristics and binding process can demystify its essence. In this article, doused with in-depth knowledge and insight, we delve headfirst into the all-inclusive understanding of spray foam — its core composition, distinctive features, and how it aptly bonds with varied surfaces. To start, we will unearth the fundamental makeup of spray foam in "Comprehending the Composition of Spray Foam," illuminating the inherent elements that propel its effectiveness. Next, we will illuminate the unique traits of spray foam that set it apart from the crowd in "Understanding the Characteristics of Spray Foam". Lastly, we will explore the bonding process of spray foam, tackling how it coheres seamlessly to distinct surfaces in "How Spray Foam Bonds with Different Surfaces". Journey with us as we transition to our first stop - comprehending the unique composition of spray foam!

Comprehending the Composition of Spray Foam

Comprehending the Composition of Spray Foam Spray foam, a ubiquitous ingredient in insulation processes, carves out its status due to its robust and insulating nature. The crux of this foam stems from its unique composition, which is integral to its characteristic properties and eventual performance. Spray foam is essentially a concoction of two primary components - polyol resin and an isocyanate. These ingredients are kept separately until just before application, amalgamating to generate the foam when mixed. Polyol resin provides an elastic and resilient quality to the synthetic foam. Its primary function is to promote cell structure development and stability in the foam, all the while resisting moisture, heat, and sound. On the other hand, isocyanates induce rigidity and ensure structural integrity. This chemical compound is the key to spray foam’s longevity and resistance, offering the tenacious holding capacity essential for insulation purposes. The amalgamation of the polyol resin and isocyanate results in a blend brought to life by a chemical reaction. The mixing results in a foam-forming exothermic reaction, causing the solution to expand rapidly and substantially - up to 60 times its liquid volume. This compiled concoction then hardens and cures into the rugged material we recognize as spray foam. Understanding this composition is cardinal to comprehend the effectiveness and durability of spray foam as well as how it interacts with our skin. It lays the foundation for understanding its removal methods in case of accidental contact and adherence, providing an insight into the intricacies of spray foam behavior and its reactive nature. Ingesting this information is a steppingstone to safely, swiftly, and successfully dealing with spray foam. Knowledge of spray foam's composition will also aid in choosing products that are well-suited to specific needs and contexts. By delving into the chemical make-up and interactions between components, we can determine what to prioritize – be it resilience, moisture resistance, or longevity of the product. Synthesizing this knowledge, we can contribute to formulating a well-rounded understanding of spray foam, promoting informed choices, and guaranteeing safe and effective usage.

Understanding the Characteristics of Spray Foam

Understanding the Characteristics of Spray Foam Spray foam, an insulating material renowned for its proficiency in energy conservation, holds a spectrum of unique characteristics that contribute to its efficacy. Being lightweight yet durable, spray foam carries a distinct dynamic in the realm of insulation materials. Once applied, it rapidly expands and hardens into an encasing blanket that has excellent adhesion, a factor that reduces air gaps and leakage significantly. Its adaptability to different surfaces and shapes makes it a reliable choice for a diverse array of application scenarios. Unlike traditional insulation materials like fiberglass or cellulose, spray foam brings out an extraordinary performance, offering a higher R-value – the measure of insulating ability. Equipped with excellent thermal resistance, it significantly curbs heat transfer, ensuring a consistent indoor temperature regardless of outdoor influences. It's not just a barrier against weather elements but also a deterrent to moisture infiltration, enhancing the structure's overall protection against potential dampness issues. Spray foam's composition does not entice pests, making it an implicitly pest-resistant material – an attribute that adds to the durability of the structure. Additionally, it is highly resistant to mold growth, protecting the building against various organic threats. However, one aspect that garners special attention is the chemical complexity of spray foam. Polyurethane, a primary component of spray foam, is a synthetic material that can cause irritation or allergic reactions during application. Therefore, proper precautions, including the use of personal protective equipment, are necessary when handling or removing spray foam. This element of safety reaffirms the importance of professional application and proper removal when it makes skin contact. To summarize, the characteristics of spray foam span across various functional and health considerations. Being an exceptional insulator with pest and mold resistance, it seems almost unparalleled in its usability. Yet, its chemical complexity calls for caution, thereby certifying the need for professional handling while applying and removing this robust insulation material.

How Spray Foam Bonds with Different Surfaces

Spray foam, with its versatile application and adaptable properties, forms a thriving connection with various surfaces, embedding itself into the pores and imperfections of a broad array of materials. Essentially, spray foam is a polyurethane-based product that expands to fill gaps, cracks, and crevices when sprayed. It generates a closed-cell structure that hardens into place, creating a robust seal that's both insulating and weather-resistant. Its bonding prowess extends to an assortment of surfaces like wood, metal, glass, masonry, and most plastics. The science behind how spray foam bonds is quite fascinating. When the foam is applied, it's in its liquid state, allowing it to seep into minute crevices of the surface, making the most of any irregularities or textures it encounters. As it begins to expand, it fortifies its grip, building a strong adhesion that's tough to break. The foam, once dried, creates a remarkably resilient bond that withstands not just weather conditions, but also thermal fluctuations and physical impacts. The bond created by spray foam is a perfect example of chemical adherence, where the foam undergoes a reaction with the moisture in the air to expand and harden. It's the foam's expansive growth and the resultant pressure, coupled with its tenacious adherence, that makes a spray foam bond remarkably sturdy. Combined with the foam's inherent ability to resist moisture and deny air permeability, it's plain to see why spray foam is the go-to for creating an insulated, secure space. Regardless of the type of surface — be it the wooden underside of your roof, the metallic edges of your HVAC system, or the concrete expanse of your basement, spray foam adheres with an effectiveness that's hard to match. However, the strength of the bond also makes it quite challenging to remove it, should it come into contact with your skin. In summary, the chemical interactions and physical expansions of spray foam make it a truly adhesive force, contributing to its efficacy and popularity in insulation and sealant roles across various industries. Therefore, in understanding spray foam, its bonding capabilities with different surfaces are crucial elements to consider.

Proper Usage of Spray Foam and Safety Precautions

Spray foam has gained popularity for its robust insulating properties and versatility in a myriad of projects. However, its application can be complicated and potentially hazardous without the right knowledge. Hence, learning about the proper use of spray foam and safety precautions is crucial. Our comprehensive guide covers three key areas to ensure successful and safe spray foam application: "Best Practices When Using Spray Foam," "Common Mistakes to Avoid When Applying Spray Foam," and "Safety Measures When Handling Spray Foam." These provide in-depth discussion advising on expert-approved methods, proactive caution against typical errors, and paramount safety procedures, respectively. Understanding these components equips you to fully harness potential benefits while mitigating risks. To begin with, we'll delve into "Best Practices When Using Spray Foam." Knowing the do's and don'ts in practical application plays a huge role in harnessing touch-and-seal capability of this efficient sealant. Not only will it ensure optimum insulation effectiveness, but it also sets a firm foundation of your application skills, making subsequent steps smoother and less prone to mistakes. Let's explore these best practices in detail.

Best Practices When Using Spray Foam

Spray foam insulation is a popular choice for many homeowners and builders due to its excellent insulating properties. However, it's important to adhere to best practices when using spray foam to ensure maximum effectiveness and safety. Firstly, preparation is key. You should always wear personal protective equipment when applying spray foam, including safety glasses, gloves, and a respiratory mask to avoid inhalation. A well-ventilated workspace is also crucial to mitigate the harmful effects of any emissions. Secondly, it's essential to familiarize yourself with the product instructions before starting your spray foam project. Each product will have unique guidelines relating to temperature, application methods, and curing time. Over-spraying can lead to waste and ineffective insulation, while under-spraying can result in gaps and inefficiencies. Using spray foam appropriately not only saves money but also ensures a premium finish and optimal insulation performance. Moreover, always consider the expansion rate of the foam. Remember, spray foam expands after it's applied - and this can be by a significant amount. By acknowledging the foam's expansion capabilities, you can avert potential damage and achieve an even, protective layer of insulation. Disposal of used containers should also be given prior thought. Empty containers should be properly disposed of in designated waste disposal facilities that segregate and recycle hazardous materials. Lastly, if any spray foam does accidentally get onto your skin, it's essential to know how to remove it properly to avoid skin irritation. Some suggests using acetone or nail polish remover, but remember, it's always essential to follow safety precautions when using such substances. Seek professional medical advice if skin irritation persists. Following these best practices when using spray foam will not only ensure a perfect insulation task but also a safe and healthy environment. High rankings in this sphere demand a mix of proficiency, technical knowledge, and most importantly, practical safety measures, making your spray foam project a breeze to execute. Differentiate your approach to maintain quality work and implement strategies, which anticipate possible hurdles and eliminate them.

Common Mistakes To Avoid When Applying Spray Foam

Applying spray foam is a task that requires an understanding of the proper methods to maximize effectiveness while ensuring safety. However, errors are common among users, contributing to negative outcomes and potential health risks. One common mistake to avoid is not wearing appropriate personal protective equipment (PPE). Spray foam contains certain chemicals that can be harmful to the skin and eyes. It is crucial to wear protective clothing, goggles, and gloves to avoid direct contact with the skin. Another common mistake is applying too much foam in a single application. It's important to remember that spray foam expands, so applying excessive amounts may lead to unnecessary waste and may even compromise the structural integrity of the area where it is applied. Instead, it is advisable to spray in layers, allowing each layer to expand and cure before the next application, ensuring maximum insulation effectiveness. Additionally, the application of spray foam in inappropriate weather conditions is a common error. Conditions that are too hot or too cold can both affect the effectiveness of the foam's performance. It is suggested to apply the spray foam in moderate weather conditions to ensure optimal performance and longevity. Furthermore, some users neglect to prepare the surface adequately before application. Surfaces should be clean and free from dust and debris to ensure the foam adheres properly. A poorly prepared surface will lessen the insulation properties of the foam and may lead to peeling. Lastly, not giving the foam enough time to cure before tampering with it is another common mistake. The foam needs sufficient time to cure and attain its full insulative properties. Early disturbance can compromise the foam's longevity and effectiveness. In summary, spray foam application must be understood comprehensively to avoid potential mistakes. Proper usage and safety precautions are non-negotiable aspects that users must adhere to. The health and structural risks that arise from incorrect application can be easily avoided when an informed and cautious approach to using spray foam is applied.

Safety Measures When Handling Spray Foam

Spray foam, due to its adhesive properties and chemical composition, requires careful handling and stringent safety measures to ensure protection for both users and the environment. One of the preliminary safety measures to keep in mind is proper ventilation. Given that spray foam releases fumes during application which can be harmful if inhaled in large quantities, it is imperative to operate in a well-ventilated space. This may involve the use of exhaust fans, open windows, or an outdoor setting whenever possible. Additionally, the usage of appropriate personal protective equipment (PPE) is crucial. This includes wearing gloves and protective clothing to prevent the foam from coming into contact with your skin. Spraying without skin protection may lead to irritation, or worse, chemical burns in severe cases. It’s also advisable to wear safety goggles to guard against any inadvertent sprays to the eyes, which could cause short-term discomfort or adverse long-term effects. An essential resource that shouldn't be overlooked is a respirator mask. As previously mentioned, the fumes emanating from spray foam can be detrimental to the respiratory system; hence this mask can offer a vital line of defense. The equipment itself should also be handled with care. Consider particularly the pressure at which the foam sprays out of the canister. High-pressure sprays could ricochet off surfaces or become uncontrollable, leading to potential injuries or property damage. Thus, it's recommended to familiarize oneself with the operating instructions and pressure settings prior to use. Similarly, spent spray foam canisters must be disposed of responsibly. Once they're used up, they should never be punctured or incinerated due to the risk of explosion. They should be adequately sealed and taken to a designated waste facility to prevent any harmful environmental impact. Practice makes perfect, yet it is important to remember that no one becomes an expert overnight. Every new endeavor involves learning and making mistakes. Therefore, consider starting with small projects, gradually gaining experience and confidence. Following these recommended safety measures will ensure an effective, efficient, and most importantly, secure utilization of spray foam. Promoting safety while handling spray foam should be a priority for anyone approaching a project involving its use. Safety measures protect the user as well as those nearby, ensuring a safe and efficient working environment. By equipping oneself with the correct protective gear and adhering to secure handling procedures, the risks associated with spray foam can be significantly reduced. Hence, always bear in mind: Safety First!

Effective Techniques on How to Get Spray Foam off Skin

Spray foam, while a convenient tool for filling gaps and cracks at home, can be a real pain when it adheres to the skin. As such, this article aims to educate readers on effective techniques on how to get spray foam off skin. First, we will delve into the initial steps to take once you realize you have unwanted foam on your skin, a vital preventive measure to avoid worsening the situation. Next, we will examine the recommended home remedies for spray foam removal. Sometimes, all you may need is available within your reach, safe and natural solutions in your kitchen or bathroom that can help without causing harm to your skin. Finally, for stubborn residues or if you suddenly find you are allergic to the spray foam, there are professional treatments to consider. These options, though may seem more serious or daunting, is necessary when other methods prove ineffective. Now, let's start discussing the initial steps to remove spray foam from your skin.

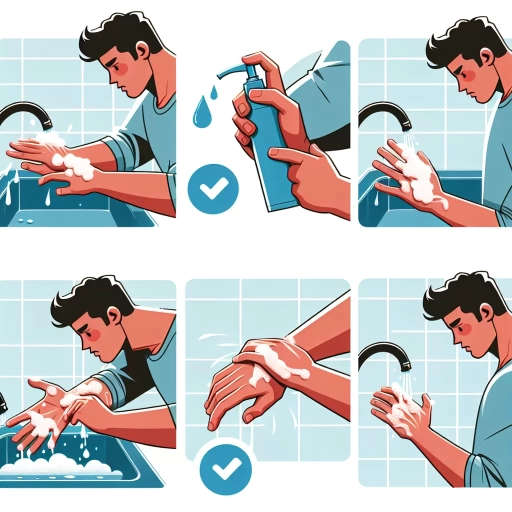

Initial Steps to Remove Spray Foam from Skin

The first and foremost step in successfully removing spray foam from skin is to take prompt action as quick response is key. If you discover that your skin has come in contact with spray foam, it's essential not to let it cure or harden. The uncured foam is easier to remove as it hasn’t set yet. Begin by wiping off the bulk of the foam with a paper towel, avoiding too much rubbing as it can potentially cause irritation. It's important to be gentle and patient during this process to avoid causing any damage or harm to the skin. Next, it is advised to rinse the affected area gently with cool - not hot - water and a mild soap. This helps to loosen the foam and rid the skin of any residual substances. Hot water should be avoided as it could open up the pores, pushing the foam deeper into the skin. Keep in mind to not use harsh or abrasive soaps as these can cause further irritation. Should the foam continue to linger on your skin after rinsing, you can apply a generous coating of petroleum jelly or mineral oil to the area. These substances are known to break down the adhesive components of the spray foam, making it easier to remove. Let it sit for a few minutes, then lightly scrub using a soft, clean cloth. If necessary, repeat this step. For stubborn patches of spray foam that still won’t come off, a fingernail polish remover with acetone can be used. However, apply this only as a last resort, since acetone can be harsh on the skin, and always test it on a small, less sensitive area first. Bear in mind, even with all these careful steps, the process of getting spray foam off the skin can cause some degree of discomfort, and might even lead to minor irritations. Using a soothing lotion or aloe vera gel afterwards is recommended to help soothe and repair the skin. Following these initial steps with diligence will ensure an effective and safe removal of spray foam from the skin. For more serious or extensive skin coverage, though, seeking professional medical help should be considered.

Recommended Home Remedies for Spray Foam Removal

Recommended home remedies for spray foam removal can be quite effective, serving as a powerful complement to commercial solutions. The commonality between these remedies is their approach to breaking down the adhesive properties of the spray foam, improving the ease of removal from your skin. For starters, many people find significant success using white vinegar. White vinegar is a gentle acid which works to degrade the adhesion of the foam. Simply apply a small amount of vinegar to a cloth and gently rub it on the affected area. The vinegar helps disintegrate the foam allowing it to be easily wiped or peeled off. Another widely used home remedy is any kind of vegetable oil. The lipid content in oils has an amazing effect in loosening the firm grip of the spray foam. Olive oil and even canola oil are exceptional owing to their high-fat concentrations. Lightly rub the oil on the skin stained with the foam and let it sit for 15 minutes; the spray foam will start to peel off on its own, leaving your skin smooth and unaffected. Peanut butter is another alternative to commercial spray foam removers. The oily nature of peanut butter can breakdown the spray foam residue stuck to your skin. Just rub the peanut butter on the foam-touched skin and let it sit for a moment before attempting to rub off the foam. Rinse and repeat the process if necessary. If the foam has hardened completely, a mild physical exfoliant can be used. Oatmeal mixed with a bit of water can provide a gentle abrasive action, removing the foam without causing damage to the skin. These remedies underline the principle of using safe, non-abrasive materials to remove the spray foam. However, caution should be observed in case of any allergic reactions or if the foam covers a large part of your body. In such a situation, it is recommended to consult a healthcare professional immediately for a safe and thorough removal. In conclusion, these home remedies for spray foam removal are non-toxic, gentle on the skin, and effective. They serve as handy solutions for minor incidents at home when getting professional help might not be immediately available. Using these methods can save not just your skin but also your time and money. But remember, prevention is always better the cure. So, always make sure to wear protective gear when working with spray foam to avoid any unnecessary complications.

Professional Treatments to Consider When Spray Foam Cannot Be Removed At Home

Even with the most calculated precautions, mishaps involving spray foam insulation can occur, leading the sticky substance to cling onto your skin stubbornly. Yet, not every situation can be handled at home using rudimentary methods, requiring professional intervention to safely rectify. Professional dermatological treatments are an ideal recourse for cases where the foam has adhered extensively or penetrated deep into the skin layers. Experts in skin care and treatment, dermatologists leverage advanced and safe-methods that entirely extract the foam while maintaining the integrity of the skin. Medical-grade solvents are commonly employed by these professionals, which are more powerful than everyday household options, yet gentle on the skin, ensuring no residual damage. For more stubborn or extensive cases, physical removal techniques such as precision scraping and dermatological lasers can be used. These techniques allow for targeted removal of the foam without causing unnecessary injury to surrounding skin tissue. Microdermabrasion deserves special mention in the toolbox of professional treatments. This non-invasive procedure utilizes tiny crystals to exfoliate and remove the outermost layer of dry, dead skin cells where the foam might be lodged. This process is highly controlled and monitored under the guidance of trained professionals, minimizing any potential side effects. Photodynamic Therapy (PDT) is another option worth mentioning. It is a two-step treatment process that employs a topical photosensitizing agent, followed by a light-based treatment to eliminate the foam residue. PDT also helps stimulate collagen production, ensuring your skin heals healthily and effectively post-procedure. In conclusion, it's crucial to remember that the health and well-being of your skin should always come first. Spray foam can be a troublesome adversary to contend with, but enlisting the help of a skilled professional can ensure the safest and most effective removal technique for your situation. Endeavor to handle such circumstances under professional supervision rather than risking potential skin damage at home.