How Do Torque Sticks Work

In the world of mechanics and engineering, precision is key to ensuring the safety and efficiency of various systems and structures. One crucial tool that plays a vital role in achieving this precision is the torque stick. A torque stick is a simple yet effective device that helps to apply a specific amount of rotational force to a bolt or nut, preventing over-tightening or under-tightening. But have you ever wondered how a torque stick works its magic? What are the key factors that affect its accuracy, and what are the benefits of using one in various applications? In this article, we will delve into the inner workings of a torque stick, exploring its mechanism, the factors that impact its precision, and its applications in different fields. So, let's start by understanding the basics of a torque stick and how it works.

What is a Torque Stick and How Does it Work?

A torque stick is a simple, yet effective tool used to apply a specific amount of torque to a bolt or nut. It is commonly used in various industries, including automotive, aerospace, and construction. But have you ever wondered what a torque stick is and how it works? In this article, we will delve into the world of torque sticks, exploring their definition and purpose, basic components, and operating principle. By understanding these key aspects, you will gain a deeper appreciation for the importance of torque sticks in ensuring the safety and reliability of various mechanical systems. So, let's start by examining the definition and purpose of a torque stick.

Definition and Purpose of a Torque Stick

A torque stick is a tool used to measure the rotational force, or torque, applied to a fastener, such as a bolt or nut. The primary purpose of a torque stick is to ensure that the correct amount of torque is applied to a fastener, which is critical in various industries, including automotive, aerospace, and construction. The correct application of torque is essential to prevent over-tightening or under-tightening, which can lead to damage, injury, or even catastrophic failure. A torque stick typically consists of a calibrated shaft with a socket or wrench attached to the end, which is used to apply the torque to the fastener. The stick is designed to slip or break away when the predetermined torque value is reached, providing a clear indication that the correct torque has been applied. By using a torque stick, users can ensure that the correct torque is applied consistently and accurately, reducing the risk of errors and improving overall safety and reliability.

Basic Components of a Torque Stick

A torque stick is a tool used to measure the rotational force, or torque, applied to a fastener, such as a bolt or nut. The basic components of a torque stick include a handle, a shaft, and a socket or bit. The handle is typically made of a durable material, such as metal or fiberglass, and is designed to provide a comfortable grip for the user. The shaft is usually a long, thin rod that connects the handle to the socket or bit, and is typically made of a strong, lightweight material, such as steel or aluminum. The socket or bit is attached to the end of the shaft and is designed to fit onto the fastener, allowing the user to apply torque to it. Some torque sticks may also include additional features, such as a ratchet mechanism or a adjustable torque setting, to make it easier to use and more accurate. Overall, the basic components of a torque stick work together to provide a simple and effective way to measure and apply torque to fasteners.

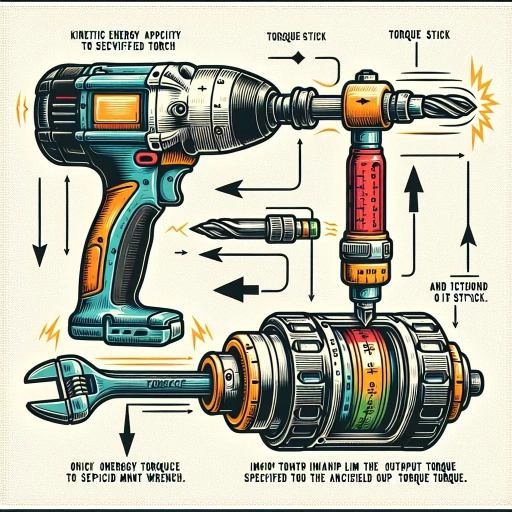

Operating Principle of a Torque Stick

A torque stick is a tool used to apply a specific amount of torque to a fastener, such as a bolt or nut. The operating principle of a torque stick is based on the concept of mechanical advantage, where a small amount of force applied to the handle of the tool is amplified to produce a much larger torque at the output end. The torque stick consists of a long handle attached to a socket or wrench head, which is designed to fit onto the fastener. Inside the handle, there is a calibrated spring or mechanism that stores energy as the handle is turned. As the handle is turned, the spring or mechanism is compressed, and when the desired torque is reached, the spring or mechanism releases its stored energy, causing the handle to slip or "break away" from the socket or wrench head. This break-away action indicates that the desired torque has been applied to the fastener. The torque stick is typically calibrated to a specific torque value, and the user can adjust the torque setting by changing the position of the spring or mechanism inside the handle. By using a torque stick, users can ensure that the correct amount of torque is applied to a fastener, which is critical in many applications, such as in the automotive, aerospace, and construction industries, where over- or under-tightening can lead to serious consequences.

Key Factors Affecting the Accuracy of a Torque Stick

The accuracy of a torque stick is influenced by a multitude of factors, which can significantly impact its performance and reliability. Three key factors that play a crucial role in determining the accuracy of a torque stick are its material and construction, calibration and maintenance, and environmental factors. The material and construction of the torque stick can affect its durability and resistance to wear and tear, which in turn can impact its accuracy over time. Calibration and maintenance of the torque stick are also essential to ensure that it is functioning correctly and providing accurate readings. Additionally, environmental factors such as temperature, humidity, and vibration can also influence the accuracy of the torque stick. In this article, we will explore each of these factors in more detail, starting with the material and construction of the torque stick.

Material and Construction of the Torque Stick

The material and construction of a torque stick play a crucial role in its accuracy and reliability. Typically, torque sticks are made from high-strength, lightweight materials such as aluminum, steel, or fiberglass. The choice of material depends on the intended application, with aluminum being a popular choice for its corrosion resistance and durability. The construction of a torque stick involves a combination of machining, welding, and assembly processes. The stick's body is usually machined from a single piece of material, with the socket and handle ends being welded or attached using a strong adhesive. The socket end is designed to fit snugly onto the bolt or nut, while the handle end is typically ergonomic and comfortable to grip. Some torque sticks may also feature additional components, such as a ratchet mechanism or a built-in torque limiter, which can enhance their functionality and accuracy. The quality of the materials and construction methods used can significantly impact the torque stick's performance, with high-quality sticks providing more consistent and reliable results. Additionally, the use of advanced materials and manufacturing techniques, such as 3D printing, can enable the creation of complex geometries and customized designs that can further improve the accuracy and functionality of torque sticks.

Calibration and Maintenance of the Torque Stick

Calibration and maintenance of a torque stick are crucial to ensure its accuracy and longevity. Calibration involves comparing the torque stick's output to a known standard, typically a calibrated torque wrench or a deadweight tester, to verify its accuracy. This process should be performed regularly, ideally every 6-12 months, or as recommended by the manufacturer. During calibration, any deviations from the standard are noted, and adjustments are made to the torque stick to bring it within the acceptable tolerance range. Maintenance, on the other hand, involves regular cleaning and inspection of the torque stick to prevent damage and wear. This includes checking for signs of wear on the handle, shaft, and socket, as well as ensuring that all moving parts are properly lubricated. Additionally, the torque stick should be stored in a dry, clean environment, away from direct sunlight and extreme temperatures. By following a regular calibration and maintenance schedule, users can ensure that their torque stick remains accurate and reliable, reducing the risk of errors and improving overall productivity. Furthermore, many manufacturers offer calibration and maintenance services, which can provide an added layer of assurance and support. By prioritizing calibration and maintenance, users can extend the lifespan of their torque stick and maintain its accuracy, ultimately saving time and money in the long run.

Environmental Factors Influencing Torque Stick Accuracy

Environmental factors play a significant role in influencing the accuracy of a torque stick. Temperature, humidity, and vibrations are some of the key environmental factors that can impact the performance of a torque stick. Temperature fluctuations can cause the materials used in the torque stick to expand or contract, leading to variations in the stick's length and, consequently, affecting the accuracy of the torque measurement. Similarly, high humidity levels can cause corrosion or rust on the stick's surface, which can also impact the accuracy of the measurement. Vibrations, on the other hand, can cause the stick to oscillate, leading to inconsistent readings. Furthermore, exposure to extreme temperatures, such as those found in outdoor environments, can also affect the stick's calibration and accuracy. Therefore, it is essential to consider these environmental factors when using a torque stick to ensure accurate and reliable measurements.

Applications and Benefits of Using a Torque Stick

Torque sticks are a crucial tool in various industries, providing a simple and efficient way to apply a specific amount of torque to a bolt or nut. The applications and benefits of using a torque stick are numerous, and in this article, we will explore the common industries and applications of torque sticks, the advantages of using a torque stick over other methods, and the cost-effectiveness and efficiency of torque sticks. From ensuring the safety and reliability of critical equipment to reducing the risk of over-tightening and damage, torque sticks play a vital role in many industries. By understanding the benefits and applications of torque sticks, professionals can make informed decisions about when to use them and how to get the most out of this valuable tool. With their versatility and precision, torque sticks are an essential component of many industries, and their use is widespread in various sectors. Let's take a closer look at the common industries and applications of torque sticks.

Common Industries and Applications of Torque Sticks

Torque sticks are widely used in various industries and applications where precise torque control is crucial. In the automotive industry, torque sticks are used to tighten lug nuts, wheel bearings, and other critical components to ensure safety and prevent damage. In the aerospace industry, torque sticks are used to assemble and maintain aircraft engines, landing gear, and other critical systems. In the construction industry, torque sticks are used to tighten bolts and nuts on heavy machinery, such as cranes and excavators. In the manufacturing industry, torque sticks are used to assemble and test products, such as engines, gearboxes, and other mechanical components. In the oil and gas industry, torque sticks are used to tighten pipe fittings, valves, and other equipment to prevent leaks and ensure safety. In the medical industry, torque sticks are used to assemble and maintain medical equipment, such as surgical instruments and hospital furniture. In the sports industry, torque sticks are used to tighten bolts and nuts on bicycles, motorcycles, and other sports equipment. Overall, torque sticks are an essential tool in many industries where precise torque control is critical to ensure safety, prevent damage, and maintain equipment performance.

Advantages of Using a Torque Stick Over Other Methods

The use of a torque stick offers several advantages over other methods of applying torque, making it a preferred choice in various industries. One of the primary benefits is its ability to provide a high level of accuracy and consistency, ensuring that the correct amount of torque is applied every time. This is particularly important in applications where over-tightening or under-tightening can have serious consequences, such as in the aerospace or automotive industries. Additionally, torque sticks are often more efficient and faster than other methods, allowing for increased productivity and reduced labor costs. They are also typically more compact and lightweight, making them easier to maneuver in tight spaces and reducing operator fatigue. Furthermore, torque sticks are often less expensive than other torque application methods, such as pneumatic or electric wrenches, and require less maintenance, making them a cost-effective solution. Overall, the use of a torque stick provides a reliable, efficient, and cost-effective way to apply torque, making it an essential tool in many industries.

Cost-Effectiveness and Efficiency of Torque Sticks

The cost-effectiveness and efficiency of torque sticks are significant advantages in various industries. By utilizing a torque stick, operators can achieve precise torque control, reducing the risk of over-tightening or under-tightening, which can lead to costly repairs, rework, or even safety hazards. This precision also enables the use of lower-torque tools, decreasing the physical strain on operators and minimizing the risk of injury. Furthermore, torque sticks can be easily calibrated and maintained, extending their lifespan and reducing replacement costs. In addition, the simplicity and portability of torque sticks make them an ideal solution for applications where space is limited or access is restricted. Overall, the cost-effectiveness and efficiency of torque sticks make them an essential tool in industries where precision and reliability are paramount.